Window and hole combined flow guide regular filler sheet and filler

A structured packing, combined technology, applied in chemical/physical/physical-chemical processes, chemical instruments and methods, chemical/physical processes, etc. Window sealing and other problems, to achieve the effect of increasing gas-liquid flux, increasing the degree of liquid film turbulence, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

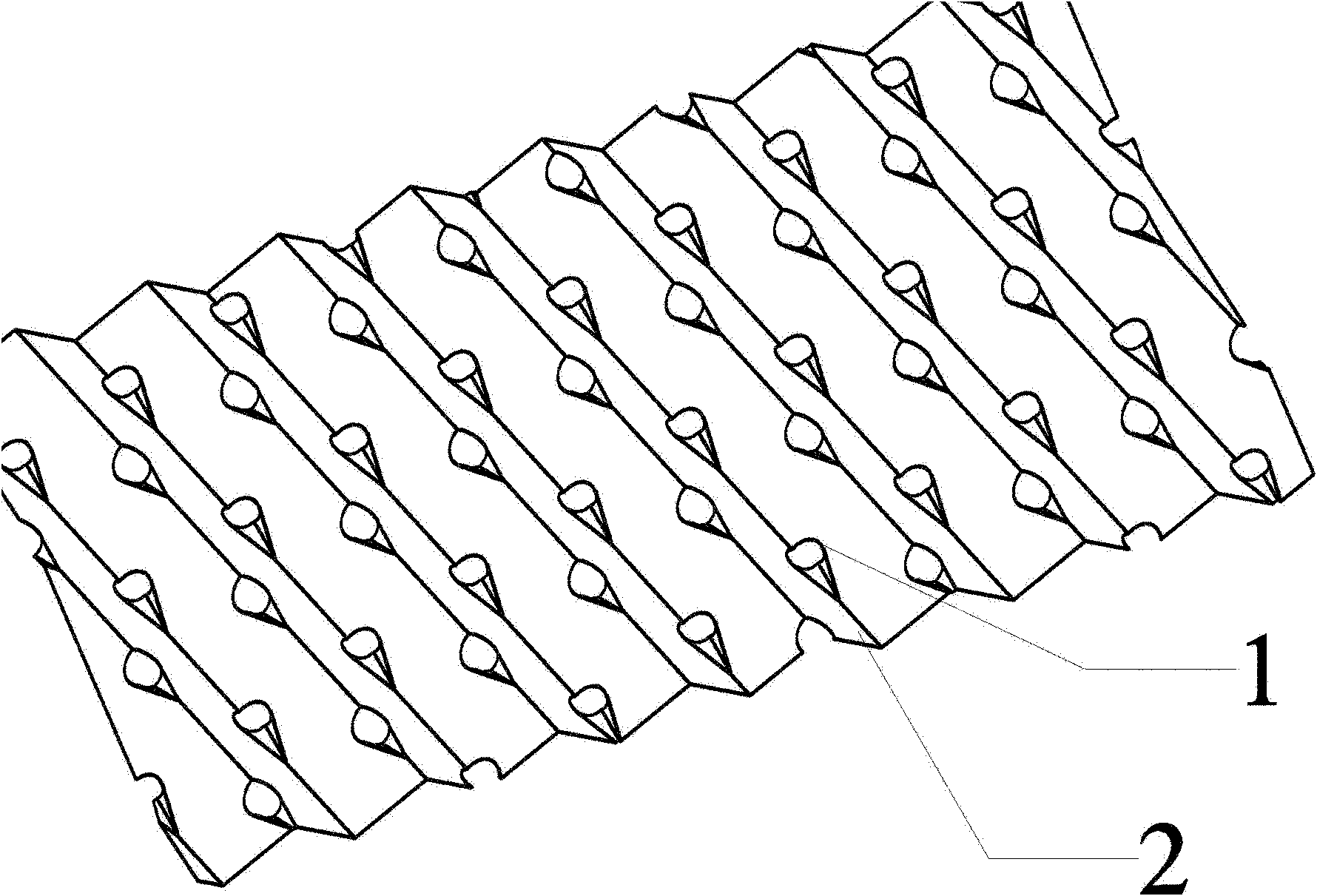

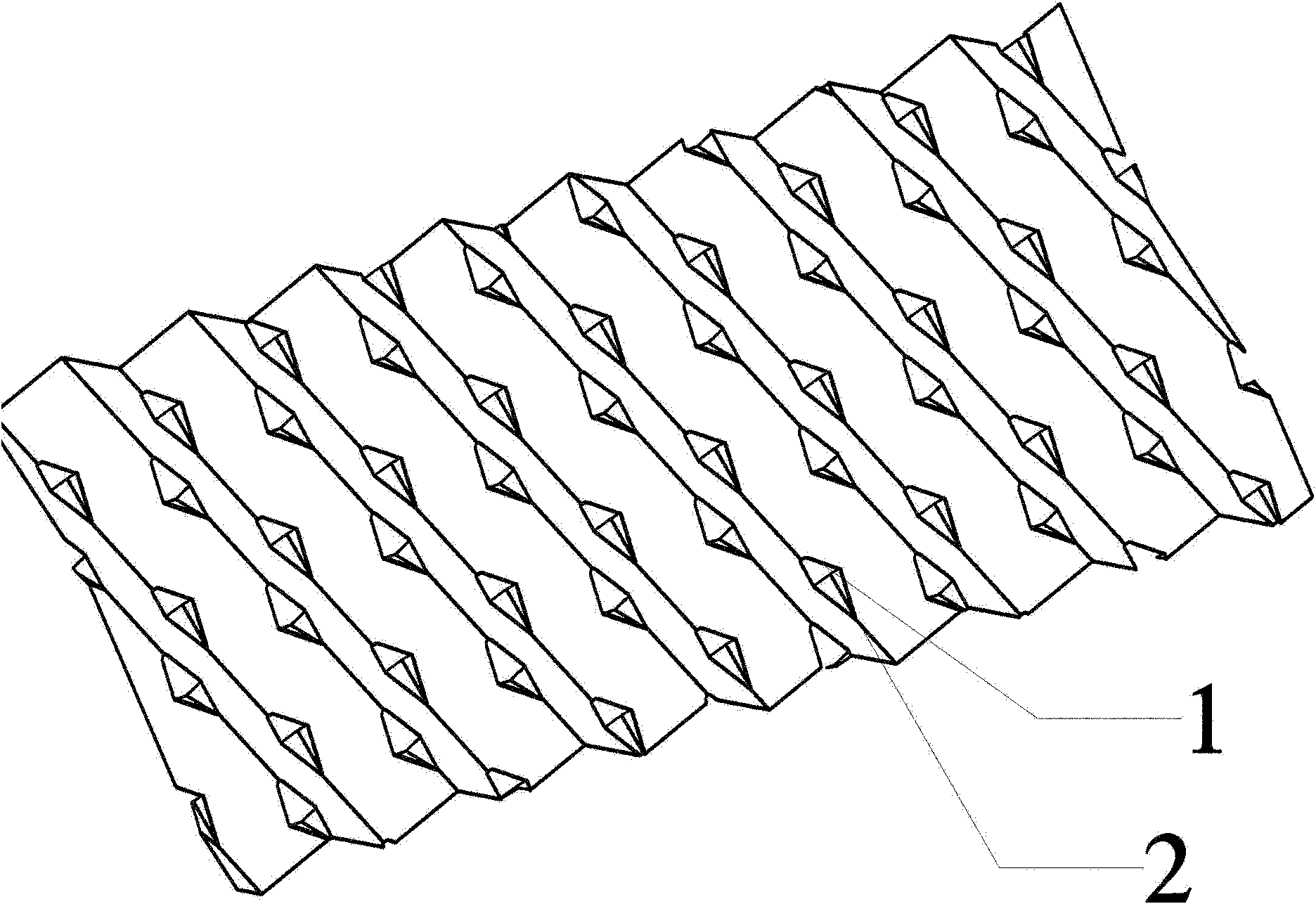

