An extraction method for high-efficiency enrichment and recovery of low-concentration rare earth ions

A technology of rare earth ions and rare earth ion solutions, which is applied in the direction of improving process efficiency, etc., to achieve the effects of fast mass transfer rate, large specific surface area, and short mass transfer distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

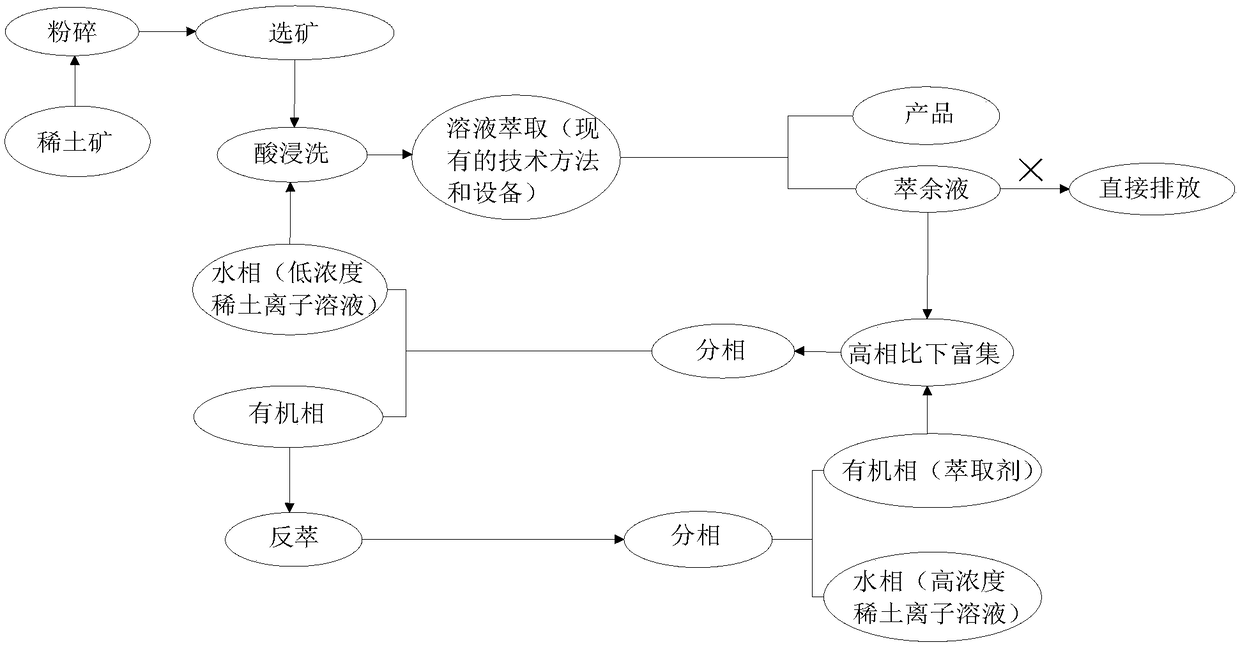

[0025] see figure 1 , Dissolve the chloride of neodymium with hydrochloric acid aqueous solution of pH=4, and make rare earth ion solution (initial concentration is 90mg / L). Take 34mL of monoisooctyl phosphate (P507) and 66mL of sulfonated kerosene and stir to obtain a homogeneous solution, wherein the concentration of the extractant is 1mol / L. Open the gas valve, the gas mass flow meter, and the switches of the two advection pumps, and adjust the direction of the five-way ball valve so that the length of the outlet pipe stays at 2m. In the first-stage membrane dispersion micro-extractor, the gas is the dispersed phase, and the organic phase is the continuous phase; in the second-stage membrane dispersion micro-extractor, the gas-in-oil structure is the dispersed phase, and the continuous phase is the rare earth ion solution. The flow rate of the water phase is adjusted to 40mL / min, the flow rate of the oil phase is 0.2mL / min, and the flow rate of the gas phase is 90mL / min. ...

Embodiment 2

[0027] The chloride of europium was dissolved in aqueous hydrochloric acid solution with pH=4 to prepare a rare earth ion solution (initial concentration: 50mg / L). Take 34mL of monoisooctyl phosphate (P507) and 66mL of sulfonated kerosene and stir to obtain a homogeneous solution, wherein the concentration of the extractant is 1mol / L. Open the gas valve, the gas mass flow meter, and the switches of the two advection pumps, and adjust the direction of the five-way ball valve so that the length of the outlet pipe stays at 2m. In the first-stage membrane dispersion micro-extractor, the gas is the dispersed phase, and the organic phase is the continuous phase; in the second-stage membrane dispersion micro-extractor, the gas-in-oil structure is the dispersed phase, and the continuous phase is the rare earth ion solution. The flow rate of the water phase is adjusted to 40mL / min, the flow rate of the oil phase is 0.2mL / min, and the flow rate of the gas phase is 90mL / min. After the f...

Embodiment 3

[0029] Dissolve erbium chloride with aqueous hydrochloric acid solution at pH=4 to form a rare earth ion solution (initial concentration: 10 mg / L). Take 34mL of monoisooctyl phosphate (P507) and 66mL of sulfonated kerosene and stir to obtain a homogeneous solution, wherein the concentration of the extractant is 1mol / L. Open the gas valve, the gas mass flow meter, and the switches of the two advection pumps, and adjust the direction of the five-way ball valve so that the length of the outlet pipe stays at 2m. In the first-stage membrane dispersion micro-extractor, the gas is the dispersed phase, and the organic phase is the continuous phase; in the second-stage membrane dispersion micro-extractor, the gas-in-oil structure is the dispersed phase, and the continuous phase is the rare earth ion solution. The flow rate of the water phase is adjusted to 40mL / min, the flow rate of the oil phase is 0.2mL / min, and the flow rate of the gas phase is 90mL / min. After the fluid flowed for 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com