Method for continuously catalyzing and degrading lignin bio-oil into aromatic hydrocarbons and naphthenic hydrocarbons with micro-channel reaction device

A micro-channel reaction and micro-channel reactor technology, applied in the field of aromatic hydrocarbons and naphthenes, can solve the problems of poor selectivity of aromatic hydrocarbons and naphthenes, and achieve good reaction effect, large specific surface area, fast heat transfer and mass transfer rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

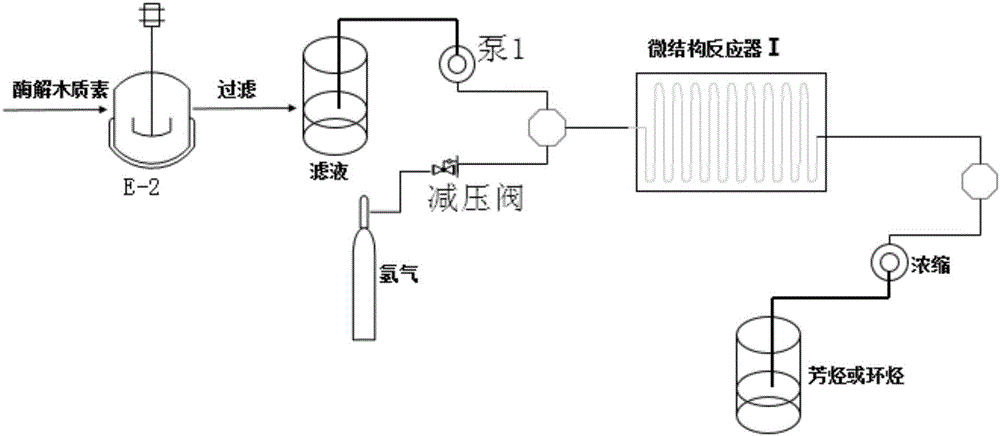

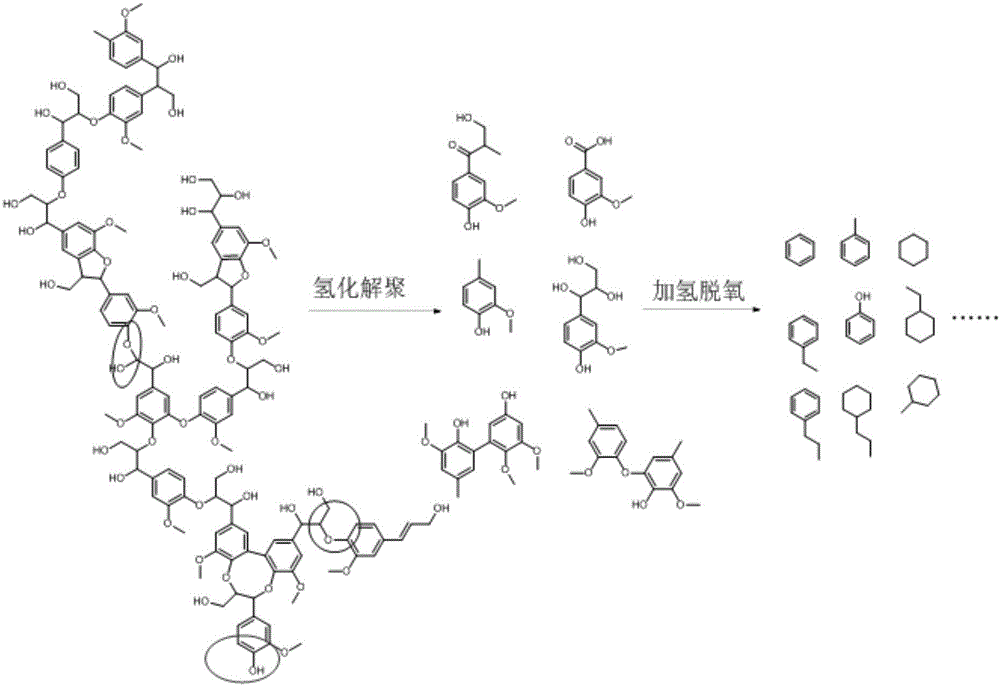

Method used

Image

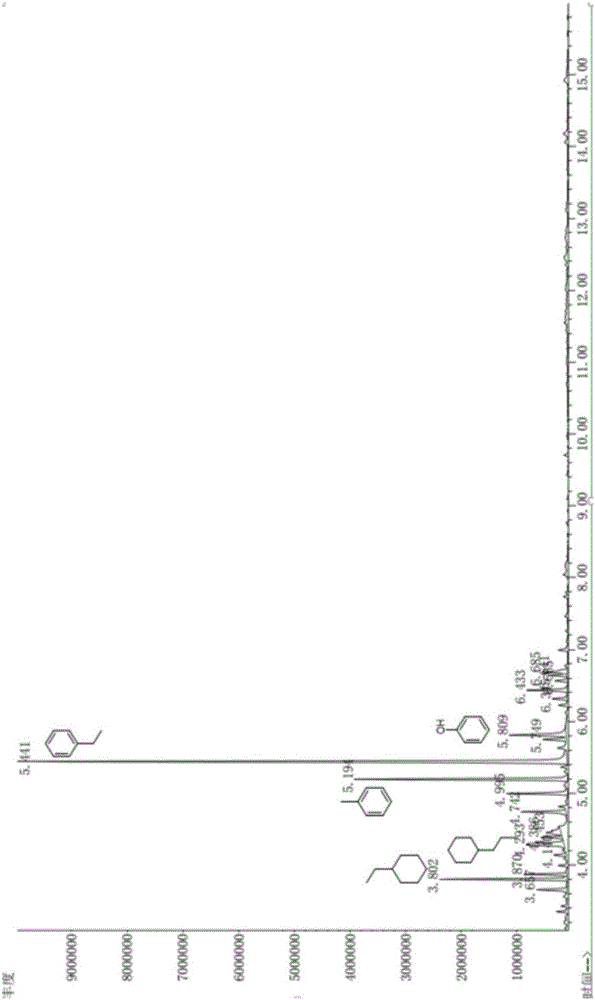

Examples

Embodiment 1~2

[0030] Accurately weigh 2g of enzymatic lignin in the reactor, add 50ml of methanol (Example 1) or ethanol (Example 2), add 0.5g of magnesium aluminum hydrotalcite (Mg-Al HT) to it, and feed 2MP hydrogen, reacted at 220°C for 8 hours, filtered after the reaction, removed the solid alkali catalyst and residue, and took the filtrate to detect the components.

[0031] Selectivity and conversion rate of table 1 embodiment 1~2

[0032] Example

Embodiment 3~4

[0034] Accurately weigh 2g of enzymatic lignin in the reactor, add 50ml of methanol therein, add 0.5g of magnesium aluminum hydrotalcite (Mg-Al HT) (embodiment 3), calcium oxide (CaO) (embodiment 4) wherein ), feed 3MP hydrogen, react at 220°C for 8h, filter after the reaction, remove the solid alkali catalyst and residue, and take the filtrate to detect components.

[0035] Selectivity and conversion rate of table 2 embodiment 3~4

[0036] Example

Embodiment 5~6

[0038] Accurately weigh 2g of enzymatic lignin in the reaction kettle, add 50ml of methanol to it, add 0.25g of magnesium aluminum hydrotalcite (Mg-Al HT) to it, feed 3MP hydrogen, and react at 200°C (Example 5) React at 220° C. (Example 6) for 8 hours, filter after the reaction, remove the solid base catalyst and residue, and take the filtrate to detect components.

[0039] Selectivity and conversion rate of table 3 embodiment 5-6

[0040] Example

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com