Patents

Literature

36results about How to "Small secondary pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antibacterial fabric/fiber finishing liquid for expelling and killing insect pollination and application method and fabric product/fiber product/paper product thereof

InactiveCN107761374AFix compatibility issuesSimple compositionBiochemical treatment with wool-protecting/anti-moth agentsPaper/cardboardFiberPollination

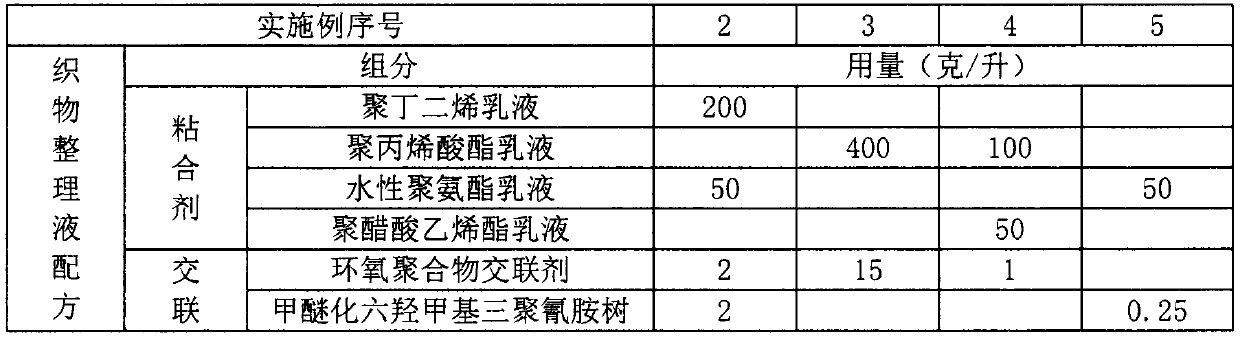

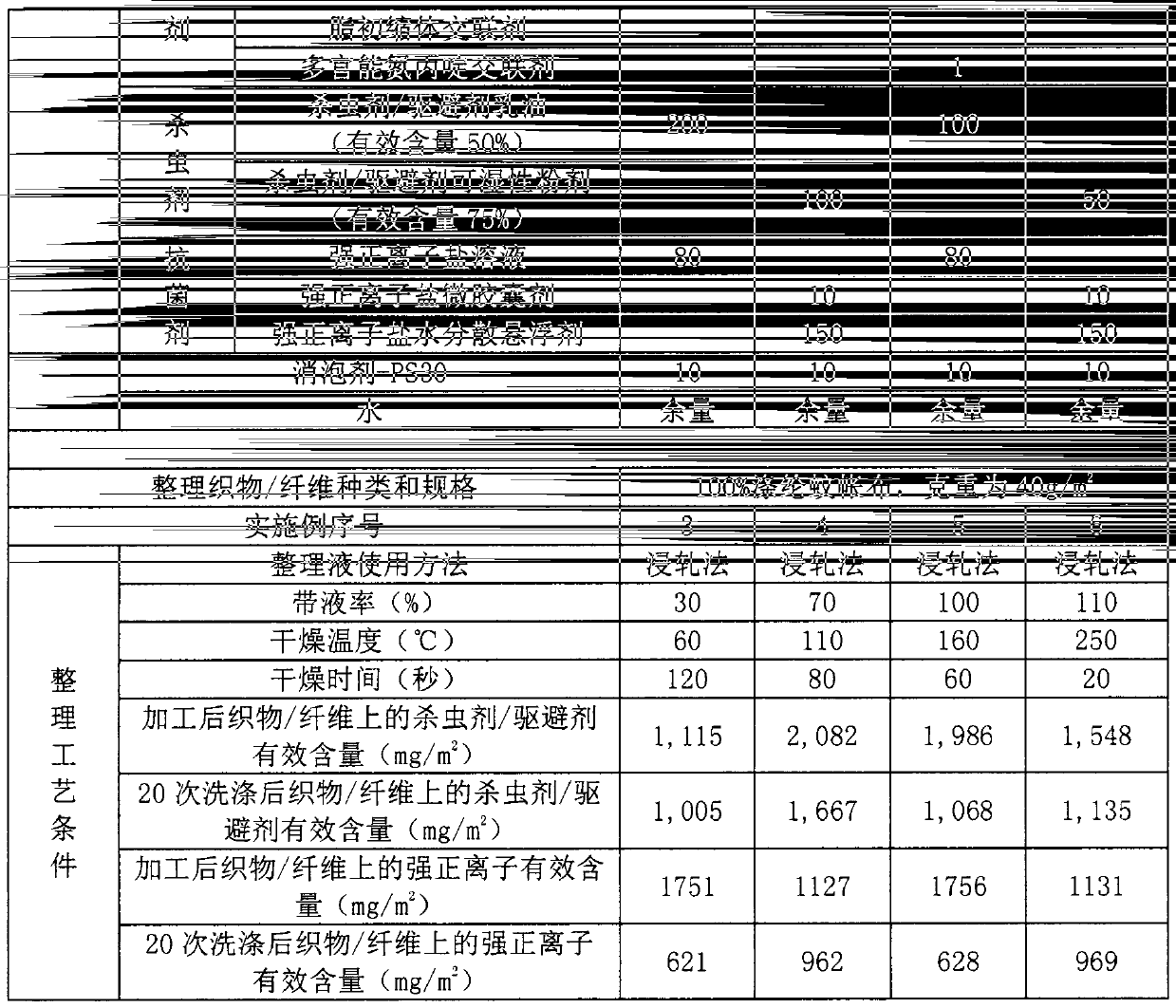

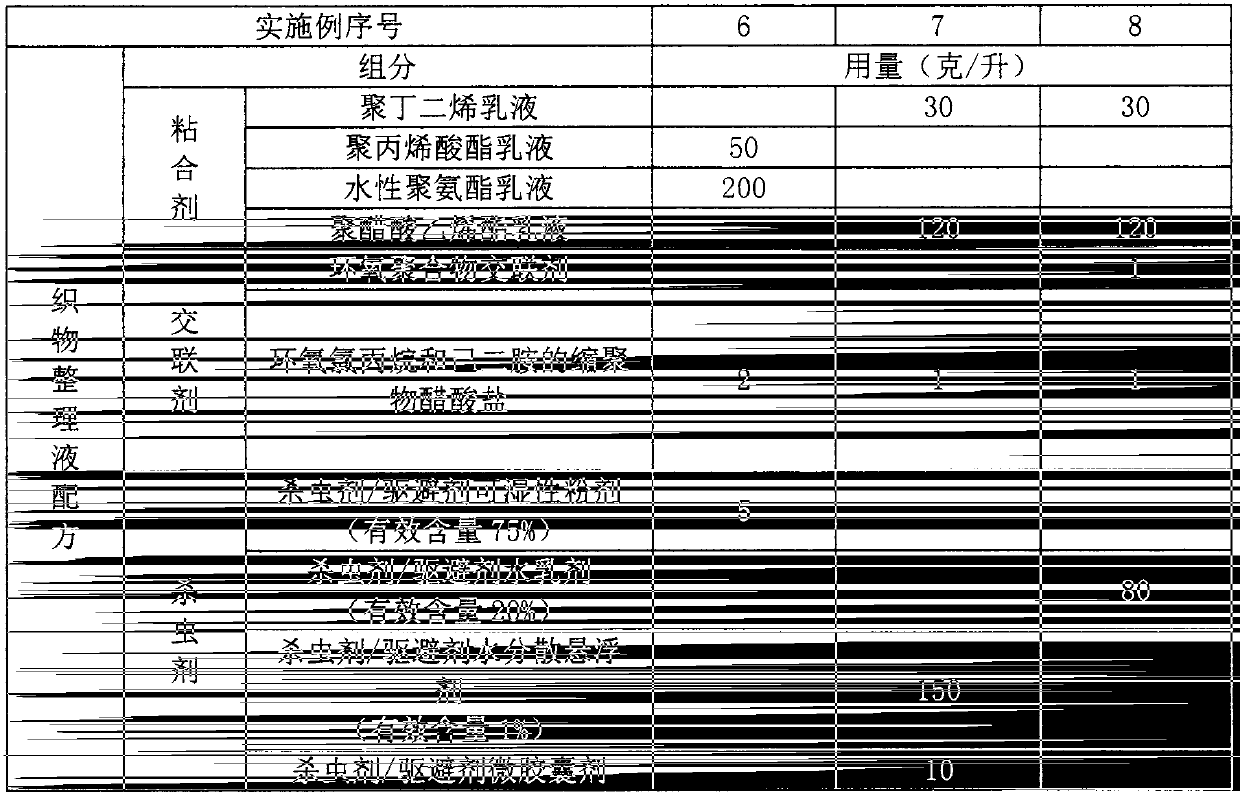

The invention relates to a fabric / fiber finishing solution for antibacterial and insecticide repelling, its use method and fabric / fiber product / paper product. The mass percentage formula of the fabric / fiber finishing solution is: 0.05-40% of insecticide / repellent; 0.05-20% of antibacterial agent; 5.00-35% of binder; and 0.025-5% of crosslinking agent. The method for using the fabric / fiber finishing liquid of the present invention can be selected according to the difference of the finishing fabric / fiber material, one of the padding method, the spraying method or the dipping method. The fabric / fiber product / paper product is obtained by finishing the fabric / fiber finishing liquid or / and the method of using the fabric / fiber finishing liquid of the present invention. The fabric / fiber finishing liquid and its products of the present invention have the advantages of high efficacy, strong adhesion, water washing resistance, can reach the WHO standard, low cost, good applicability, convenient use and popularization, and the like.

Owner:牛绍英

Fabric finishing liquid for insecticidal medium, and its use method and fabric product

InactiveCN1851109AImprove efficiencyHigh efficiency in repelling insect vectorsFibre treatmentLiquid/gas/vapor textile treatmentEpoxyCross-link

The invention relates to an insecticide -used fabric finishing liquid and the use method thereof as well as the fabric goods. And the formula of the fabric finishing liquid comprises: insecticide 0.5-40m% (mass percent); adhesive 5-40m%; cross- linking agent 0.025-1.50m%; water the rest, where the insecticide is 1-99% DDT (dichloro-diphenyl- trichloroethane) in any form; the adhesive is 30-50% adhesive in water aqua form; the cross-linking agent is epoxy polymer cross-linking agent, or methyl-etherized hexahydroxy-methyl-melamine resin primary contractor cross-linking agent, or other cross-linking agent. And the use method can select dip rolling process, or spraying process, or dipping process according to different fabric finishing materials. And the fabric goods is obtained by the fabric finishing liquid or / and the use method of the invention. And the fabric finishing liquid and the fabric goods have high effectiveness, strong adhesion, water washing resistance, etc.

Owner:TIANJIN YORKOOL INT TRADING

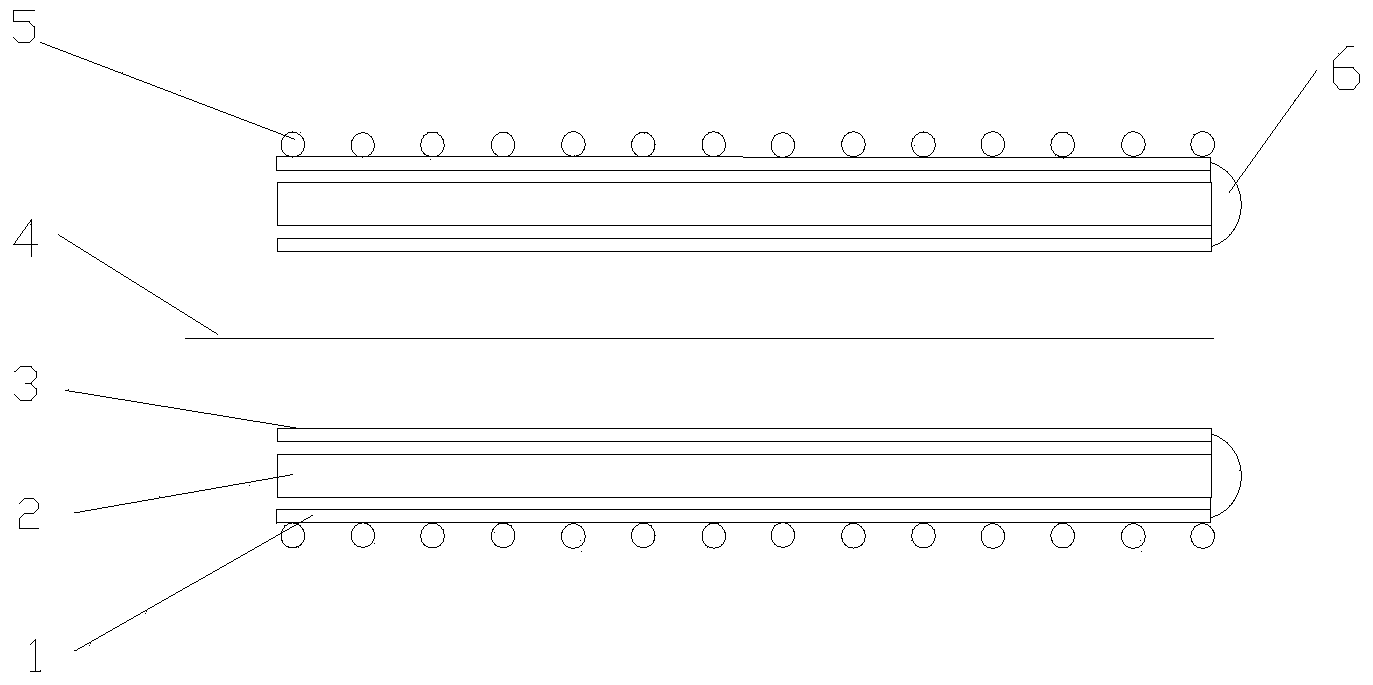

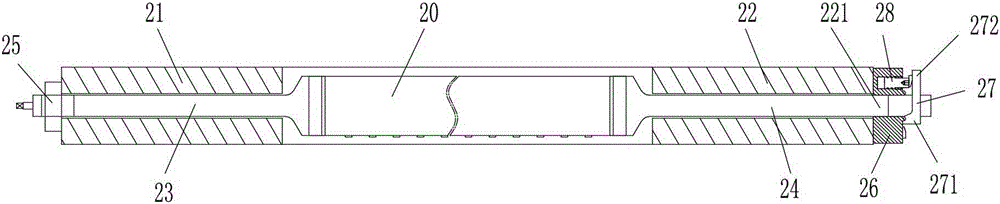

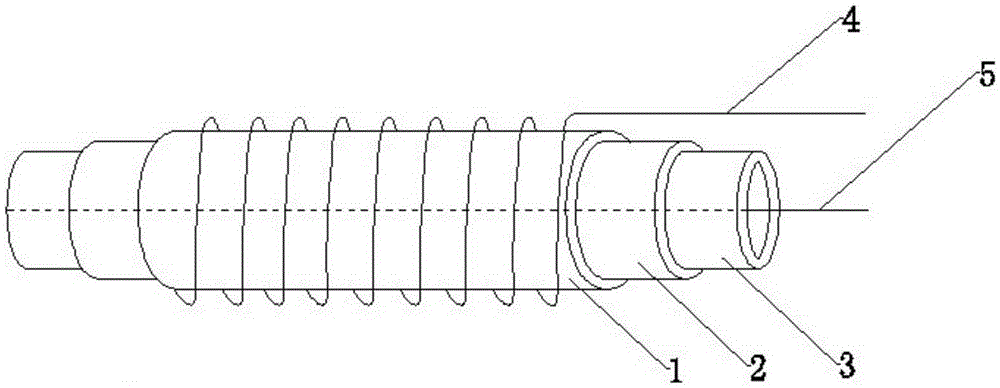

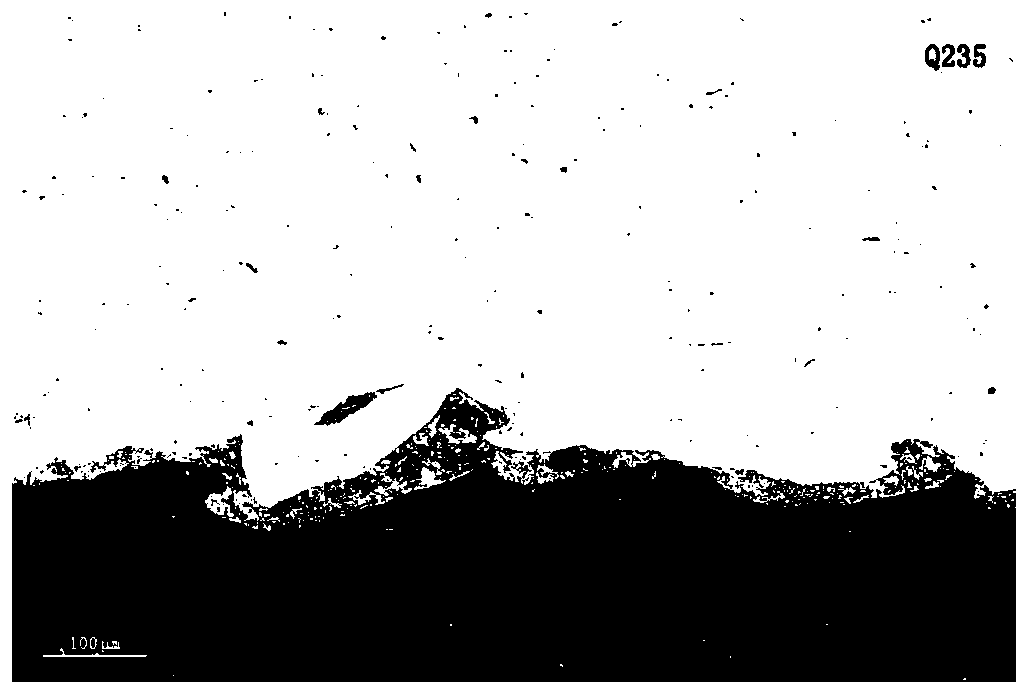

Explosive cladding tube manufacturing process

ActiveCN103639584AEasy to operatePracticalWelding/soldering/cutting articlesMetal working apparatusExplosive claddingEngineering

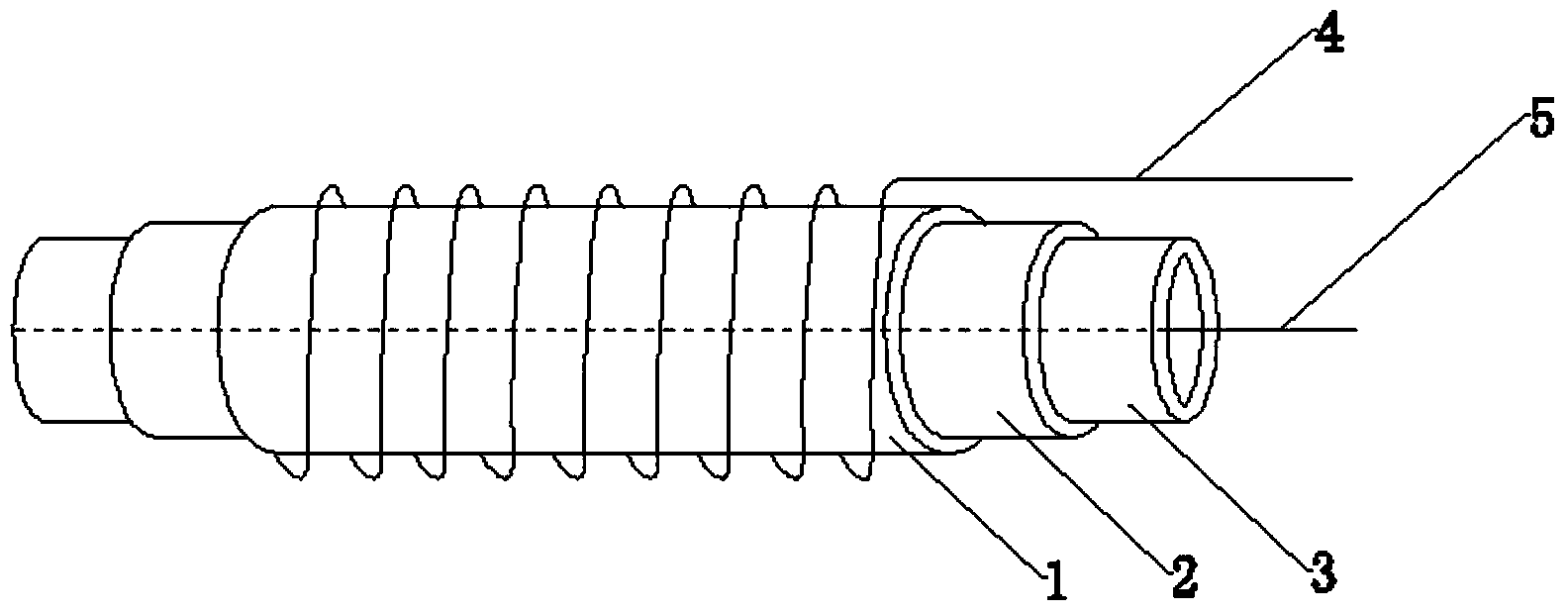

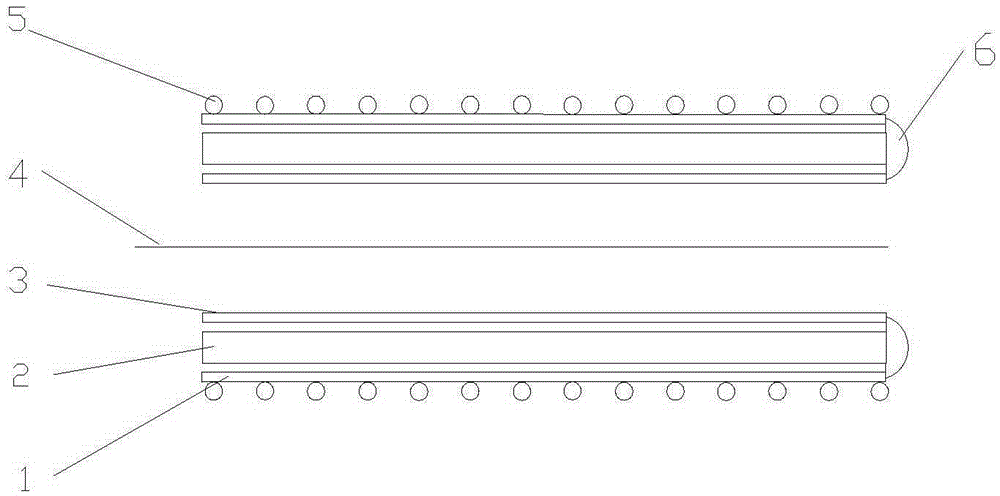

The invention discloses an explosive cladding tube manufacturing process. The explosive cladding tube manufacturing process includes the following operations that a tube needing cladding is prepared, wherein the tube at least comprises a cladding tube and a lining tube; a first explosive fiber spirally and evenly winds the cladding tube; after the required explosive amount is wound, the first explosive fiber is loosened, so that gaps of the preset distance are kept between the first explosive fiber and the outer wall of the cladding tube; a second explosive fiber is inserted into the lining tube and fixed by a plug with a hole; the first explosive fiber and the second explosive fiber are connected to a same detonator to form a whole device, the whole device is placed in water storage equipment, and a part needing cladding is placed under water; eventually, detonation is conducted. Actual experimental results show that the explosive cladding method of a long tube and a superlong tube is innovative and has innovativeness in multiple aspects and outstanding advantages.

