Pretreatment method of waste emulsion

A waste emulsion and pretreatment technology, applied in chemical instruments and methods, pathogenic microorganism wastewater treatment, water/sewage treatment, etc., can solve the problems of low operating costs, high investment and operating costs, and low automation , to achieve the effects of small footprint, short response time and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

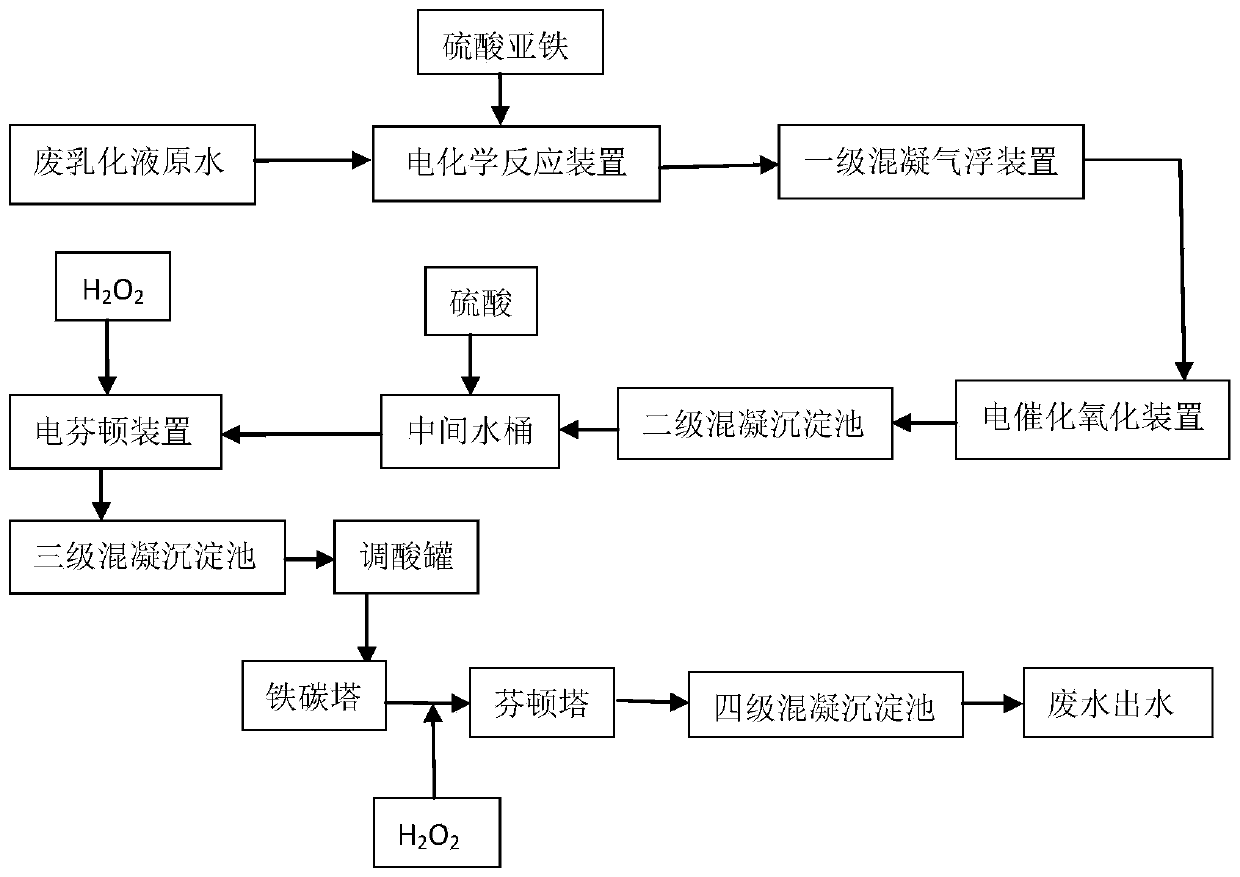

[0044] Embodiment one: if figure 1 As shown, the COD of the waste emulsion raw water is 80000mg / L, the suspended solids (SS) is 1000mg / L, the petroleum is 5000mg / L, the pH is 6, and the BOD / COD is 0.1.

