Jetting and agitating construction method and jetting and agitating device

A construction method and technology of spray nozzles, which are applied in foundation structure engineering, soil protection, sheet pile walls, etc., can solve the problems of increased funds, insufficient foundation hardening materials, and increased cost of jet mixing construction methods, so as to reduce wasteful use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

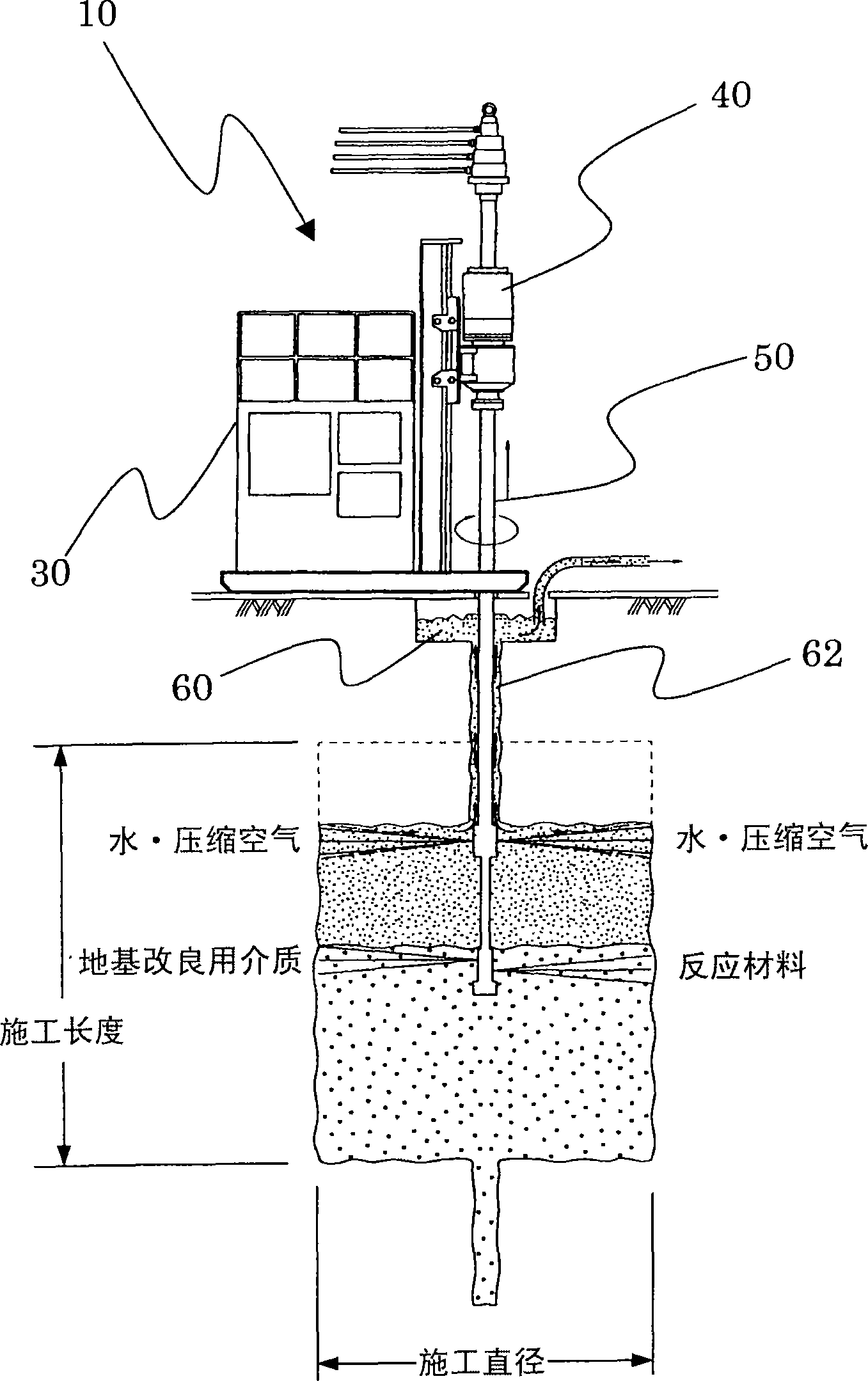

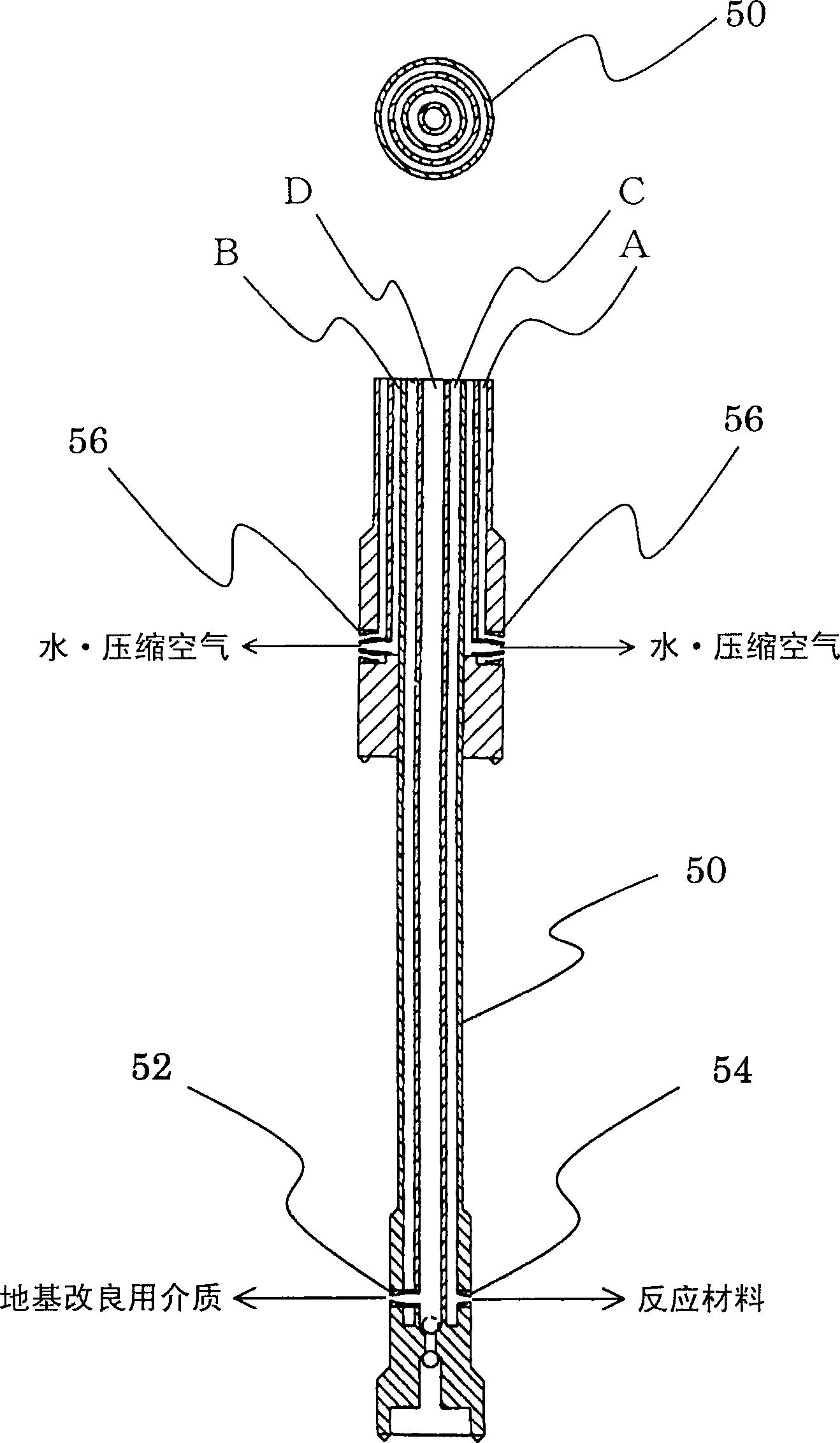

