Device and method for efficiently realizing acidic gas absorption by ionic liquid

A technology for ionic liquids and acid gases, applied in separation methods, gas treatment, chemical instruments and methods, etc., can solve the problems of slow industrial application of ionic liquids, poor mass transfer performance of batch reactors, and reduced gas absorption speed, etc. Achieve the effect of reducing consumption and energy consumption, short mass transfer distance and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

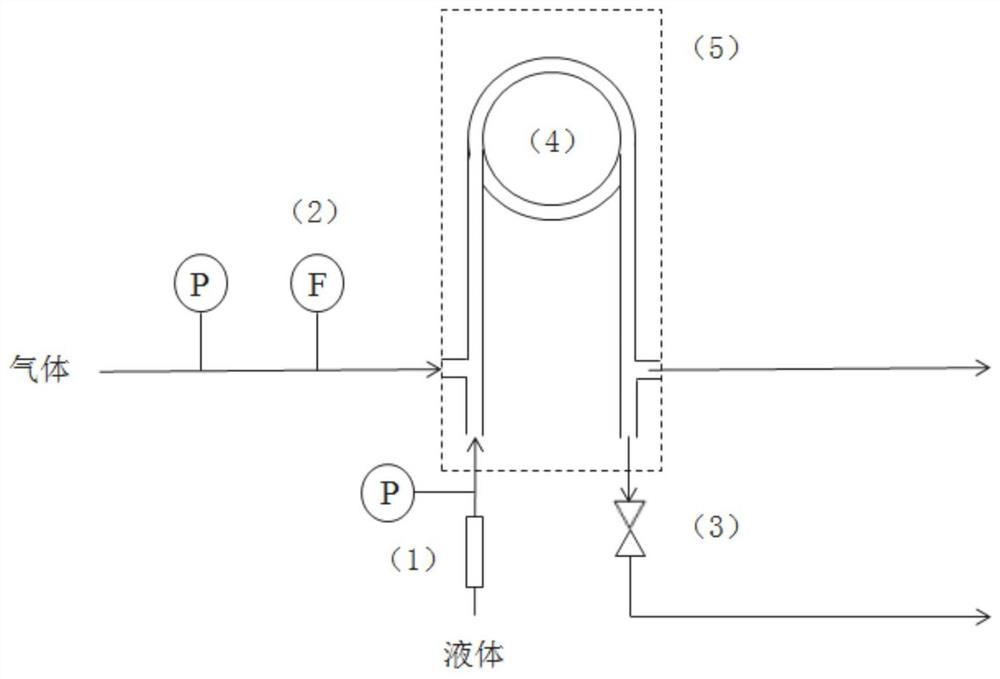

Method used

Image

Examples

Embodiment 1

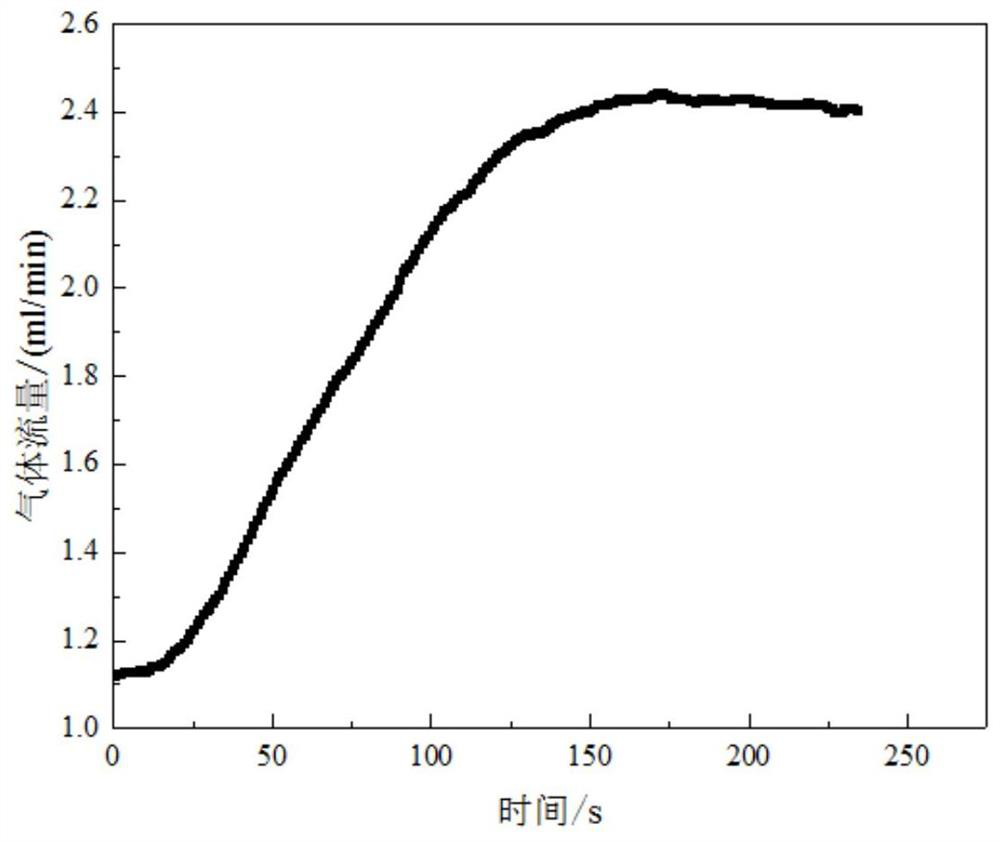

[0032] Pour the ionic liquid into a blue-capped bottle, heat the ionic liquid to 60°C with a magnetic heating stirrer, and vacuumize it for 1 hour through a circulating water vacuum pump for degassing. Immerse the micro-membrane contactor unit in a water bath (control the temperature at 40°C), inject the degassed ionic liquid ([Pmmim][Tf2N]) into the liquid pipeline of the membrane contactor unit through a syringe pump, and the gas supply unit passes The mass flow meter will CO 2 Enter the gas line of the membrane contactor unit. The membrane material used in the membrane contactor unit is Teflon AF-2400 with an inner diameter of 0.6mm and an outer diameter of 0.8mm. The gas pressure is controlled at 0.4MPa, and the liquid pressure is controlled at 0.5MPa. When the system is stable, turn on the recording function of the gas mass flowmeter and record the gas flow online in real time.

[0033] Observe the reading of the gas mass flowmeter. When the reading does not change, sh...

Embodiment 2

