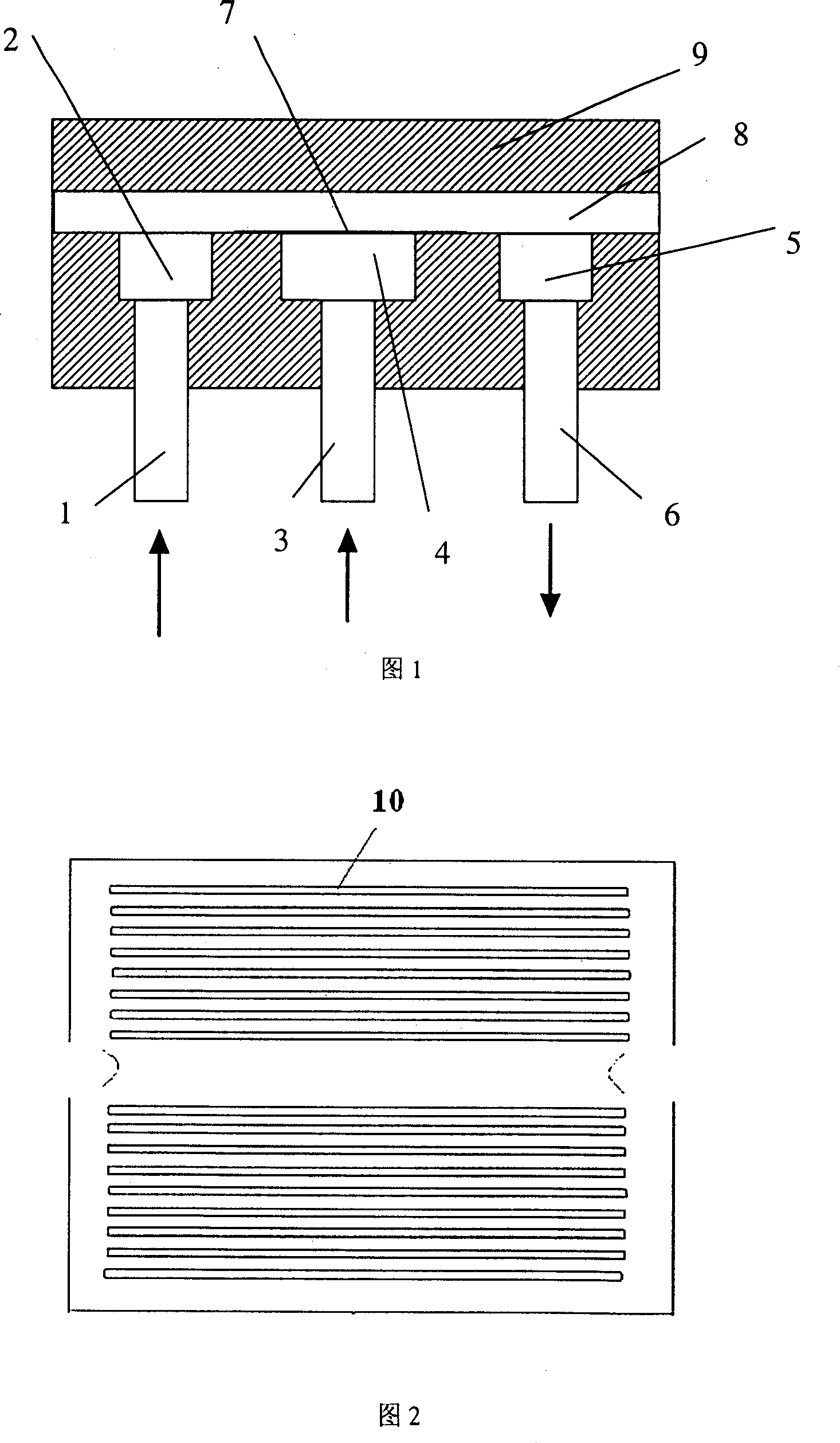

Multi-channeled micro-structured reactor

A microstructure reactor and multi-channel technology, applied in chemical methods, chemical instruments and methods, chemical/physical/physicochemical processes for reacting liquid and gaseous media, can solve the problems that cannot meet the needs of large-scale production, Problems such as expensive processing costs and high equipment costs, to achieve the effect of low operating costs, simple equipment, and large equipment processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Using 4% caustic soda solution as the dispersed phase, gasoline with a petroleum acid content of 2.061mgKOH / g as the continuous phase, and a 10-micron stainless steel porous medium as the dispersion medium, a microstructure reactor containing 10 parallel channels in the continuous phase parallel channel plate Medium reaction deacidification, when the ratio (continuous phase volume flow rate: dispersed phase volume flow rate) is 20:1, the deacidification rate is 98%, the acid value after alkali washing is less than 0.04mgKOH / g, and the gasoline processing capacity can reach 320L / h, the processing capacity of each channel is 32L / h.

Embodiment 2

[0016] Using 4% caustic soda solution as the continuous phase, diesel oil with a petroleum acid content of 1.455mgKOH / g as the dispersed phase, and using a 20-micron stainless steel microfiltration membrane as the dispersion medium, mixed deacidification in a microstructure reactor containing 20 parallel channels , when the ratio (dispersed phase flow rate: continuous phase flow rate) is 30:1, the deacidification rate is 93%, the acid value after alkali washing is less than 0.06mgKOH / g, and the diesel oil treatment capacity can reach 4000L / h, each channel The processing capacity is 200L / h.

Embodiment 3

[0018] Using fuming sulfuric acid as the dispersed phase, 10% cyclohexane carboxylic acid n-hexane solution as the continuous phase, and using 1 micron stainless steel microfiltration membrane as the dispersion medium, cyclohexane was reacted in a microstructure reactor containing 5 parallel channels For alkanoic anhydride, when the ratio (continuous phase flow rate: dispersed phase flow rate) is 50:1, measure the remaining cyclohexanecarboxylic acid concentration in the normal hexane solution after the reaction, and obtain the reaction conversion rate based on cyclohexanecarboxylic acid It is 85%, the selectivity is 99%, the continuous phase flow rate is 20L / h, and the processing capacity of each channel is 4L / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com