Owner:UNIV OF SCI & TECH OF CHINA

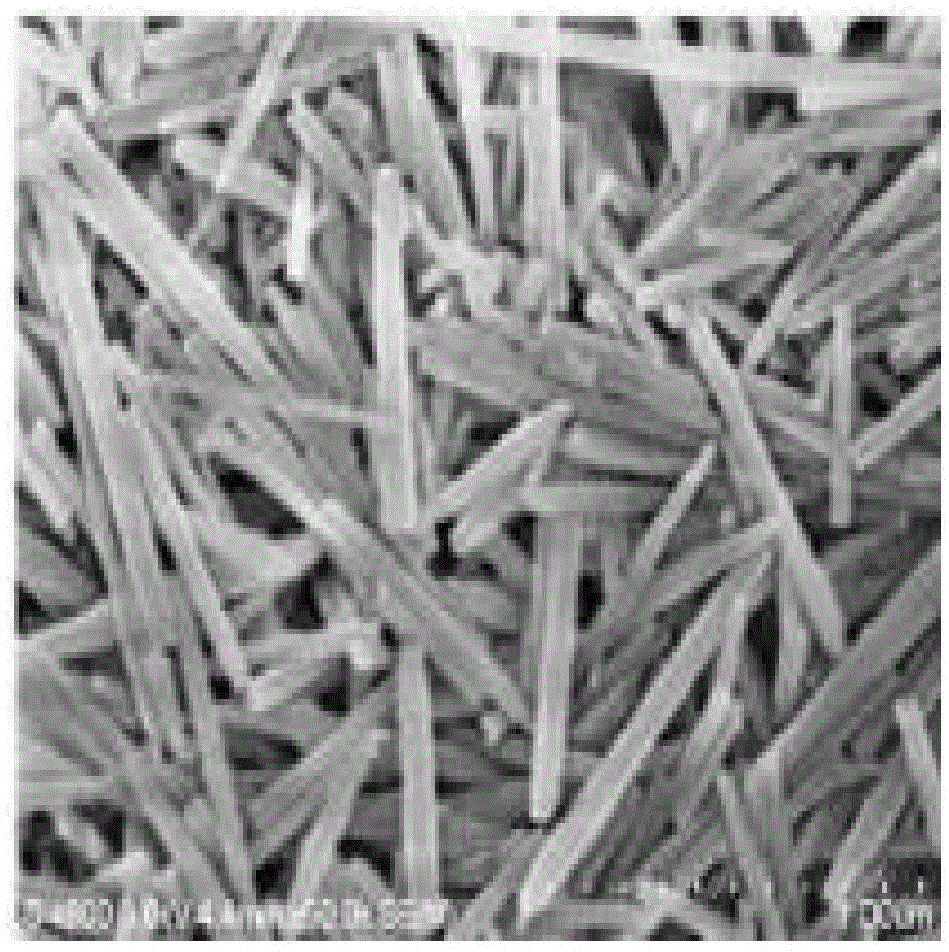

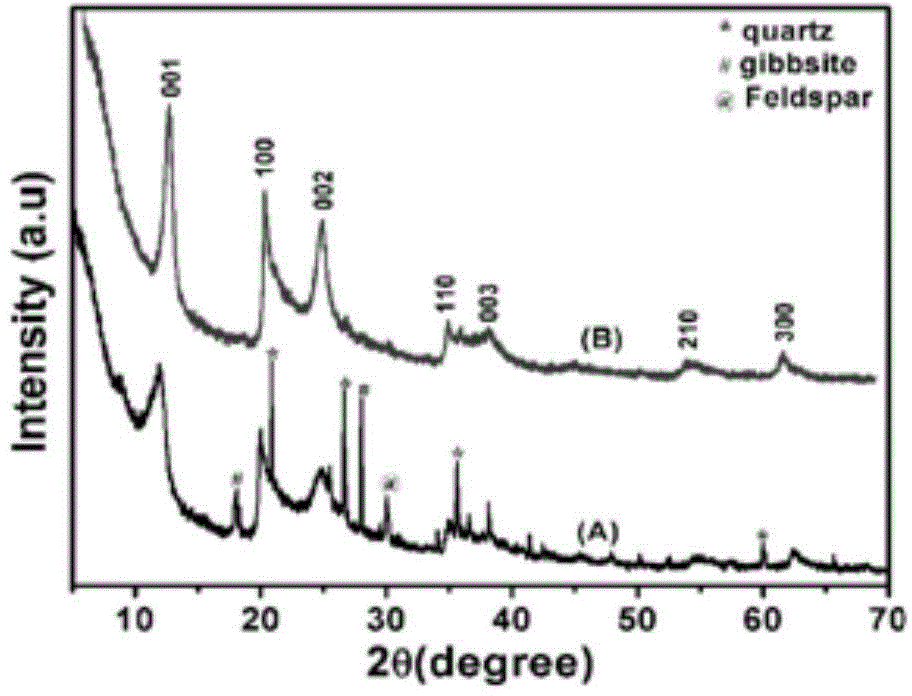

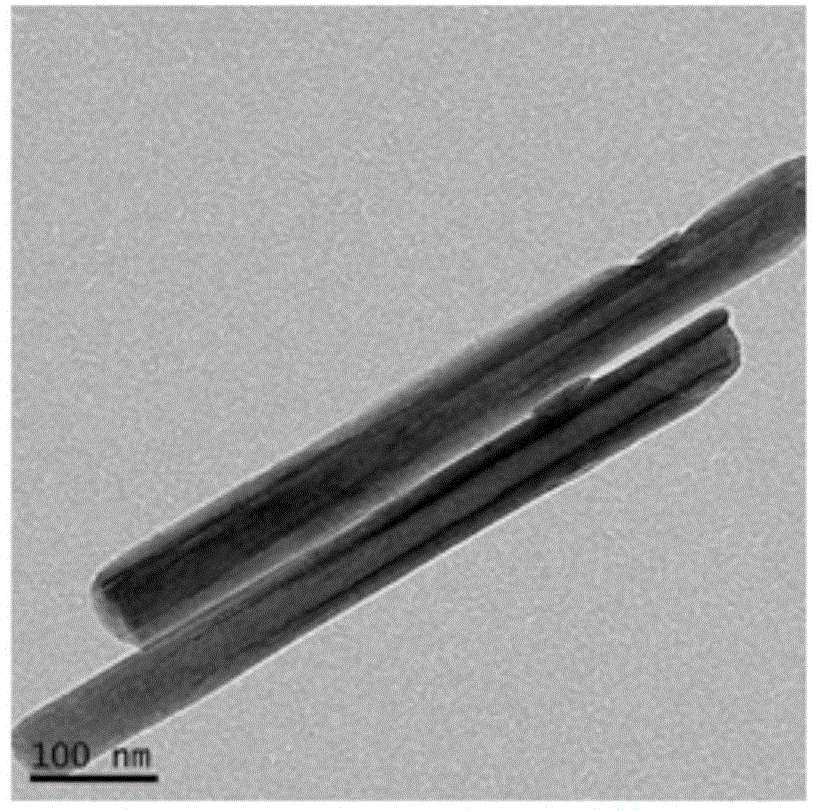

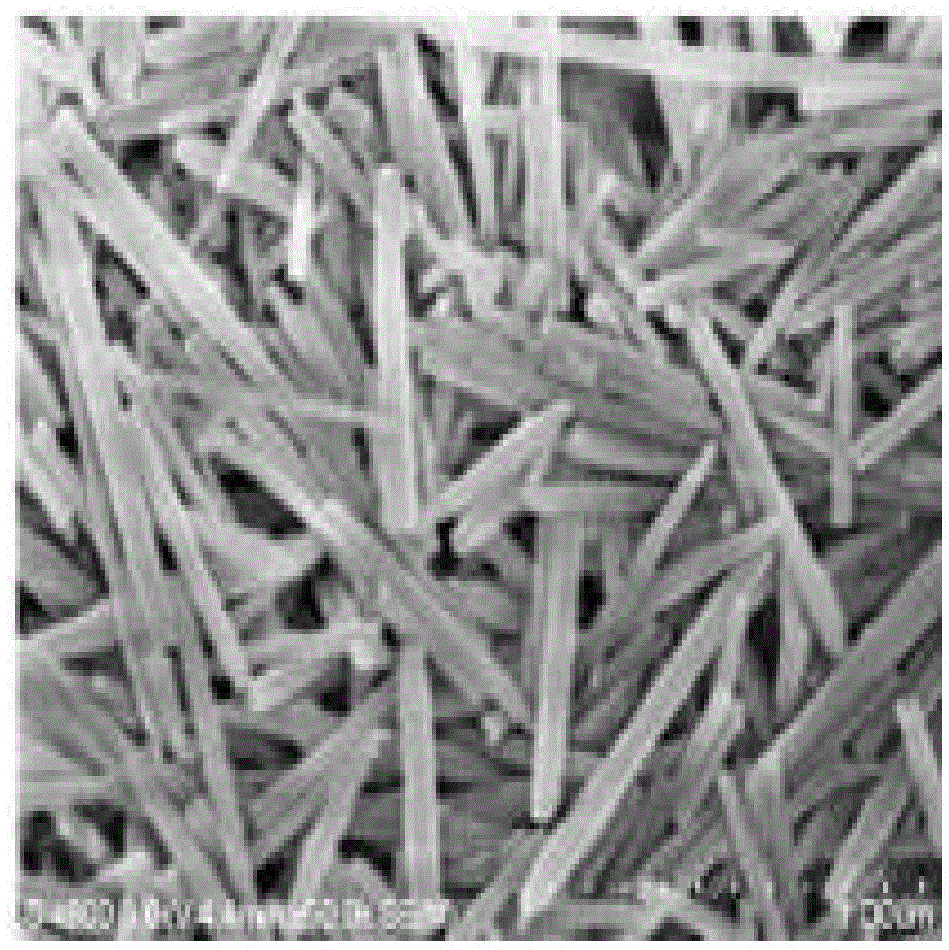

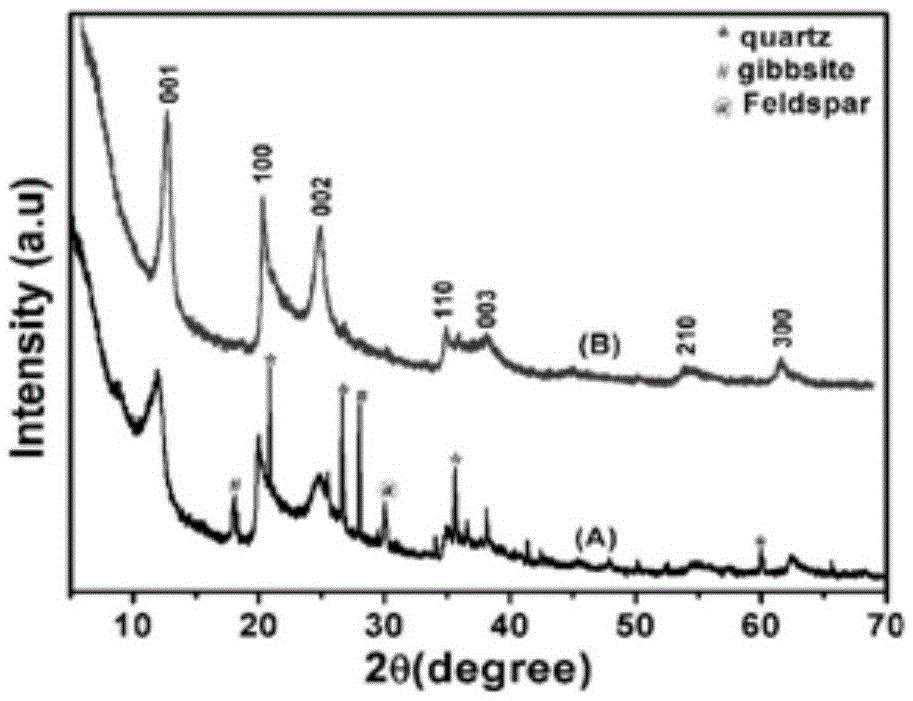

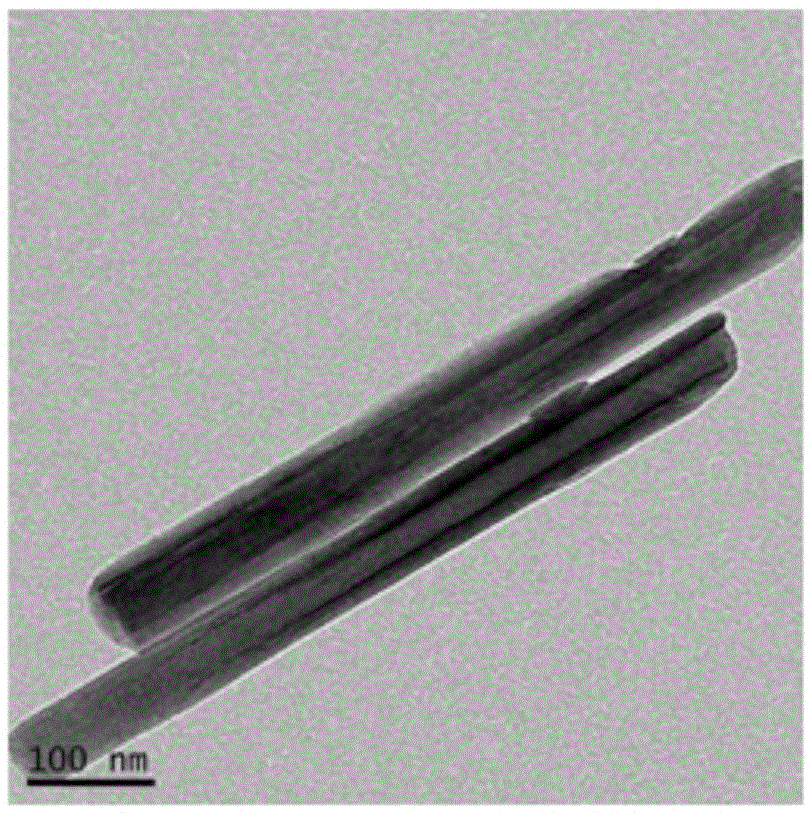

Large-aperture one-dimensional tubular zeolite and preparation method thereof

InactiveCN104556098AAchieve diffusionControlled diffusionCrystalline aluminosilicate zeolitesHalloysitePollution

The invention relates to large-aperture one-dimensional tubular zeolite and a preparation method thereof. The large-aperture one-dimensional tubular zeolite has a nanometer one-dimensional hollow tube structure, the internal diameter of the large-aperture one-dimensional tubular zeolite is 70-90nm, the tube wall thickness is 15-22nm, and the tube length is 0.65-1 micron. The preparation method of the large-aperture one-dimensional tubular zeolite comprises the following steps: 1) preparing purified halloysite; and 2) preparing the large-aperture one-dimensional tubular zeolite: under the conditions of normal temperature and normal pressure, grinding the purified halloysite until the particle size is less than or equal to 200mesh, adding the ground purified halloysite into a sodium hydroxide solution, uniformly mixing, putting in a hydrothermal reaction kettle, carrying out hydrothermal reaction for 20-24h under the condition with the temperature to be 100-110 DEG C, and then carrying out post-processing to obtain the large-aperture one-dimensional tubular zeolite. The method is simple in step, mild in reaction condition, short in production period, simple in procedure, low in cost and little in secondary pollution and is suitable for scale production.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

