A preparation method of explosive composite pipe with high energy utilization rate

A composite tube and utilization rate technology, applied in the field of explosive welding, can solve the problems of not fully utilizing the detonation reaction energy, not fully utilizing the energy, and cumbersome preparation of explosive fibers, etc., to achieve easy operation, high energy utilization rate, and reduce the number of experiments Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

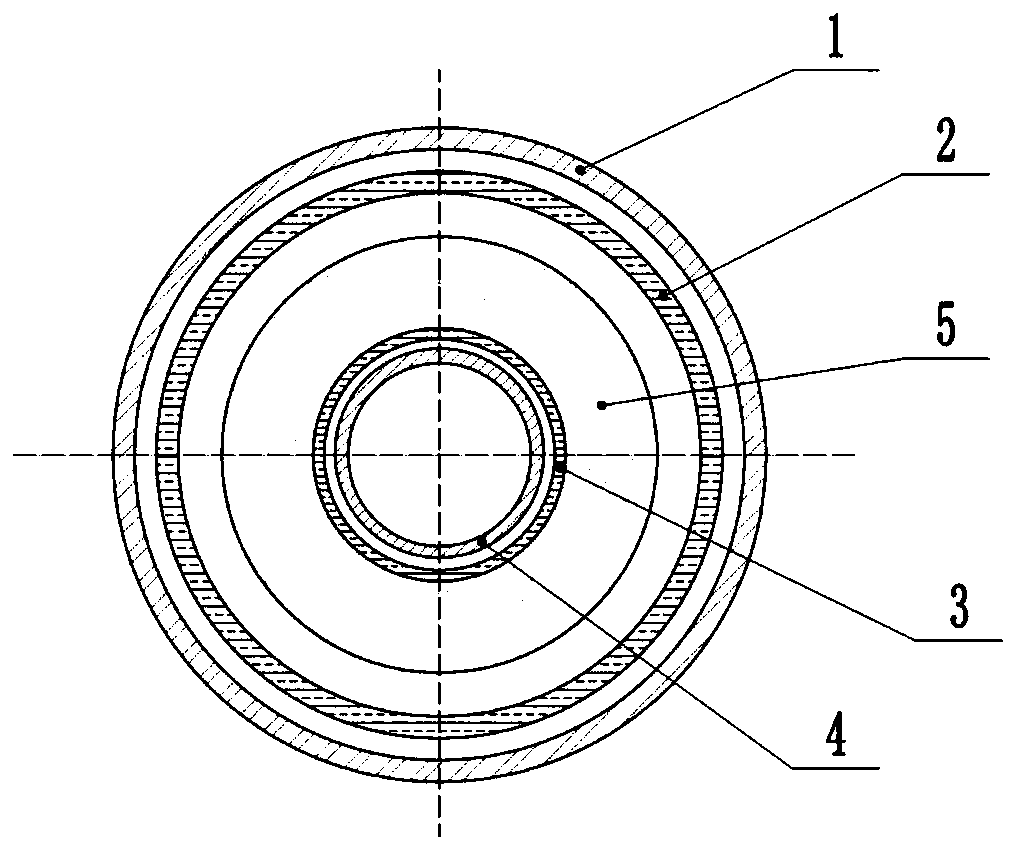

[0030] The invention provides a method for preparing an explosive composite pipe, comprising: arranging the first pipe to be composited, the second pipe to be composited, the third pipe to be composited and the fourth pipe to be composited coaxially from outside to inside, and An annular charge column is filled between the second pipe material to be compounded and the third pipe material to be compounded; the ring charge column is detonated to obtain the first explosive composite pipe and the second explosive composite pipe.

[0031] The preparation method provided by the invention is simple in process and easy to operate, and two explosive composite pipes with good welding quality can be obtained by one detonation, the energy utilization rate is high, the number of experiments is reduced, and secondary pollution such as noise and vibration generated by the experiment There was also a marked decline.

[0032] The present invention has no special limitation on the sources of al...