[0045] Adjust the pH value of the raw water of the waste emulsion to 4, and add 3g / L FeSO 4 , into the electrochemical reaction device to carry out a primary demulsification reaction, the anode of the electrochemical reaction device uses a titanium-based lead dioxide coating electrode, and the cathode uses a stainless steel electrode; the distance between the electrode plates is 2 cm, and the current density of the electrode plates is 10mA / cm 2 , the power supply is a high-frequency pulsed DC power supply, the pulse frequency is 5000Hz, the duty cycle is 50%, the aeration volume at the bottom is twice the flow rate of the wastewater, and the residence time of the wastewater in the electrocatalytic oxidation device is 30 minutes. The waste emulsion after the demulsification r...

Embodiment 2

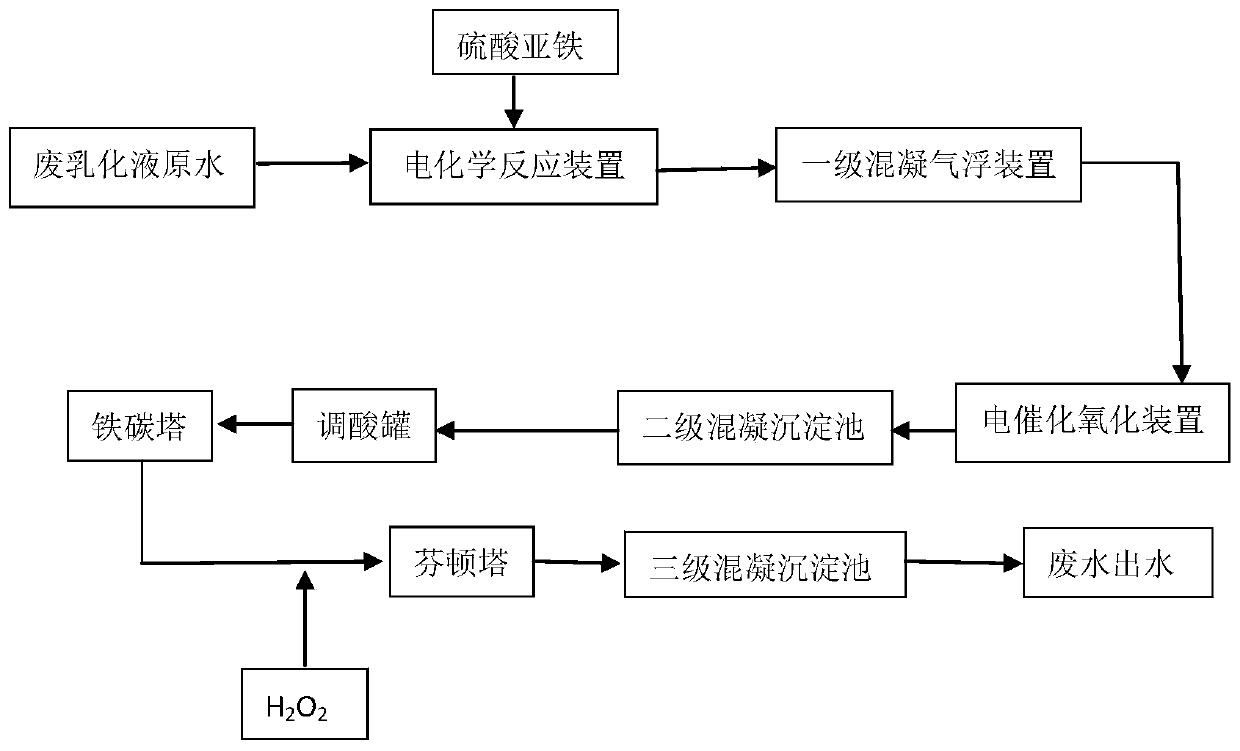

[0056] Embodiment two: if figure 2As shown, the COD of the waste emulsion raw water is 150000mg / L, the suspended solids (SS) is 2000mg / L, the petroleum is 10000mg / L, the pH is 9, and the BOD / COD is 0.1.

[0057] Adjust the pH value of the raw water of the waste emulsion to 6, and add 10g / L of FeSO 4 , into the electrochemical reaction device to carry out a primary demulsification reaction, the anode of the electrochemical reaction device uses a titanium-based tin dioxide coating electrode, and the cathode uses a graphite electrode; the distance between the electrode plates is 1 cm, and the current density of the electrode plates is 100mA / cm 2 , the power supply is a high-frequency pulsed DC power supply, the pulse frequency is 20000Hz, the duty cycle is 100%, the bottom aeration volume is twice the wastewater flow rate, and the residence time of the wastewater in the electrocatalytic oxidation device is 10 minutes. The waste emulsion after the demulsification reaction enter...