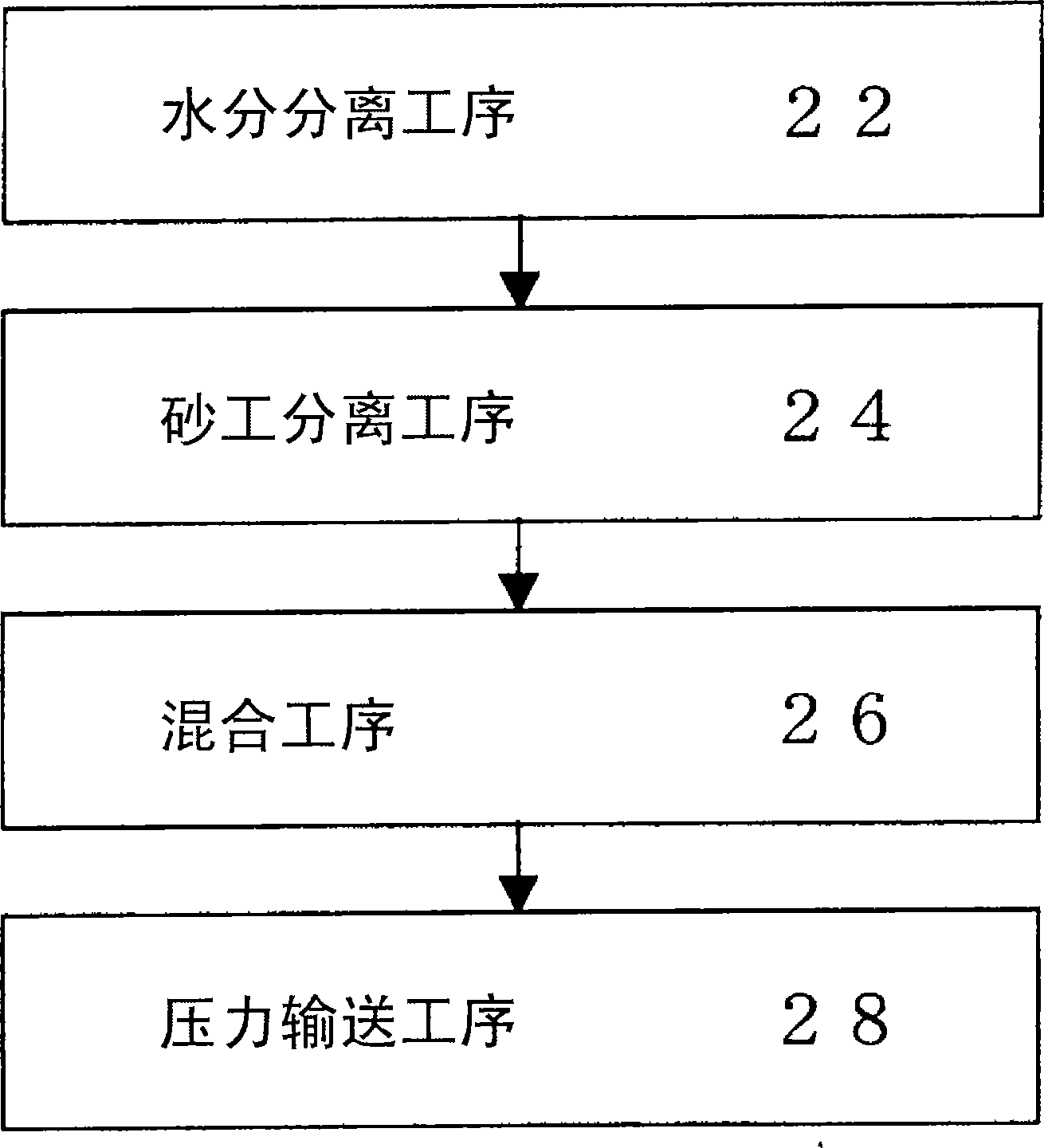

[0027] The jet mixing construction method and the jet mixing device of the present invention will be described in detail below with reference to the embodiments shown in the accompanying drawings. figure 1 is a schematic diagram of the jet stirring device of the present invention, figure 2 is a cross-sectional view of a part of the multi-tubular rod of the present invention, image 3 It is a flowchart of the mud treatment of the jet mixing construction method of the present invention, Figure 4 It is a configuration diagram of a connection example of connecting a plurality of pressure feeding pumps of the embodiment.

[0028] Figure 5 It is a schematic diagram which shows embodiment of the jet agitation apparatus used for the jet agitation construction method of another Example of this invention. Fig. 6 is an injector portion of a jet mixing device showing a jet mixing construction method according to another embodiment of the present invention, (a) is a transverse sectiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com