Graphite phase-change thermal conduction silicone grease and preparation method thereof

A technology of thermal conductive silicone grease and graphite phase, which is applied in the field of graphite phase change thermal conductive silicone grease and its preparation, can solve the problems of battery sheet temperature rise, power generation efficiency reduction, and unsatisfactory heat dissipation effect, and achieve high adsorption, long life, The effect of excellent heat transfer function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 9 parts by weight of petrolatum was heated to 65°C to melt, and 1 part by weight of nanoporous graphite powder was slowly put into the melted petrolatum, and magnetically stirred for 10 minutes to obtain nanoporous graphite powder encapsulated with petrolatum.

[0034] 5 parts by weight of nanoporous graphite powder encapsulated with vaseline and 1 part by weight of simethicone were mixed on a three-roll mill for 5 minutes to obtain a paste-like high thermal conductivity filled with nanoporous graphite-based phase change materials silicone grease.

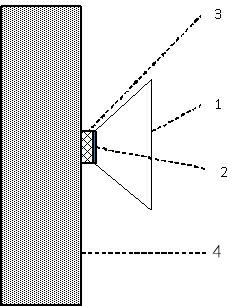

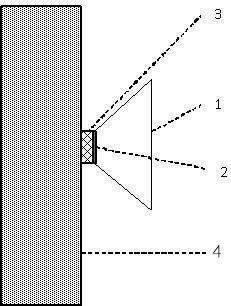

[0035] figure 1 It is a schematic diagram of the application of the high thermal conductive silicone grease of this embodiment, wherein 1 is a condenser lens, 2 is a condenser cell sheet, 3 is an insulating thermal conductive silicone grease or silica gel, and 4 is aluminum filled with the high thermal conductive silicone grease of this embodiment. Tube. The high thermal conductive silicone grease is filled in the aluminum...

Embodiment 2

[0038] 8 parts by weight of petrolatum was heated to 65°C to melt, 2 parts by weight of nanoporous graphite powder was slowly put into the melted petrolatum, and magnetically stirred for 20 minutes to obtain nanoporous graphite powder encapsulated with petrolatum.

[0039] 9 parts by weight of nanoporous graphite powder encapsulated with vaseline and 1 part by weight of benzyl silicone oil were mixed on a planetary ball mill for 10 minutes to obtain a paste-like high thermal conductivity silicon filled with nanoporous graphite-based phase change materials. fat.

[0040]

Embodiment 3

[0042] Heat 9 parts by weight of vaseline to 65°C for melting, slowly put 1 part by weight of expanded graphite powder into the molten vaseline, and stir for 20 minutes in a constant temperature water bath with stirring function to obtain expanded graphite powder encapsulated with vaseline.

[0043] A mixture of 7 parts by weight of expanded graphite powder encapsulated with vaseline and 1 part by weight of simethicone and hydroxyl silicone oil was mixed on a kneader for 20 minutes to obtain a paste-like high-quality powder filled with expanded graphite-based phase change materials. Thermal Grease.

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com