Solid tobacco tar and preparation method and application thereof

An e-liquid and solid-state technology, which is applied in the field of atomization, can solve problems such as liquid leakage, difficult storage, and poor atomization effect of solid-state e-liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

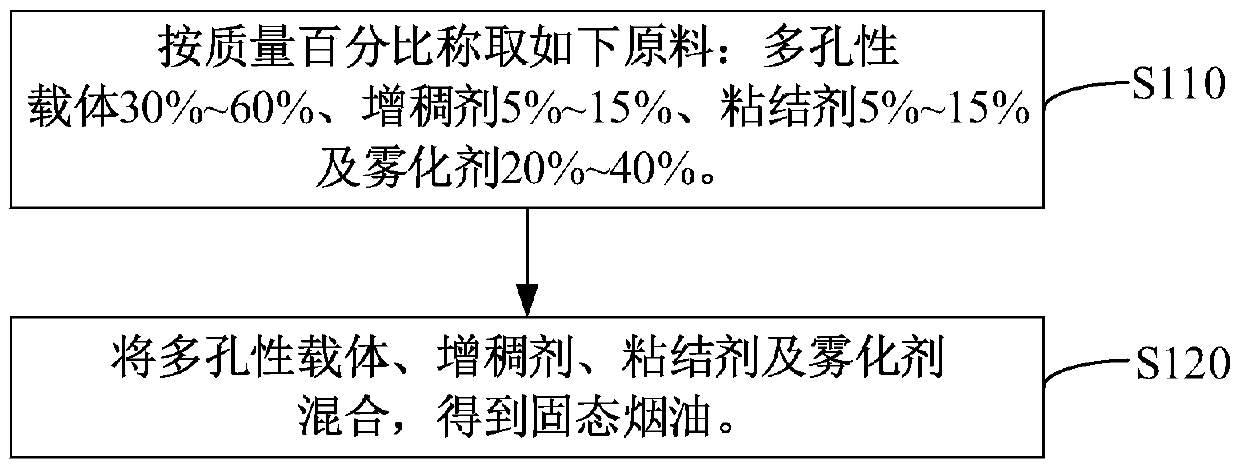

[0034] see figure 1 , a method for preparing solid e-liquid in one embodiment, comprising the following steps:

[0035] Step S110: Weigh the following raw materials by mass percentage: 30%-60% of porous carrier, 5%-15% of thickener, 5%-15% of binder and 20%-40% of atomizing agent.

[0036] Wherein, the porous carrier is selected from at least one of peanut shells, lotus leaves, tea leaves, eggplant leaves and walnut shells.

[0037] The thickener is at least one selected from glyceryl monostearate, carbomer, sodium carboxymethylcellulose, methylcellulose and hypromellose.

[0038] The binder is at least one selected from carrageenan, xanthan gum, guar gum, acacia gum, alginate, agar, konjac gum and locust bean gum.

[0039] The atomizing agent is selected from one of glycerin and propylene glycol.

[0040] Further, step S110 also includes the step of weighing 5%-30% of the essence by mass percentage. Flavors include tobacco flavors.

[0041] Step S120: Mix the porous carr...

Embodiment 1

[0055] The preparation process of the solid e-liquid of this embodiment is as follows:

[0056] (1) Weigh the following raw materials by mass percentage: 40% peanut shell, 10% essence, 20% glycerin, 5% xanthan gum, 10% carrageenan, 5% sodium carboxymethylcellulose and 10% carbomer.

[0057] (2) Crush the peanut shells and pass through a 200-mesh sieve to obtain fine peanut powder for later use.

[0058] (3) Mixing food essence and glycerin to obtain the first intermediate.

[0059] (4) Mixing the fine peanut powder with the first intermediate to obtain the second intermediate.

[0060] (5) Slowly add xanthan gum into the second intermediate, and stir evenly while adding to obtain the third intermediate.

[0061] (6) Add carboxymethylcellulose sodium into the third intermediate, and stir while adding to obtain the fourth intermediate.

[0062] (7) Add carrageenan to the fourth intermediate, and stir evenly while adding to obtain the fifth intermediate.

[0063] (8) Add the ...

Embodiment 2

[0067] The preparation process of the solid e-liquid of this embodiment is as follows:

[0068] (1) The following raw materials were weighed by mass percentage: 40% of dried lotus leaf, 10% of essence, 20% of glycerin, 5% of xanthan gum, 5% of guar gum, 5% of alginate and 15% of carbomer.

[0069] (2) Grinding the dried lotus leaves and passing through a 200-mesh sieve to obtain fine lotus leaf powder for later use.

[0070] (3) Mixing food essence and glycerin to obtain the first intermediate.

[0071] (4) The fine lotus leaf powder is mixed with the first intermediate to obtain the second intermediate.

[0072] (5) Slowly add xanthan gum into the second intermediate, and stir evenly while adding to obtain the third intermediate.

[0073] (6) Add alginate to the third intermediate, and stir evenly while adding to obtain the fourth intermediate.

[0074] (7) Add guar gum to the fourth intermediate, and stir evenly while adding to obtain the fifth intermediate.

[0075] (8)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com