Technology for cutting granite quarry stone

A cutting technology, granite technology, applied in the field of granite block cutting technology, can solve the problems of high cost, rising cutting cost, heavy maintenance workload, etc., and achieve the effect of reducing production cost, improving processing performance and low system consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

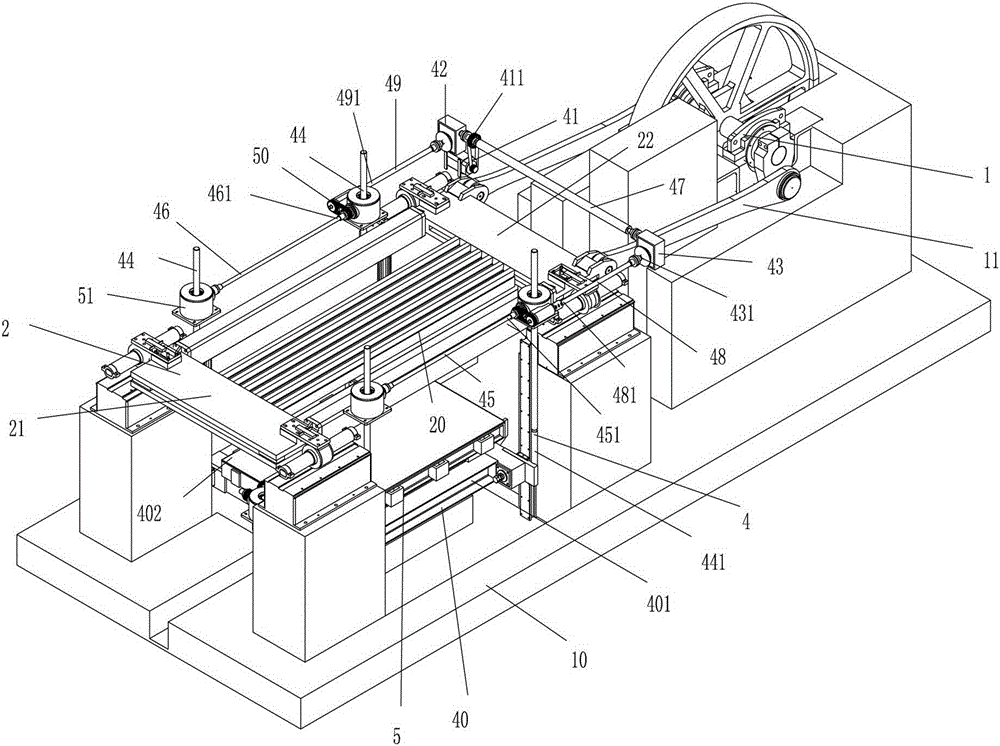

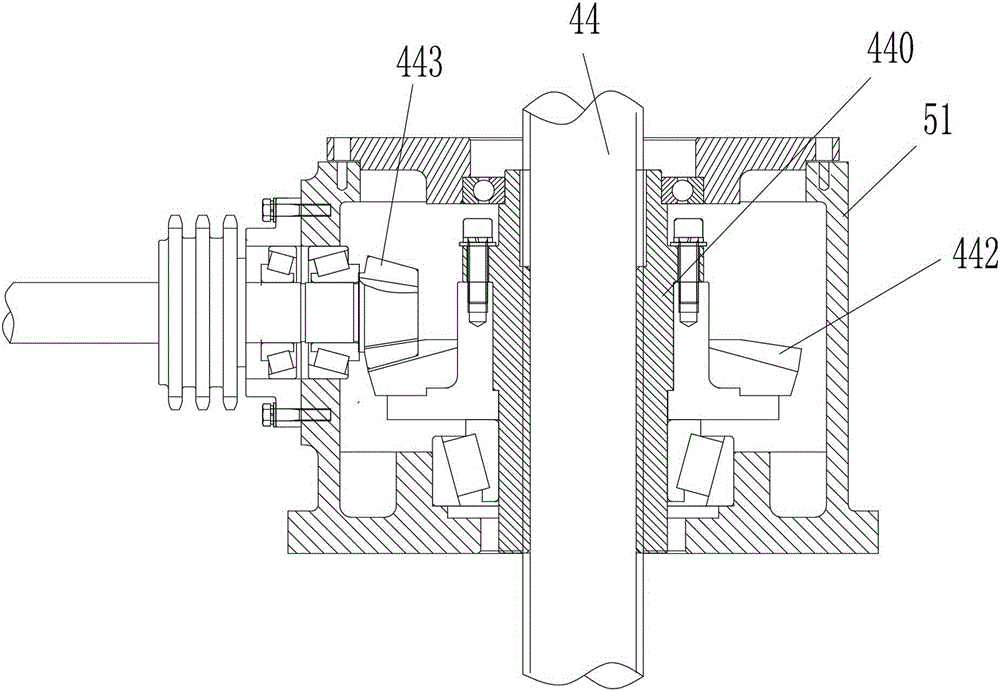

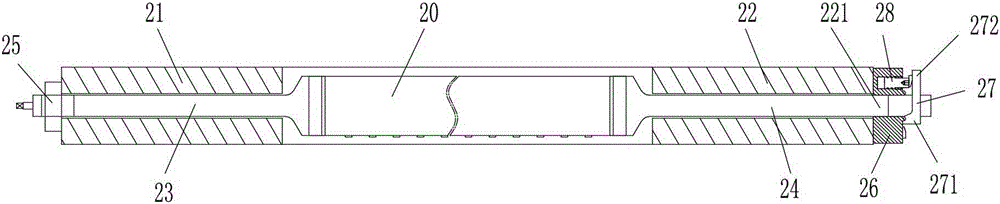

[0016] Such as Figure 1 to Figure 3 As shown, a granite block cutting process adopts a frame saw for cutting. The base installation structure 10 of the frame saw is provided with a spindle drive device 1, a saw frame assembly 2 slidingly arranged on the base installation structure 10, and erected on the base installation structure 10. The saw blade 20 on the left saw frame 21 and the right saw frame 22 of the saw frame assembly, the lifting device 4, the charging cart 5 placed on the lifting device, and the numerical control system that controls the feeding of the saw blade 20 and the lifting of the lifting device 4 ( not shown), the main shaft driving device 1 is connected to the saw frame assembly 2 through the connecting rod 11; when cutting, the numerical control system controls the saw blade processing feed mode to be divided into five levels of feed: the first l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com