[0036] Pour the ionic liquid into a blue-capped bottle, heat the ionic liquid to 30°C with a magnetic heating stirrer, and vacuumize it for 0.8h through a circulating water vacuum pump for degassing. Immerse the micro-membrane contactor unit in a water bath (control the temperature at 30°C), inject the degassed ionic liquid ([Bmmim][Tf2N]) into the liquid pipeline of the membrane contactor unit through a syringe pump, and the gas supply unit passes The mass flow meter will CO 2 Enter the gas line of the membrane contactor unit. The membrane material used in the membrane contactor unit is Teflon AF-2400 with an inner diameter of 0.6mm and an outer diameter of 0.8mm. The gas pressure is controlled at 0.4MPa, and the liquid pressure is controlled at 0.5MPa. When the system is stable, turn on the recording function of the gas mass flowmeter and record the gas flow online in real time.

[0037] Observe the mass flow meter reading, when the reading no longer changes, shut down th...

Embodiment 3

[0040] Pour the ionic liquid into a blue-capped bottle, heat the ionic liquid to 50°C with a magnetic heating stirrer, and vacuumize it for 0.5h through a circulating water vacuum pump for degassing. Immerse the micro-membrane contactor unit in a water bath (control the temperature at 60°C), inject the degassed ionic liquid ([Emmim][Tf2N]) into the liquid pipeline of the membrane contactor unit through a syringe pump, and the gas supply unit passes The mass flow meter will CO 2Enter the gas line of the membrane contactor unit. The membrane material used in the membrane contactor unit is Teflon AF-2400 with an inner diameter of 0.6mm and an outer diameter of 0.8mm. The gas pressure is controlled at 0.4MPa, and the liquid pressure is controlled at 0.5MPa. When the system is stable, turn on the recording function of the gas mass flowmeter and record the gas flow online in real time.

[0041] Observe the mass flow meter reading, when the reading no longer changes, shut down the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com