Rapid crystallization method for synthesizing EMT molecular sieve

A molecular sieve, chemical synthesis technology, applied in chemical instruments and methods, molecular sieves and alkali exchange compounds, inorganic chemistry, etc., can solve the problems of slow crystallization rate, shortened crystallization time, shortened crystallization time, etc. Effects of generation, increased mass transfer rate, and shortened crystallization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

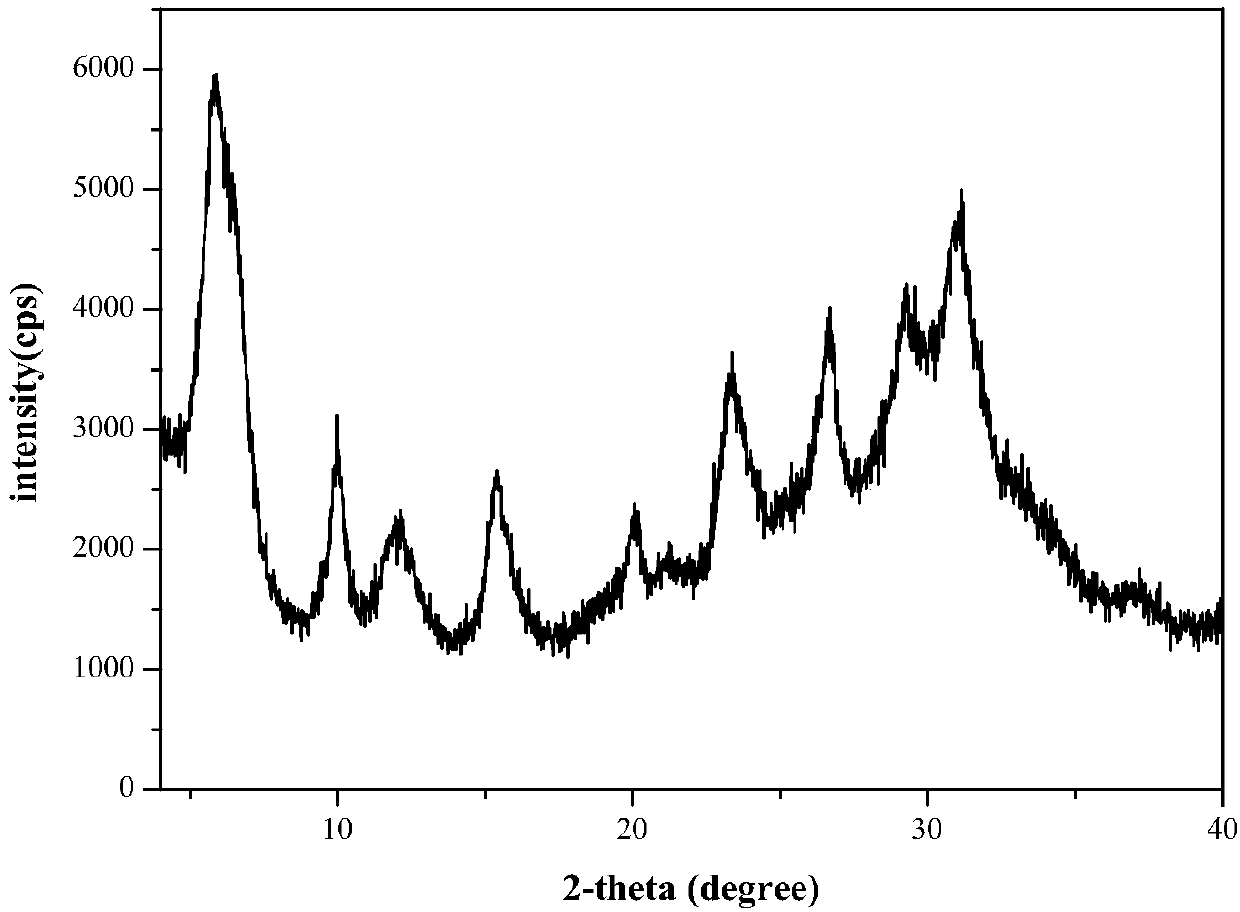

[0042] At room temperature, weigh 4.976g of sodium metaaluminate, add 20.000g of water, add 7.923g of sodium hydroxide during stirring, stir and mix until a clear solution, and place it at room temperature. Weigh 24.0g of silica sol with a mass fraction of 25%, add 20g of sodium hydroxide, add 40g of water during the process, stir and dissolve continuously, and when the solution is cooled to room temperature, slowly add the configured sodium metaaluminate solution dropwise, and stir for 2h. Crystallize at 30°C for 36h to obtain the desired EMT molecular sieve seed A, figure 1 The XRD spectrum of the prepared EMT seed crystal, the characteristic peaks of the spectrum are consistent with those reported in the literature [Science, 2012, 335:70-73].

Embodiment 2

[0044] At room temperature, weigh 10.00g of sodium metaaluminate and 1.80g of sodium hydroxide, add 100.2g of water, stir continuously, add 40.00g of sodium hydroxide, continue stirring until clear, cool to room temperature for later use. Weigh 57.70g of water glass with a modulus of 3.2, add 80.3g of water, and add 20.0g of sodium hydroxide during the stirring process. After stirring evenly and cooling to room temperature, slowly add sodium metaaluminate solution dropwise, and stir for 0.5h to obtain the obtained The desired EMT molecular sieve seed crystal B.

