Thermal Desorption Remediation Method for Chlorine Contaminated Soil

A technology of polluted soil and soil heat, which is applied in the field of remediation of polluted soil, can solve the problems of high fuel and energy consumption, and achieve the effects of reducing fuel consumption, reducing the amount of soil, and reducing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

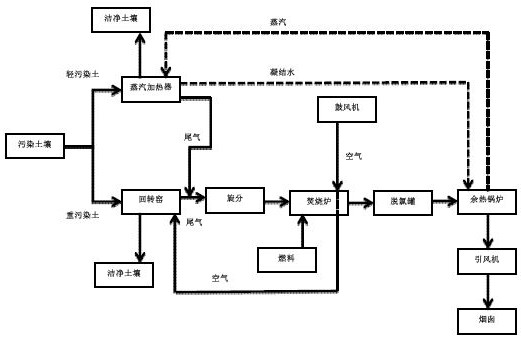

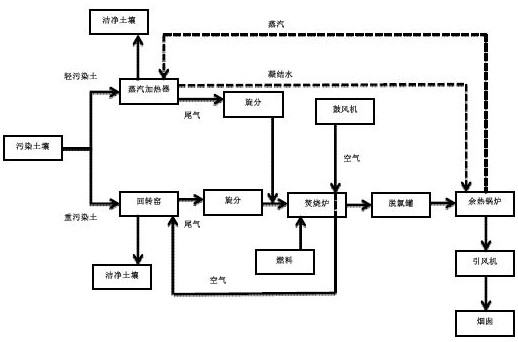

Method used

Image

Examples

Embodiment 1

[0039] 1) According to the situation of field adjustment, the polluted soil is classified by screening, among which the feeding amount of heavily polluted soil is 5t / h, and the feeding amount of lightly polluted soil is 30t / h.

[0040] 2) Heat the lightly polluted soil with 1.0MPaG steam produced by the waste heat boiler to generate 2000m3n / h of tail gas at 130°C, and the condensed water is boosted by the pump and sent back to the waste heat boiler to produce steam;

[0041] 3) The heavily polluted soil is sent to the rotary kiln, and the hot air at 1000 ° C is introduced into the rotary kiln, and the amount of hot air is 12000m 3 n / h, producing 13000m exhaust gas at 180°C 3 n / h, internal pressure of rotary kiln -60Pa;

[0042] 4) After the clean soil produced in step 2) and step 3) is qualified, it is merged into the silo for cooling, and a small amount of water is sprayed to ensure the moisture content of the repaired soil, reduce dust, and then reuse the soil.

[0043] 5)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com