Micro-contact mixer

A mixer and micro-contact technology, applied in mixing methods, chemical instruments and methods, dissolution and other directions, can solve the problems of difficult to meet large-scale production in chemical processes, high equipment costs, and difficult processing, and achieve uniform and controllable residence time. , The equipment has a compact structure, and the effect of saving manufacturing materials and space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

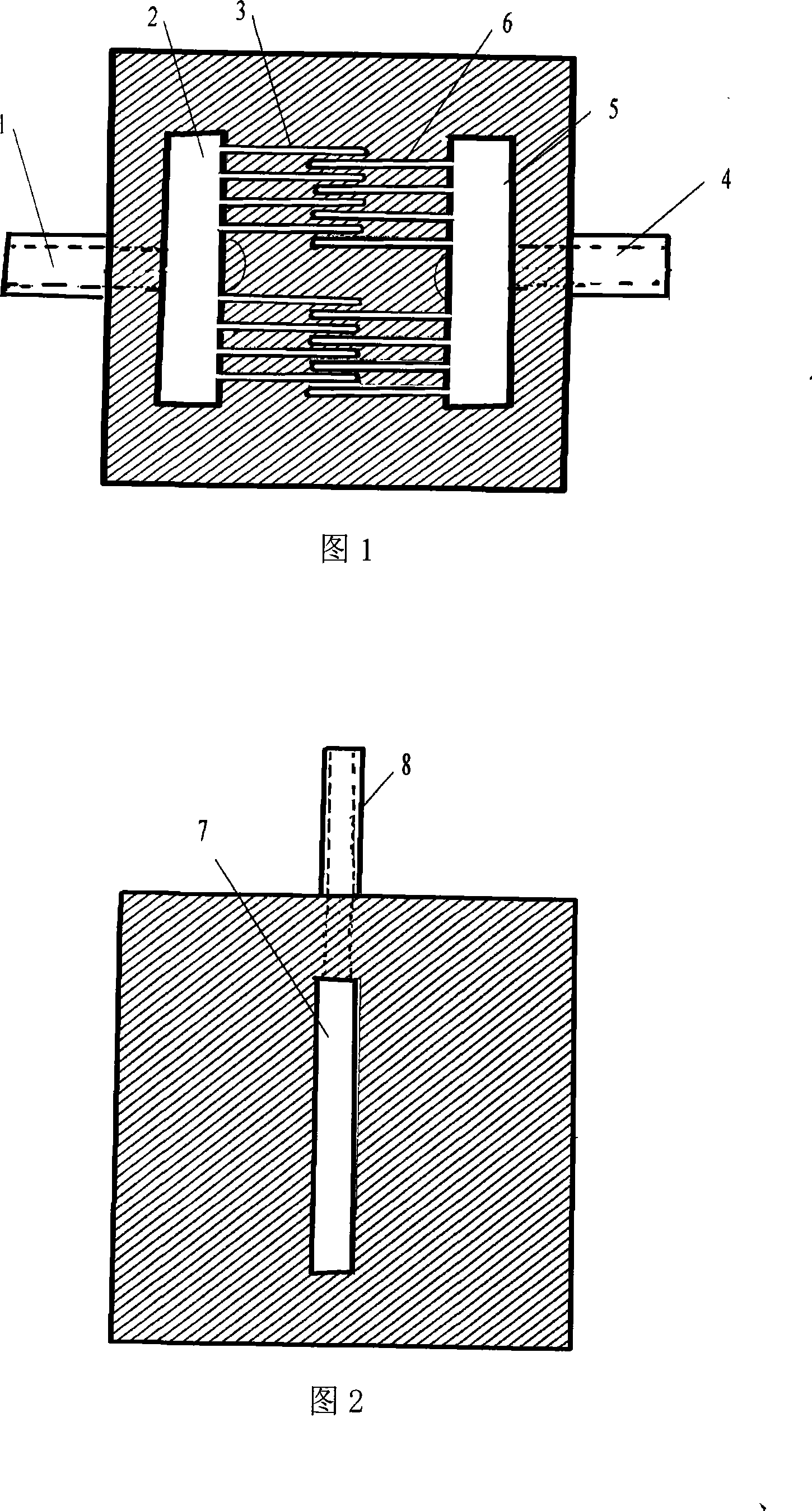

Image

Examples

Embodiment 1

[0018] Adopt n-butanol to extract succinic acid, for the double continuous multi-thin-layer micro-contact mixer that contains 10 parallel passages, when oil phase (material A) volume flow rate: when water phase (material B) volume flow rate is 1: 1, When the residence time is 0.21s, the extraction efficiency is 97.6%. The processing capacity of succinic acid solution can reach 60L / h, and the processing capacity of each channel is 12L / h.

Embodiment 2

[0020] Adopt n-butanol to extract phosphoric acid, for the double continuous multi-thin-layer micro-contact mixer that contains 20 parallel passages, when oil phase (material A) volume flow rate: water phase (material B) volume flow rate is 1: 1, when staying When the time is 0.23s, the extraction efficiency is 98.3%. The processing capacity of phosphoric acid solution can reach 100L / h, and the processing capacity of each channel is 10L / h.

Embodiment 3

[0022] Adopt 30%TBP-kerosene to extract nitric acid, for the double continuous multi-thin-layer micro-contact mixer that contains 16 parallel passages, when oil phase (material A) volume flow: when water phase (material B) volume flow is 1: 1, When the residence time is 0.25s, the extraction efficiency is 99.1%. The treatment capacity of nitric acid solution can reach 150L / h, and the treatment capacity of each channel is 18L / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com