Embodiment 3

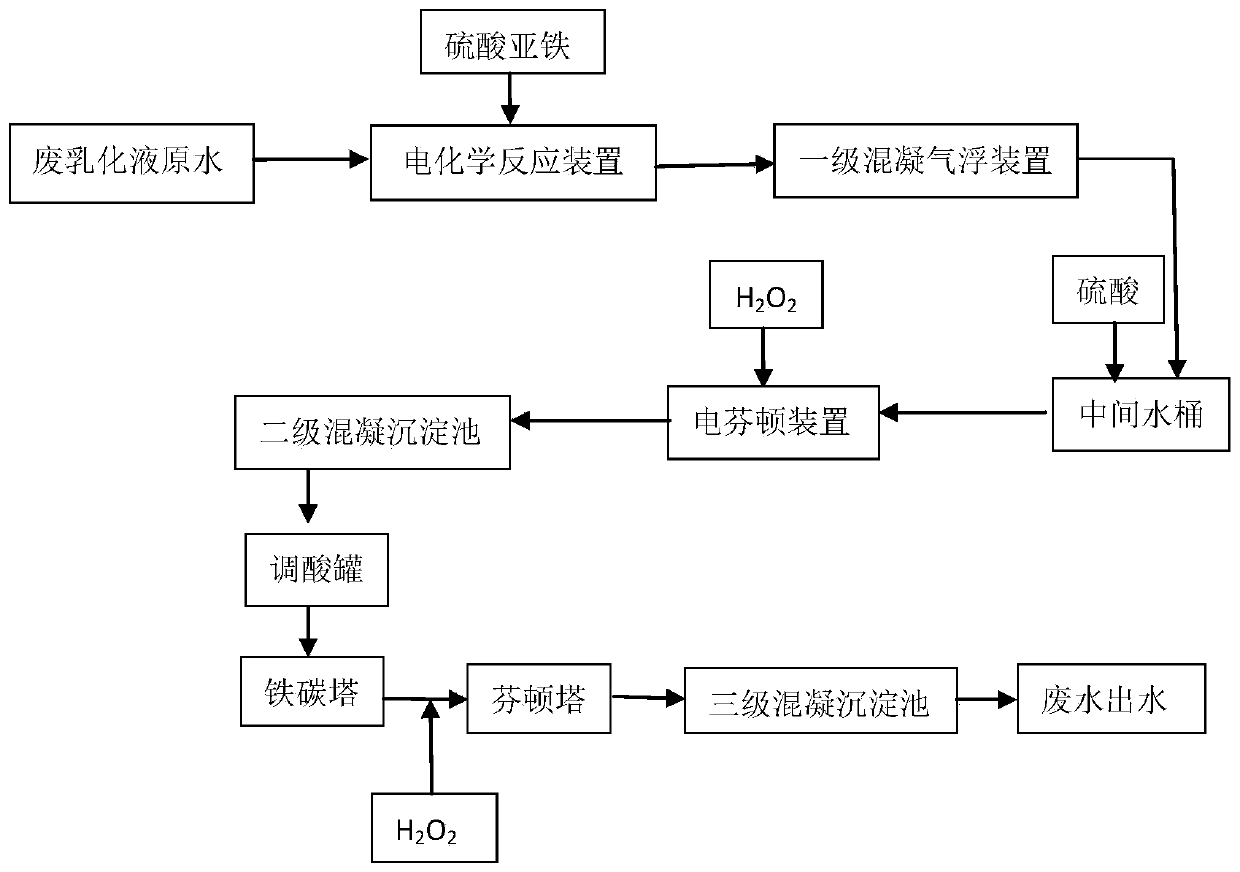

[0066] Embodiment three: as image 3 As shown, the COD of the waste emulsion raw water is 120000mg / L, the suspended solids (SS) is 1500mg / L, the petroleum is 1000mg / L, the pH is 7, and the BOD / COD is 0.17.

[0067] Adjust the pH value of the raw water of the waste emulsion to 5, and add 6g / L of FeSO 4 , into the electrochemical reaction device to carry out a primary demulsification reaction, the anode of the electrochemical reaction device uses a titanium-based lead dioxide coating electrode, and the cathode uses a stainless steel electrode; the distance between the electrode plates is 2 cm, and the current density of the electrode plates is 50mA / cm 2 , the power supply is a high-frequency pulsed DC power supply, the pulse frequency is 10000Hz, the duty cycle is 10%, the aeration volume at the bottom is 1 times the flow rate of the wastewater, and the residence time of the wastewater in the electrocatalytic oxidation device is 20 minutes. The waste emulsion after the demulsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com