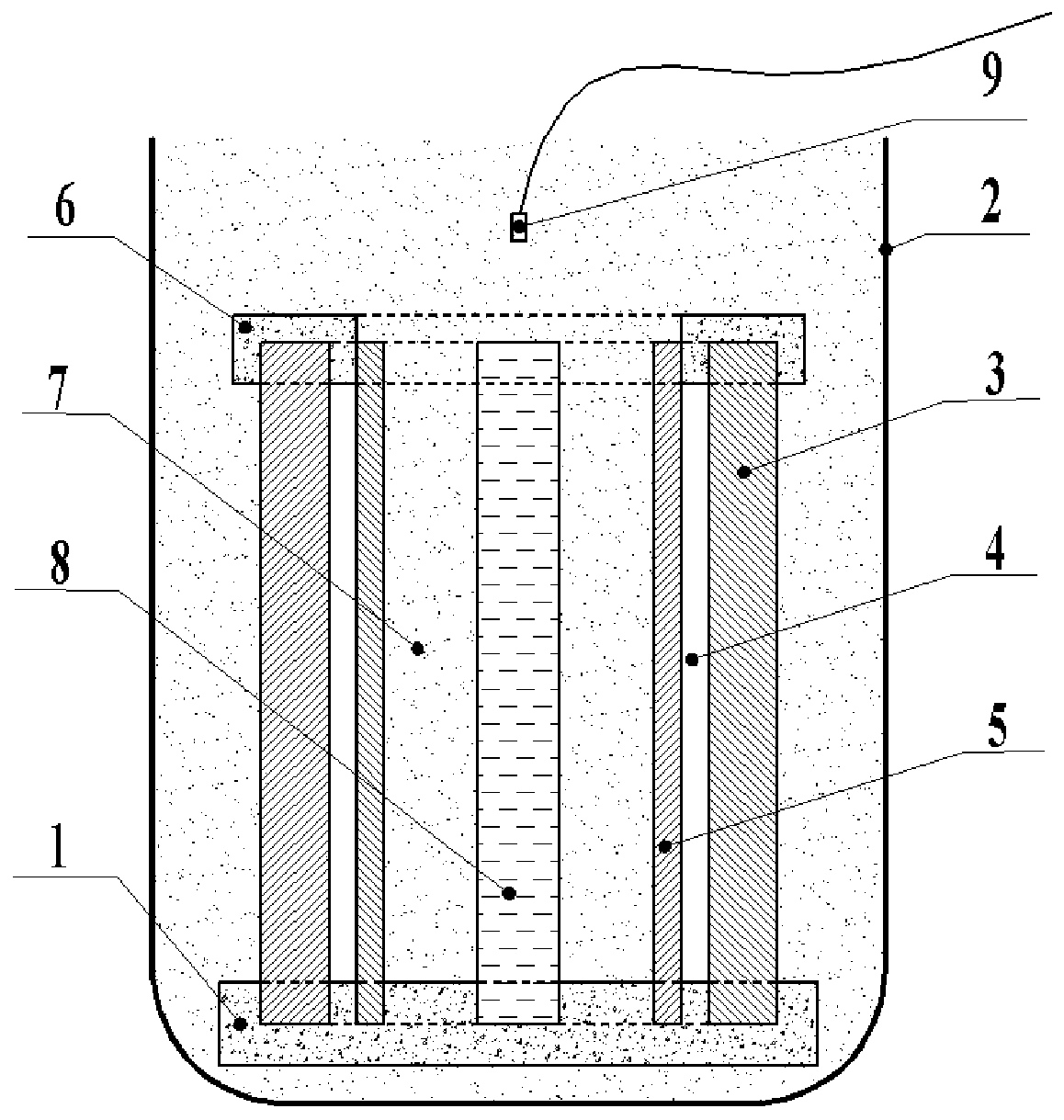

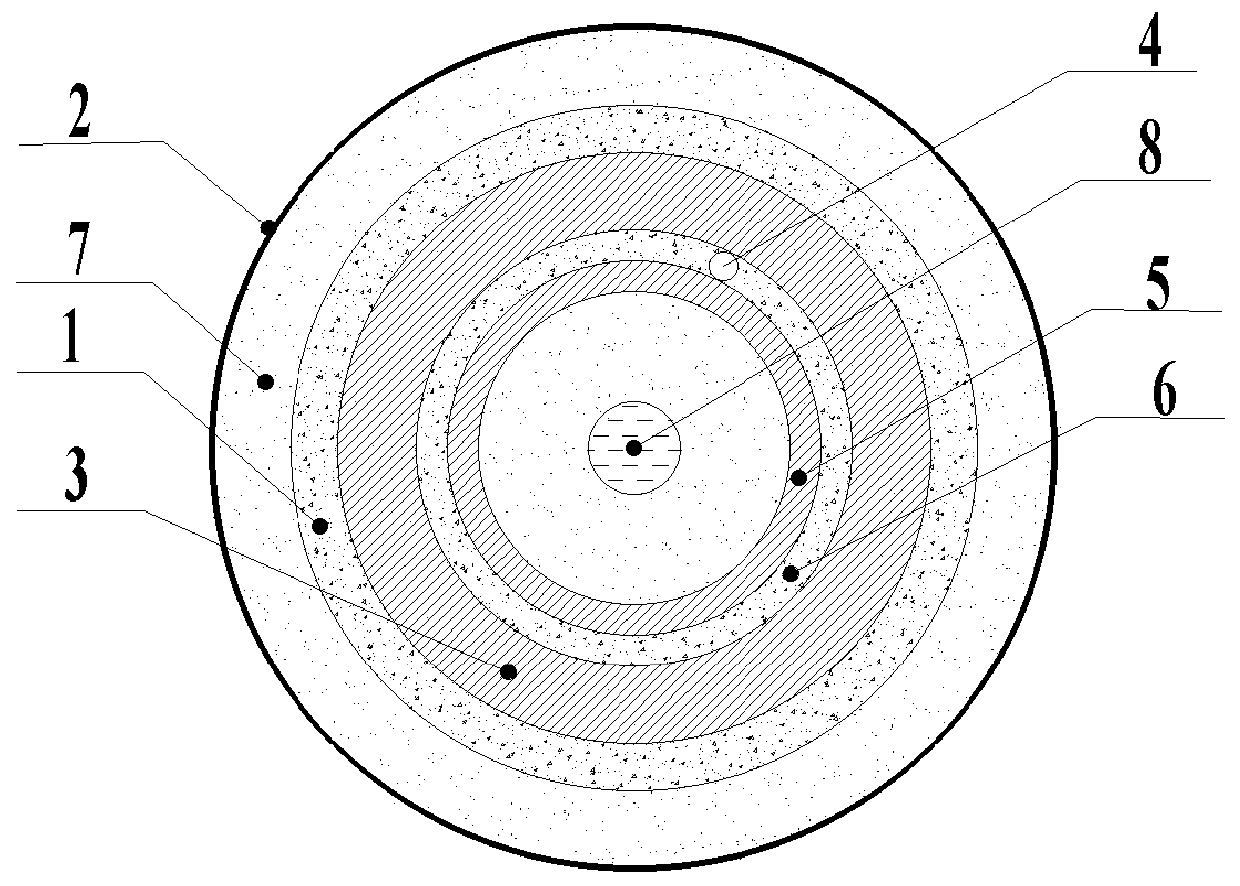

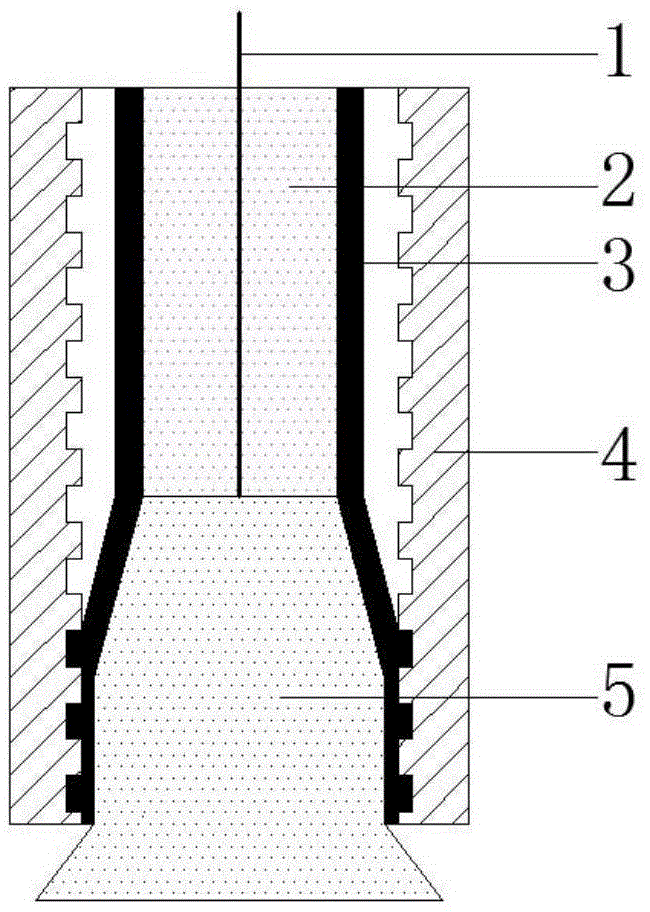

Manufacturing process of explosive composite pipe with negative pressure cavity based on liquid explosive

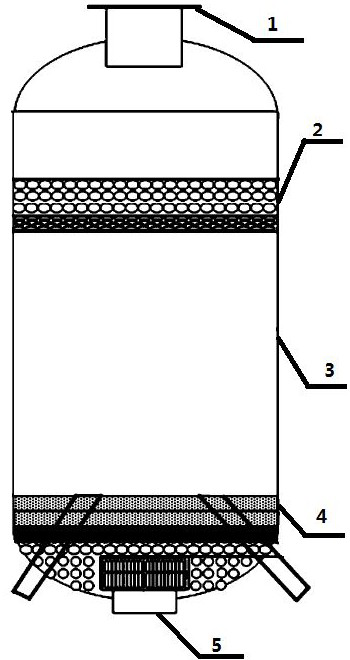

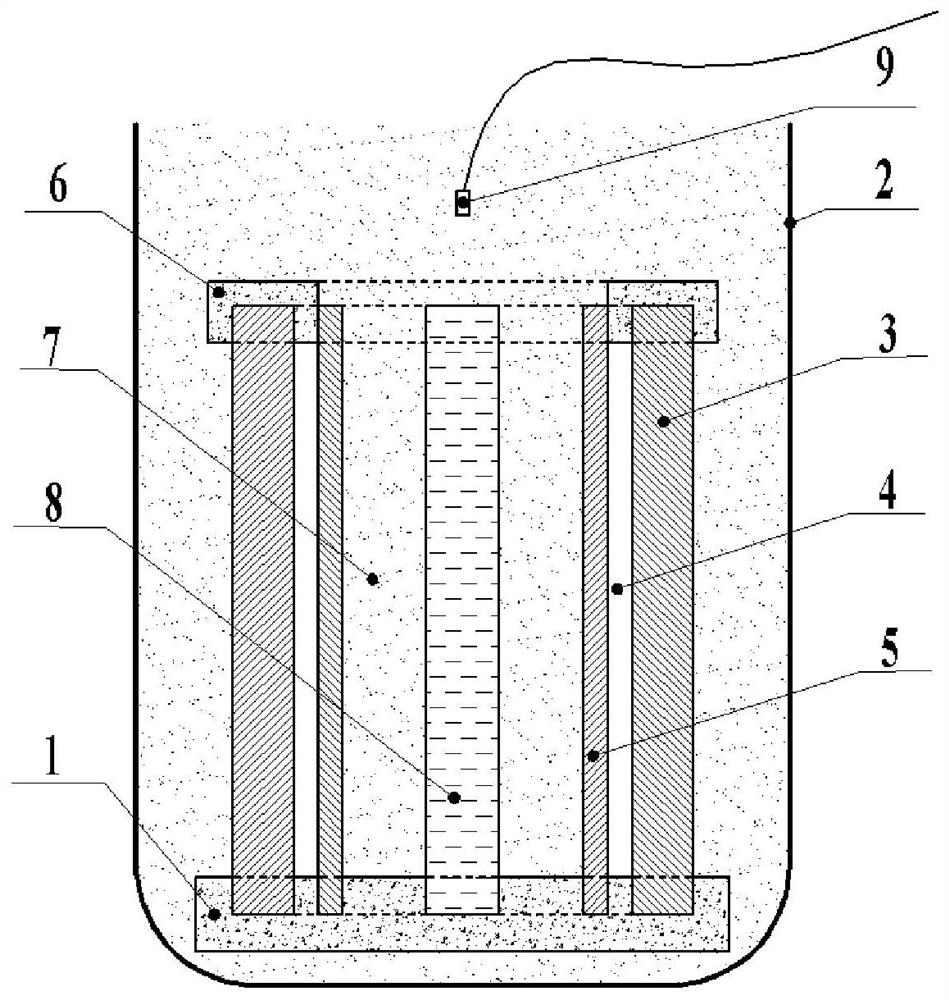

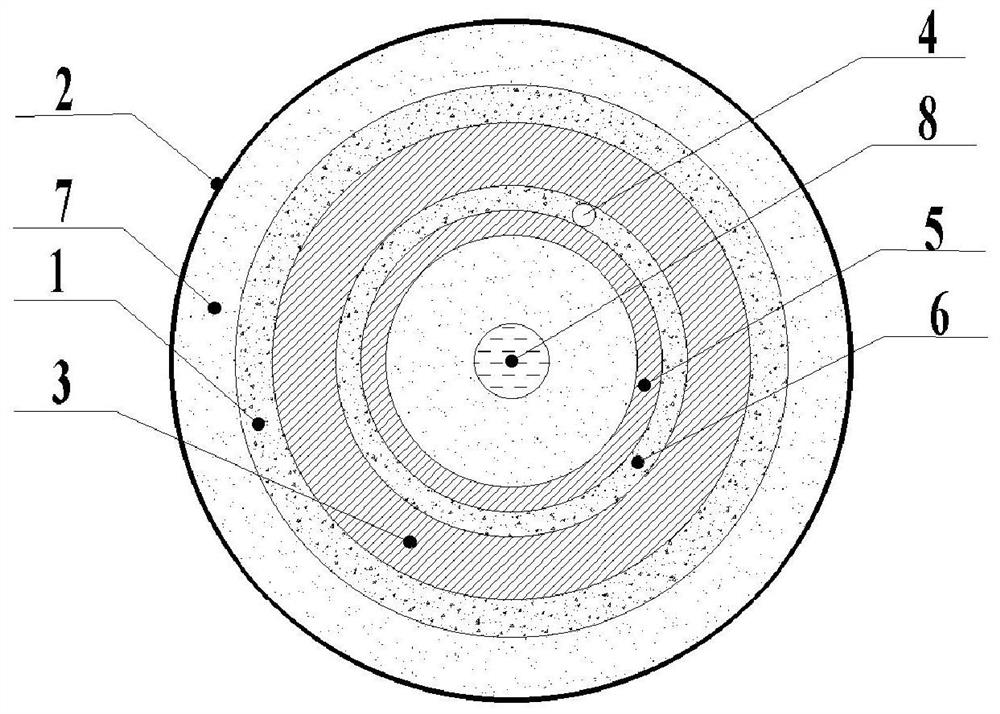

ActiveCN111085769AIncrease binding rateImprove welding qualityNon-electric welding apparatusTEX-explosivePipe

The invention provides a manufacturing process of an explosive composite pipe with a negative pressure cavity based on a liquid explosive. The manufacturing process comprises the following steps thata covering pipe and a base pipe are sequentially and coaxially mounted on a soft base from inside to outside, the explosive amount is calculated according to the specification of a to-be-composited pipe blank, and meanwhile an inner pipe dose adjusting water column is mounted; the upper end of an annular cylindrical gap between the covering pipe and the base pipe is sealed through a sealing ring,and an annular cylindrical cavity is sealed after being pumped into negative pressure through a vacuum pump; and the assembled to-be-composited pipe blank and a container are coaxially arranged, and then liquid explosive is injected, and the explosive is ignited so that a metal composite pipe can be obtained. According to the manufacturing process, the production efficiency can be greatly improved, explosive charging is uniform, the bonding rate of the composite pipe is high, the welding quality is good, and a constraint mold does not need to be applied in the welding process, so that the production cost can be greatly reduced; and meanwhile, the vacuum pump is adopted for pumping the cylindrical cavity into negative pressure, the influence of air on explosive welding is greatly reduced, the bonding quality of the composite pipe is improved, and the use amount of explosives can be reduced.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

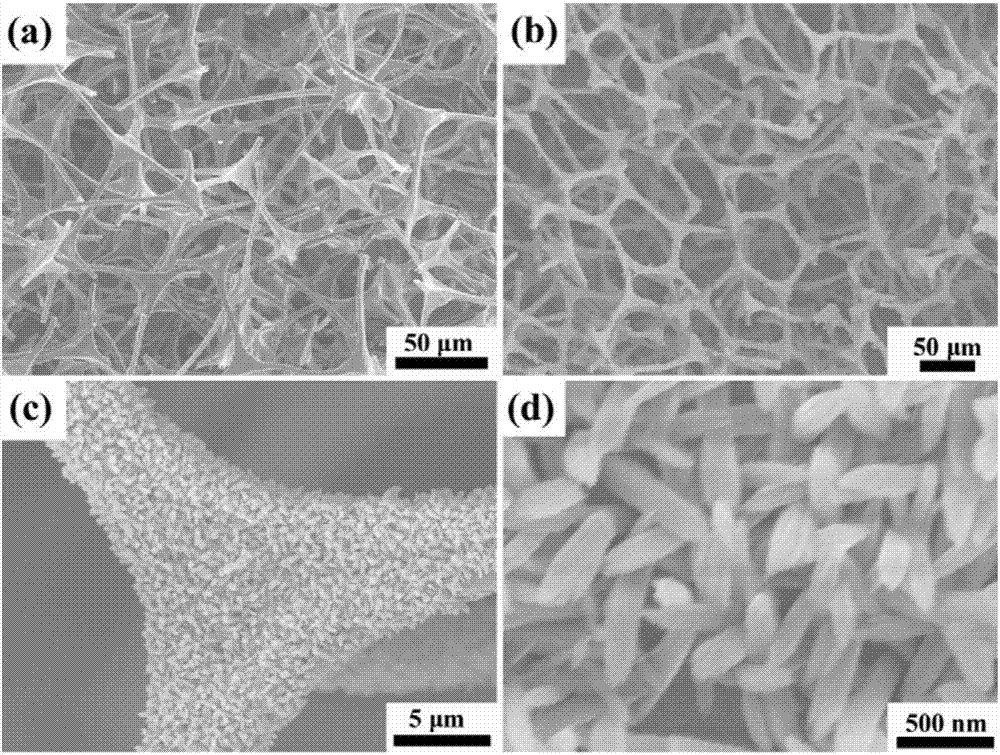

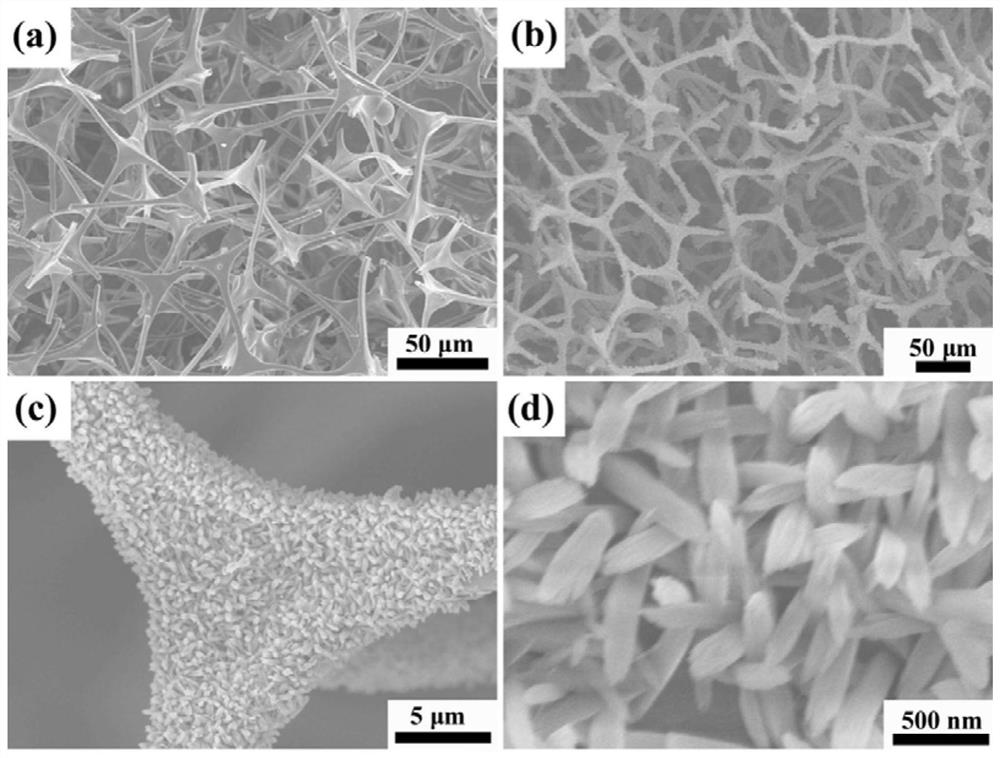

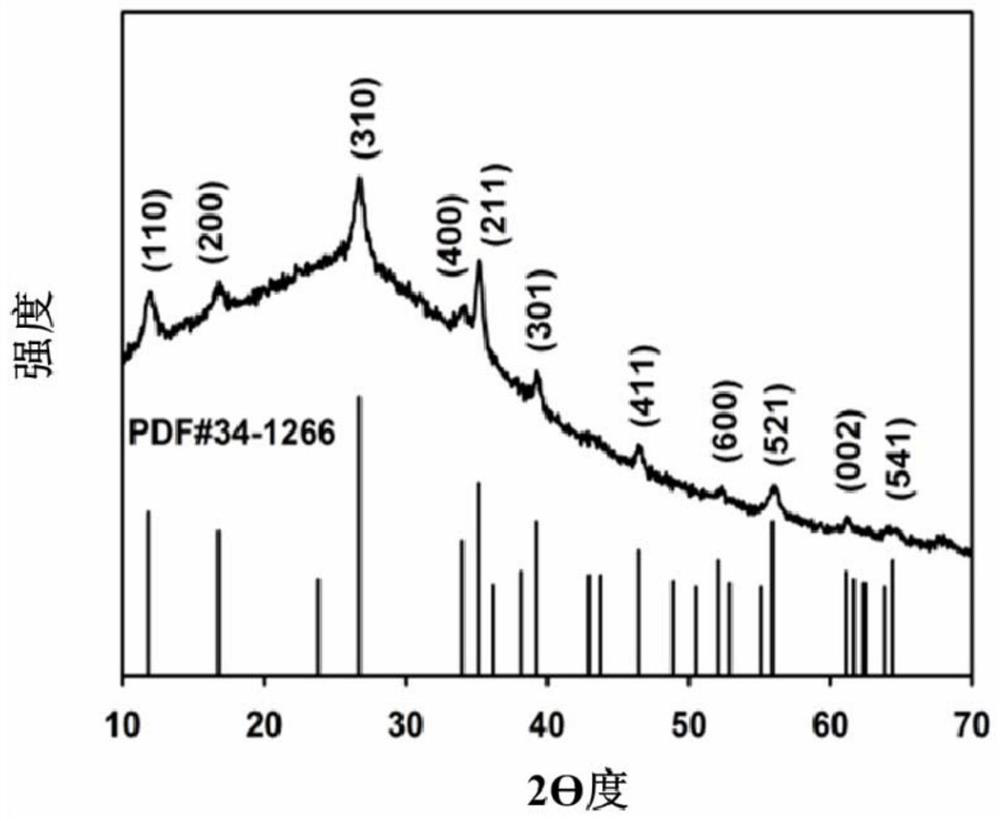

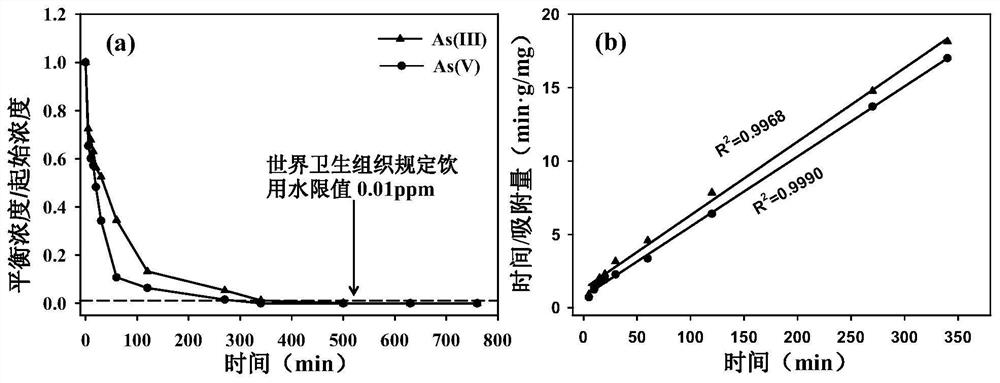

Iron oxyhydroxide nanorod/foam carbon composite material and preparation method and application thereof

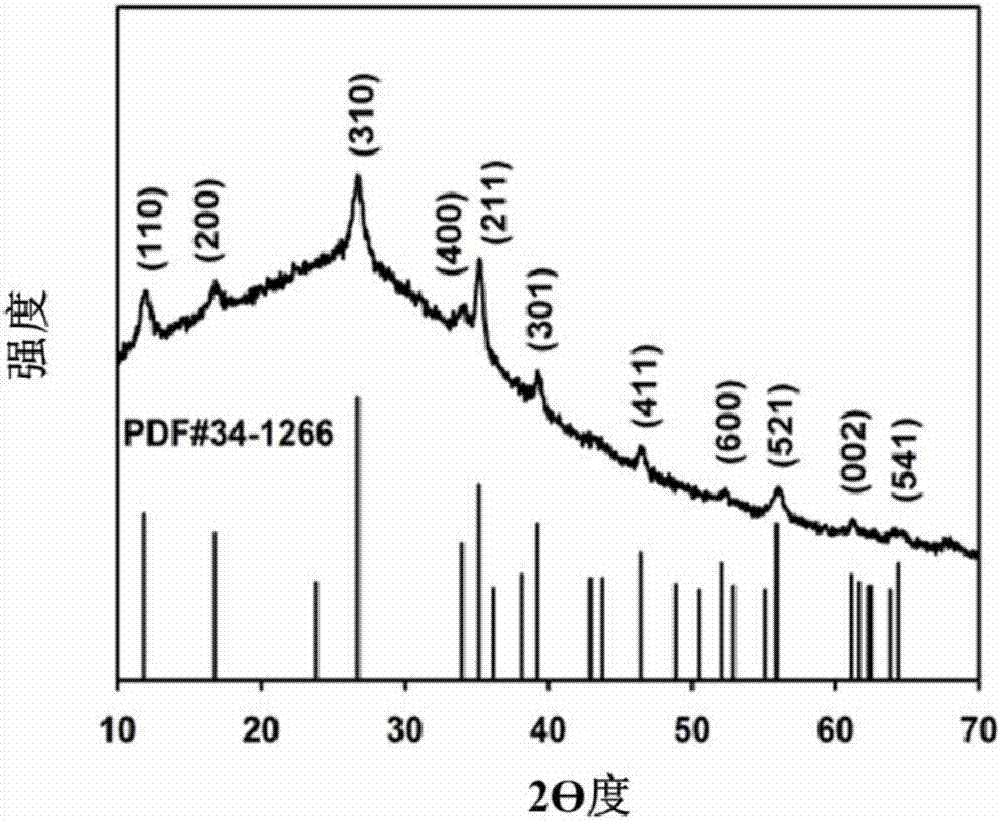

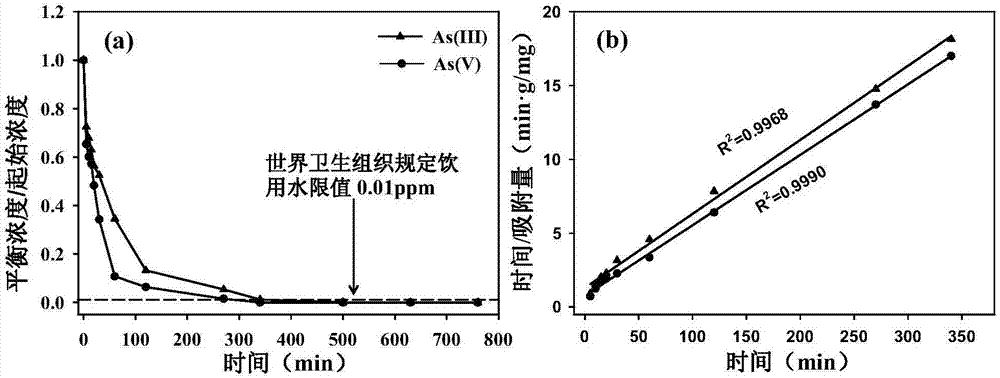

ActiveCN107082467AImprove adsorption capacitySmall secondary pollutionOther chemical processesWater contaminantsCarbon compositesSorbent

