Vacuum cleaner with wet method cleaning function

A vacuum cleaner and cleaning technology, which is applied in the direction of vacuum cleaners, cleaning equipment, cleaning machinery, etc., can solve the problems of water pollution, etc., and achieve the effect of shortened cleaning time and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings. In the figures, the same parts are denoted by the same reference numerals in all figures. In the following description, well-known related functions and constructions are omitted for conciseness.

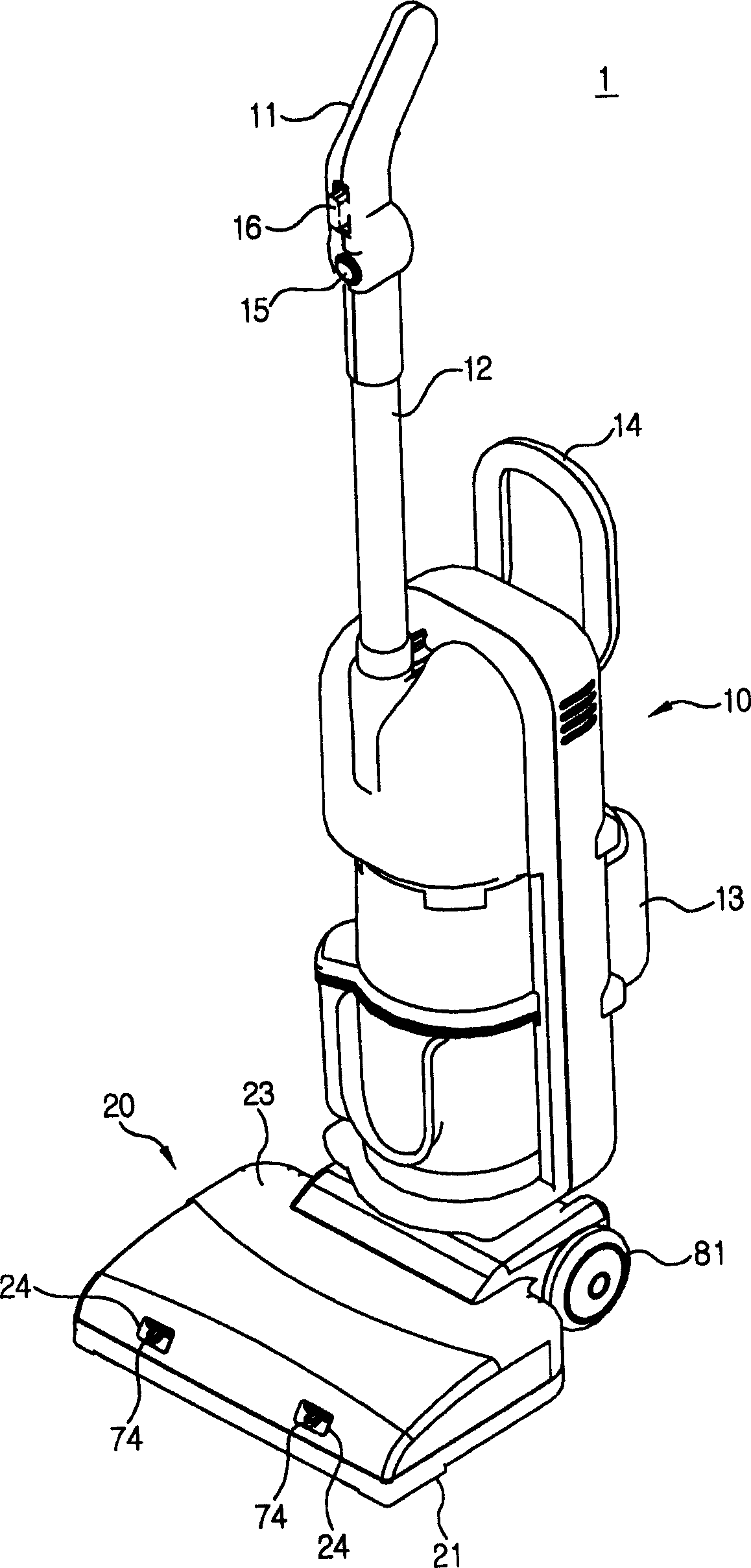

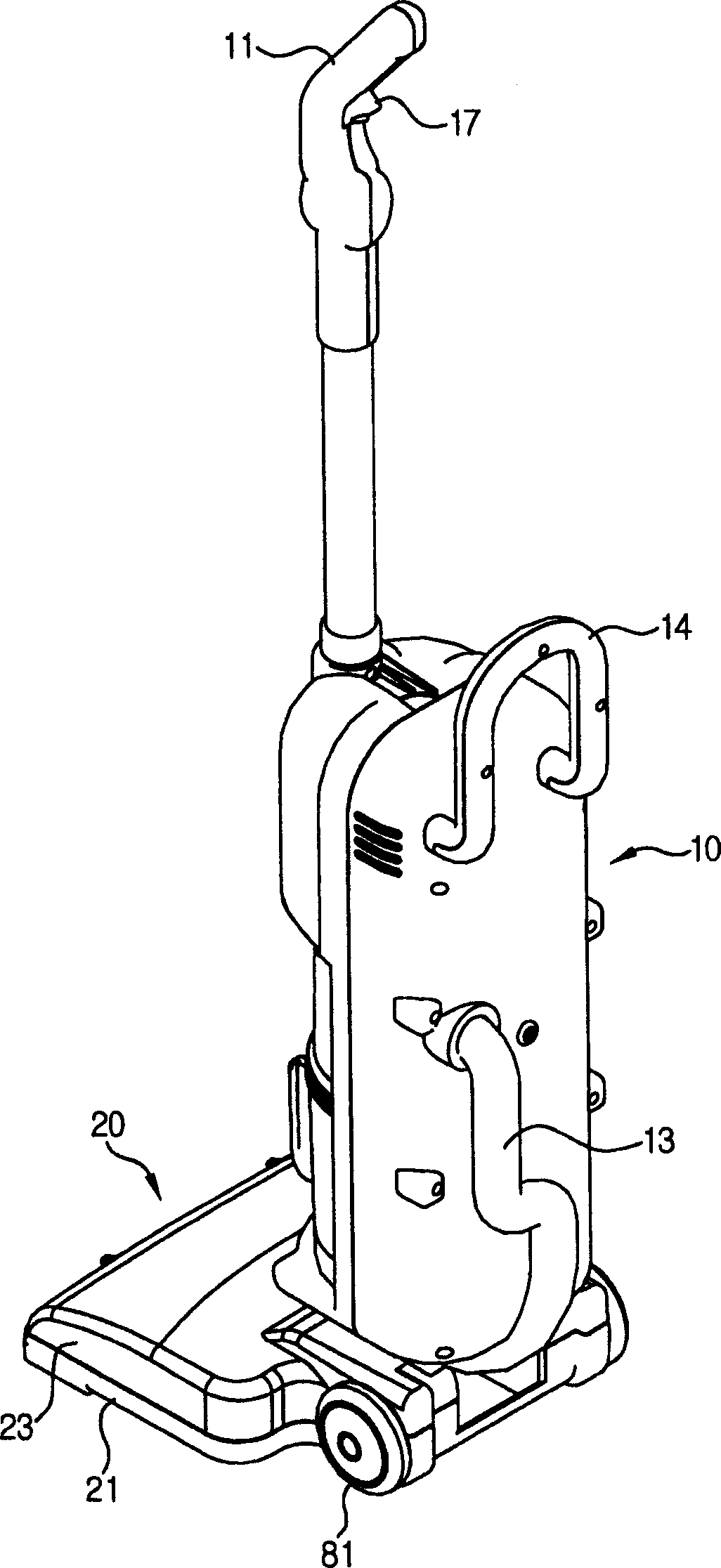

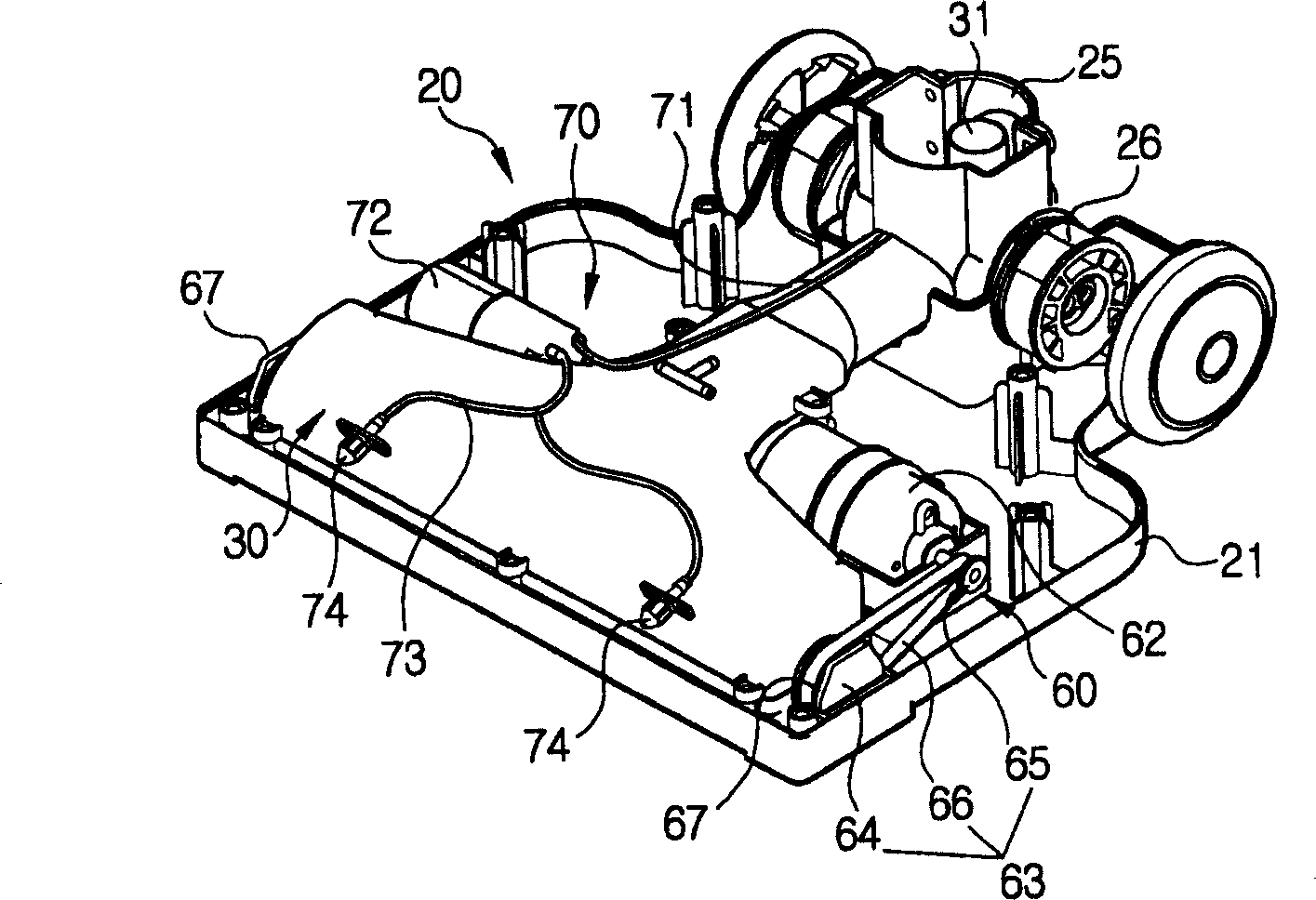

[0032] see figure 1 and 2 , the vacuum cleaner with wet cleaning function includes a main body 10 and a brush assembly 20 .

[0033] The main body 10 includes: a motor assembly (not shown) for generating suction; a dirt collection container (not shown) for collecting dirt and water sucked by the brush assembly 20; and storing water for wet cleaning water tank (not shown). The upper end of the main body 10 has a handle 11 for a user to hold. The handle 11 is connected to the main body 10 through an extension tube 12 . The rear side of the main body 10 has a hose 13 connecting the brush assembly 20 and the dirt collection container of the main body 10 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com