Guiding sieve plate float valve tower

A floating valve tower and sieve plate technology, which is applied in the direction of distillation and separation, chemical instruments and methods, separation methods, etc., can solve the problems of easy blockage of small holes, poor operating flexibility and poor plate efficiency, and achieve the elimination of liquid level drop and increase of plate Efficiency, effect of reducing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In view of the importance of improving the operating flexibility and separation efficiency of the rectification tower, a new method of combining guided trays, sieve trays and float valves has been developed to develop a guided sieve tray valve column with greater operating flexibility and higher separation efficiency. .

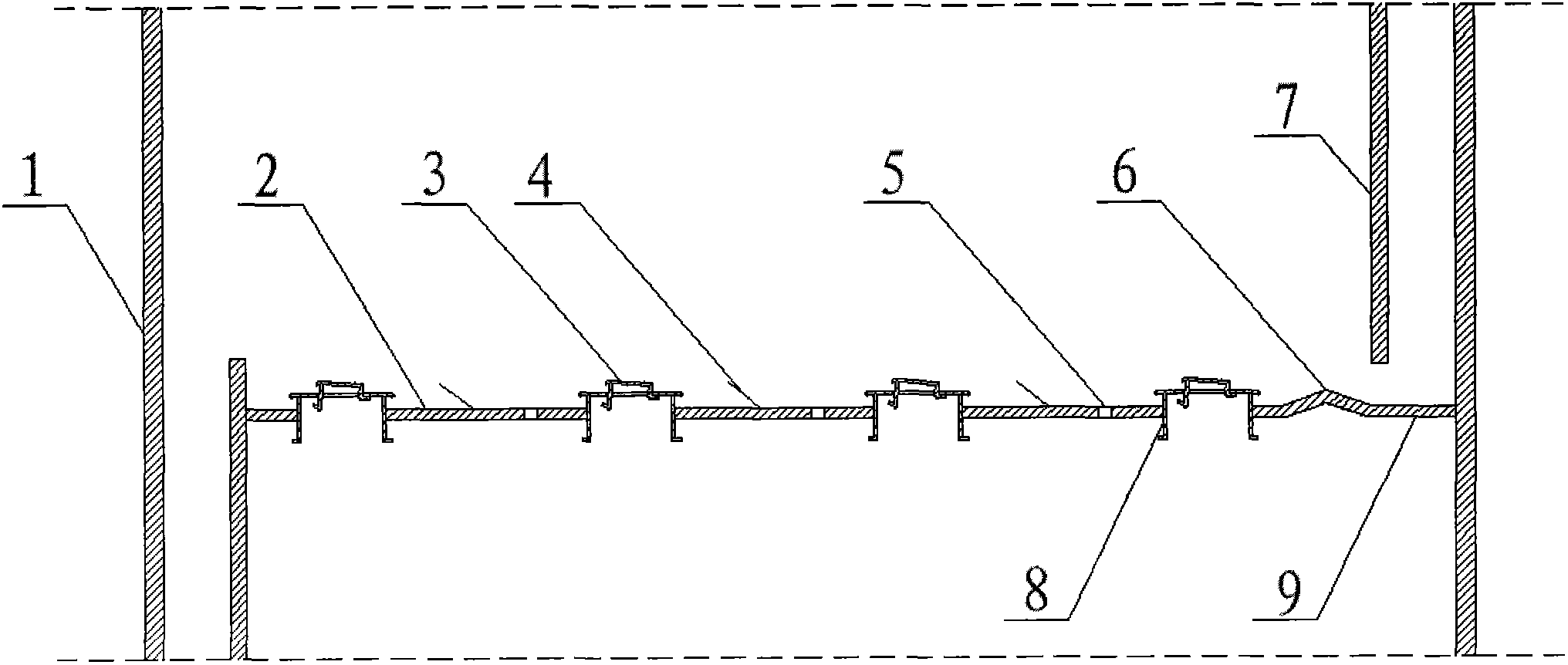

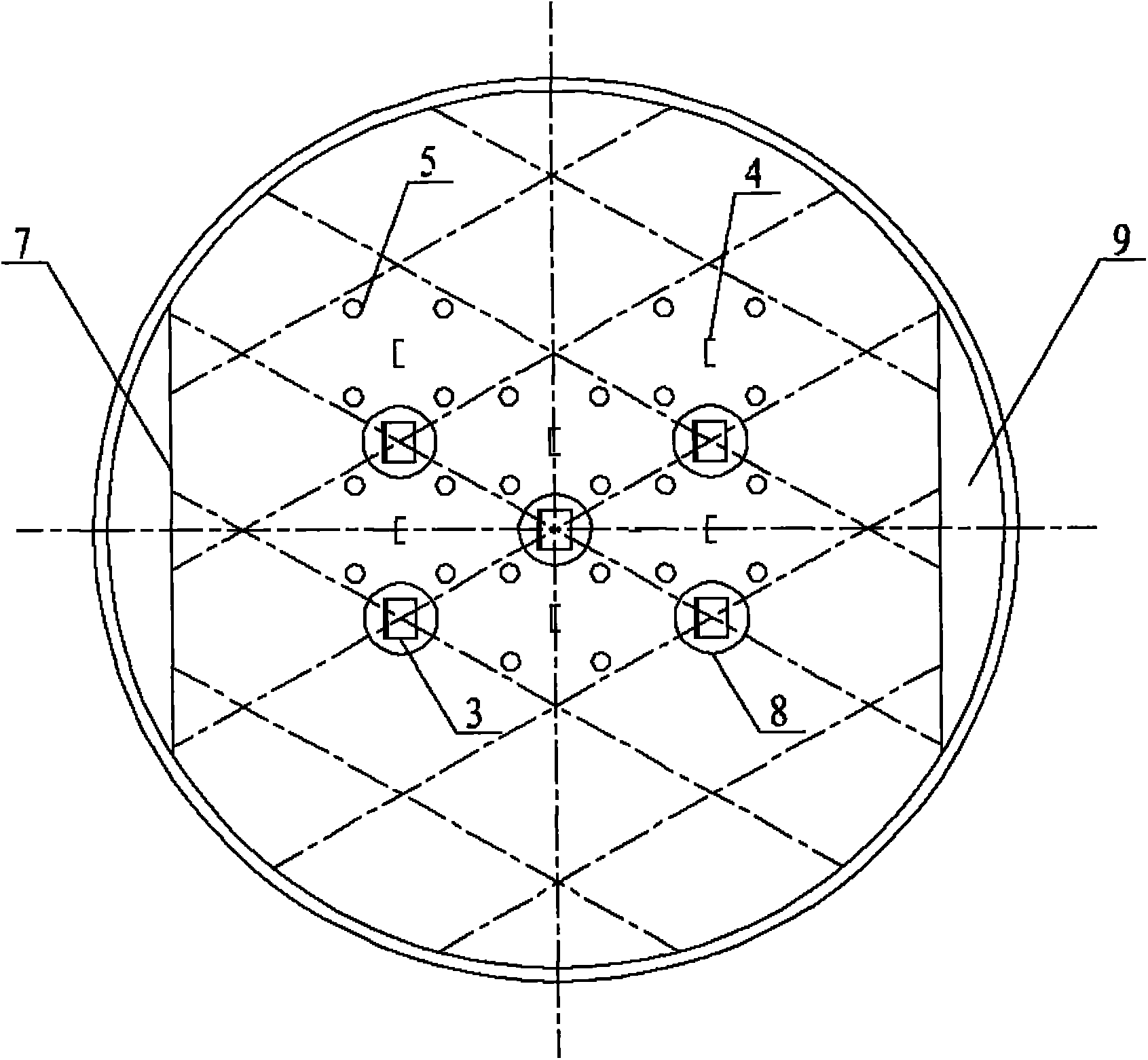

[0021] like figure 1 , 2 As shown, the basic structure of the guided sieve plate float valve tower composed of disc-shaped float valves includes a tower body 1, a tray 2, a downcomer plate 7, and a liquid receiving plate 9, and a bubbling accelerator is set at the liquid inlet of the tray 2 6. There are floating tongues 3, guide holes 4, sieve holes 5 and disc-shaped floating valves 8 on the surface of the tray 2.

