Multi-nozzle jet-flow micro-nano bubble aerator

A bubble aerator, multi-nozzle technology, applied in aerobic process treatment, sustainable biological treatment and other directions, can solve the problems of inability to greatly increase the oxygen content in water, small mass transfer area, short residence time, etc., to achieve enhanced biochemical The effect of reaction efficiency, increasing residence time, and improving dissolved oxygen efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

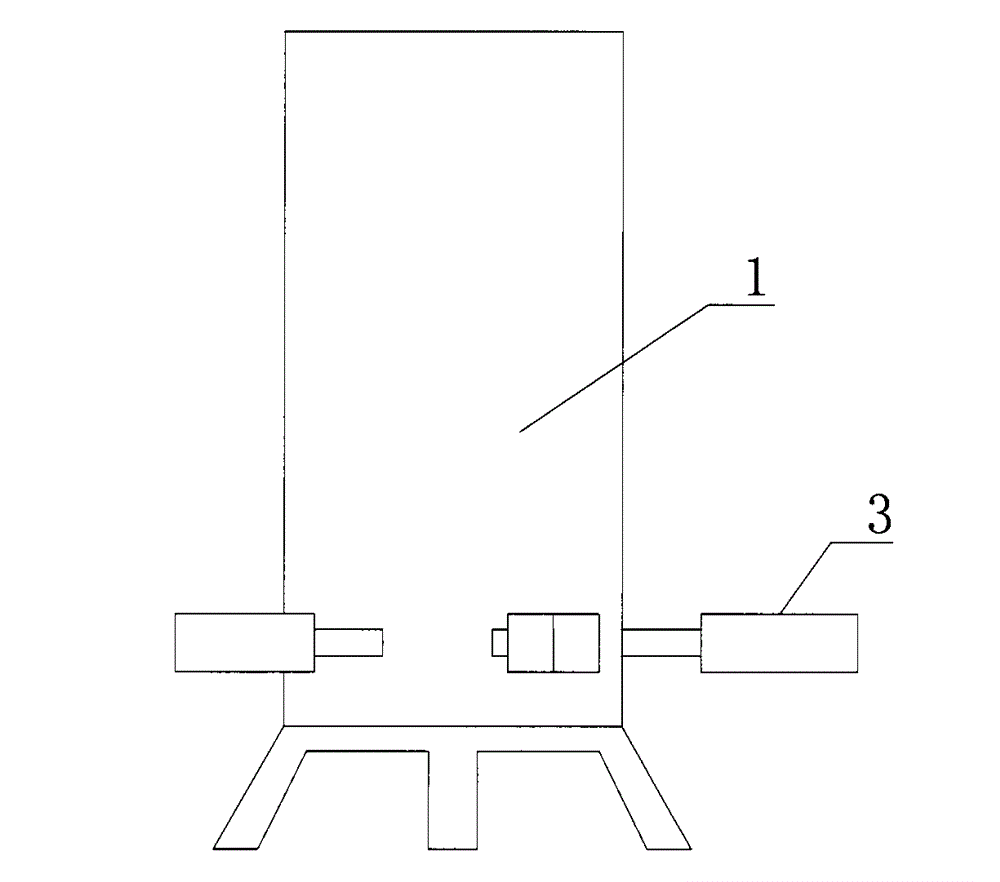

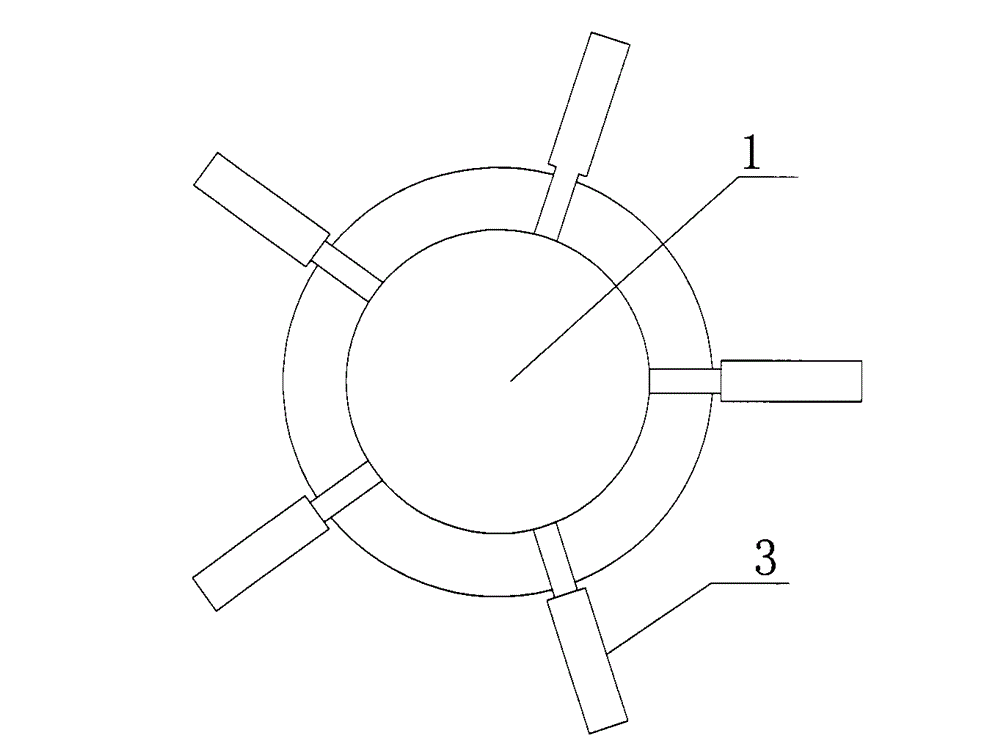

[0022] like figure 1 , 2 As shown, the multi-nozzle jet micro-nano bubble aerator includes a water pump 1 with five nozzles connected in parallel, and bubble aeration nozzles 3 respectively connected to each nozzle of the water pump 1 .

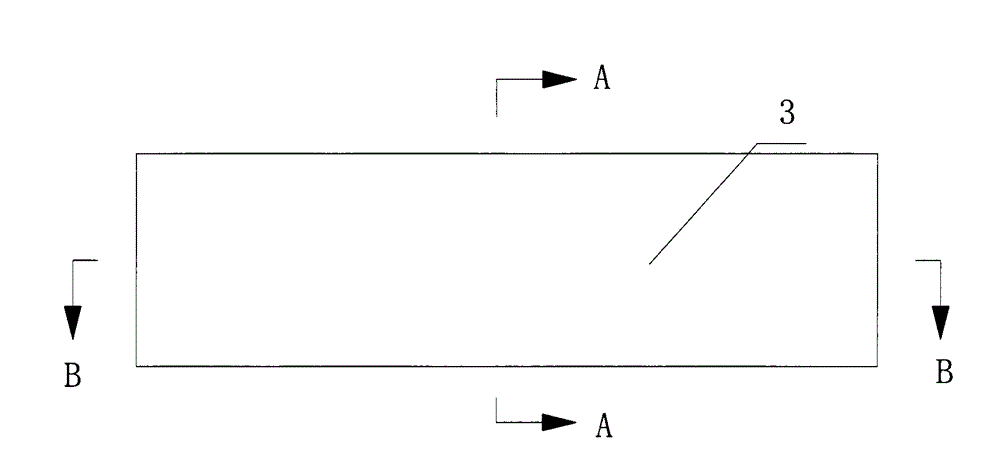

[0023] like image 3 , 4 , 5, and 6, each of the air bubble aeration nozzles 3 includes an aeration nozzle body 31, a water passage 32 extending in a straight line through the aeration nozzle body 31, and an air outlet connected to the water passage 32. Distribution pipeline 33 .

[0024] Each nozzle of the water pump 1 is provided with an external thread, and the water pipe 32 is provided with an internal thread that matches the external thread. The water pipe 32 is threadedly connected with the nozzle of the water pump 1, and the air bubbles need only be directly aerated during use. The mouth 3 can be directly screwed on the nozzle of the water pump 1, which is very convenient to use.

[0025] The air distribution pipe 33 includes an a...

Embodiment 2

[0029] like Figure 7 As shown, the difference between the second embodiment and the first embodiment is that the main and branch pipes 3321 are only arranged on two opposite 1 / 4 circular surfaces.

[0030] In summary, the present invention has the following advantages compared with existing aeration devices:

[0031] (1) Retention: The micro-nano bubbles rise very slowly in the water body, like smoke permeating the water, and can stay in the water for 3 to 4 hours, so the micro-nano bubbles will stay in the water for a long time. This characteristic is also the core of its high dissolution efficiency.

[0032] (2) Ionization phenomenon: The solubility of gas in water is greatly affected by the air pressure, but the ionized water of the electrolyte can make the surface of the dissolved micro-nano bubbles form double-layer electric ions, and shrink sharply with the continuous decrease of the surface area, which can The gas dissipation in the bubble is suppressed, thereby grea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com