The invention discloses an iron oxyhydroxide nanorod / foam carbon composite material and a preparation method and application thereof. According to the iron oxyhydroxide nanorod / foam carbon composite material, foam carbon is used as a substrate, and iron oxyhydroxide nanorods are uniformly loaded on the substrate. The iron oxyhydroxide nanorod / foam carbon composite material is prepared by uniformly loading iron oxyhydroxide nanorods on the foam carbon substrate through a hydrothermal synthesis method. The iron oxyhydroxide nanorod / foam carbon composite material can be directly used as an adsorbent for removing arsenic from a water body. The iron oxyhydroxide nanorod / foam carbon composite material has strong adsorption capacity and less secondary pollution, is easy to separate and recover, has fast mass transfer rate, is low-cost, and can achieve rapid, efficient and selective removal of arsenic in a water body.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

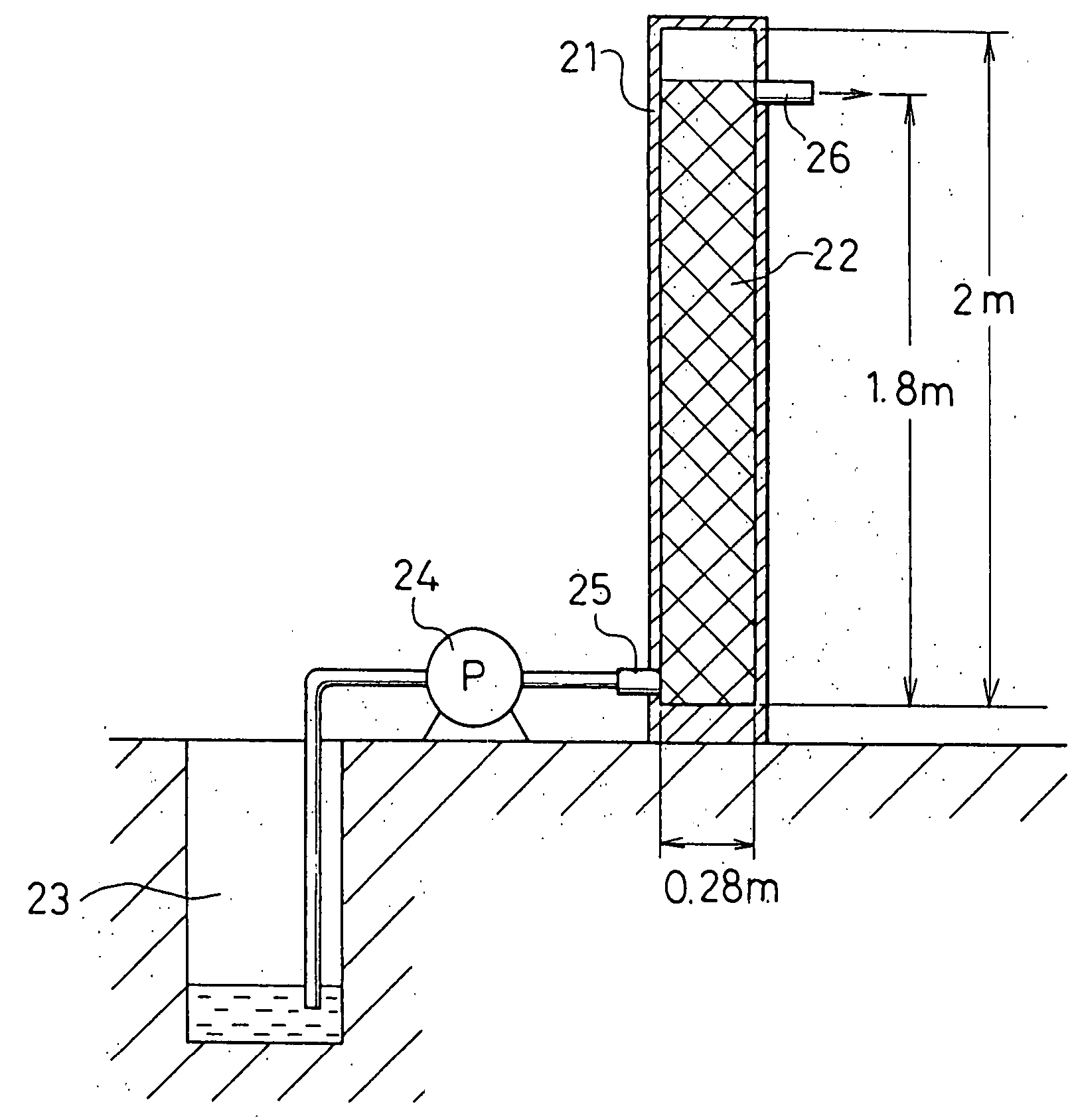

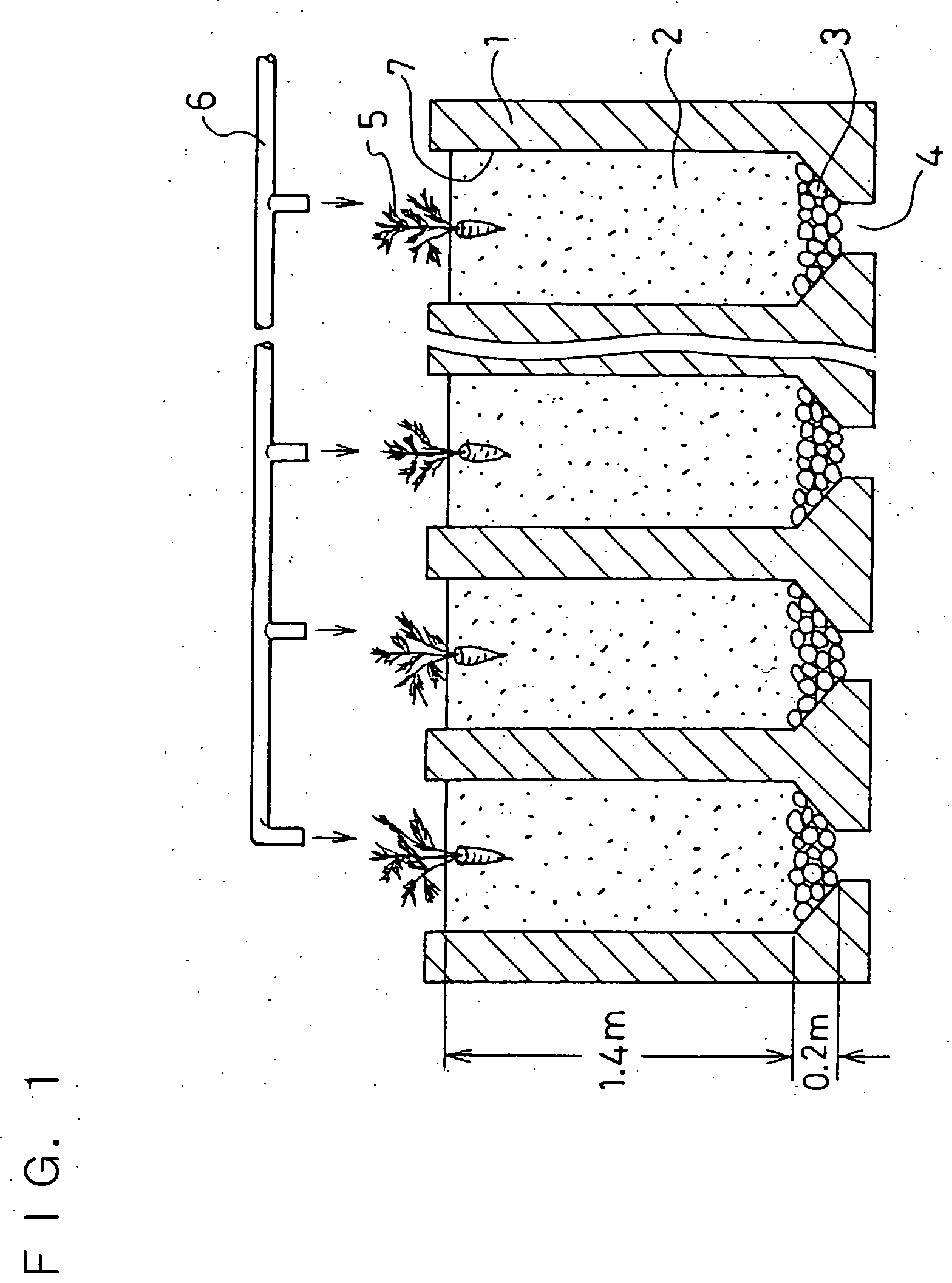

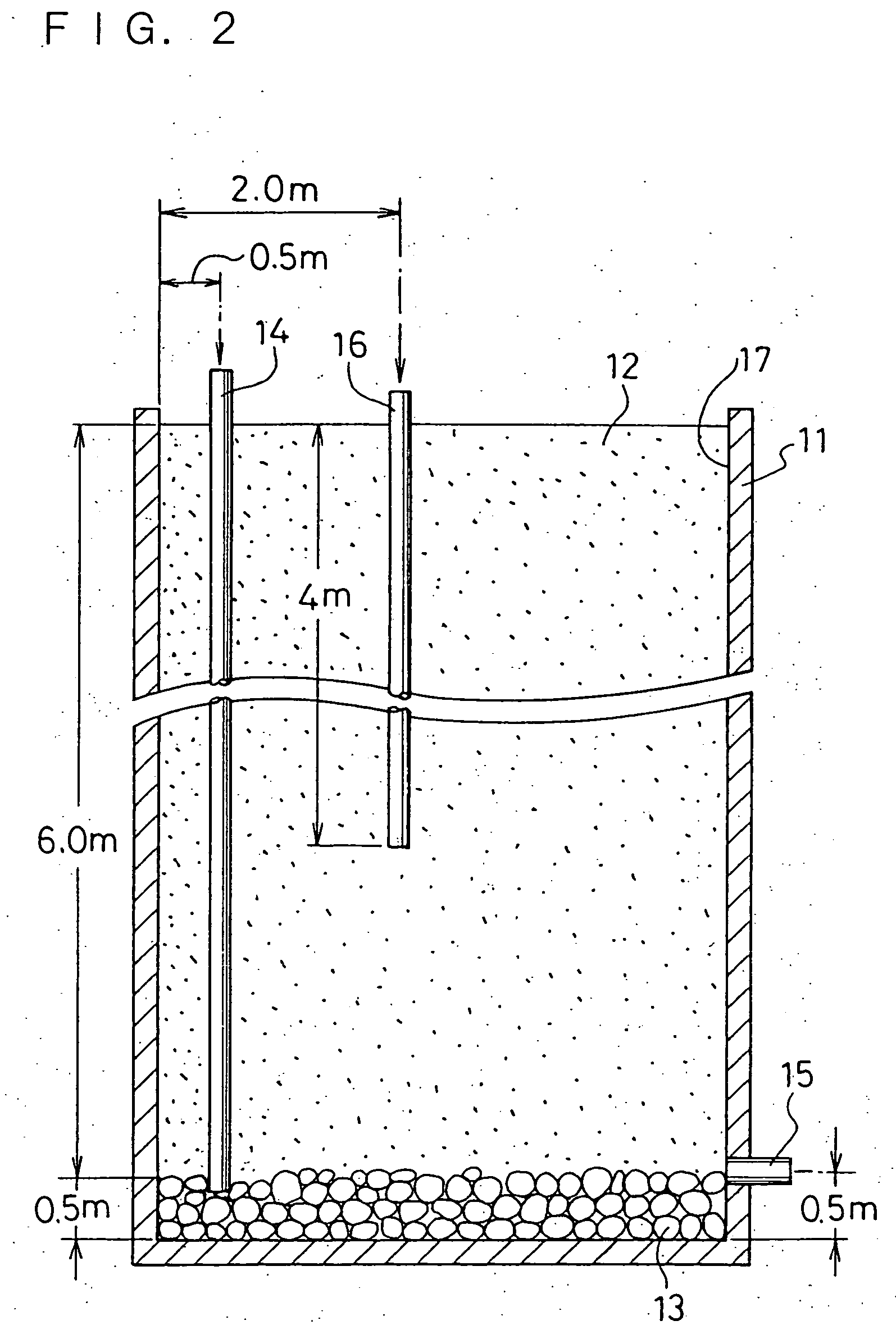

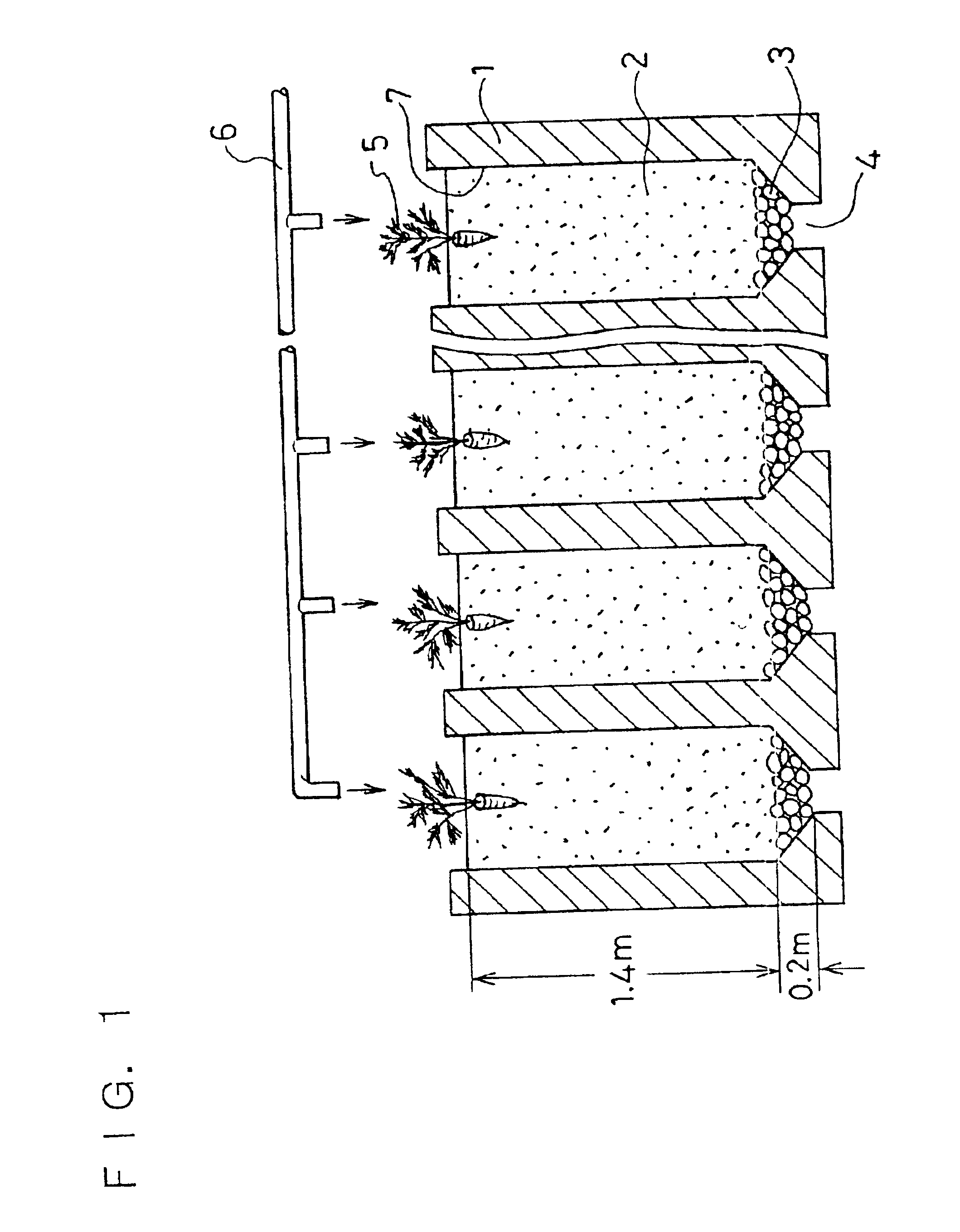

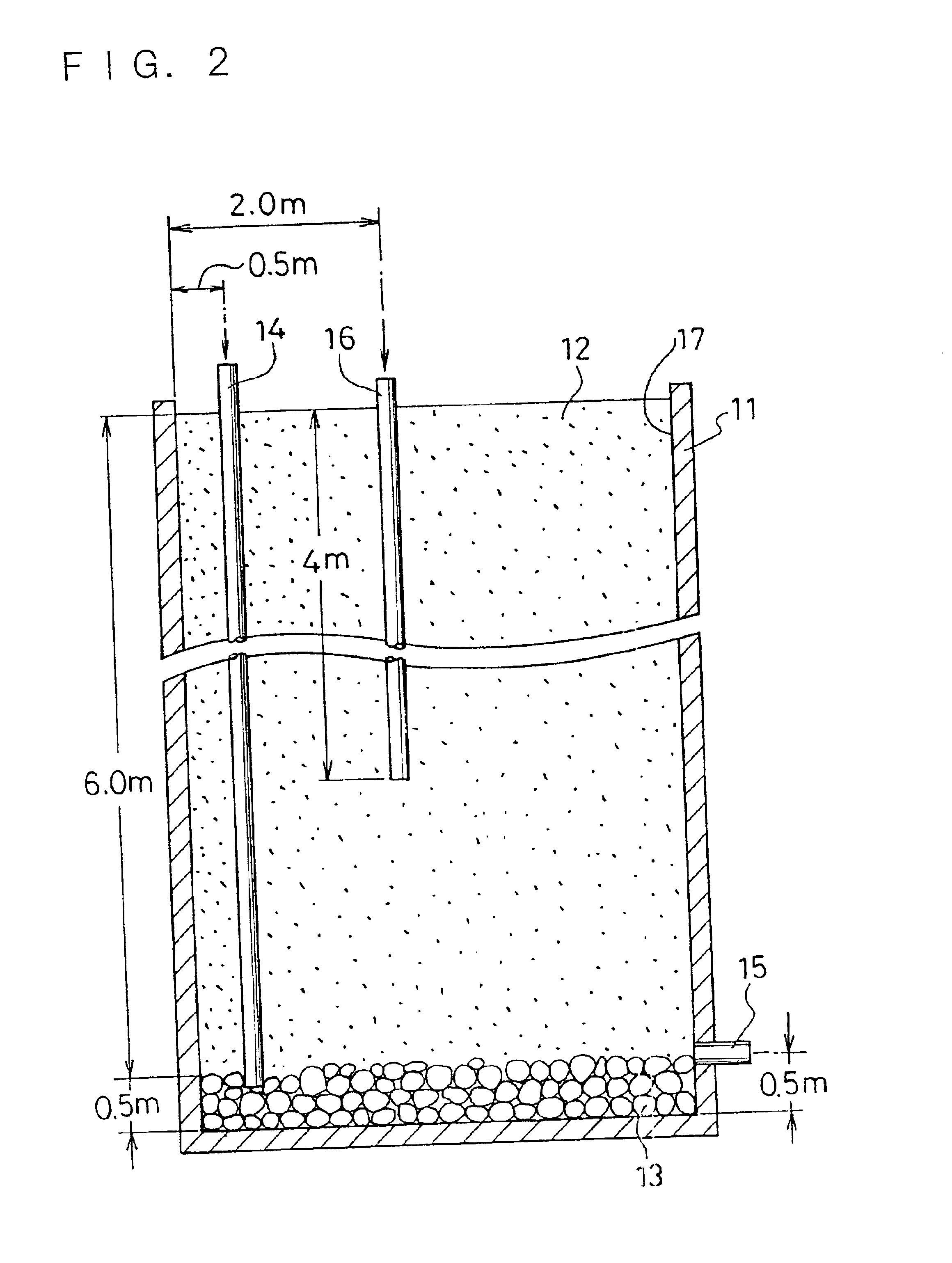

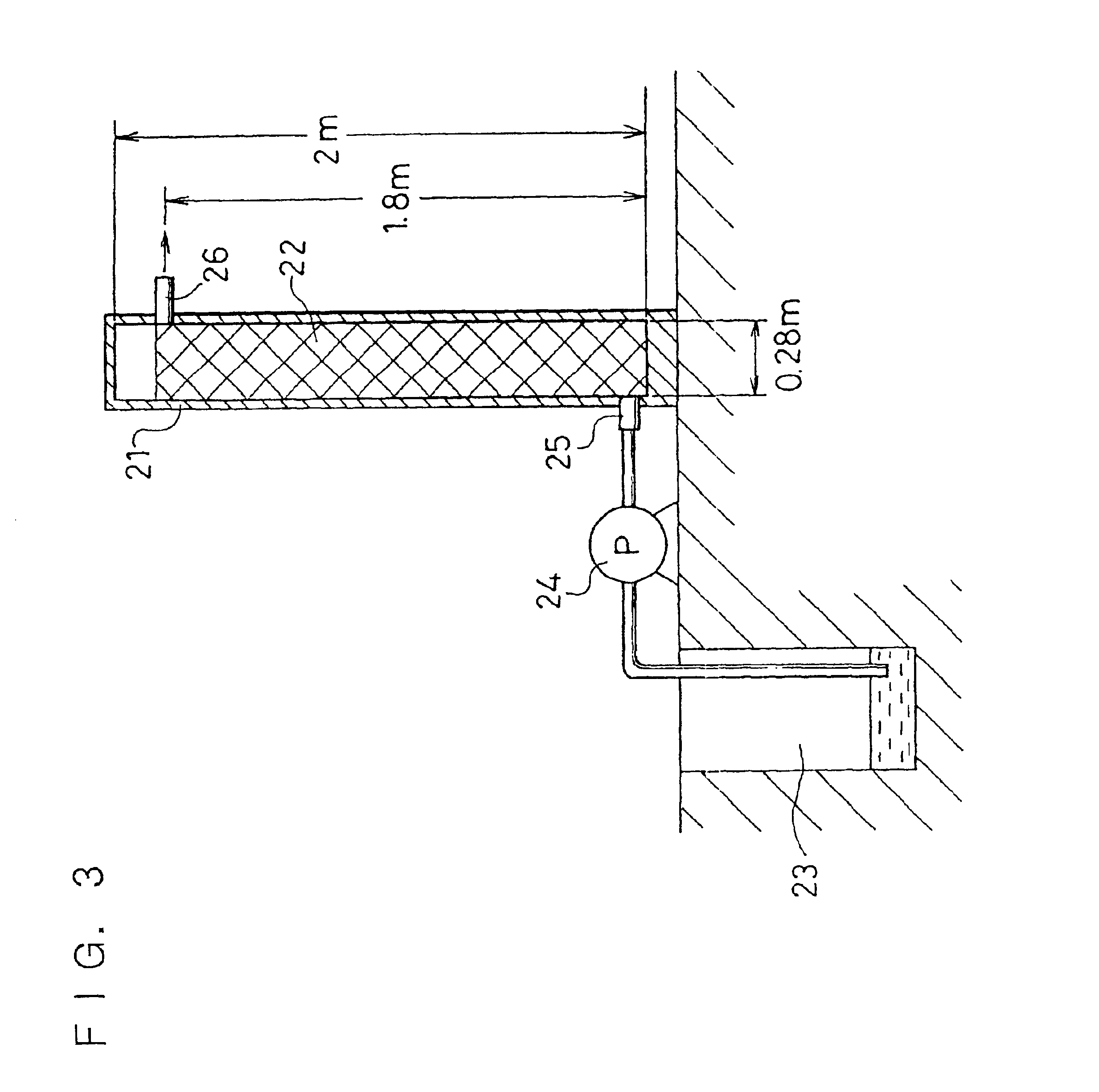

Method of decreasing nitrate nitrogen and volatile organic compound in soil and groundwater

InactiveUS20050178724A1Reduce compoundingImprove abilitiesWater contaminantsContaminated soil reclamationSites treatmentGlycerol

A method of decreasing nitrate nitrogen and volatile organic compounds in soil and groundwater by burying a fatty acid having 10 or more carbon atoms, an alcohol having 12 or more carbon atoms, an ester of a linear saturated fatty acid having 14 or more carbon atoms and a monohydric alcohol, an ester of a linear saturated fatty acid having 14 or more carbon atoms and a polyhydric alcohol, an ester of a fatty acid having 16 or more carbon atoms and glycerine, and the like in soil containing nitrate nitrogen and volatile organic compounds or by contacting groundwater with same This method allows for on site treatment, a high biological denitrification and a decrease in volatile organic compounds secondary pollution by the release of organic matter and nitrogen into the environment.

Owner:PANASONIC CORP

Method of decreasing nitrate nitrogen and volatile organic compound in soil and groundwater

InactiveUS6894203B2High biological denitrification abilityReduce capacityWater contaminantsContaminated soil reclamationSites treatmentGlycerol

A method of decreasing nitrate nitrogen and volatile organic compounds in soil and groundwater by burying a fatty acid having 10 or more carbon atoms, an alcohol having 12 or more carbon atoms, an ester of a linear saturated fatty acid having 14 or more carbon atoms and a monohydric alcohol, an ester of a linear saturated fatty acid having 14 or more carbon atoms and a polyhydric alcohol, an ester of a fatty acid having 16 or more carbon atoms and glycerine, and the like in soil containing nitrate nitrogen and volatile organic compounds. This method allows for on site treatment, high biological denitrification and a decrease in volatile organic compounds secondary pollution by the release of organic matter and nitrogen into the environment is extremely small.

Owner:PANASONIC CORP

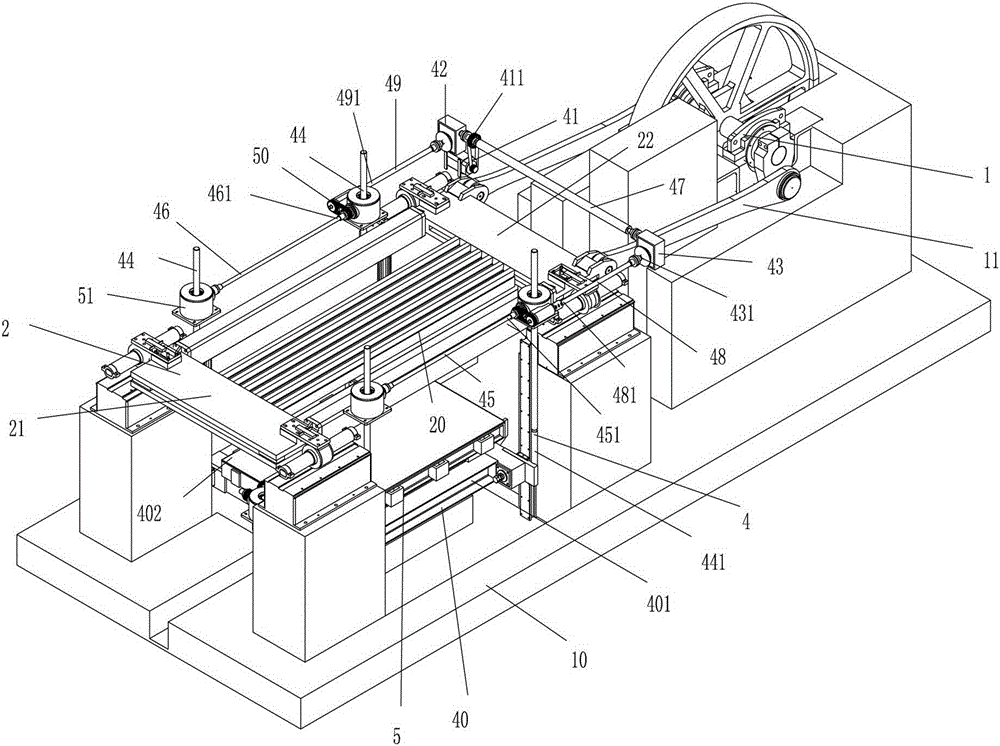

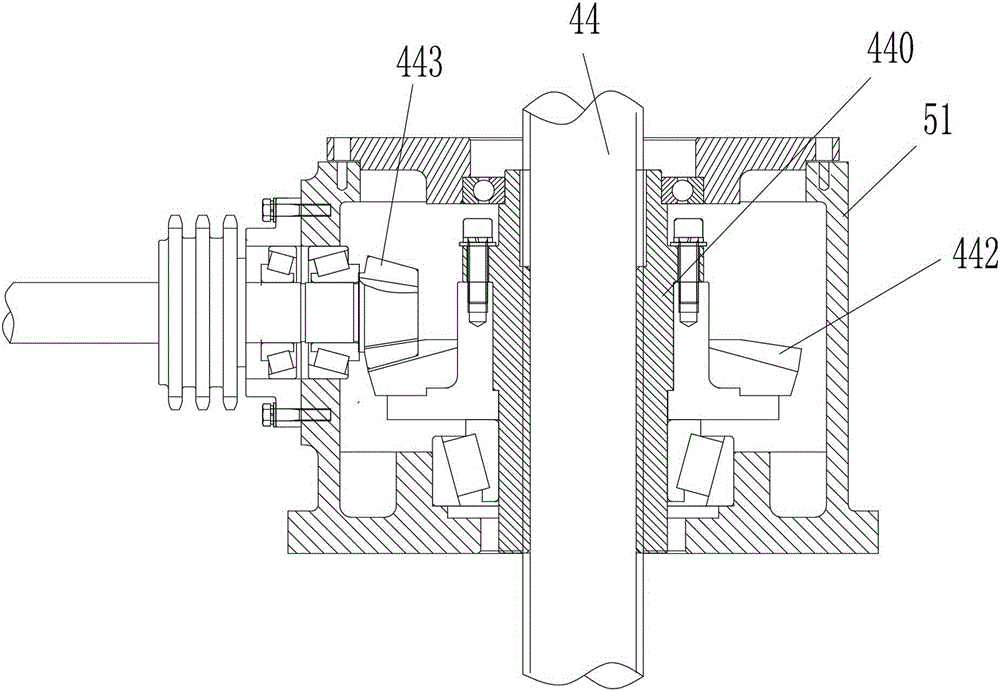

Technology for cutting granite quarry stone

ActiveCN105235072ACompact structureReasonable structureWorking accessoriesStone-like material working toolsLow speedGranolithic

The invention discloses a technology for cutting granite quarry stone. Cutting is carried out through a frame saw. A main shaft driving device, a saw frame assembly, a lifting device, a loading cart and a numerical control system are arranged on a basic installation structure of the frame saw, wherein the saw frame assembly is arranged on a rack in a sliding manner, the loading cart is arranged on the lifting device, and the numerical control system controls saw blades of the saw frame assembly to conduct feeding and controls the lifting device to be lifted. The main shaft driving device is in transmission connection with the saw frame assembly through connecting rods. When cutting is carried out, the numerical control system controls a processing feeding manner to conduct feeding in five grades, wherein the first grade is a rapid feeding, so that the granite quarry stone rapidly gets close to the saw blades; the second grade is low-speed feeding for processing, so that the saw blades cut the granite quarry stone by a certain depth at the speed lower than the conventional speed; the third grade is characterized in that the saw blades carry out cutting feeding at the normal speed; the fourth grade is characterized in that the saw blades complete final processing in a low-speed feeding manner; and the fifth grade is characterized in that the loading cart rapidly returns to the original position.

