Technology for deep-treating printing and dyeing wastewater by attapulgite catalyst

An attapulgite and printing and dyeing wastewater technology, applied in the field of environmental engineering, can solve the problems of difficulty in meeting production and environmental protection requirements, COD removal rate of less than 30%, poor biodegradability of printing and dyeing wastewater, etc. effect, improve the efficiency of biochemical reactions, the ability to degrade organic matter, and improve the effect of biochemical treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

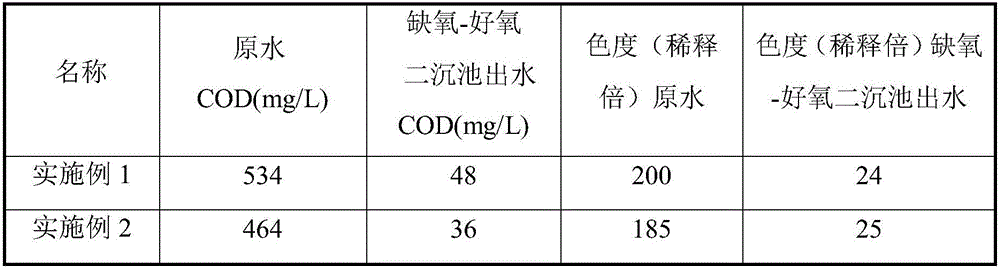

Embodiment 1

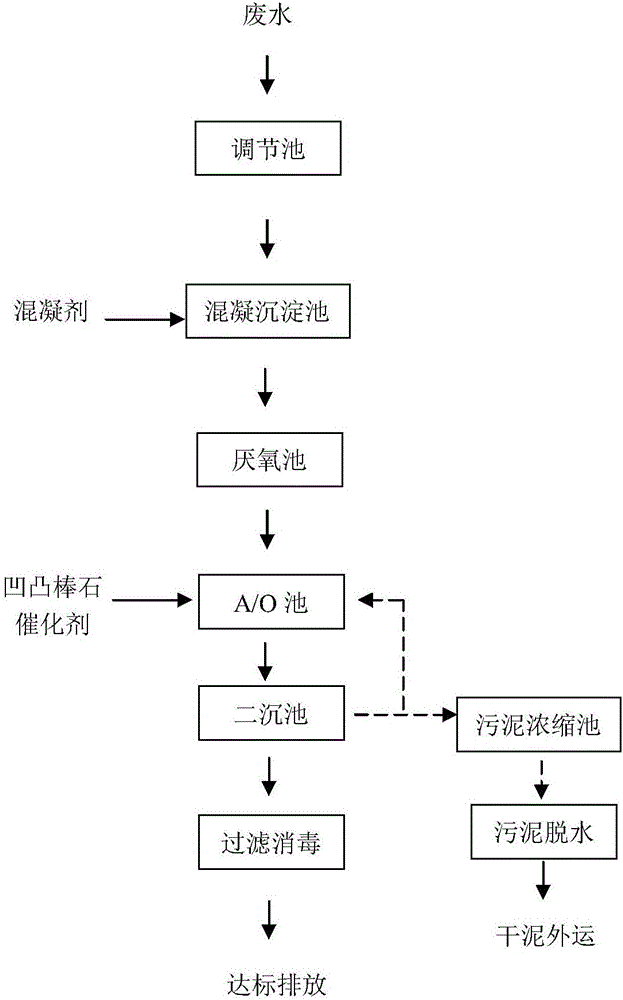

[0029] The method for advanced treatment of printing and dyeing wastewater by attapulgite catalyst in this embodiment is as follows:

[0030] 1. Collect the printing and dyeing wastewater after the initial biochemical treatment to the adjustment tank, and adjust the water volume and water quality. The adjustment time is controlled at more than 8 hours, so that the influent can be mixed evenly;

[0031] 2. The printing and dyeing wastewater adjusted by water volume and water quality shall be pumped according to 150m 3The flow rate per hour is pumped into the coagulation sedimentation tank, mixed with coagulant for coagulation and sedimentation treatment; the pH value of printing and dyeing wastewater is 6.0, PAC and PAM are used as coagulants, and the proportion of PAC is 0.01-0.03% of the wastewater quality Dosing, PAM is added according to the proportion of 0.001-0.003% of the wastewater quality (PAC and PAM are respectively configured into a solution with a mass concentratio...

Embodiment 2

[0039] The method for advanced treatment of printing and dyeing wastewater by attapulgite catalyst in this embodiment is as follows:

[0040] 1. Collect the printing and dyeing wastewater after the initial biochemical treatment to the adjustment tank, and adjust the water volume and water quality. The adjustment time is controlled at more than 8 hours, so that the influent can be mixed evenly;

[0041] 2. After adjusting the water volume and water quality, the printing and dyeing wastewater is pumped according to 250m 3 The flow rate per hour is pumped into the coagulation sedimentation tank, mixed with coagulant for coagulation and sedimentation treatment; the pH value of printing and dyeing wastewater is 5.5, PAC and PAM are used as coagulants, and the proportion of PAC is 0.01-0.03% of the wastewater quality Dosing, PAM is added according to the proportion of 0.001-0.003% of the wastewater quality (PAC and PAM are respectively configured into a solution with a mass concentr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com