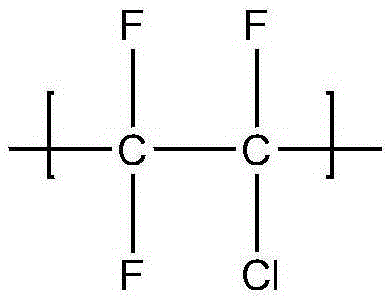

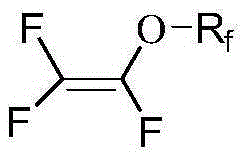

Polychlorotrifluoroethylene resin and preparation method thereof

A technology of polychlorotrifluoroethylene and chlorotrifluoroethylene, which is applied in coatings, anti-corrosion coatings, etc., can solve the problems of low specific gravity of emulsion, low temperature of strength loss, pollution, etc., reduce impurity metal ions, increase reaction speed, The effect of increasing the mass transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

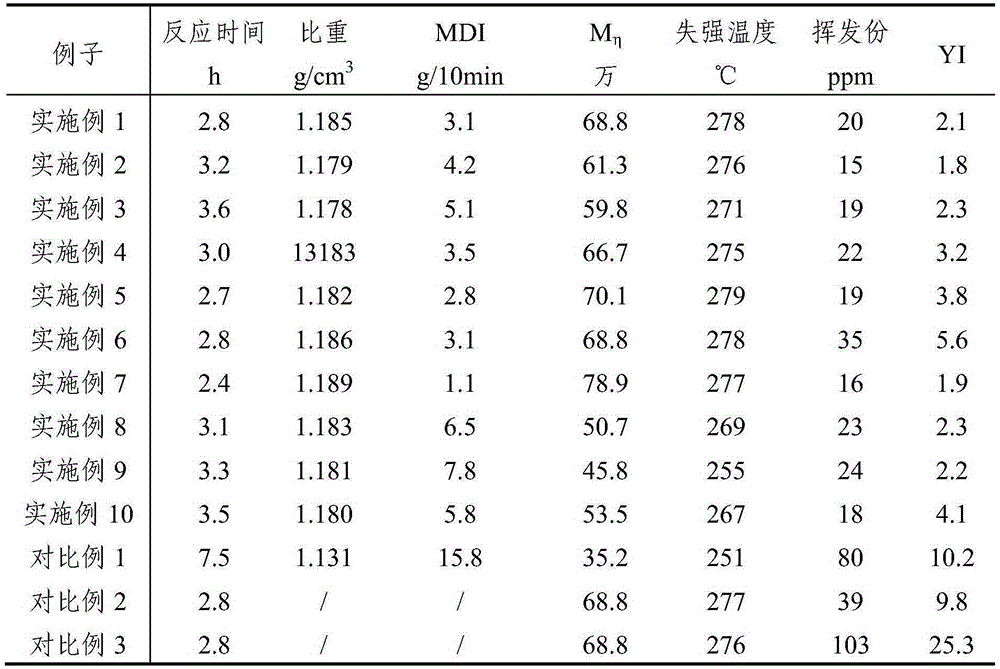

Embodiment 1

[0089] In a 10L stainless steel reactor with a stirrer, the material is 904L, the ratio of length to diameter is 2.0, and 6.0kg of deionized water is added. Use a vacuum pump to evacuate the air in the reactor, and then replace it with nitrogen. Repeat nitrogen filling and evacuation and degassing until the oxygen content reaches 30ppm or less. Then replace with chlorotrifluoroethylene (CTFE) monomer until the oxygen content in the reactor drops to Below 30ppm. Then turn on the stirring, the speed is 50rpm, the temperature is raised to 40°C, and the CTFE monomer is added to the reactor through the compressor until the kettle pressure reaches 1.0MPa. After the temperature and pressure are stable, add 2.0g of NaOH, 1.0g of ferrous sulfate, and 10g of Na through the micrometering pump. 2 S 2 O 5 , 10g potassium persulfate, start the reaction. Continuously replenish the reacted monomer through the compressor to maintain the pressure of the reactor at 1.0 MPa. The reaction was sto...

Embodiment 2

[0092] According to the method of Example 1, the initiator is changed to perfluorodipropionyl peroxide, and the others remain unchanged. Take some samples for testing, and the results are listed in Table 1.

Embodiment 3

[0094] According to the method of Example 1, change the initiator to IPP, and the others remain unchanged. Take some samples for testing, and the results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| yellowness index | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com