Device for guiding powdery fluidic media

A technology for fluidized medium and conveying medium, which is applied in the field of devices for conveying powdery fluidized medium, especially powder paint, can solve the problems of impairing the effectiveness of pump functions and reducing the conveying efficiency of devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

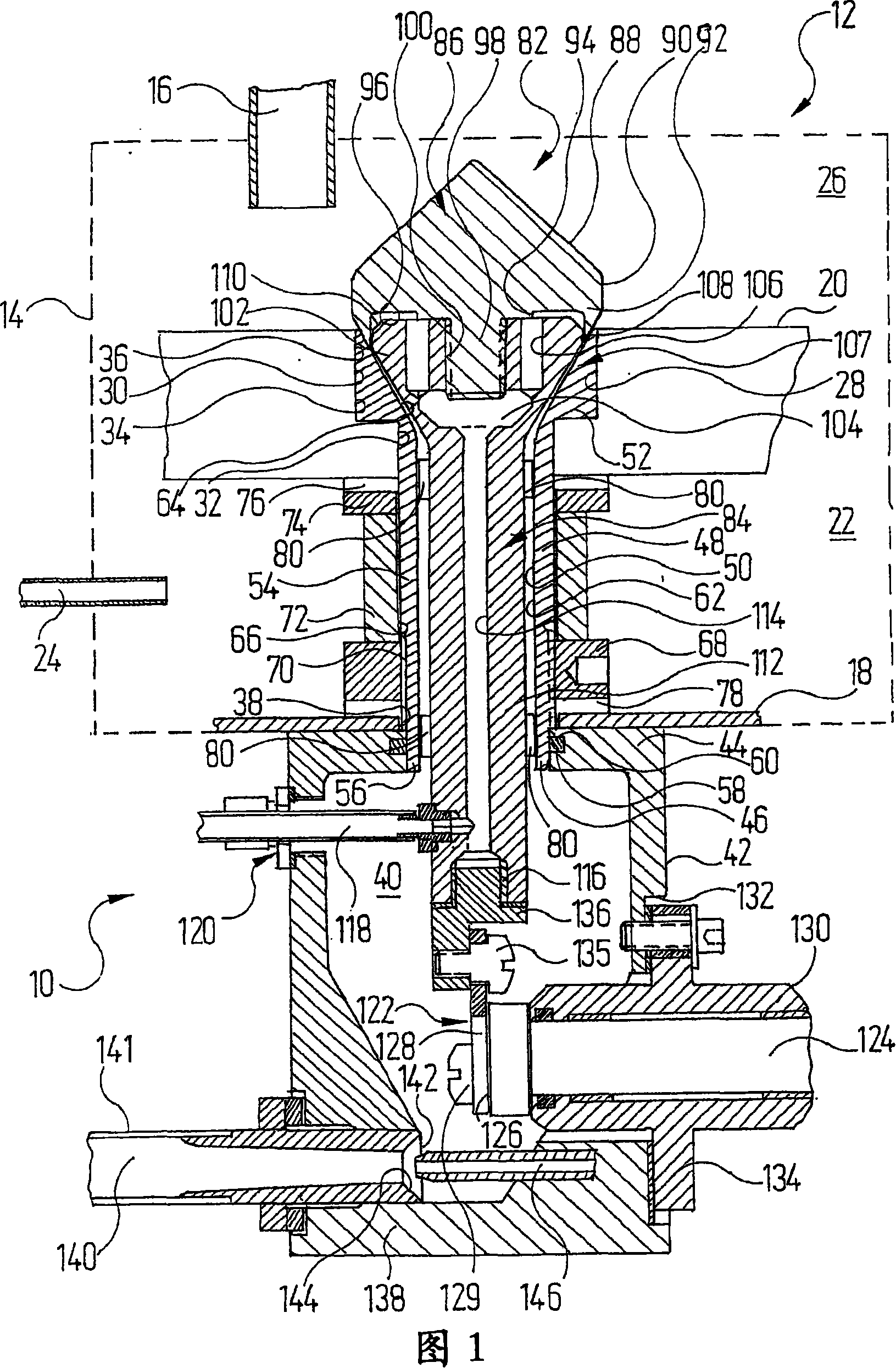

[0023] The device 10 comprises a container 12 with a housing 14 schematically indicated in dashed lines, into which powder paint is fed via a line 16 in a known manner.

[0024] At a certain distance above the bottom surface 18 of the container 12, the container 12 has a fluidization floor 20 consisting of a porous material. Compressed air is supplied via a line 24 into a pressure chamber 22 formed between the bottom surface 18 and the fluidizing bottom 20 . The compressed air penetrates through the fluidizing floor 20 into the interior 26 of the container 12 located above the floor, fluidizing the powder paint there and thus making the powder paint there flowable.

[0025] The fluidizing bottom plate 20 has a continuous stepped bore 28 with a first bore section 30 facing the interior 26 and a second bore section 32 facing the pressure chamber 22 . The second bore section 32 has a smaller diameter than the first bore section 30 . The first hole section 30 of the stepped hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com