Embodiment 1

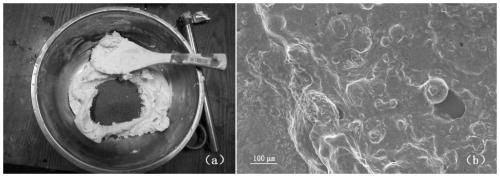

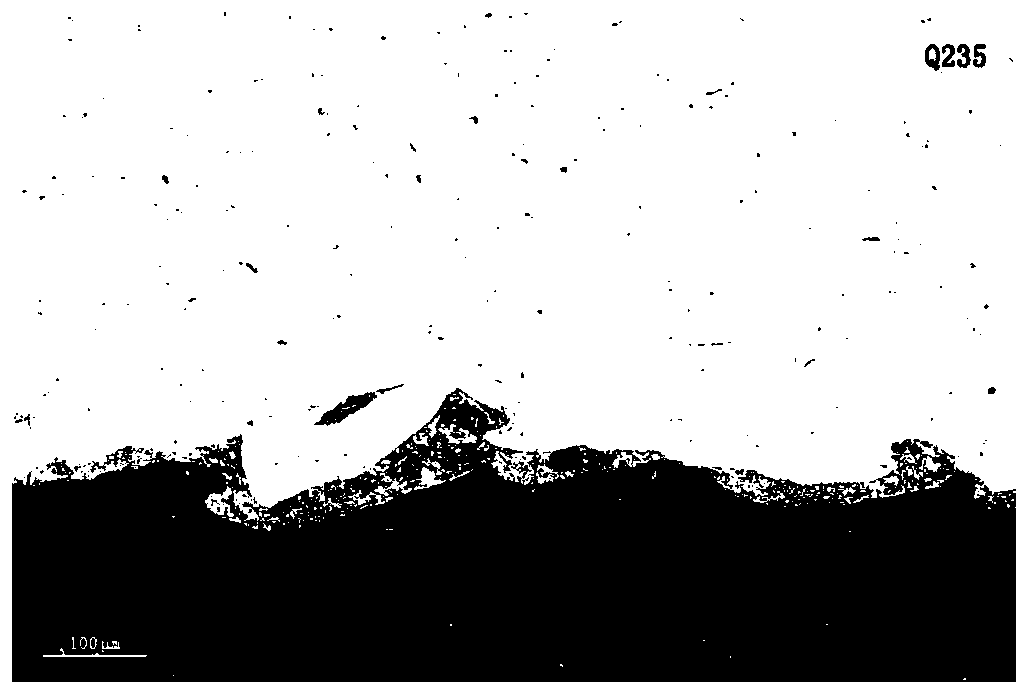

[0056] The first to fourth pipes to be composited are: Q235 ordinary carbon steel, T2 red copper, 1050 industrial pure aluminum and TA2 titanium. Their ID / OD are: 64 / 75, 56 / 60, 26 / 30 and 20 / 24mm. At the same time, according to the Chinese patent application number CN201710476936.5, a low detonation velocity emulsion explosive is prepared: take 85kg of emulsion explosive (physical sensitization of hollow glass microspheres), 15kg of ordinary clay, and mix them evenly to obtain a detonation velocity of 2650m / s , a low detonation velocity emulsion explosive with a force of 10.7mm.

[0057] Further, the low detonation velocity emulsion explosive is made into an annular charge column with an inner diameter of 30mm and an outer diameter of 50mm, and it is placed on the second to be compounded pipe, the third Between the pipes to be compounded, the annular explosive is closely attached to the third pipe to be compounded and an air gap is set between the second pipe to be compounded,...

Embodiment 2

[0060]The first to fourth composite pipes are respectively: 304 austenitic steel, T3 red copper, 1060 industrial pure aluminum and TA3 titanium. Their inner / outer diameters are: 70 / 85, 63 / 67, 30 / 35 and 24 / 28mm. At the same time, according to the Chinese patent application number CN201710476936.5, a low detonation velocity emulsion explosive is prepared: take 80kg of emulsion explosive (perlite physical sensitization), 20kg of common clay, and mix uniformly to obtain a detonation velocity of 2450m / s. A low detonation velocity emulsion explosive with a density of 10.1mm.

[0061] Further, the low detonation velocity emulsion explosive is made into an annular charge column with an inner diameter of 35mm and an outer diameter of 60mm, and it is placed on the second to be compounded pipe, the third Between the pipes to be compounded, the annular explosive is closely attached to the third pipe to be compounded and an air gap is set between the second pipe to be compounded, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com