Owner:FUJIAN JINJIANG SHENGDA MACHINERY

Soil heavy metal cadmium remover and preparation method and application thereof

InactiveCN113265257APromote recoveryEffective combinationOther chemical processesContaminated soil reclamationSoil heavy metalsPolypropylene

The invention belongs to the field of soil heavy metal cadmium removers, and particularly relates to a soil heavy metal cadmium remover which is prepared from the following raw materials in parts by weight: 6-8 parts of citric acid, 20-30 parts of straw powder, 10-20 parts of desulfurized gypsum, 6-10 parts of a coagulant aid, 50-60 parts of distilled water, 4-6 parts of polyacrylamide, 8-10 parts of terpilenol, 4-6 parts of sodium oleate, 6-8 parts of activated carbon, 10-16 parts of phanerochaete chrysosporium extracellular polymeric substance, 6-8 parts of montmorillonite, 10-14 parts of pectin and 10-20 parts of polyhydroxy amino polyether. According to the scheme, citric acid, straw powder, desulfurized gypsum, sodium sulfate and montmorillonite are designed to serve as main materials of the heavy metal cadmium remover, polyacrylamide, terpilenol, activated carbon, phanerochaete chrysosporium extracellular polymeric substances and polyhydroxy amino polyether are designed to serve as auxiliary materials, and the auxiliary materials are matched with coagulant aids, water and pectin to form the novel heavy metal cadmium remover. The heavy metal cadmium remover can be effectively combined with the heavy metal cadmium so that the purpose of removing the heavy metal cadmium in the soil can be achieved, and the soil containing the heavy metal cadmium is well recovered.

Owner:WUHAN TEXTILE UNIV +1

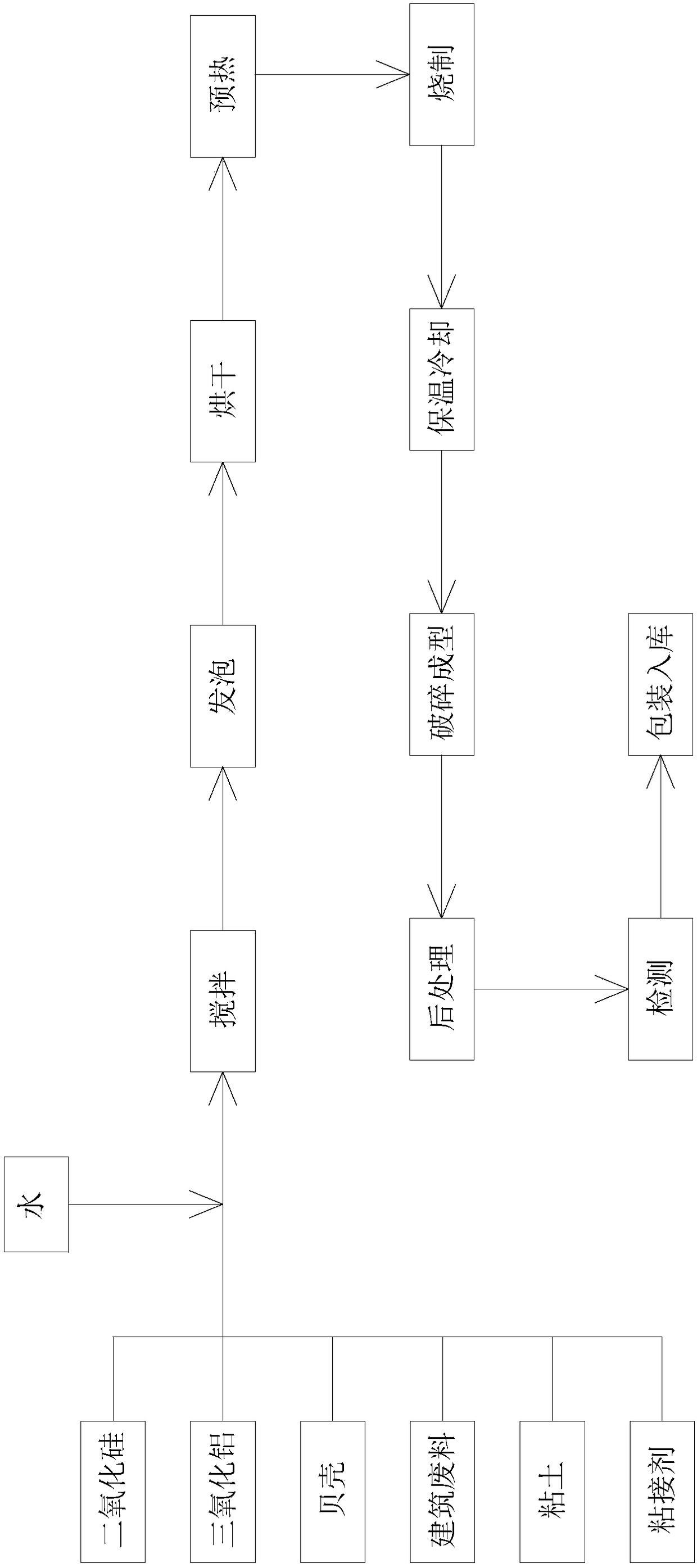

Artificial zeolite using shells and construction waste as raw materials and preparation method thereof

ActiveCN108584974AImprove adaptabilityImprove use valueOther chemical processesCrystalline aluminosilicate zeolitesChemistryScrap

The invention discloses an artificial zeolite using shells and construction waste as raw materials and a preparation method thereof and belongs to the technical field of absorbent material preparation. The artificial zeolite is prepared from, by mass, the following raw materials: 5%-20% of silicon dioxide, 25%-45% of aluminum trioxide, 1%-10% of shells, 10%-25% of construction waste, 15%-30% of clay and 12%-25% of adhesive. The artificial zeolite uses the shells and the construction waste as the raw materials, the adaptability of the raw materials is improved, the utilization value of the construction waste is improved, waste is turned into wealth, and the property of the artificial zeolite is extended. The preparation method is simple in process, easy to operate and low in production cost.

Owner:中科亿诚(珠海)环保技术有限公司

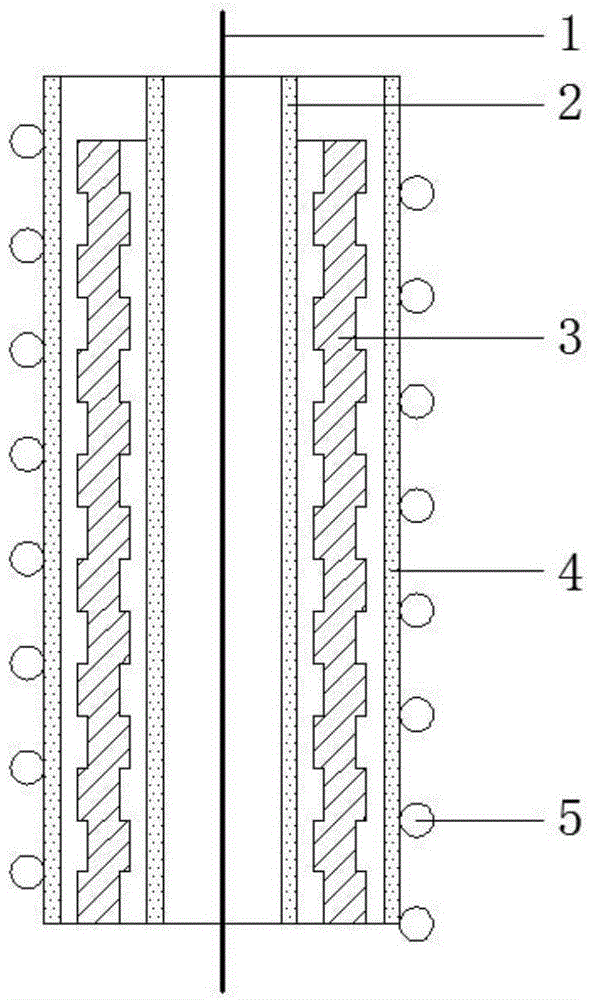

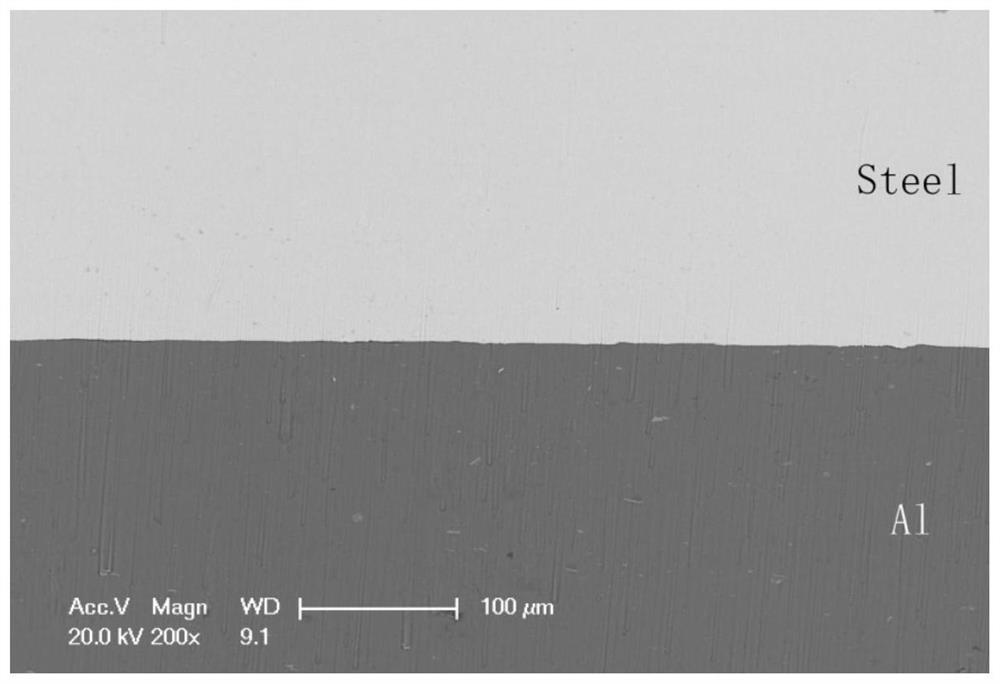

Explosive press fitting method for surface-roughened pipes

InactiveCN105436689AOptimize charge structurePracticalNon-electric welding apparatusPressure transmissionPetrochemical

The invention discloses an explosive press fitting method for surface-roughened pipes, and relates to a press fitting method for the surface-roughened pipes with explosives as the energy. According to the method, the originally smooth surface of a base pipe is roughened mechanically, uneven patterns are formed on the surface of the base pipe, and then the base pipe and a covering pipe are combined in an explosive press fitting mode through explosives. The method combines the respective advantages of machines and explosives and obtains an explosive composite pipe quite economically. An adopted charging structure is simple, convenient and easy to operate, high in practicability and suitable for industrial production. Water serves as pressure transmission medium, the use rate of the explosives is greatly improved, damage of the explosives to the pipe wall is avoided, the use rate of the explosives is improved, the cost is reduced, and secondary pollution is reduced. The composite pipe produced through the method has good mechanical performance and excellent corrosion resistance, and has wide application prospects in the petrochemical industry, especially in a corrosive environment like an offshore oil and gas field.

