A kind of anionic surfactant sewage treatment method

A sewage treatment method and surfactant technology, applied in water/sewage multi-stage treatment, neutralized water/sewage treatment, flotation water/sewage treatment, etc., can solve high treatment cost, secondary pollution, and low adsorption efficiency and other problems, to achieve the effect of stable process operation, small secondary pollution and low treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

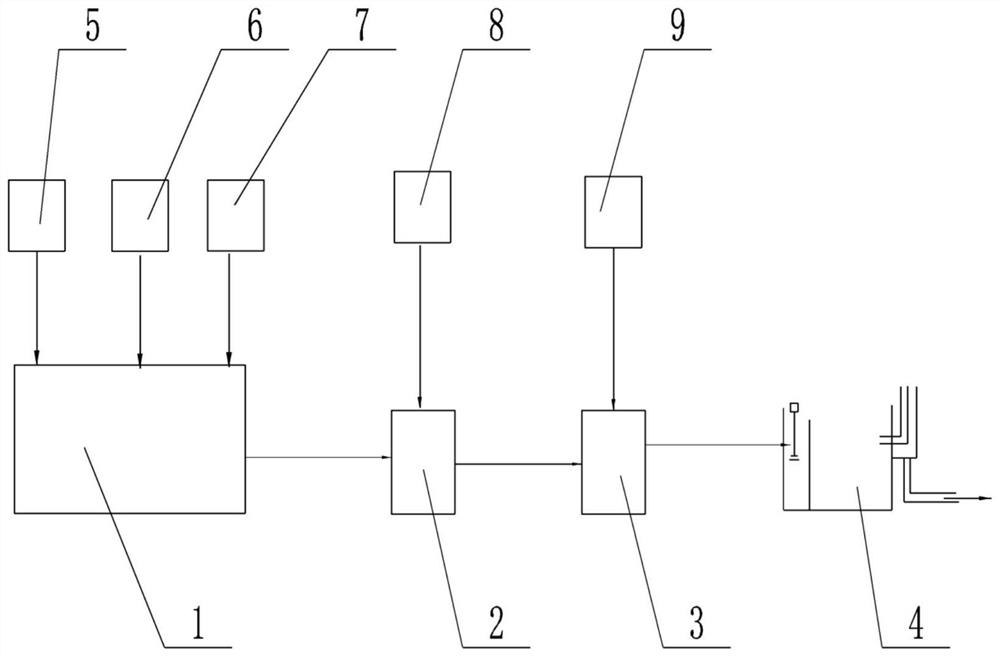

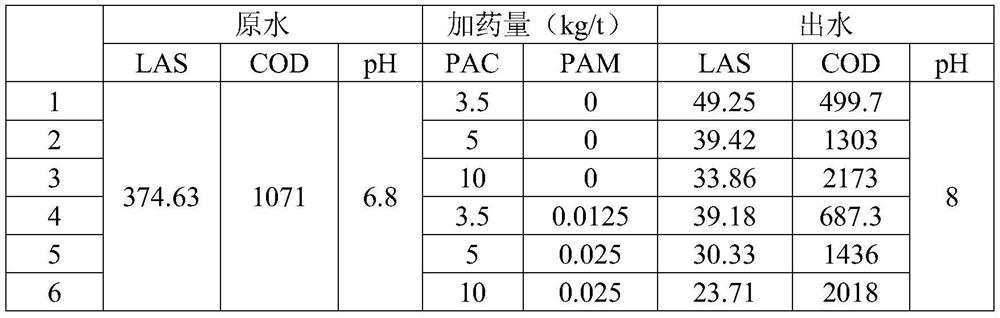

Method used

Image

Examples

Embodiment 1

[0031] A novel anionic surfactant sewage treatment method, the steps of which are:

[0032] (1) Surfactant sewage pretreatment: Inject sewage containing surfactant into the regulating tank, the inflow of COD is 1095mg / L, the inflow of anionic surfactant is 173.64mg / L, and the sewage is in the regulating tank Carry out homogeneous treatment for 1 hour, and at the same time, add acid or lye through the acid storage tank or lye storage tank to adjust the pH value of the sewage in the adjustment tank, so that the pH value reaches 10:

[0033] (2) Determination of dosage: the sewage in the regulating pool is mainly anionic surfactants, including sodium dodecylsulfonate, sodium lauryl sulfate and ethoxylated alkyl sodium sulfate, and cationic surfactants are added to the sewage in the regulating pool Determination of dosage of surfactant dodecyldimethylbenzyl ammonium chloride 1227;

[0034] The method of determination is:

[0035] a. Configuration of cationic surfactant standard ...

Embodiment 2

[0043] A novel anionic surfactant sewage treatment method, the steps of which are:

[0044](1) Surfactant sewage pretreatment: Inject sewage containing surfactant into the regulating tank, the inflow of COD is 1085mg / L, the inflow of anionic surfactant is 118.92mg / L, and the sewage is in the regulating tank Carry out homogeneous treatment for 1 hour, and at the same time, add acid or lye through the acid storage tank or lye storage tank to adjust the pH value of the sewage in the adjustment tank, so that the pH value reaches 10.1:

[0045] (2) Determination of dosage: the sewage in the regulating tank is mainly anionic surfactants, including sodium lauryl sulfate, sodium dodecylsulfonate and sodium ethoxylated alkyl sulfate, and cationic surfactants are added to the sewage in the regulating tank Determination of dosage of surfactant dodecyldimethylbenzyl ammonium chloride 1227;

[0046] The method of determination is:

[0047] a. Configuration of cationic surfactant standard...

Embodiment 3

[0055] A novel anionic surfactant sewage treatment method, the steps of which are:

[0056] (1) Surfactant sewage pretreatment: Inject sewage containing surfactant into the regulating tank, the inflow of COD is 3780mg / L, the inflow of anionic surfactant is 2119mg / L, and the sewage is treated in the regulating tank Homogenize for 1 hour, and at the same time, add acid or lye through the acid storage tank or lye storage tank to adjust the pH value of the sewage in the adjustment tank, so that the pH value reaches 10.2:

[0057] (2) Determination of dosage: the sewage in the regulating tank is mainly anionic surfactants, including sodium lauryl sulfate, sodium dodecylsulfonate and sodium ethoxylated alkyl sulfate, and cationic surfactants are added to the sewage in the regulating tank Determination of dosage of surfactant dodecyldimethylbenzyl ammonium chloride 1227;

[0058] The method of determination is:

[0059] a. Configuration of cationic surfactant standard solution: Wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com