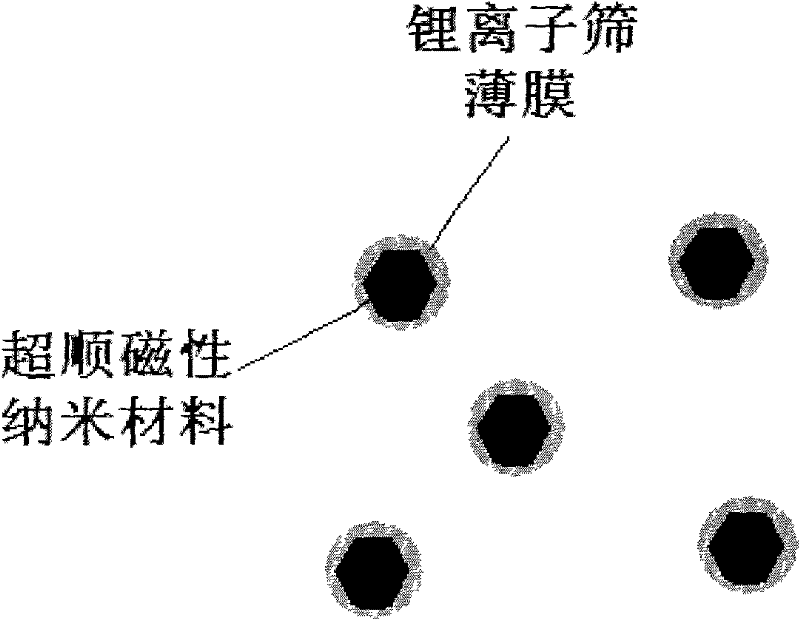

Magnetic nano lithium ion sieve adsorbent and preparation method thereof

A magnetic nanometer and lithium ion technology, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc. To achieve the effect of small mass transfer scale, improved adsorption and desorption performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

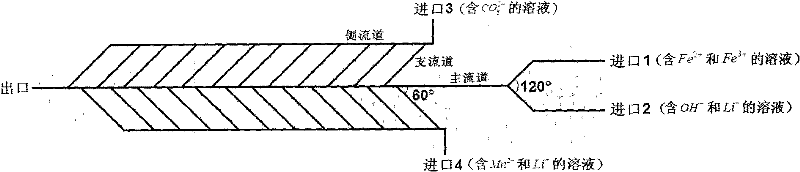

[0041] A preparation method of a magnetic nano-lithium ion sieve, the specific steps are:

[0042] The configured Fe-containing 2+ and Fe 3+ solution, containing OH - and Li + solution, containing solution containing Mn 2+ and Li + The solutions were put into 4 storage tanks respectively. Open the nitrogen cylinder, and under the action of nitrogen pressure, the feed liquid in the 4 storage tanks is quickly pressed out along the respective pipelines through the flow meter into the 4 inlets of the narrow channel impingement flow reactor, and the 4 strands are adjusted and controlled. The flow rate of the feed liquid. The process of preparing magnetic nano-lithium ion sieves by using a narrow channel impingement flow reactor is as follows: figure 2 As shown, the width of the narrow passage in the narrow passage impinging flow reactor is 1mm, and the depth is 5mm. Contains Fe 2+ and Fe 3+ The solution in the first inlet 1, containing OH - and Li + The solution in t...

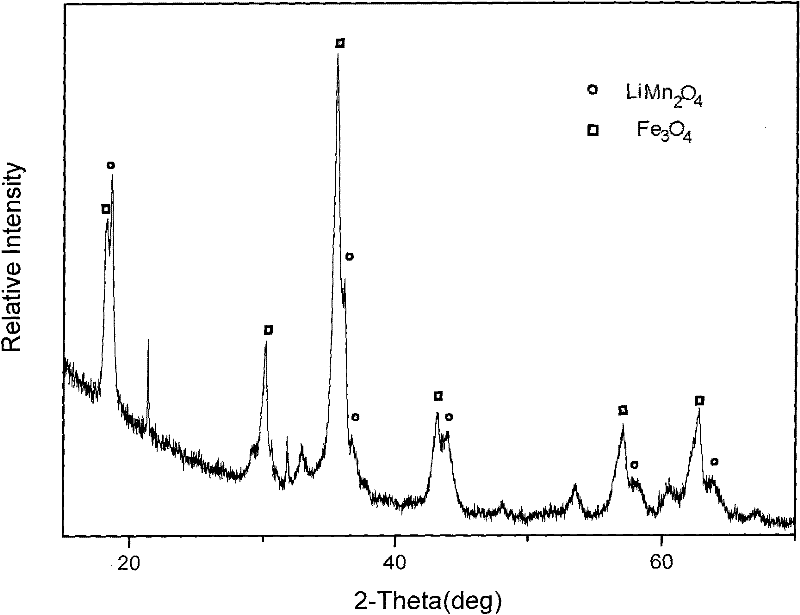

Embodiment 1

[0050] Preparation of mixed ferric nitrate salt solution Fe 2+ Concentration is 0.3mol / L, Fe 3+ / Fe 2+ The molar ratio is 1.6; prepare mixed lye, wherein the concentration of lithium hydroxide is 0.4mol / L, and the concentration of ammonia water is 1.74mol / L; prepare a mixed solution of manganese nitrate and lithium nitrate, wherein the concentration of manganese nitrate is 0.78mol / L solution, lithium nitrate The concentration is 0.4mol / L; the ammonium carbonate solution of 1.18mol / L is prepared and poured into respective storage tanks. The volumes of the four feed solutions are all 380ml, and the initial temperatures are all at room temperature. Open the nitrogen cylinder so that nitrogen with a pressure of 0.3 MPa enters the above four storage tanks at the same time. Under the action of nitrogen pressure, the four feed liquids enter the narrow channel impingement flow reaction device, and the flow rate of the four feed liquids is controlled to be 300ml. / min, the front 6 wa...

Embodiment 2

[0052] Preparation of mixed ferric nitrate salt solution Fe 2+ Concentration is 0.1mol / L, Fe 3+ / Fe 2+ The molar ratio is 1.8; the concentration of lithium hydroxide solution is prepared at 0.84mol / L; the mixed solution of manganese nitrate and lithium nitrate is prepared, the concentration of manganese nitrate is 0.84mol / L, and the concentration of lithium nitrate is 0.84mol / L; the concentration of preparation is 1.68mol / L The ammonium carbonate solution was poured into respective storage tanks, the volumes of the four feed liquids were 380ml, and the initial temperatures were room temperature. Open the nitrogen cylinder so that nitrogen with a pressure of 0.3MPa enters the above four storage tanks at the same time. Under the action of nitrogen pressure, the four feed liquids enter the narrow channel impingement flow reaction device, and the flow rate of the four feed liquids is controlled to be 450ml. / min, the feed liquid in the third and fourth inlets flows out from 12 b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com