Owner:UNIV OF SCI & TECH OF CHINA

Low-temperature rubber crushing accelerator for well fracturing

ActiveCN102757776BInhibits hydration swellingAvoid cloggingDrilling compositionFracturing fluidEconomic benefits

The invention discloses a low-temperature rubber crushing accelerator for well fracturing. The low-temperature rubber crushing accelerator for well fracturing can effectively restrain clay hydration expansion, prevents pore plugging and improves reservoir permeability. As to an oil well of which the temperature of an oil layer is smaller than or equal to 50 DEG C, a prescription of fracturing fluid added with an accelerator is adopted, the low-temperature rubber crushing performance of the fracturing fluid is improved, and the problems that the fracturing fluid is not thoroughly hydrated, the flowback is difficult, and secondary pollution of the oil layer is generated are solved. The low-temperature rubber crushing accelerator is applied to a new well of a well area and a hollow well of an old area; the economic benefit of oil enhancement is remarkable, and the low-temperature rubber crushing accelerator has the advantages that the preparation method is simple, and no secondary damage to the oil layer is generated, and preparation at normal temperature can be achieved, can be widely applied to low-temperature oil well fracturing construction. Compared with the prior art, the low-temperature rubber crushing accelerator has the advantages that the cementing quality is high, the toxic property of the product is small, and pollution on stratum after use is light.

Owner:克拉玛依新科澳石油天然气技术股份有限公司

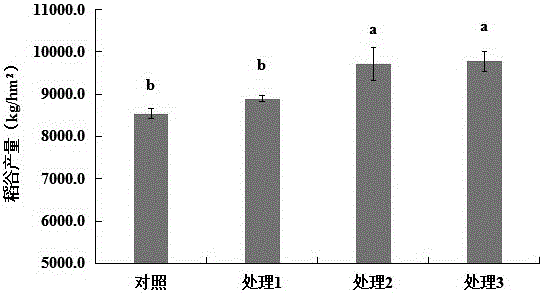

Rice planting method based on wheat straw returning to field

InactiveCN107173137AImprove strong reducing conditionsImprove breathabilityRice cultivationSoil-working methodsCarbamide peroxideRice farming

The invention provides a rice planting method based on wheat straw returning to a field. The method includes the steps that crushing full doses of wheat straw to return to the field; using shallow water to soak the field, and conducting soil preparation through wet rotary tillage; when applying base fertilizers and tillering fertilizers, applying calcium peroxide or / and carbamide peroxide in a combining mode, and transplanting rice seedlings; at late rice tillering stage, ditching before field drying; carrying out field management until the rice matures. The rice planting method has the advantages of ecological environmental friendliness, effective utilization of farmland resources, improvement of soil environment and stable yield increase of the rice.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

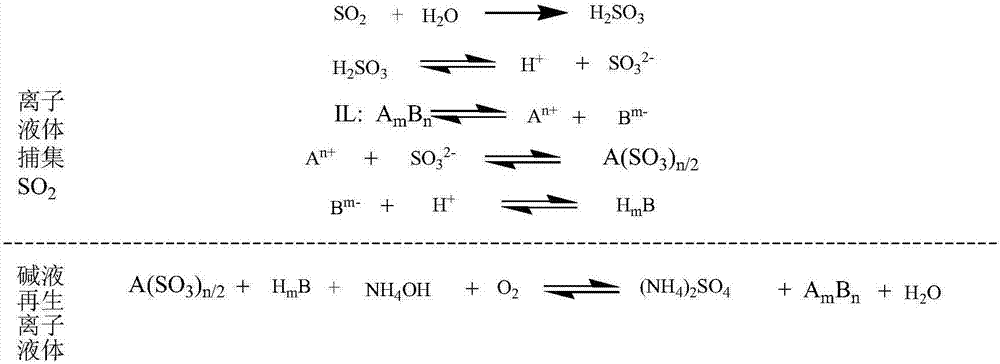

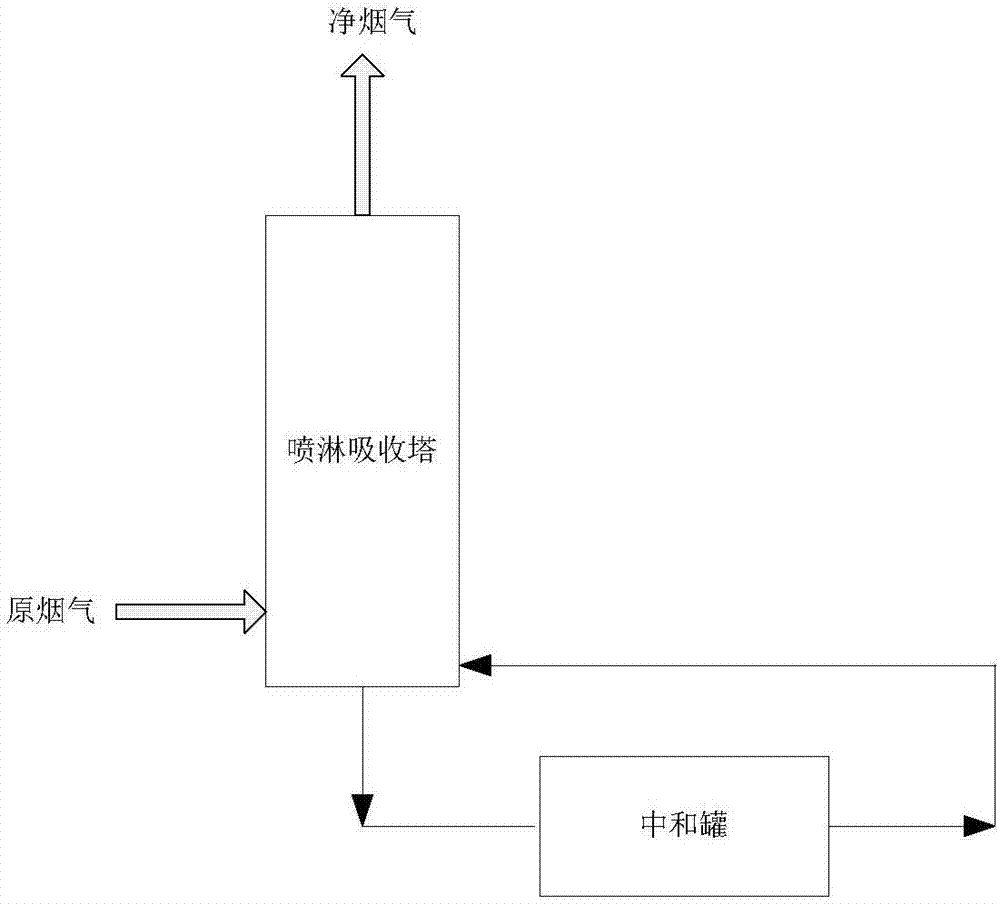

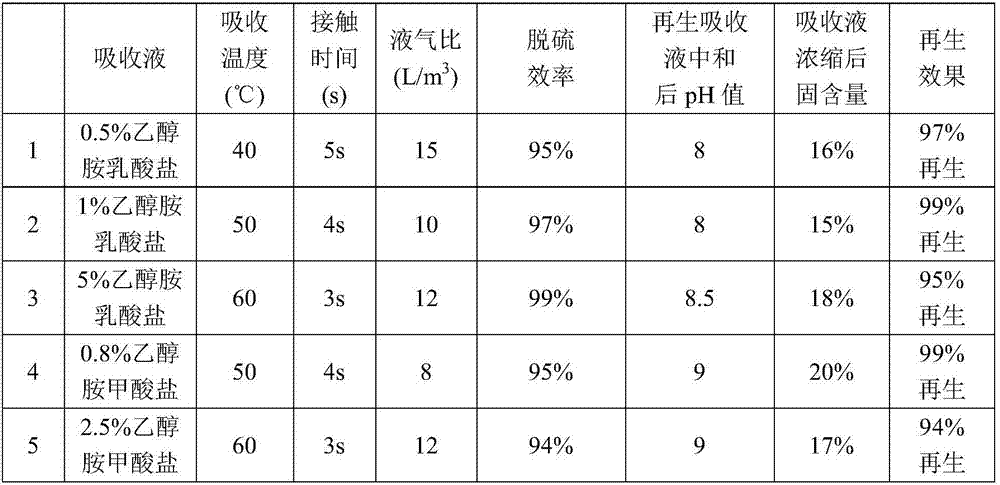

Wet flue gas desulfurization method

InactiveCN107198937AReduce dosageSimple resource utilization processGas treatmentDispersed particle separationResource utilizationLiquid water

The invention discloses a wet flue gas desulfurization method. The wet flue gas desulfurization method comprises the following steps: enabling original flue gas to enter into from the lower part of a spraying absorption tower, enabling the original flue gas to be in reverse contact with an absorption liquid from bottom to top, so that SO2 in the flue gas is adsorbed by the absorption liquid, and finally discharging pure flue gas from the upper part of the tower; when the desulphurization efficiency is reduced, discharging the absorption liquid from the bottom of the spraying absorption tower, and entering into an absorption liquid regeneration system; in the absorption liquid regeneration system, firstly using an alkaline liquid to neutralize the absorption liquid, then concentrating and crystallizing, then carrying out centrifugal separation to obtain a regenerated ion liquid and an ammonium sulfate byproduct; enabling the regenerated ion liquid to enter the spraying absorption tower for cyclic utilization, wherein the absorption liquid is an ion liquid water solution. The method disclosed by the invention has the advantages of high removal efficiency and low removal cost of pollutants, relatively simple technological process and byproduct resource utilization, and has wide application prospects in the field of fire coal flue gas purification.

Owner:XIAN THERMAL POWER RES INST CO LTD

A manufacturing process of explosive composite pipe

ActiveCN103639584BInnovativeWith adjustmentWelding/soldering/cutting articlesMetal working apparatusFiberDetonator

The invention discloses an explosive cladding tube manufacturing process. The explosive cladding tube manufacturing process includes the following operations that a tube needing cladding is prepared, wherein the tube at least comprises a cladding tube and a lining tube; a first explosive fiber spirally and evenly winds the cladding tube; after the required explosive amount is wound, the first explosive fiber is loosened, so that gaps of the preset distance are kept between the first explosive fiber and the outer wall of the cladding tube; a second explosive fiber is inserted into the lining tube and fixed by a plug with a hole; the first explosive fiber and the second explosive fiber are connected to a same detonator to form a whole device, the whole device is placed in water storage equipment, and a part needing cladding is placed under water; eventually, detonation is conducted. Actual experimental results show that the explosive cladding method of a long tube and a superlong tube is innovative and has innovativeness in multiple aspects and outstanding advantages.

Owner:UNIV OF SCI & TECH OF CHINA

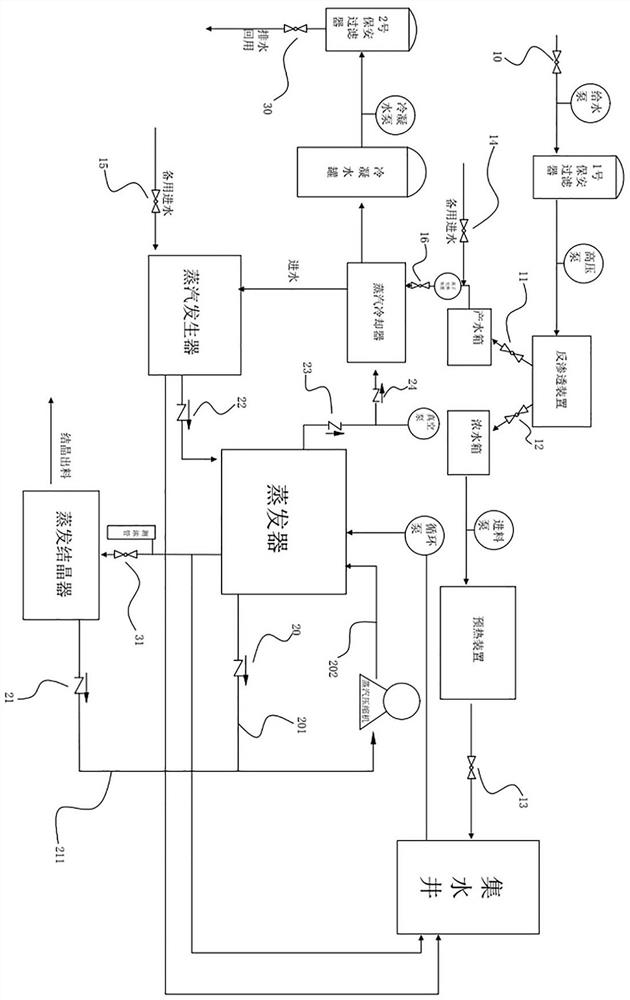

Ion exchange resin regenerated and activated wastewater distillation and concentration treatment method

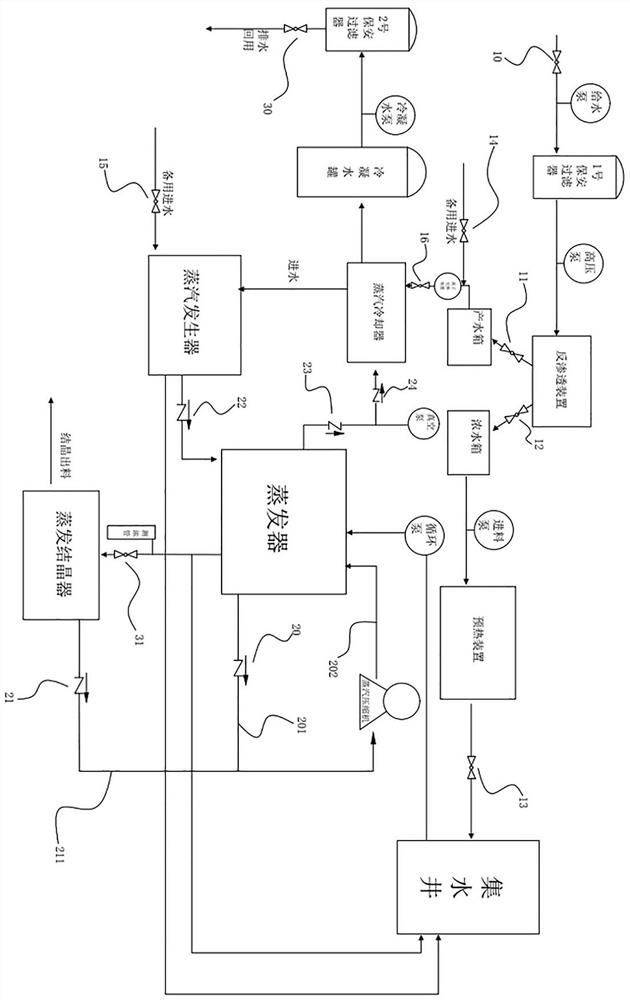

ActiveCN113800704ATake advantage ofHigh precisionWater treatment parameter controlSpecific water treatment objectivesSteam pressureDistillation

The invention discloses an ion exchange resin regenerated and activated wastewater distillation and concentration treatment method which comprises the steps: treating activated wastewater by a reverse osmosis device, and respectively collecting wastewater clear liquid and wastewater concentrated liquid; S2, when the liquid level of the wastewater concentrated liquid in a water collecting well reaches 70-80% of the maximum value, turning on a standby water inlet valve and a power supply of a steam generator, and heating inlet water; and S3, when the steam pressure in the steam generator reaches a set value, turning on a steam outlet valve of the steam generator, and enabling heating steam to enter a heat exchange pipe of the evaporator; and meanwhile, starting a circulating pump, spraying the preheated wastewater concentrated liquid in the water collecting well into an evaporation chamber from the upper part of the evaporator for heat exchange, and circularly spraying and concentrating the wastewater concentrated liquid. The treatment method disclosed by the invention can realize resource utilization of the wastewater, and is energy-saving and environment-friendly.

Owner:SYNGARS TECH CO LTD

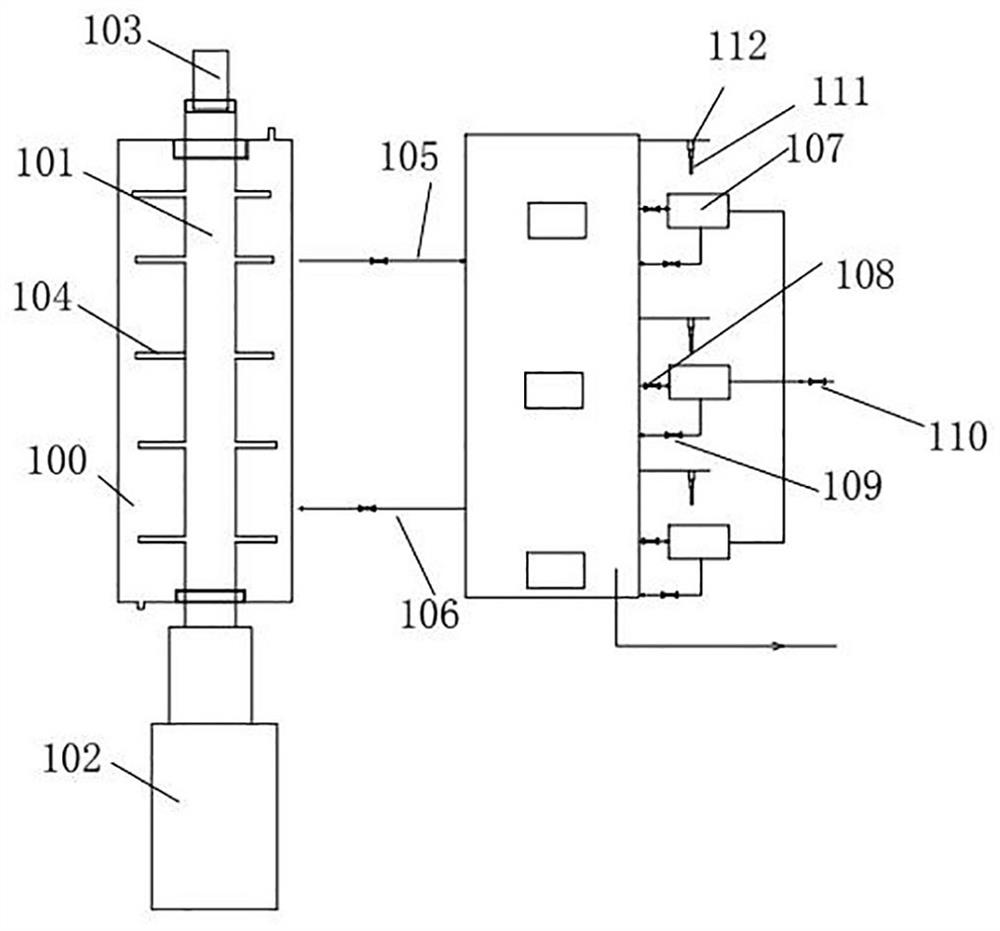

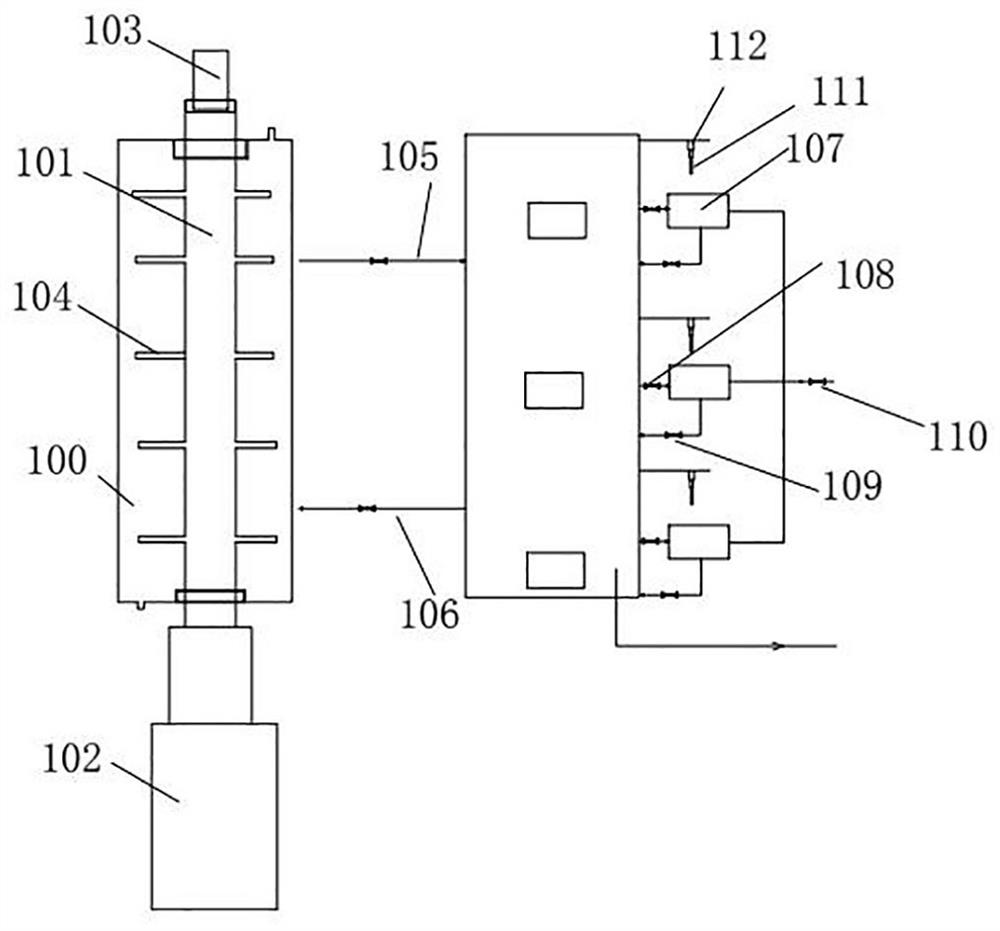

Comprehensive wastewater treatment device for physical and chemical laboratory

InactiveCN105948380AAdvanced technologyShort processBiological treatment apparatusMultistage water/sewage treatmentParticulatesElectrolysis

The invention discloses a comprehensive wastewater treatment device for a physical and chemical laboratory. The comprehensive wastewater treatment device comprises a wastewater collecting device, a microelectrolysis detoxification module, a solid microorganism degrading and purifying module, an automatic pH regulating module, an automatic dissolved oxygen adjusting module, a terminal particle separation module, a solid-liquid separation device and a control module, wherein the microelectrolysis detoxification module is connected with the wastewater collecting device to perform electrolytic treatment on wastewater; the solid microorganism degrading and purifying module is connected with the microelectrolysis detoxification module to perform biological degradation on the wastewater after electrolytic treatment; the automatic pH regulating module is connected with the microelectrolysis detoxification module and the solid microorganism degrading and purifying module to perform pH regulation on the wastewater entering the microelectrolysis detoxification module and the solid microorganism degrading and purifying module; the solid-liquid separation device is connected with the microelectrolysis detoxification module and the solid microorganism degrading and purifying module. According to the wastewater treatment device of the embodiment of the invention, the technology is advanced, the process is short, and the secondary pollution is small.

