Large-aperture one-dimensional tubular zeolite and preparation method thereof

A large-aperture, tubular technology, applied in the field of large-aperture one-dimensional tubular zeolite and its preparation, can solve the problems of increased adsorption sites and capacity, large inner diameter, large inner space of the tube, etc., and achieves multiple contact sites and contact spaces. Mild conditions and the effect of increasing the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Preparation of purified halloysite: Add 50g of HNT to 1000mL of distilled water, then add 2g of sodium hexametaphosphate as a dispersant, adjust the pH value between 8-9, then ultrasonically disperse for 10 minutes and then stir in a water bath at 60°C After 12 hours, a HNT suspension was obtained. The suspension was left to stand for 24 hours, the lower solid was discarded, the upper suspension was centrifuged at a speed of 2000 r / min, and the separated solid was placed in an oven and dried at 70°C for 24 hours to obtain purified HNT.

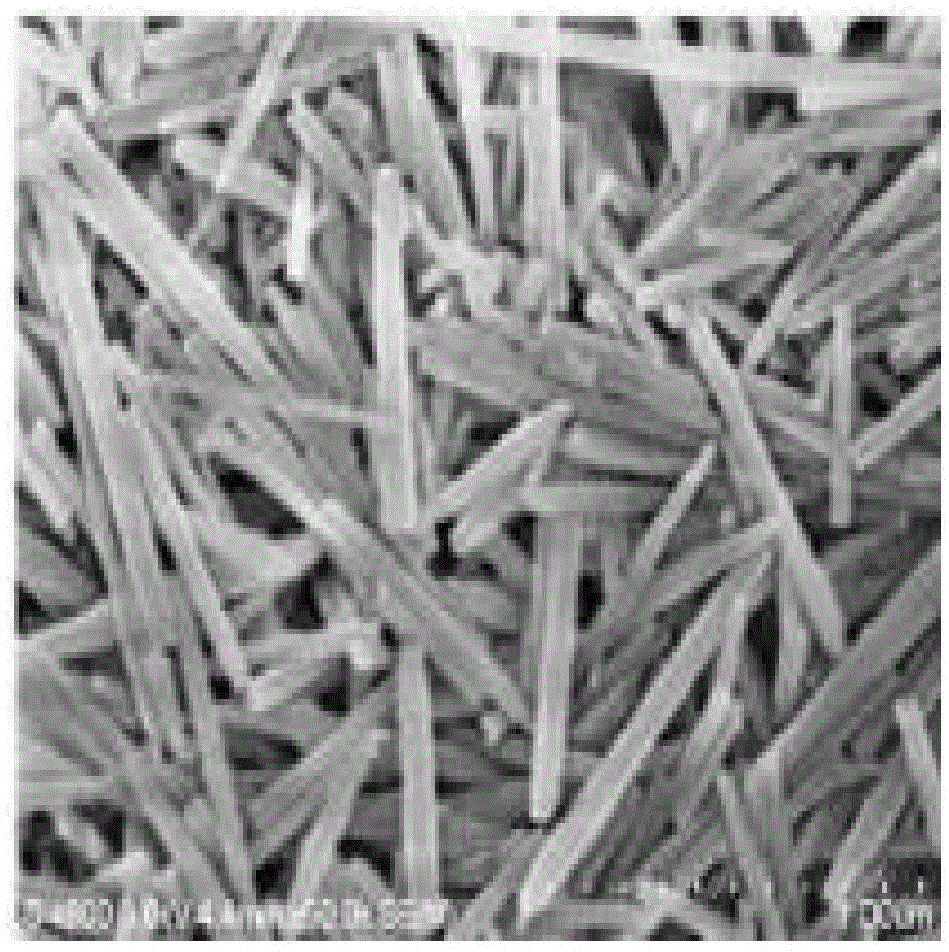

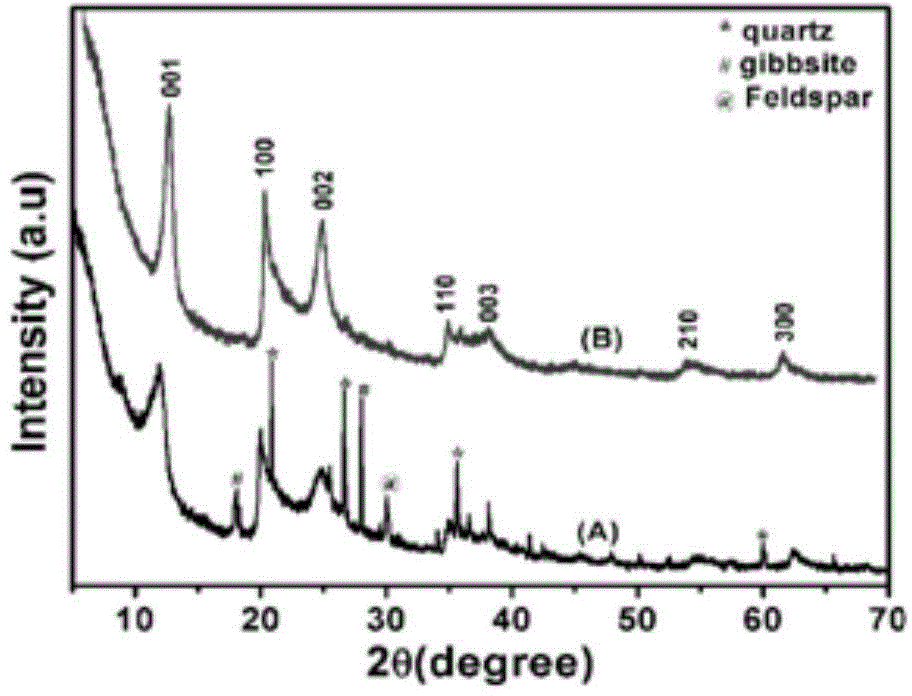

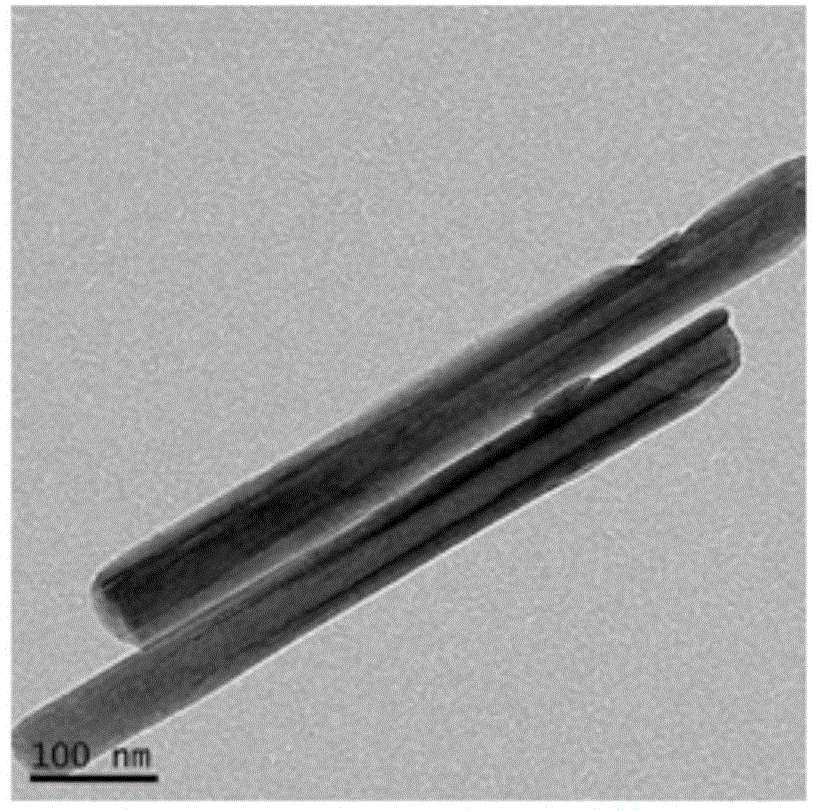

[0028] 2) Preparation of large-pore one-dimensional tubular zeolite: under normal temperature and pressure conditions, grind 1.5g of purified halloysite to a particle size of ≤200 mesh, add 58.5mL of 2wt% sodium hydroxide solution, stir for 20min, and then transfer to polytetrafluoroethylene In an ethylene hydrothermal tank, conduct a hydrothermal reaction at 100°C for 24 hours. After cooling to room temperature, wash the product rep...

Embodiment 2

