Production method for glyoxalate

A technology of glyoxylate and production method, applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of low yield of glyoxylate and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

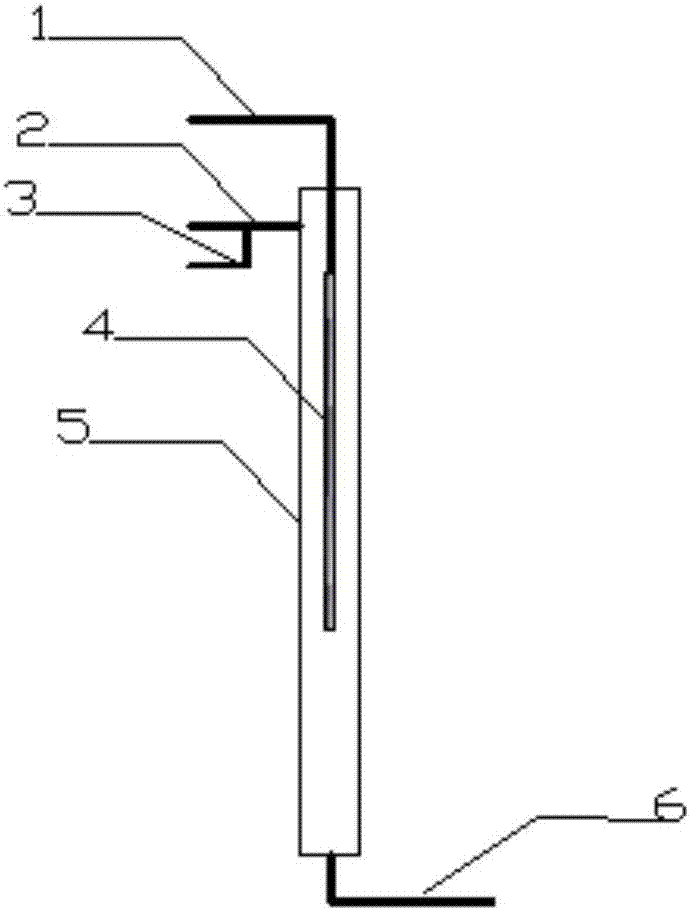

[0030] Get 60g the catalyst that contains 3 parts of V, 7 parts of Sn and 90 parts of alumina carriers and load as figure 1 inside the reactor shown. The methyl glycolate diluted with water enters from inlet 2, the carrier gas nitrogen enters from inlet 3 and mixes with the methyl glycolate aqueous solution and enters the reactor together, and the air enters from inlet 1, passing through a height of 60% of the catalyst bed height, membrane The α-alumina ceramic membrane oxygen distributor with a pore size of 0.48 μm reacts with methyl glycolate on the catalyst. Control the reaction temperature to 250°C, the reaction pressure to 0.1MPa, and the space velocity to 0.5h -1 , the molar ratio of diluent to methyl glycolate is 1:1, the molar ratio of oxygen to methyl glycolate is 0.7:1, and the molar ratio of nitrogen to methyl glycolate is 50:1. After the reaction, the product was analyzed by gas-liquid separation and sampling. The conversion rate of methyl glycolate was 98.1%, an...

Embodiment 2

[0032] Get 60g the catalyst that contains 3 parts of V, 7 parts of Sn and 90 parts of alumina carriers and load as figure 1 inside the reactor shown. The methyl glycolate diluted with water enters from inlet 2, the carrier gas nitrogen enters from inlet 3 and mixes with the methyl glycolate aqueous solution and enters the reactor together, and the air enters from inlet 1, passing through a height of 60% of the catalyst bed height, membrane A silicon oxide ceramic membrane oxygen distributor with a pore size of 0.13 μm reacts with methyl glycolate on the catalyst. Control the reaction temperature to 250°C, the reaction pressure to 0.1MPa, and the space velocity to 0.5h -1 , the molar ratio of diluent to methyl glycolate is 1:1, the molar ratio of oxygen to methyl glycolate is 0.7:1, and the molar ratio of nitrogen to methyl glycolate is 50:1. After the reaction, the product was analyzed by gas-liquid separation and sampling. The conversion rate of methyl glycolate was 98.2%, ...

Embodiment 3

[0034] Get 60g the catalyst that contains 3 parts of V, 7 parts of Sn and 90 parts of alumina carriers and load as figure 1 inside the reactor shown. The methyl glycolate diluted with water enters from inlet 2, the carrier gas nitrogen enters from inlet 3 and mixes with the methyl glycolate aqueous solution and enters the reactor together, and the air enters from inlet 1, passing through a height of 60% of the catalyst bed height, membrane A titanium oxide ceramic membrane oxygen distributor with a pore size of 0.24 μm reacts with methyl glycolate on the catalyst. Control the reaction temperature to 250°C, the reaction pressure to 0.1MPa, and the space velocity to 0.5h -1 , the molar ratio of diluent to methyl glycolate is 1:1, the molar ratio of oxygen to methyl glycolate is 0.7:1, and the molar ratio of nitrogen to methyl glycolate is 50:1. After the reaction, the product was analyzed by gas-liquid separation and sampling. The conversion rate of methyl glycolate was 98.6%,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com