Environment-friendly PVC (Polyvinyl Chloride) waterproof roll and preparation method thereof

A kind of waterproof membrane, environment-friendly technology, applied in the field of PVC waterproof membrane for construction, environment-friendly PVC waterproof membrane and its preparation, can solve the problems of poor stability, harm to human health, impact on waterproof performance, etc., and achieve good stability , excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

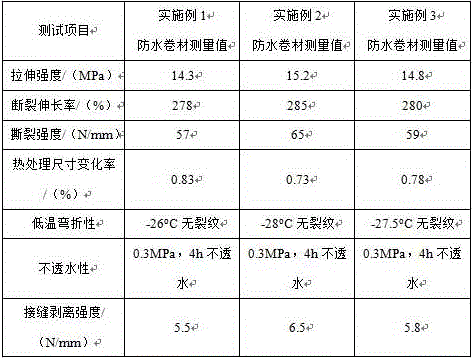

Embodiment 1

[0035] Embodiment 1 A kind of environment-friendly PVC waterproof coiled material

[0036] The waterproof membrane includes the following raw material components, in parts by mass:

[0037] Raw material components by mass

[0038] PVC resin 98 parts

[0039] 45 parts plasticizer

[0040] 2 parts heat stabilizer

[0041] 5 parts epoxy soybean oil

[0042] Filling 20 parts

[0043] Antioxidant 0.2 parts

[0044] 0.2 parts of light stabilizer;

[0045] The PVC resin is loose SG-3;

[0046] The plasticizer is DOP;

[0047] The thermal stabilizer is a calcium / zinc liquid stabilizer;

[0048] The filler is light calcium carbonate with a mesh number of 2500 to 5000 mesh;

[0049] Described antioxidant is antioxidant B225, is formed by mixing antioxidant 1010 and antioxidant 168 by mass ratio 2:1;

[0050] The light stabilizer is an ultraviolet absorber UV-9.

Embodiment 2

[0051] Embodiment 2 A kind of environment-friendly PVC waterproof coiled material

[0052] The waterproof membrane includes the following raw material components, in parts by mass:

[0053] Raw material components by mass

[0054] PVC resin 100 parts

[0055] 51 parts of plasticizer

[0056] 2 parts heat stabilizer

[0057] 5 parts epoxy soybean oil

[0058] Filling 25 parts

[0059] Antioxidant 0.5 parts

[0060] 0.5 part of light stabilizer;

[0061] The PVC resin is loose SG-3;

[0062] The plasticizer is DOP;

[0063] The thermal stabilizer is a calcium / zinc liquid stabilizer;

[0064] The filler is light calcium carbonate with a mesh number of 2500 to 5000 mesh;

[0065] The antioxidant is antioxidant B225;

[0066] The light stabilizer is an ultraviolet absorber UV-9.

Embodiment 3

[0067] Embodiment 3 A kind of environment-friendly PVC waterproof coiled material

[0068] The waterproof membrane includes the following raw material components, in parts by mass:

[0069] Raw material components by mass

[0070] PVC resin 102 parts

[0071] 55 parts of plasticizer

[0072] Heat stabilizer 2.5 parts

[0073] 6 parts epoxy soybean oil

[0074] Filling 30 parts

[0075] Antioxidant 0.6 part

[0076] 0.6 parts of light stabilizer;

[0077] The PVC resin is loose SG-3;

[0078] The plasticizer is DOP;

[0079] The thermal stabilizer is a calcium / zinc liquid stabilizer;

[0080] The filler is light calcium carbonate with a mesh number of 2500 to 5000 mesh;

[0081] The antioxidant is antioxidant B225;

[0082] The light stabilizer is an ultraviolet absorber UV-9.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com