Artificial zeolite using shells and construction waste as raw materials and preparation method thereof

A construction waste, artificial zeolite technology, applied in chemical instruments and methods, crystalline aluminosilicate zeolite, other chemical processes, etc., can solve the problem that natural zeolite reserves or adsorption performance cannot reach industrial applications, and natural zeolite is slow and difficult to generate. Large-scale production and other problems, to achieve the effect of improving the utilization value, good expansion rate and adsorption performance, and reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

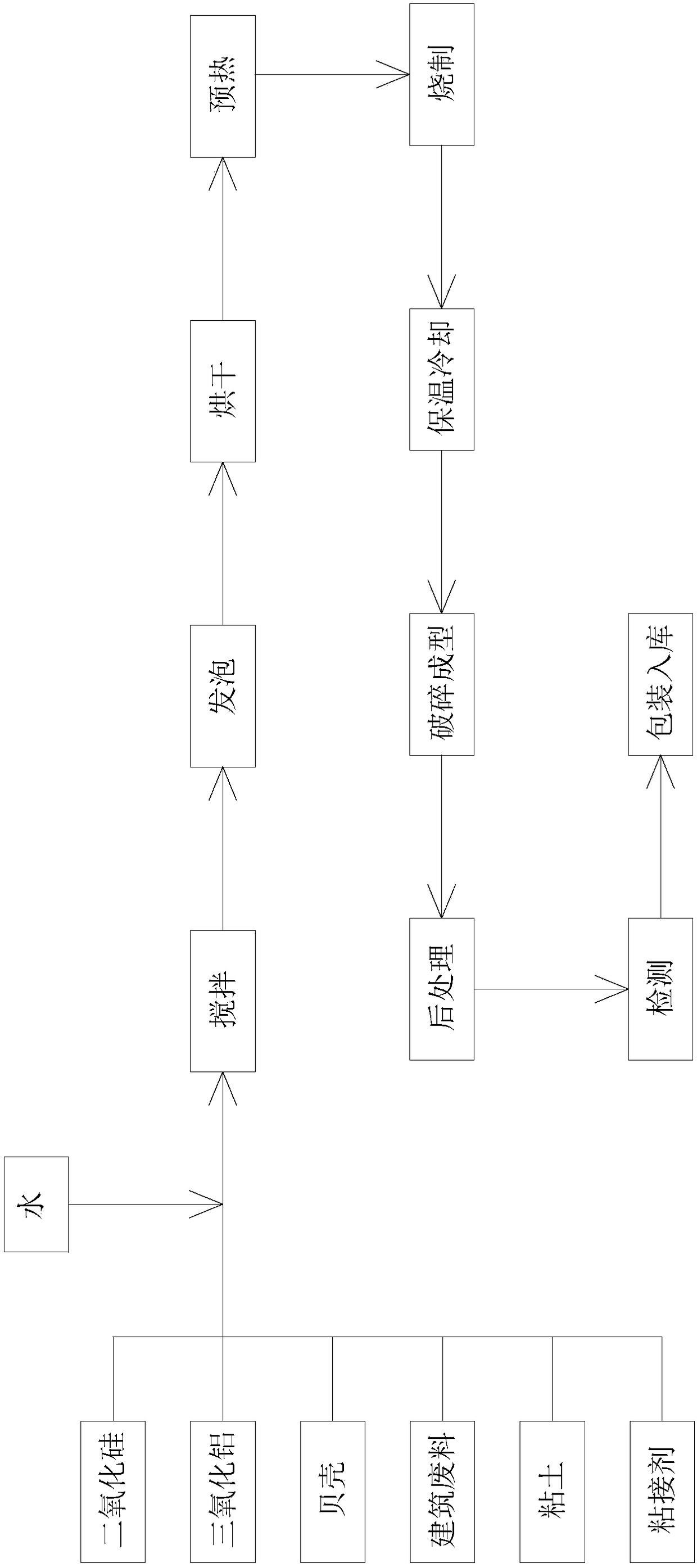

Image

Examples

Embodiment 1

[0029] An artificial zeolite using shells and construction waste as raw materials, which includes the following raw materials in terms of mass percentages: 10% silicon dioxide, 35% aluminum oxide, 5% shells, 12% construction waste, 18% clay, bonding Agent 20%. Wherein, the adhesive is made of water glass and sodium carboxymethyl cellulose in a ratio of 30%:70%.

[0030] The preparation method of the above-mentioned artificial zeolite with shells and construction waste as raw material comprises the following steps:

[0031] 1) Grinding and grinding shells and construction waste respectively, grinding to 300 mesh, mixing with silica, alumina and clay, then adding adhesive and stirring at 85°C for 3 hours;

[0032] 2) Add foaming agent sodium bicarbonate to the mixture prepared in step 1) in a ratio of 0.5ml / g, mix uniformly in a high-speed mixer, and perform foaming treatment. The stirring and foaming temperature is 90°C, and the foaming time is 1.5h;

[0033] 3) Transport th...

Embodiment 2

[0039] An artificial zeolite using shells and construction waste as raw materials, which includes the following raw materials in terms of mass percentages: 20% silicon dioxide, 25% aluminum oxide, 8% shells, 16% construction waste, 15% clay, bonding Agent 16%. Wherein, the adhesive is made of water glass and sodium carboxymethyl cellulose in a ratio of 30%:70%.

[0040] The preparation method of the above-mentioned artificial zeolite with shells and construction waste as raw material comprises the following steps:

[0041] 1) Grinding and grinding shells and construction waste respectively, grinding to 400 mesh, mixing with silica, alumina and clay, then adding adhesive and stirring at 100°C for 2 hours;

[0042] 2) Add foaming agent sodium bicarbonate in the ratio of 0.8ml / g to the mixture prepared in step 1), mix evenly in a high-speed mixer, and perform foaming treatment. The stirring and foaming temperature is 45°C, and the foaming time is for 2h;

[0043]3) Transport t...

Embodiment 3

[0049] An artificial zeolite with shells and construction waste as raw materials, which includes the following raw materials in terms of mass percentages: 5% silicon dioxide, 25% aluminum oxide, 10% shells, 25% construction waste, 30% clay, bonding Agent 15%. Wherein, the adhesive is made of water glass and sodium carboxymethyl cellulose in a ratio of 30%:70%.

[0050] The preparation method of the above-mentioned artificial zeolite with shells and construction waste as raw material comprises the following steps:

[0051] 1) Grinding and grinding shells and construction waste respectively, grinding to 200 mesh, mixing with silica, alumina and clay, then adding adhesive and stirring at 60°C for 5 hours;

[0052] 2) Add foaming agent sodium bicarbonate in the ratio of 1ml / g to the mixture prepared in step 1), mix uniformly in a high-speed mixer, and perform foaming treatment. The stirring and foaming temperature is 105 ° C, and the foaming time is 0.5h;

[0053] 3) Transport ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com