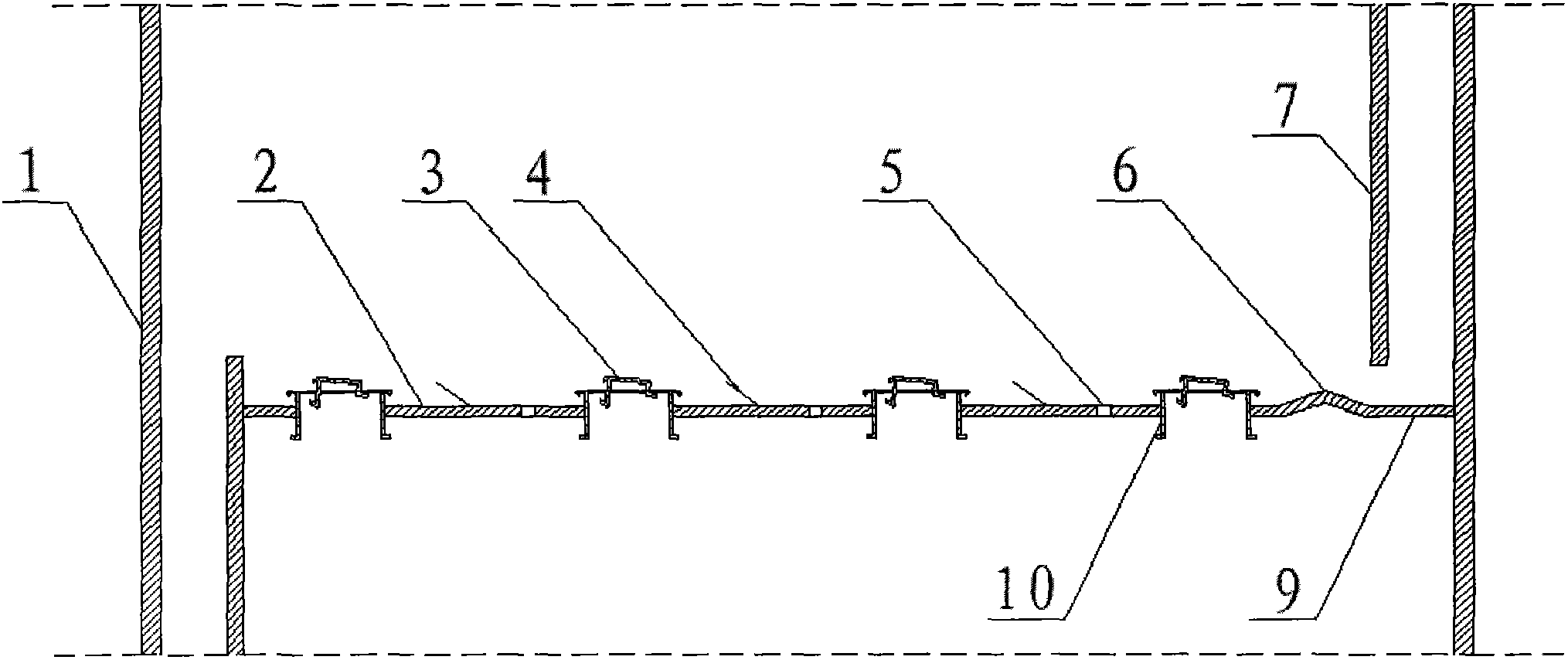

[0022] like image 3 , 4 As shown, the basic structure of the guided sieve plate float valve tower composed of strip float valves includes a tower body 1, a tray 2, a downcomer plate 7, and a liquid receiving plate 9, and a bubbling pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com