Novel fuel tank for automobile

A new type of fuel tank technology, applied in vehicle components, layout combined with internal combustion engine fuel supply, power units, etc., can solve problems such as decreased oil pipe and fuel tank tightness, gas station safety threats, secondary injuries to members, etc., to achieve tightness Increase, simple structure, reduce the effect of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

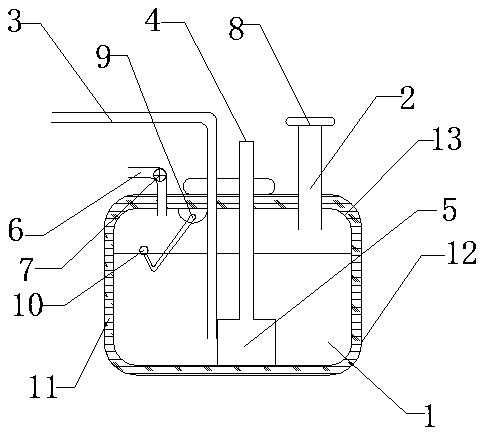

[0016] The specific embodiment: when in use, the fuel tank cap 8 is opened, and gasoline is introduced into the tank body 1 through the fuel filler port 2, and the oil level sensor 9 senses the amount of oil in the tank body 1 through the floating of the float 10, and the gasoline is pumped out by the oil pump 5. Pass out and use through the oil pipe, open the one-way valve 7 and gasoline vapor will be discharged through the gasoline vapor output pipe 6, the oil return pipe 3 of the present invention, the oil pipe 4 and the gasoline evaporation output pipe 6 adopt polytetrafluoroethylene plastic materials, so that the pipeline and The sealing between the tanks 1 is increased; the interlayer 11 provided between the outer layer 12 and the inner layer 13 is a vacuum interlayer, which has the function of insulation and heat insulation, can prevent the oil from freezing, and can also prevent the fuel tank from burning and prevent The effect of explosion caused by the rise of oil tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com