Owner:上海惠源水处理设备有限公司

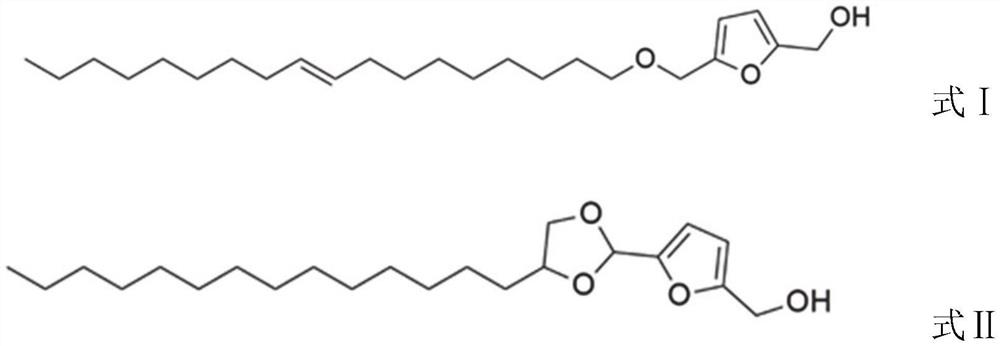

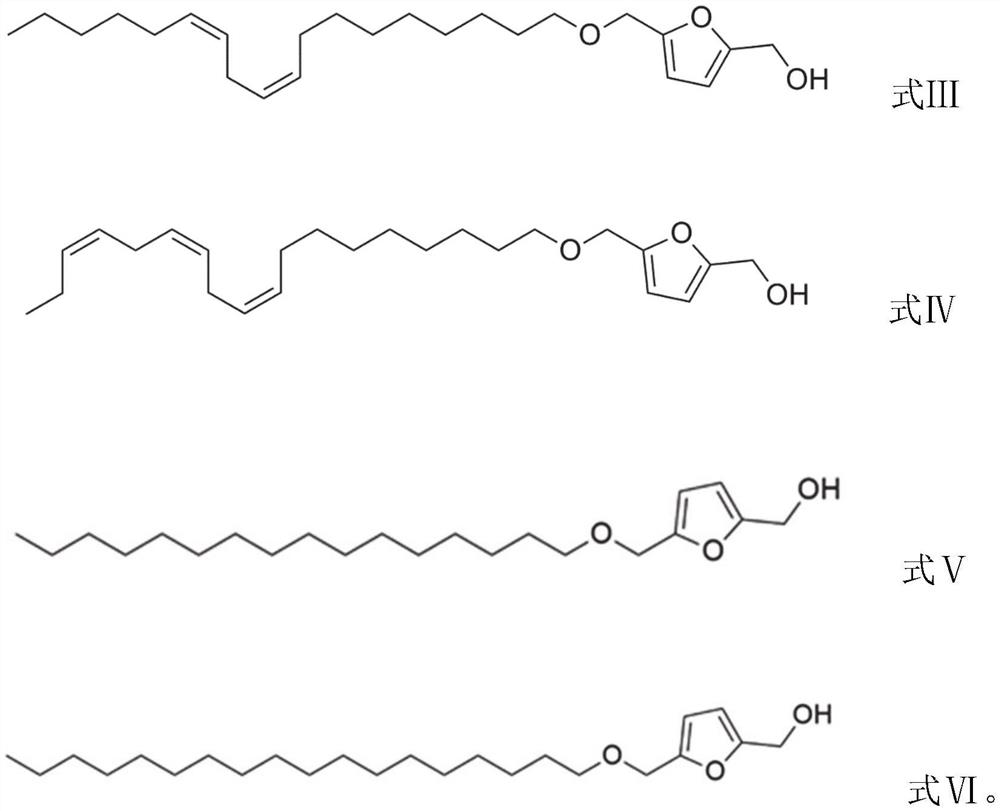

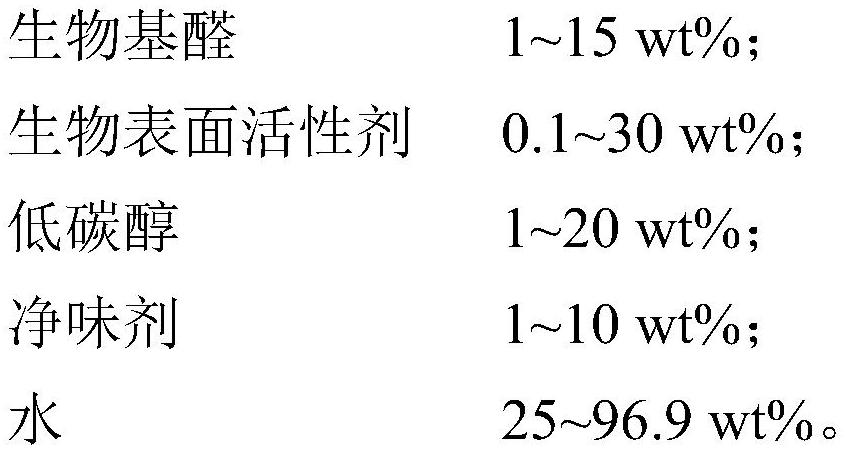

Bio-based disinfectant and preparation method thereof

InactiveCN113826623ASmall secondary pollutionBroad application development spaceBiocideOrganic chemistryAlcoholDisinfectant

The invention discloses a bio-based disinfectant and a preparation method thereof. The bio-based disinfectant contains bio-based aldehyde, a biological surfactant, low-carbon alcohol, an odor removing agent and water, wherein the pH of the disinfectant is 3.0 to 10.0. The bio-based aldehyde disinfectant provided by the invention has the characteristics of high efficiency, low toxicity, small corrosion, good stability and the like, is non-volatile, can also avoid causing extra steam hazards, and is expected to be widely applied to multi-scene disinfection and sterilization.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

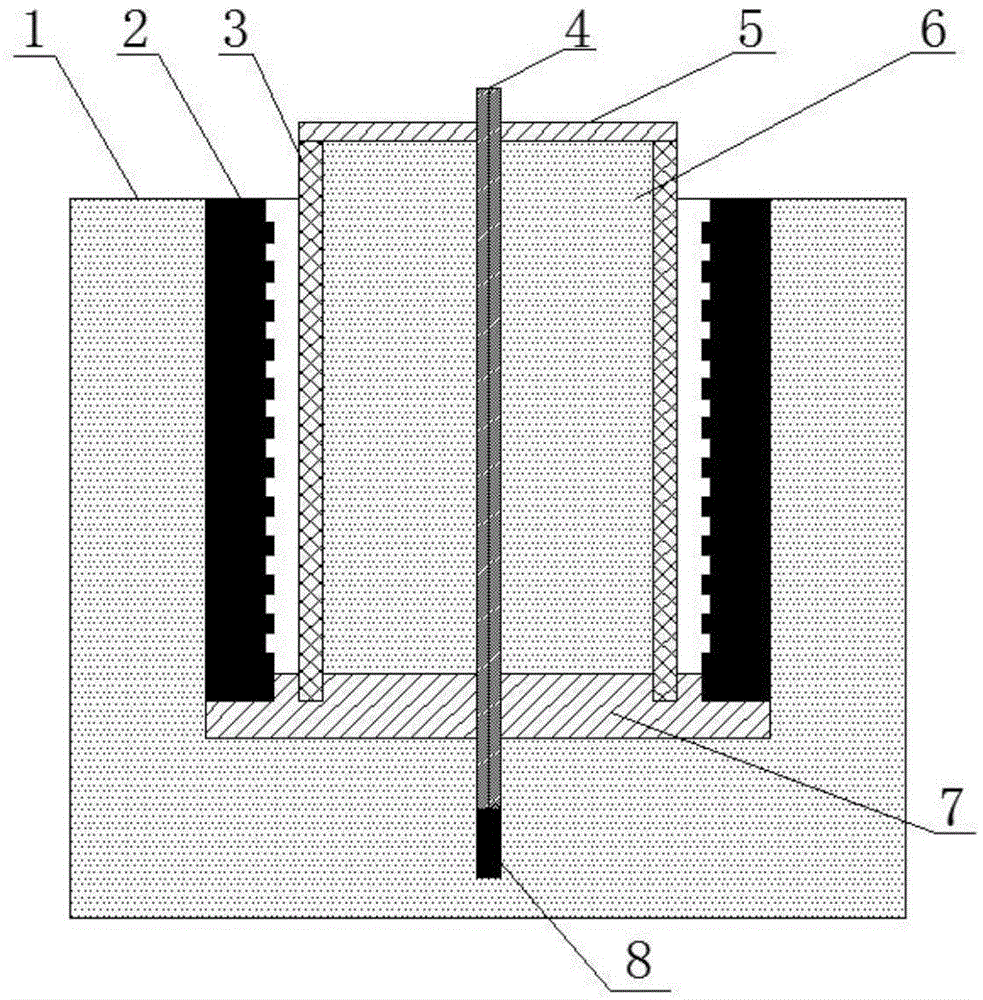

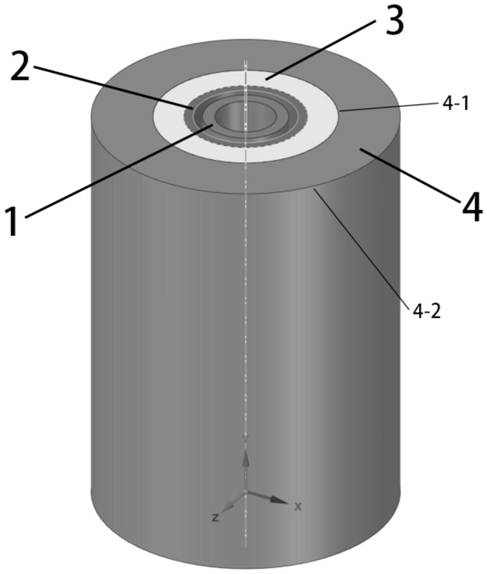

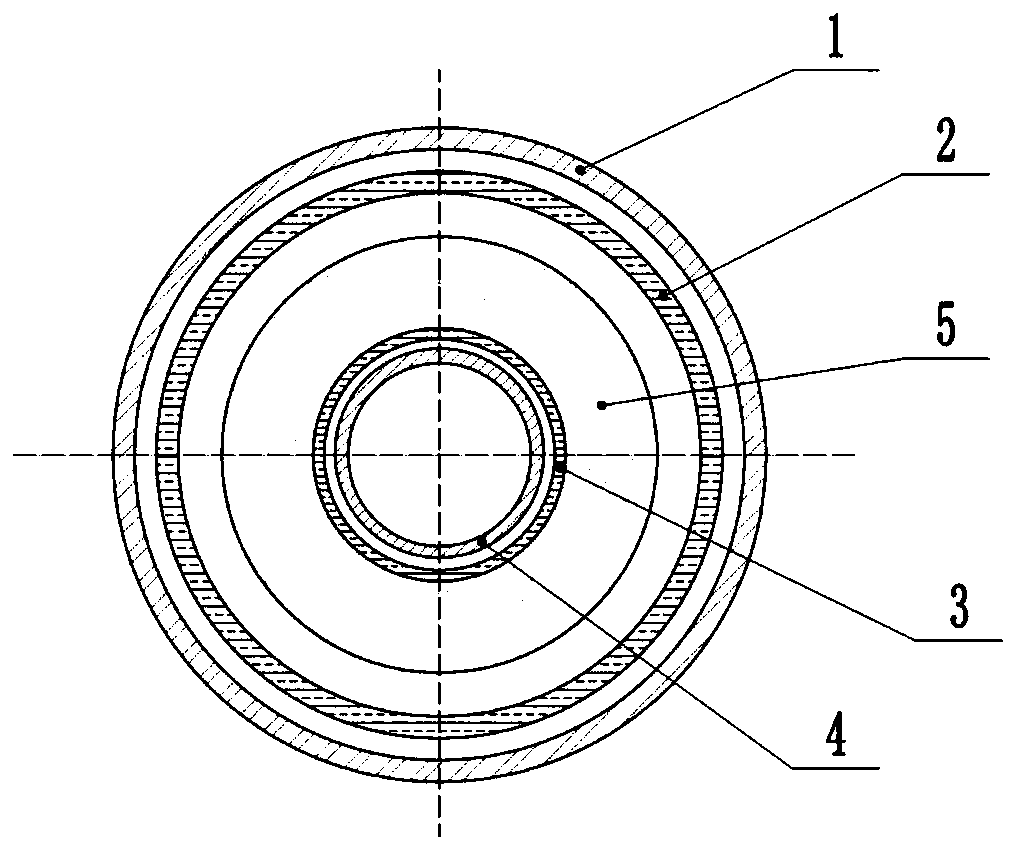

Preparation method of high-quality explosive composite tube

InactiveCN113211931AAvoid local defect problemsImprove energy utilizationLaminationLamination apparatusDetonatorIndustrial engineering

The invention provides a preparation method of a high-quality explosive composite tube. The preparation method comprises the following steps: coaxially arranging a to-be-compounded tube 1, a to-be-compounded tube 2, a small-radius PVC tube 1 and a large-radius PVC tube 2 from inside to outside, and filling space between the PVC tubes with an explosive and a detonator to prepare an explosive device of materials to be welded together; filling space among the to-be-compounded tubes and the explosive device with water to construct a water environment; and detonating the explosive device and welding and combining the to-be-compounded tube by utilizing water pressure to obtain a high-quality explosive composite rod tube. The invention provides the method for compounding the tubes by transferring high pressure generated by explosive explosion via a water medium, so dust and noise pollution in the preparation process is effectively reduced, and environmental protection and safety are taken into consideration while production quality is ensured; a water environment interlayer is reasonably utilized, so the size of the to-be-compounded tubes can be randomly selected as required; compared with a traditional technology, the operability of the method is higher, and the tubes are prevented from being damaged due to high temperature generated by explosive explosion; and the defect that composite machining of thin-wall tubes is difficult to achieve through traditional explosive welding is overcome.

Owner:ANHUI UNIV OF SCI & TECH

A fluidized bed activated carbon adsorption and denitrification method for low-sulfur flue gas

ActiveCN109999574BLarge reaction interfaceSmall particle sizeNitrous oxide captureGas treatmentActivated charcoal powderActivated carbon

Owner:SHENYANG DONGDASHANHUI ENVIRONMENTAL TECH CO LTD

Composite ecological concrete ball system based on slope protection and manufacturing method thereof

InactiveCN113371837ASimple and fast operationEasy to disassembleHops/wine cultivationSpecific water treatment objectivesMicroorganismEcological environment

The invention relates to the technical field of ecological restoration of water bodies, in particular to a composite ecological coagulation ball system based on a slope protection and a manufacturing method of the composite ecological coagulation ball system. The system comprises a positioning mechanism used for being installed in a water body of the slope protection, and a coagulation ball ecological system, a bottom aeration device, an aquatic plant system and an artificial plant system which are arranged in the positioning mechanism, a water quality purification system with good plant growing performance, large microorganism attachment density and a stable ecological network is established, aquatic plants realize synchronous treatment of water and bottom mud through root systems, stems and leaves, absorb a large amount of nutritive salt in the growth process and store the nutritive salt in bodies, a mechanical harvesting device directly harvests the aquatic plants in autumn and winter, the nutritive salt in the water body can be indirectly removed, the ecological environment of the water body is directly improved, ecological coagulation balls are filled in side slopes, and the effects of slope greening and slope protection are achieved.

Owner:芜湖沃泰环保科技有限公司

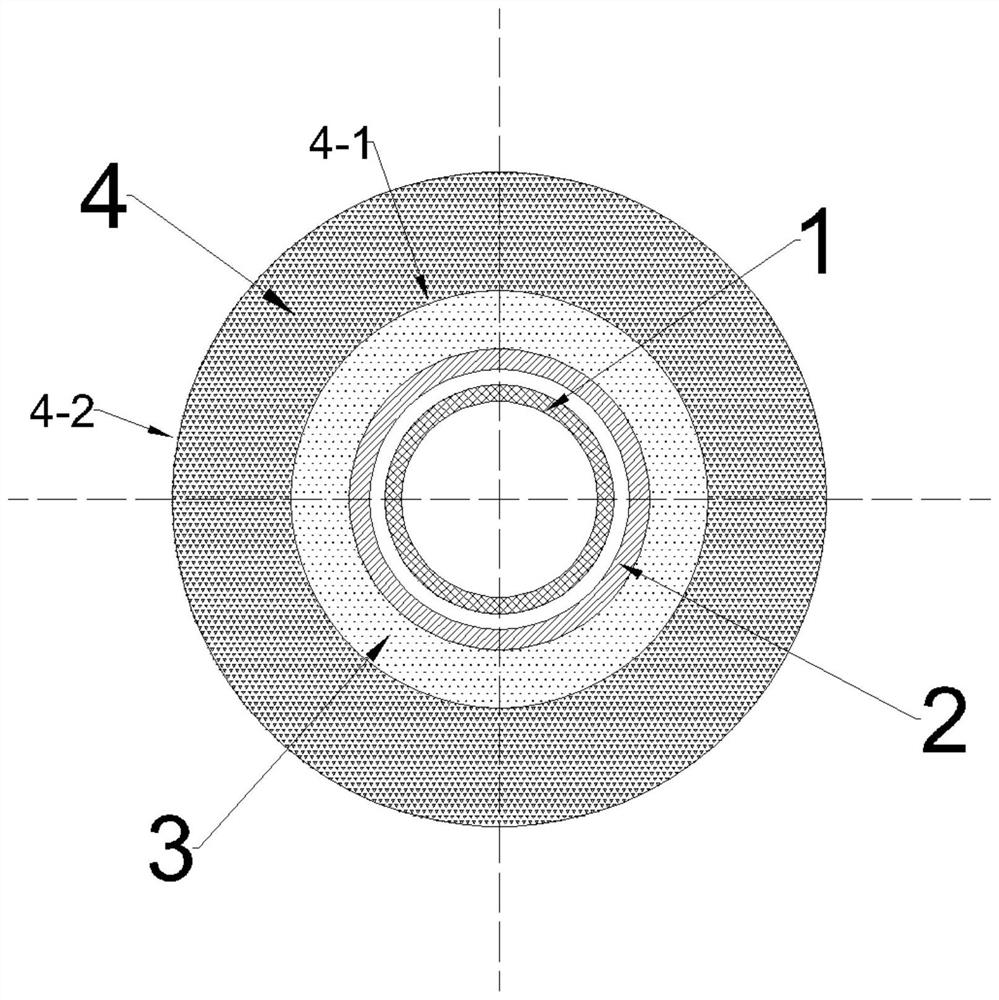

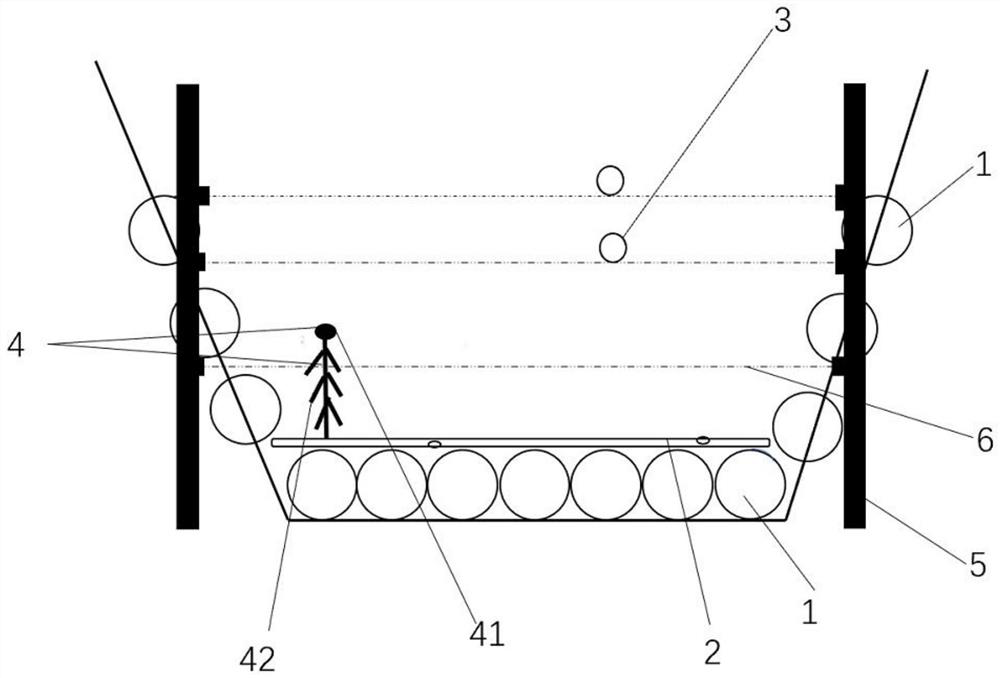

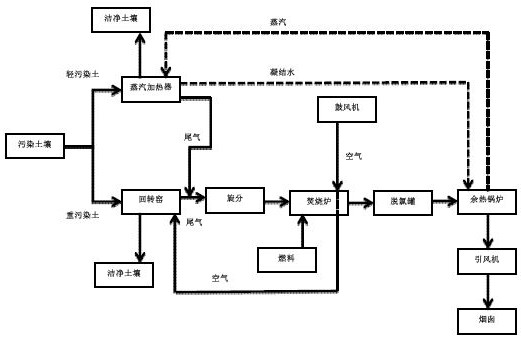

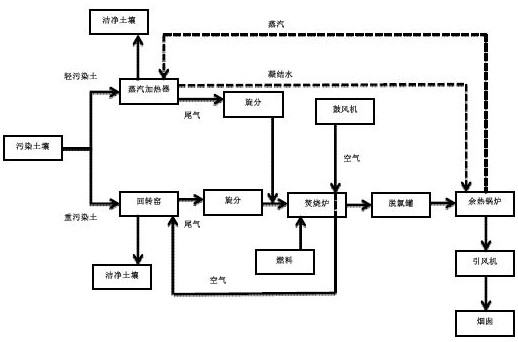

Thermal Desorption Remediation Method for Chlorine Contaminated Soil

ActiveCN110238181BReduce the amount of soilReduce generationContaminated soil reclamationDust controlThermal desorption

The invention discloses a thermal analysis treatment method for chlorine-containing polluted soil in the technical field of soil pollution control. According to the degree of pollution, the soil is divided into lightly polluted soil and heavily polluted soil; the lightly polluted soil is heated by steam, and the heated soil is clean soil; The heavily polluted soil is sent to the rotary kiln for heating, the tail gas is controlled at 150-400°C, and sent to the cyclone separator for dust removal; the tail gas at the outlet of the cyclone separator is sent to the incinerator, the heat source of the incinerator uses fuel as the heat source, and the excess oxygen in the tail gas is used as the oxygen Source, incinerator outlet tail gas temperature control 850 ℃ ~ 1600 ℃. By adopting the method of the invention, the fuel consumption and water consumption can be reduced by more than 50% and the water consumption can be reduced by more than 90%, while effectively avoiding secondary pollution such as dioxin.

