A treatment method for kitchen waste leachate after garbage sorting and recycling

A technology for sorting kitchen waste and garbage, applied in sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc. The effect of small area and more biochemical reaction

Active Publication Date: 2021-10-08

BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Anaerobic digestion of high-load organic matter is realized through IC reactors, without reflux dilution and multi-stage series connection, which solves the technical problems of many equipments and complicated control in the previous process

Through BAF-3D(An / Df)BER, on the one hand, semi-short-cut nitrification-anammox-autotrophic denitrification can be realized, and deep denitrification can be carried out without adding any carbon source, which solves the problem of effluent from anaerobic digestion in the past The denitrification and denitrification of this kind of sewage with high ammonia nitrogen and low organic matter requires a large amount of carbon source, which causes the key problem of high cost; Analyze the refractory organic matter, and realize the standard discharge of kitchen waste leachate after garbage sorting and recycling at the lowest cost

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example

[0052] Combined example: the experimental water is taken from the leachate of kitchen waste recycled by a biomass energy company in Beijing. The water quality is as follows: CODcr is 10.0-15.0 mg·mL -1 , TN is 2.5~3.0mg·mL -1 , NH 4 + -N is 2.0~2.5mg·mL -1 , NO x - -N is 10~15mg·L -1 , TP is 9.0~15.0mg·mL -1 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

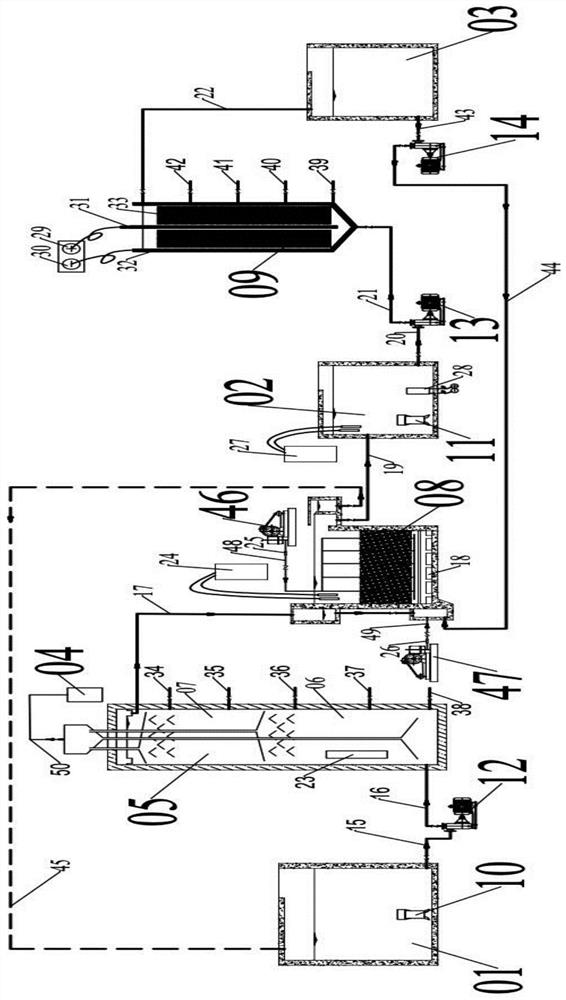

The invention discloses a method for treating kitchen waste leachate after garbage sorting and recycling, which belongs to the technical field of high-concentration ammonia nitrogen wastewater treatment. The invention is provided with a raw water tank, an internal circulation anaerobic reactor (IC), a biological aerated filter (BAF), an intermediate water tank, and a three-dimensional anaerobic ammonium oxidation coupled autotrophic denitrification biofilm electrode reactor (3D(An / Df )BER), with an internal circulation device and a three-phase separation device in the IC, an aeration device and a backwashing device in the BAF, and a light biological carrier ceramsite filler, in the 3D(An / Df)BER An anode made of carbon rods, a cathode made of carbon fiber felt and a third electrode of granular activated carbon are installed. By realizing high-load organic matter anaerobic digestion in IC, semi-short-path nitrification and deammonization in BAF, anammox, autotrophic denitrification and electro-oxidation reactions in 3D(An / Df)BER, and then garbage classification Autotrophic deep denitrification and carbon removal of kitchen waste leachate after recycling.

Description

technical field [0001] The invention relates to a method for treating kitchen waste leachate after garbage classification and recovery, and belongs to the technical field of wastewater treatment containing high-concentration organic matter and high-concentration ammonia nitrogen. The invention is provided with a raw water tank, an internal circulation anaerobic reactor (IC), a biological aerated filter (BAF), an intermediate water tank, and a three-dimensional anaerobic ammonium oxidation coupled autotrophic denitrification biofilm electrode reactor (3D(An / Df )BER), with an internal circulation device and a three-phase separation device in the IC, an aeration device and a backwashing device in the BAF, and a light biological carrier ceramsite filler, in the 3D(An / Df)BER An anode made of high-purity carbon rods, a cathode made of carbon fiber felt and a third electrode of granular activated carbon are installed. Through anaerobic digestion of high-concentration organic matter ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C02F3/30C02F3/10C02F3/00C02F101/16C02F101/30

CPCC02F3/005C02F3/106C02F3/305C02F3/307C02F2003/003C02F2101/16C02F2101/163C02F2101/30Y02W10/10

Inventor 吴莉娜苏德欣李进

Owner BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com