Atomization flash-evaporation ammonia-removing process for ammonia and nitrogen-containing wastewater

A technology of flash evaporation of ammonia nitrogen wastewater, applied in the field of ammonia removal, can solve the problems of large investment in packed towers, and achieve the effects of simple equipment structure, low operating cost and large adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

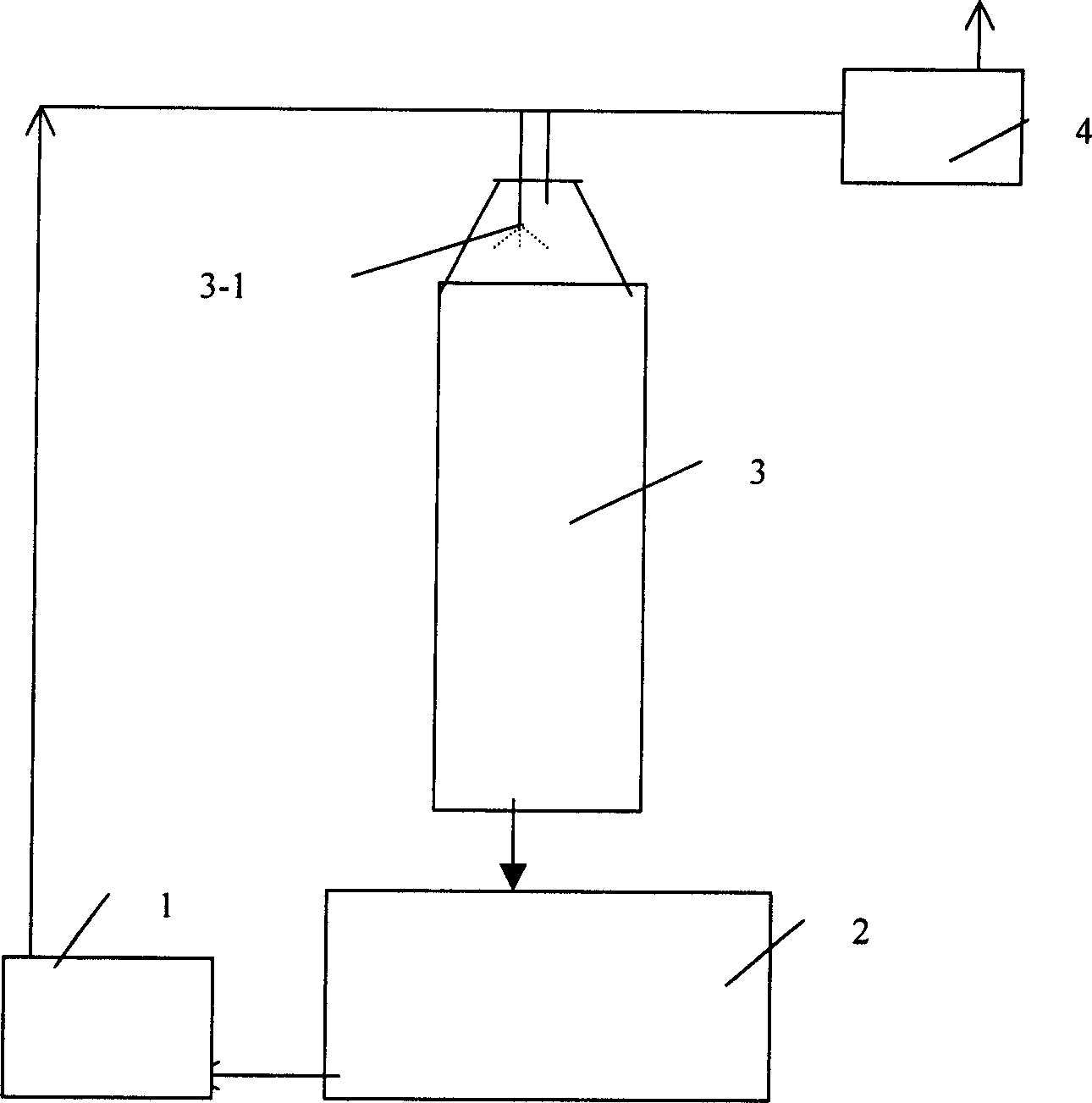

[0011] use figure 1 The treatment equipment shown adjusts the pH value of coking wastewater with a volume of 1 liter and an ammonia nitrogen concentration of 887.5mg / L to 12.08, so that the ammonia nitrogen in the wastewater is mainly converted into NH 3 form, and then at an ambient temperature of 25°C, the coking waste water is pumped 1 to transport the waste water in the high-level storage tank 2 to a spray tower 3 with a space volume of 25 liters at the top of the tower at a flow rate of 170 ml / min. In the device 3-1, highly atomized water mist or mist is formed, and the vacuum degree in the atomization tower is kept at about 0.005MPa through the connection between the tower top pipe and the vacuum pump 4 or the fan phase. In the tower under negative pressure, water mist or mist droplets move from top to bottom while ammonia nitrogen flashing occurs in the wastewater, and fall to the bottom of the tower, and then flow into the high storage tank 2, and the evaporated NH 3 I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com