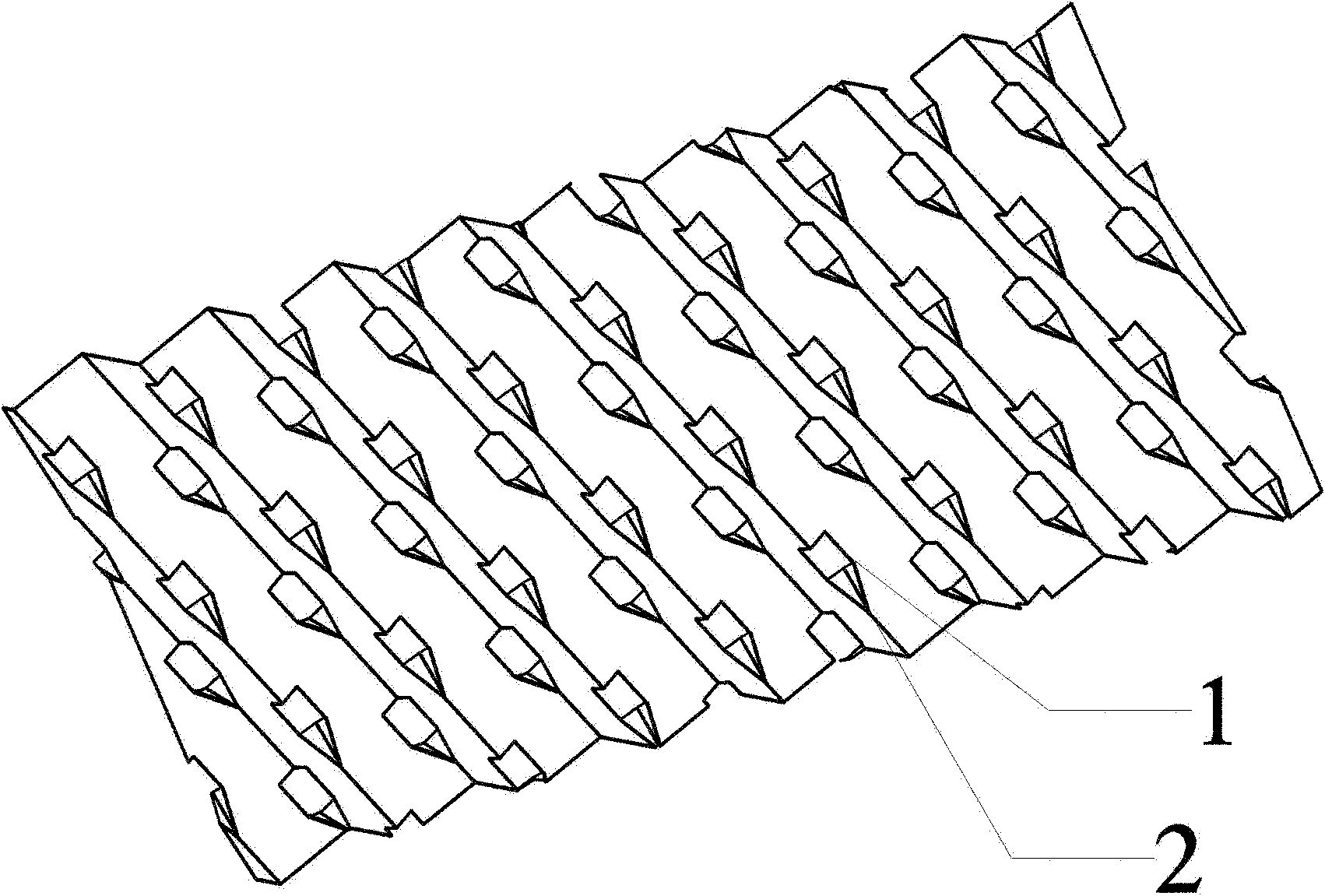

[0015] The technical characteristics of the window and hole combined diversion structured packing of the present invention will be described in more detail below in conjunction with the accompanying drawings:

[0016] The window and hole combined diversion structured packing sheet of the present invention is provided with holes and windows at the crests and troughs of the corrugated packing sheet, and the holes and windows are connected to form a window hole combined structure. The corrugation direction of the corrugated packing sheet has an inclination angle with the vertical direction. The interval between adjacent crests and troughs is 10mm to 100mm, and at the same crest or trough in the corrugation direction, the interval between adjacent opening structures is 10mm to 100mm. The shape of the opening structure of the structured packing sheet is round, triangular, square or rhombus. The diameter of the round hole is 4mm-40mm, the bottom edge of the triangular hole is 4mm-4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com