Anti-deformation pressure resistant temperature-uniforming plate

A vapor chamber and anti-deformation technology, which is applied to electrical components, electric solid devices, circuits, etc., can solve the problems that the structural strength and heat transfer efficiency of the vapor chamber cannot be maximized, and the anti-deformation and pressure resistance are not good. , to achieve the effect of improving life, heat transfer coefficient and uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0026] The present invention will be further described with reference to the drawings:

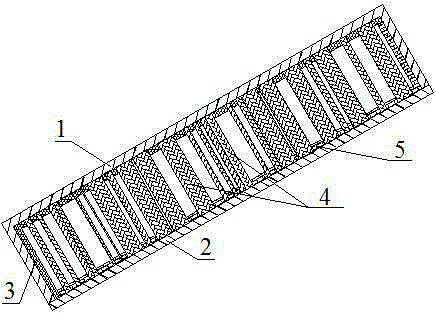

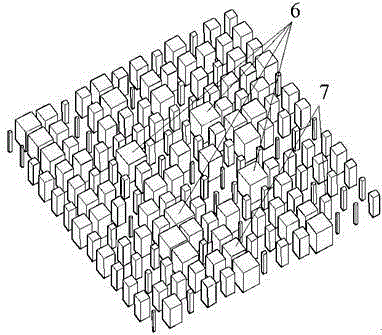

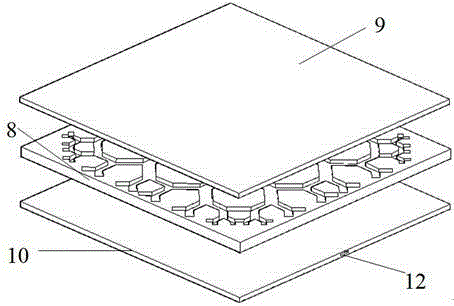

[0027] The structure of the anti-deformation and pressure-resistant uniform temperature plate proposed by the present invention is as follows figure 1 As shown, the deformation-resistant and pressure-resistant uniform temperature plate mainly includes an upper cover plate 1, a lower cover plate 2 and a supporting structure 4. The upper cover plate 1 and the lower cover plate 2 form a closed accommodating space. Layer capillary structure. The capillary structure in contact with the upper cover plate 1 is a layer of metal oxide film deposited on the inner surface of the plate by chemical vapor deposition. The surface water contact angle is only about 10°, which greatly improves the hydrophilicity of the surface. This strengthens its water absorption capacity, so that the heat can be taken away by phase change heat transfer in time, preventing damage due to excessive thermal stress; the capilla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com