[0033] 1) Preparation of purified halloysite: Add 50g of HNT to 1500mL of distilled water, then add 3g of sodium hexametaphosphate as a dispersant, adjust the pH value between 8-9, then ultrasonically disperse for 10 minutes and then stir in a water bath at 60°C After 12 hours, a HNT suspension was obtained. The suspension was left to stand for 24 hours, the lower solid was discarded, the upper suspension was centrifuged at a speed of 2000 r / min, and the separated solid was placed in an oven and dried at 70°C for 24 hours to obtain purified HNT.

[0034] 2) Preparation of large-pore one-dimensional tubular zeolite: under normal temperature and pressure conditions, grind 1.5g of purified halloysite to a particle size of ≤200 mesh, add it to 60mL of 2wt% sodium hydroxide solution, stir for 20min, and then transfer it into polytetrafluoroethylene In a hydrothermal tank, conduct a hydrothermal reaction at 100°C for 24 hours. After cooling to room temperature, wash the product repe...

Embodiment 3

[0036] 1) Preparation of purified halloysite: Add 50g of HNT to 1500mL of distilled water, then add 3g of sodium hexametaphosphate as a dispersant, adjust the pH value between 8-9, then ultrasonically disperse for 10 minutes and then stir in a water bath at 60°C After 12 hours, a HNT suspension was obtained. The suspension was left to stand for 24 hours, the lower solid was discarded, the upper suspension was centrifuged at 2000r / min, and the separated solid was placed in an oven and dried at 110°C for 12 hours to obtain purified HNT.

[0037] 2) Preparation of large-pore one-dimensional tubular zeolite: under normal temperature and pressure conditions, grind 1.5g of purified halloysite to a particle size of ≤200 mesh, add 58.5mL of 2wt% sodium hydroxide solution, stir for 20min, and then transfer to polytetrafluoroethylene In an ethylene hydrothermal tank, conduct a hydrothermal reaction at 110°C for 24 hours. After cooling to room temperature, wash the product repeatedly wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com