Owner:SINOPEC GUANGZHOU ENG CO LTD +1

A manufacturing process of explosive composite pipe with negative pressure cavity based on liquid explosive

ActiveCN111085769BIncrease binding rateImprove welding qualityNon-electric welding apparatusExplosive AgentsEngineering

The invention provides a liquid explosive-based explosive composite pipe manufacturing process with a negative pressure cavity, which includes: coaxially installing the cladding pipe and the base pipe on the soft base from the inside to the outside, and according to the Calculate the amount of explosives according to the specifications, and install the inner tube to adjust the water column, use the sealing ring to seal the upper end of the annular cylindrical gap between the covering pipe and the base pipe, and use a vacuum pump to pump the annular cylindrical cavity into a negative pressure and seal it , place the assembled tube blank coaxially with the container and inject liquid explosives, and detonate the explosives to obtain metal composite tubes. The invention can greatly improve the production efficiency; the charge is uniform, the combination rate of the composite pipe is high, the welding quality is good, no constraint mold is required during the welding process, the production cost can be greatly reduced, and the circular cylindrical cavity is pumped into a vacuum pump. Negative pressure greatly reduces the influence of air on explosive welding, which not only improves the bonding quality of composite pipes, but also reduces the amount of explosives used.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

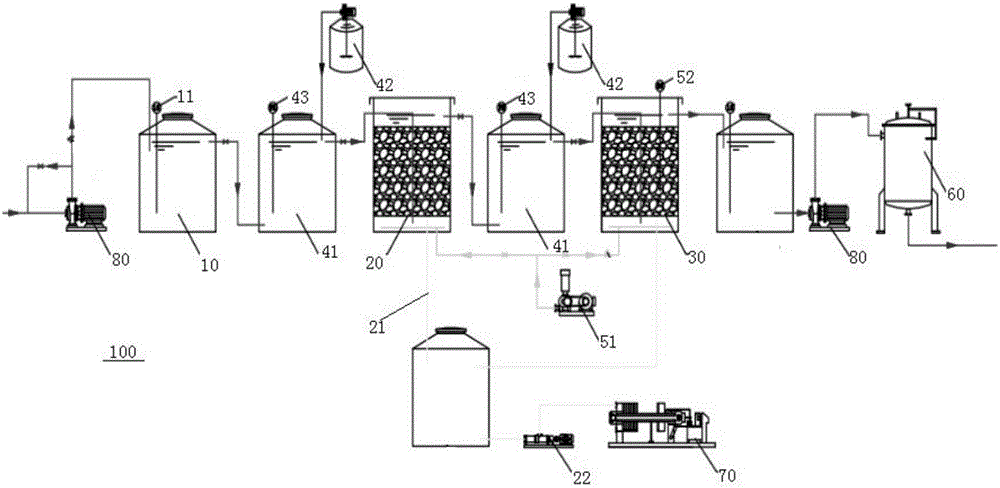

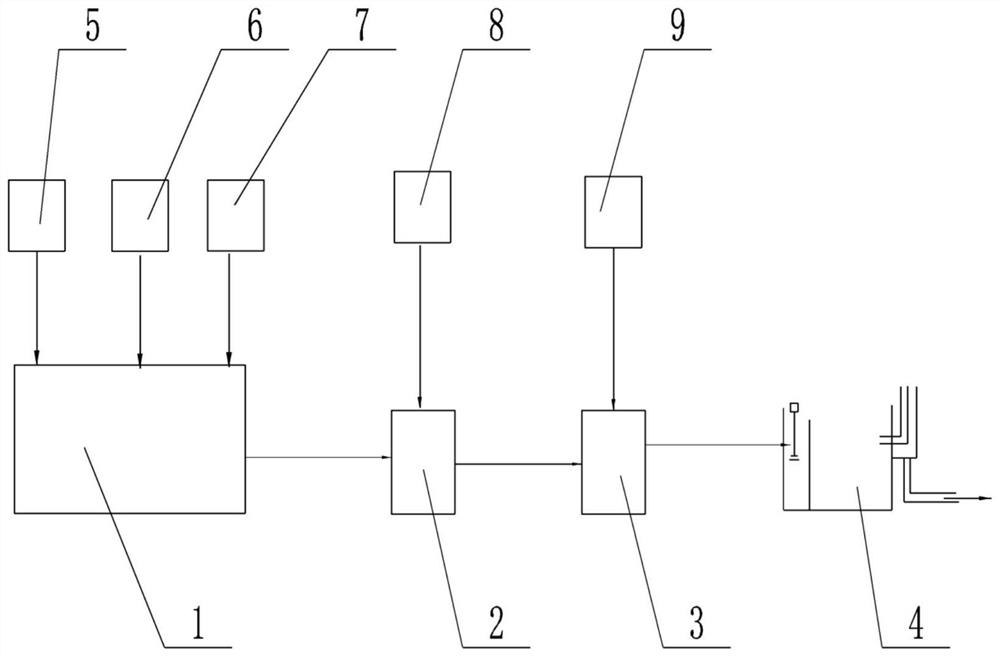

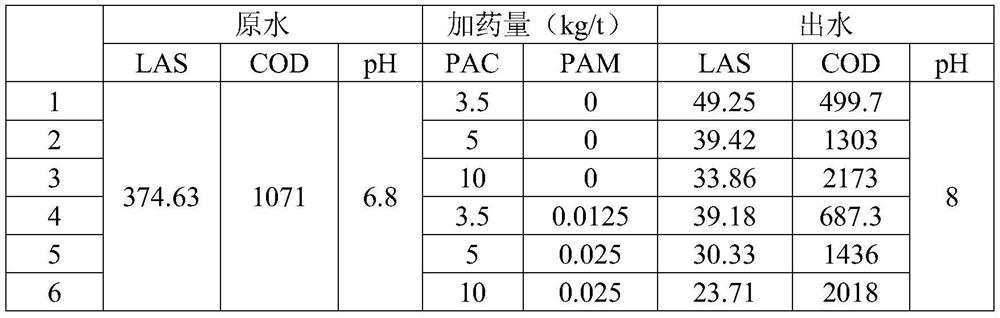

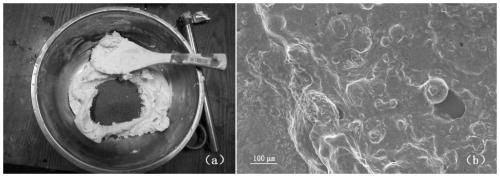

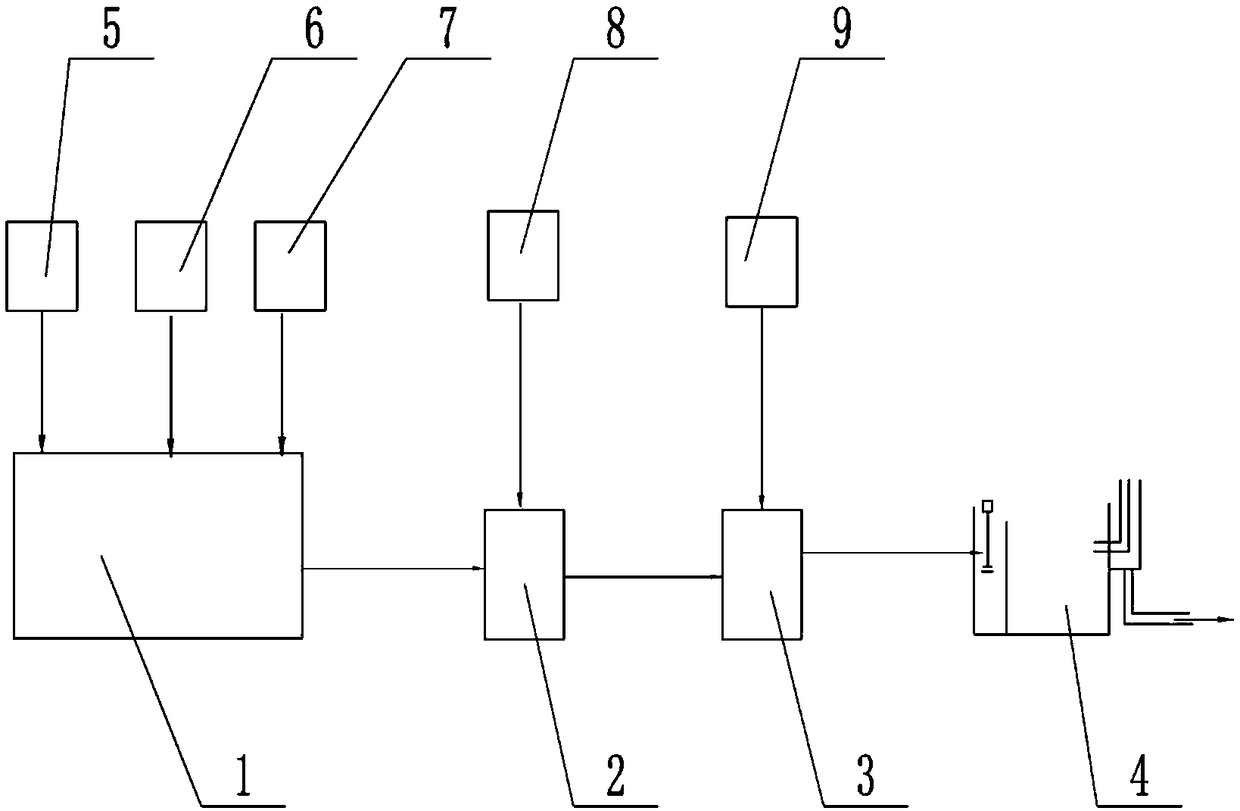

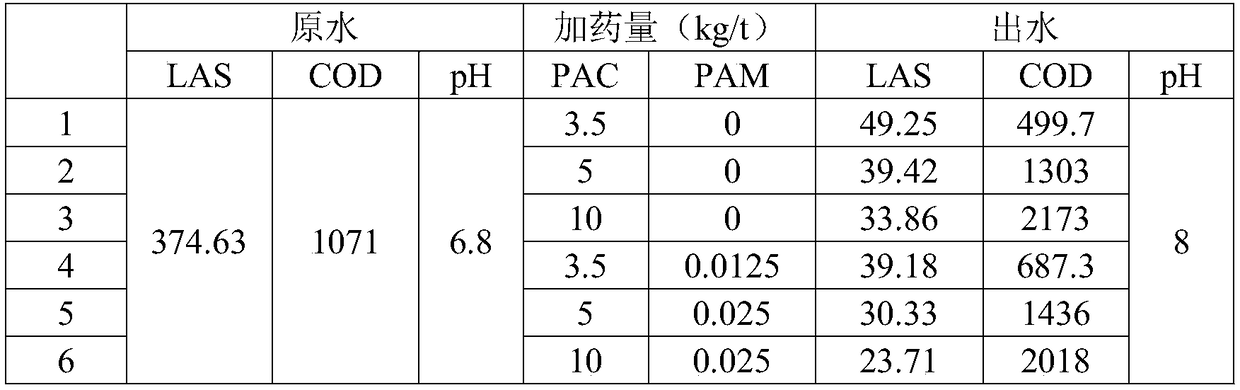

A kind of anionic surfactant sewage treatment method

ActiveCN109205827BReduce dosageReduce processing costsMultistage water/sewage treatmentWater/sewage treatment by neutralisationActive agentEngineering

A novel anionic surfactant sewage treatment method comprises the following steps: (1) surfactant sewage pretreatment; (2) dosage measurement; (3) dosing solution; (4) coagulation and precipitation. The dosage of the present invention is small, the treatment cost is low, and the concentration of anion / cation surfactant sewage is as high as thousands of milligrams per liter. Below the grade standard, the mud production is small, and the process runs stably.

Owner:TIANJIN TIANZHI FINE CHEM

A preparation method of explosive composite pipe with high energy utilization rate

ActiveCN108372357BImprove energy utilizationImprove welding qualityTubular articlesNon-electric welding apparatusDetonationHigh energy

The invention provides a method with a high energy utilization rate for preparing explosion composite tubes. The method includes sequentially coaxially arranging first to-be-subjected-to-composition tubes, second to-be-subjected-to-composition tubes, third to-be-subjected-to-composition tubes and fourth to-be-subjected-to-composition tubes from the outside to the inside and filling spaces betweenthe second to-be-subjected-to-composition tubes and the third to-be-subjected-to-composition tubes with annular grains; detonating the annular grains to obtain the first explosion composite tubes andthe second explosion composite tubes. Compared with the prior art, the method has the advantages that the method includes simple procedures and is easy to operate; every two explosion composite tubeswith excellent welding quality can be obtained by means of one-step detonation, accordingly, the method is high in energy utilization rate, the experiment frequencies of can be reduced, and secondarypollution such as noise and vibration generated by experiments can be obviously reduced.

Owner:UNIV OF SCI & TECH OF CHINA

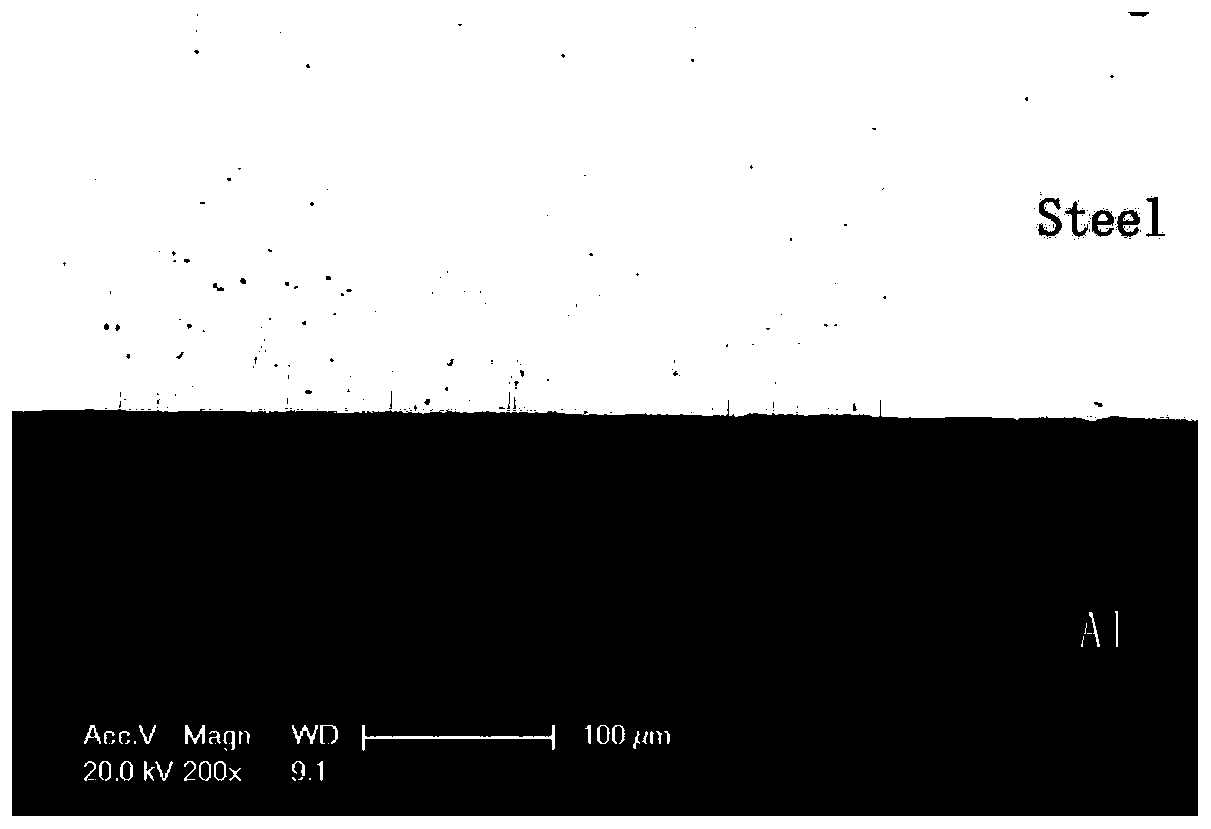

Iron oxyhydroxide nanorod/foam carbon composite material and its preparation method and application

ActiveCN107082467BImprove adsorption capacitySmall secondary pollutionOther chemical processesWater contaminantsCarbon compositesHydrothermal synthesis

The invention discloses an iron oxyhydroxide nanorod / foam carbon composite material and a preparation method and application thereof. According to the iron oxyhydroxide nanorod / foam carbon composite material, foam carbon is used as a substrate, and iron oxyhydroxide nanorods are uniformly loaded on the substrate. The iron oxyhydroxide nanorod / foam carbon composite material is prepared by uniformly loading iron oxyhydroxide nanorods on the foam carbon substrate through a hydrothermal synthesis method. The iron oxyhydroxide nanorod / foam carbon composite material can be directly used as an adsorbent for removing arsenic from a water body. The iron oxyhydroxide nanorod / foam carbon composite material has strong adsorption capacity and less secondary pollution, is easy to separate and recover, has fast mass transfer rate, is low-cost, and can achieve rapid, efficient and selective removal of arsenic in a water body.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

One-dimensional tubular zeolite with large pore size and preparation method thereof

InactiveCN104556098BAchieve diffusionControlled diffusionCrystalline aluminosilicate zeolitesHalloysitePollution

The invention relates to large-aperture one-dimensional tubular zeolite and a preparation method thereof. The large-aperture one-dimensional tubular zeolite has a nanometer one-dimensional hollow tube structure, the internal diameter of the large-aperture one-dimensional tubular zeolite is 70-90nm, the tube wall thickness is 15-22nm, and the tube length is 0.65-1 micron. The preparation method of the large-aperture one-dimensional tubular zeolite comprises the following steps: 1) preparing purified halloysite; and 2) preparing the large-aperture one-dimensional tubular zeolite: under the conditions of normal temperature and normal pressure, grinding the purified halloysite until the particle size is less than or equal to 200mesh, adding the ground purified halloysite into a sodium hydroxide solution, uniformly mixing, putting in a hydrothermal reaction kettle, carrying out hydrothermal reaction for 20-24h under the condition with the temperature to be 100-110 DEG C, and then carrying out post-processing to obtain the large-aperture one-dimensional tubular zeolite. The method is simple in step, mild in reaction condition, short in production period, simple in procedure, low in cost and little in secondary pollution and is suitable for scale production.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Distillation concentration treatment method for ion exchange resin regenerated and activated wastewater

ActiveCN113800704BTake advantage ofHigh precisionWater treatment parameter controlSpecific water treatment objectivesSteam pressureDistillation

The invention discloses a method for treating ion-exchange resin regenerated and activated wastewater by distillation and concentration, which includes treating the activated wastewater through a reverse osmosis device, and collecting respectively the wastewater clear liquid and the wastewater concentrated liquid; S2: the liquid level of the waste water concentrated liquid in the water collection well reaches the maximum value 70‑80% of the steam generator’s standby water inlet valve and power supply, and the water is heated; S3: When the steam pressure in the steam generator reaches the set value, open the steam generator’s outlet valve, and the heating steam enters the evaporator for replacement In the heat pipe; at the same time start the circulating pump, the preheated wastewater concentrate in the water collection well is sprayed from the upper part of the evaporator to the evaporation chamber for heat exchange, and the wastewater concentrate is sprayed and concentrated in a circular manner. The treatment method disclosed by the invention can realize resource utilization of waste water, and is energy-saving and environment-friendly.

Owner:SYNGARS TECH CO LTD

Novel anionic surfactant sewage treatment method

ActiveCN109205827AReduce dosageReduce processing costsMultistage water/sewage treatmentNature of treatment waterChemical solutionCompound (substance)

A novel anionic surfactant sewage treatment method comprises the following steps: (1) surfactant wastewater pretreatment; (2) determination of a dosage of a chemical; (3) chemical solution dosing; and(4) coagulation sedimentation. The method has the advantages of small dosage and low processing cost, and can treat anion / cation surfactant wastewater having a concentration of up to thousands of milligrams per liter, and the effluent water quality is good. After the quantitative dosing, the concentration of an anionic surfactant in the sewage can be reduced to national standard third-level or less. The amount of mud produced is small, and the process is stable.

Owner:TIANJIN TIANZHI FINE CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com