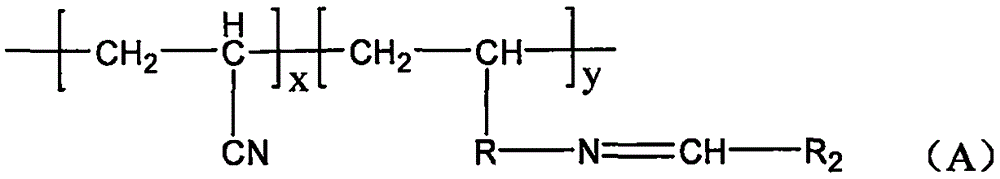

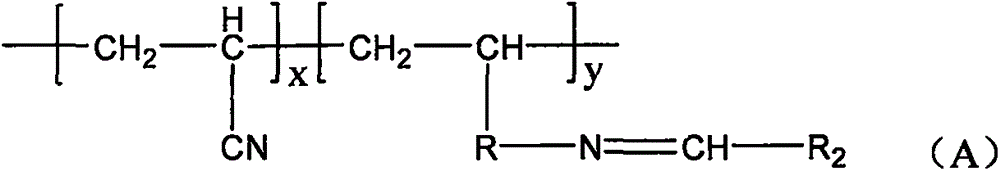

Functional fiber for boron adsorption and preparation method and application thereof

A functional fiber, polyacrylonitrile fiber technology, applied in the direction of fiber type, fiber treatment, fiber chemical characteristics, etc., can solve the problems of inability to remove boron well, low concentration adsorption rate and limited adsorption capacity, to ensure repeated adsorption. The effect of regeneration, fast adsorption rate and short mass transfer distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In an embodiment of the present invention, a method for preparing a functional fiber for boron adsorption comprises the following steps:

[0022] (1) Place polyacrylonitrile fibers in an aqueous solution of ethylenediamine with a mass content of 2% ethylenediamine, and reflux at 70°C for 4 hours to prepare aminated polyacrylonitrile fibers.

[0023] (2) Place the aminated polyacrylonitrile fiber prepared in step (1) in an aqueous D-glucose solution with a D-glucose mass content of 10%, reflux at 25°C for 1h, and vacuum dry at 60°C The boron-adsorbed functional fiber is obtained by drying.

Embodiment 2

[0025] In an embodiment of the present invention, a method for preparing a functional fiber for boron adsorption comprises the following steps:

[0026] (1) The polyacrylonitrile fibers were placed in an aqueous solution of diethylenetriamine with a mass content of 43% of diethylenetriamine amine, and refluxed at 100° C. for 6 hours to prepare aminated polyacrylonitrile fibers.

[0027] (2) Place the aminated polyacrylonitrile fiber prepared in step (1) in an aqueous D-fructose solution with a D-fructose mass content of 50%, reflux at 60°C for 4h, and vacuum-dry at 80°C The boron-adsorbed functional fiber is obtained by drying.

Embodiment 3

[0029] In an embodiment of the present invention, a method for preparing a functional fiber for boron adsorption comprises the following steps:

[0030] (1) The polyacrylonitrile fiber balls were placed in an aqueous solution of triethylamine with a mass content of 22% of triethylamine, and refluxed at 90° C. for 5.5 hours to prepare aminated polyacrylonitrile fibers.

[0031] (2) Place the aminated polyacrylonitrile fiber prepared in step (1) in an aqueous solution of D-glucose with a D-fructose mass content of 25%, reflux at 40°C for 3.5h, and then dry naturally to obtain boron Absorbent functional fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com