Nanometer coating of outer wall of wine vessel used for aging wine and wine vessel

A nano-coating and wine container technology, applied in the field of coatings, can solve the problems of wine not aging and health care functions, and achieve the effect of bright color, strong solubility, and beneficial to human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

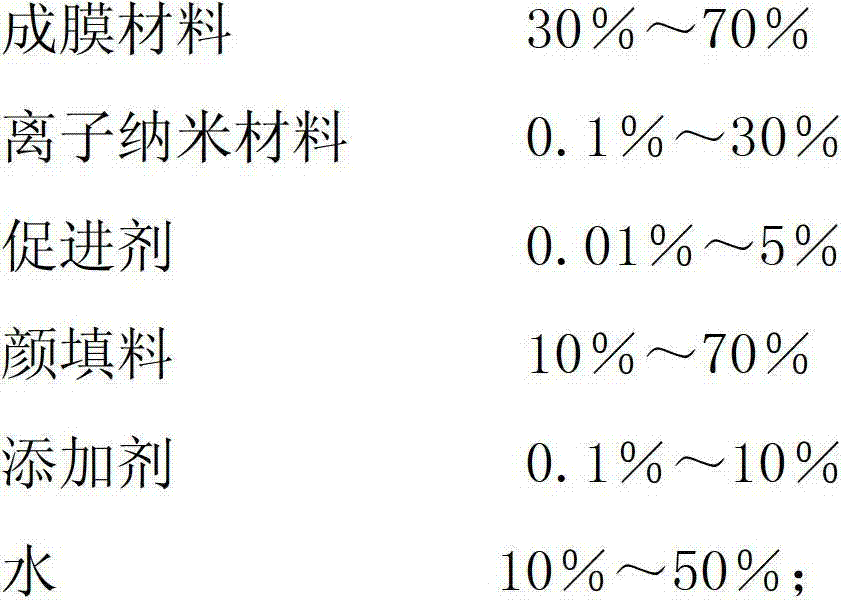

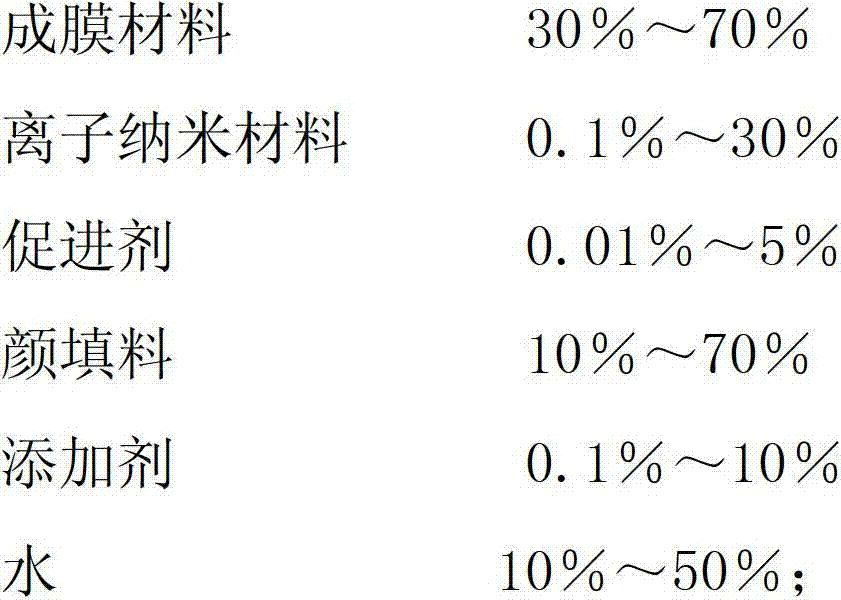

Method used

Image

Examples

Embodiment 1

[0024] A nano-coating for the outer wall of wine containers for aging wine, including 62% of film-forming materials (modified acrylic acid), 8% of pigments and fillers (red powder), accelerators (epoxy silane di Joint agent) 1.5%, ionic nanomaterials 10%, dispersant 0.3%, wetting agent 0.2%, leveling agent 0.2%, defoamer 0.3%, thickener 0.3%, antifungal agent 0.2%, film-forming aid Agent 2% and water balance.

[0025] Preparation:

[0026] (1) Add acrylic modified epoxy resin (preferably GT-800) or water-based modified acrylic polymer (preferably GT-520) and formula water into the reaction kettle according to the formula amount, and stir for 30-60 minutes to make After it is mixed evenly, it is the base material.

[0027] (2) Add pigments, fillers and water according to the formula amount, stir evenly and then add the formula amount of additives and additives, after stirring evenly, then grind to below 10 microns by a sand mill.

[0028] (3), add (2) and the film-forming ma...

Embodiment 2

[0030] A nano-coating for the outer wall of a wine container for aging wine, including a film-forming material (acrylic acid modified epoxy) 50, an ion nanomaterial 8, and an accelerator (aminosilane coupling agent) 2 calculated by weight percentage , Pigment and filler (CR-706 titanium dioxide) 20, dispersant 0.2, wetting agent 0.2, defoamer 0.3, leveling agent 0.2, tackifier 0.3, preservative 0.1, film-forming aid 1.5 and water balance.

[0031] Preparation:

[0032] (1) Add acrylic acid modified epoxy resin, water and ionic nanomaterials into the reaction kettle according to the formula quantity, and stir for 40-60 minutes to make it evenly mixed, which is the base material.

[0033] (2) Add pigments and fillers (CR-706 titanium dioxide), dispersant, wetting agent, defoamer, leveling agent according to the formula amount, after stirring evenly, and then grind to below 10 microns by a sand mill.

[0034] (3), add the film-forming material and water of (2) and the balance of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com