Cuttable flexible wire and preparation device and preparation method thereof

A flexible wire and mixing device technology, applied in bendable conductors, cable/conductor manufacturing, conductors, etc., can solve the problem of large resistance changes, difficult mass industrial production, large changes in the conductivity of flexible wires, etc. problem, to achieve the effect of stable performance and large tensile strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

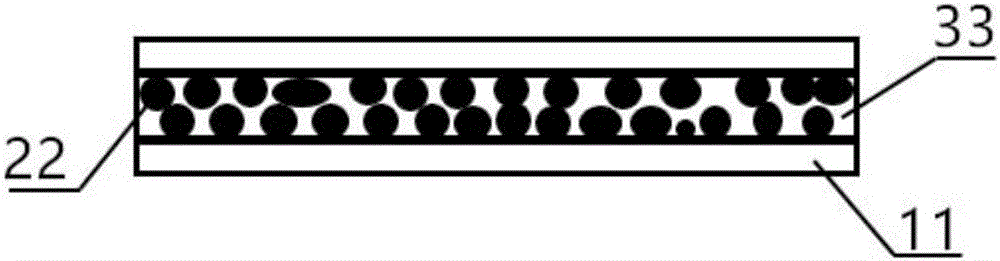

[0049] In this embodiment, flexible wires can be cut such as figure 1 As shown, it is composed of a conductor part and a protective layer 11, and the protective layer part covers the outer surface of the conductor part. The conductor part is composed of liquid metal and elastic body 33 , and the liquid metal particles 22 are dispersed in the elastic body 33 .

[0050] The liquid metal material is a gallium-indium-tin alloy, which is a liquid metal conductive material at room temperature.

[0051] The elastic body is composed of elastic material PDMS, which can deform under the action of external force.

[0052] The protective layer is made of elastic material PDMS, which can deform under the action of external force.

[0053] In the tailorable flexible wire, the volume percentage of the liquid metal material is greater than 5%.

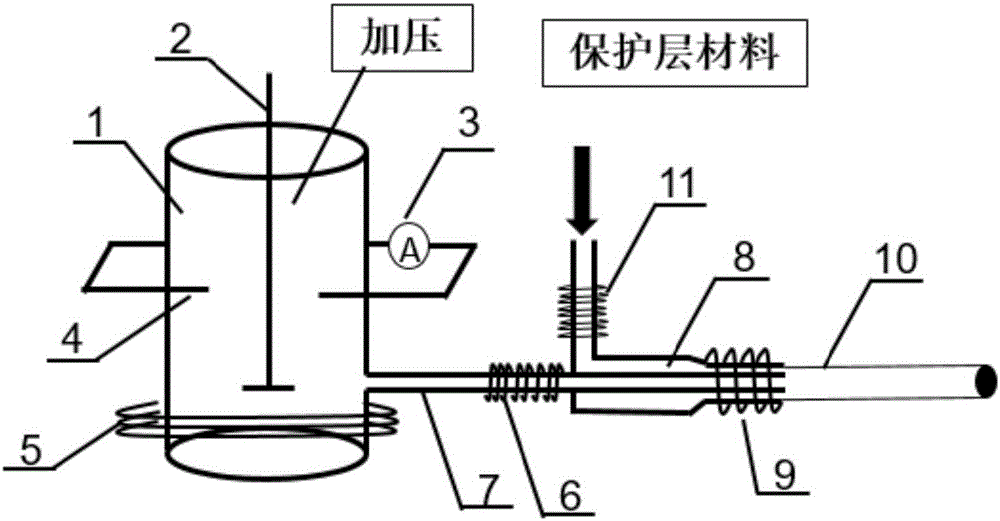

[0054] figure 2It is a schematic structural diagram of the device for preparing the above-mentioned cuttable flexible wire, including a mixing d...

Embodiment 2

[0066] In this embodiment, flexible wires can be cut such as figure 1 As shown, it is composed of a conductor part and a protective layer part, and the protective layer part covers the outer surface of the conductor part. The conductor part is composed of liquid metal and elastic body, and the liquid metal particles are dispersed in the elastic body.

[0067] The liquid metal material is a gallium-indium-tin alloy, which is a liquid metal conductive material at room temperature.

[0068] The elastic body is composed of elastic material SEBS, which can deform under the action of external force.

[0069] The protective layer is made of elastic material SEBS, which can deform under the action of external force.

[0070] In the tailorable flexible wire, the volume percentage of the liquid metal material is greater than 5%.

[0071] The structure of the device for preparing the above-mentioned cuttable flexible wire is exactly the same as that in the embodiment.

[0072] The me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com