Embodiment 3

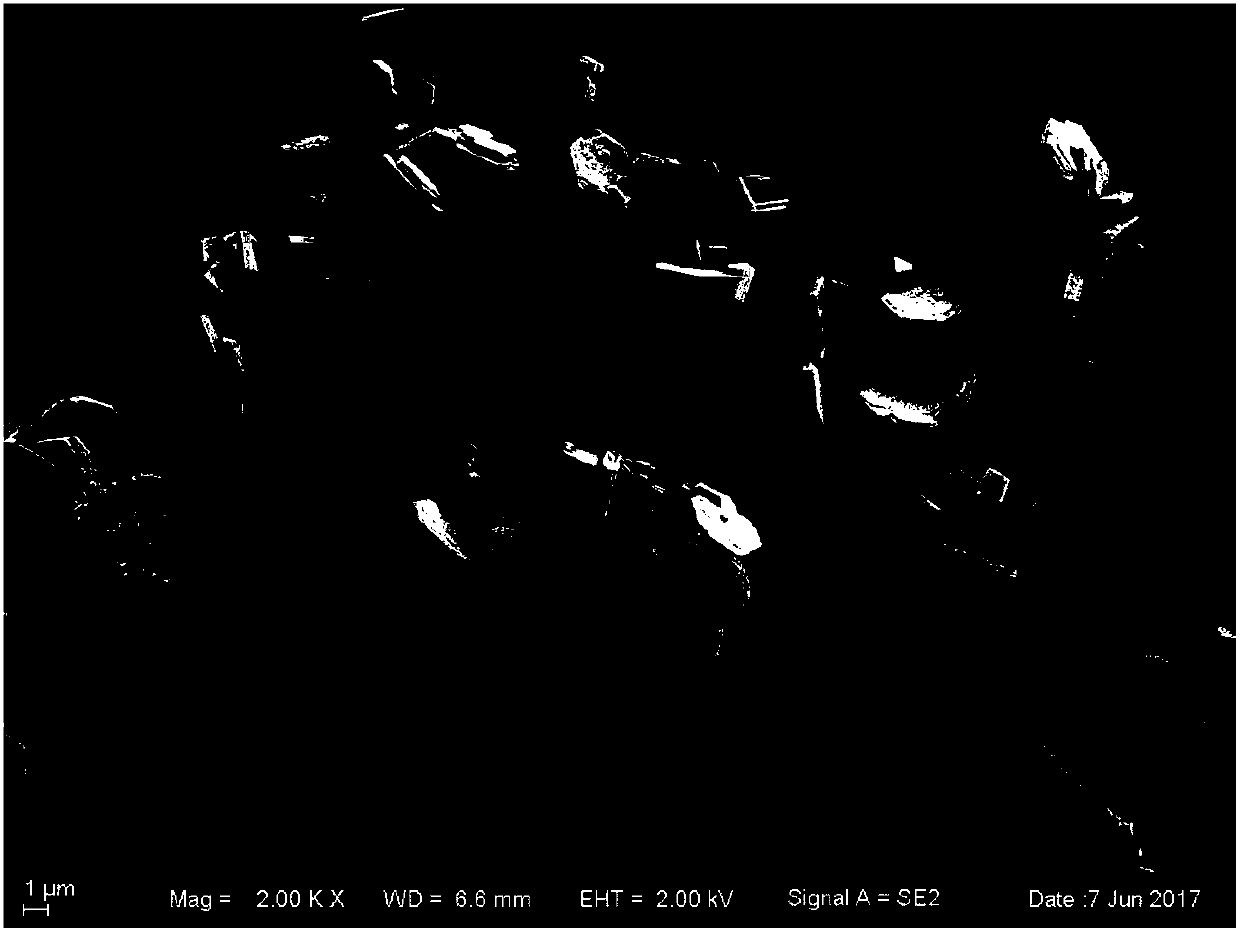

[0046] In the hydrothermal synthesis environment, the effects of different hydrothermal crystallization temperatures on the synthesis of EMT molecular sieves were investigated.

[0047] At room temperature, weigh 4.976g of sodium metaaluminate, add 10.8g of water, add 1.50g of sodium hydroxide during stirring, mix and stir until a clear solution, and cool for later use. Weigh 72.0g of silica sol with a mass fraction of 25%, add 0.529g template agent (18-crown-6 ether), mix and stir until the template agent is completely dissolved, then slowly add sodium metaaluminate solution dropwise, stir for 6h, then add 2. 232g of seed crystal A, transferred to a polytetrafluoroethylene-lined stainless steel reactor, crystallized at 70°C, 80°C, 90°C, 100°C, and 110°C for 48 hours, filtered, washed, and dried to obtain a molecular sieve sample . The obtained results are listed in Table 1.

[0048] Synthetic EMT molecular sieve result under table 1 embodiment 3 different temperatures

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com