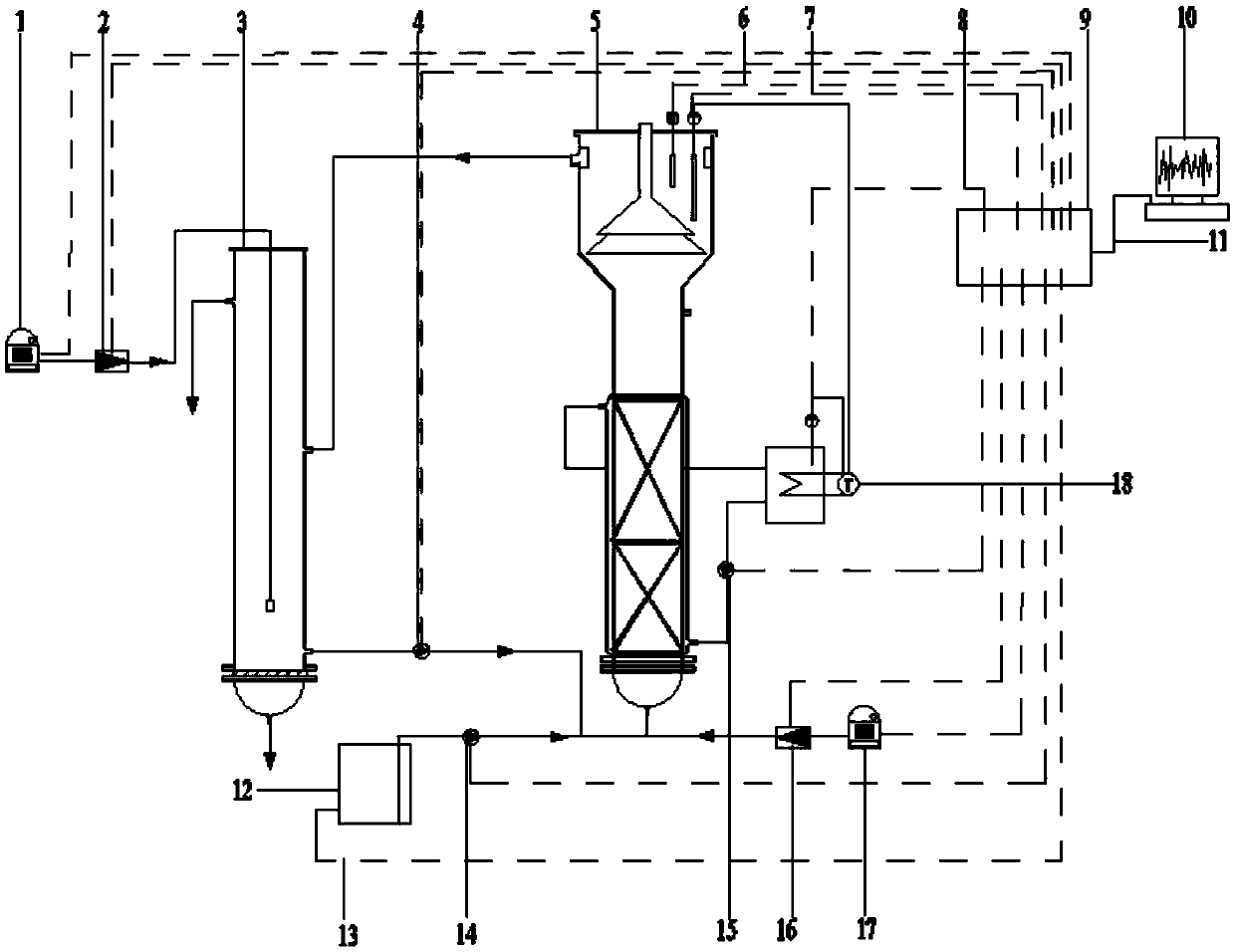

Wastewater treatment device and wastewater treatment method thereof

A technology for wastewater treatment and effluent area, applied in aerobic process treatment, sustainable biological treatment, etc., can solve the problems of low stability of treatment effect, large area, short contact time between wastewater and biofilm, etc. The effect of oxygen process optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

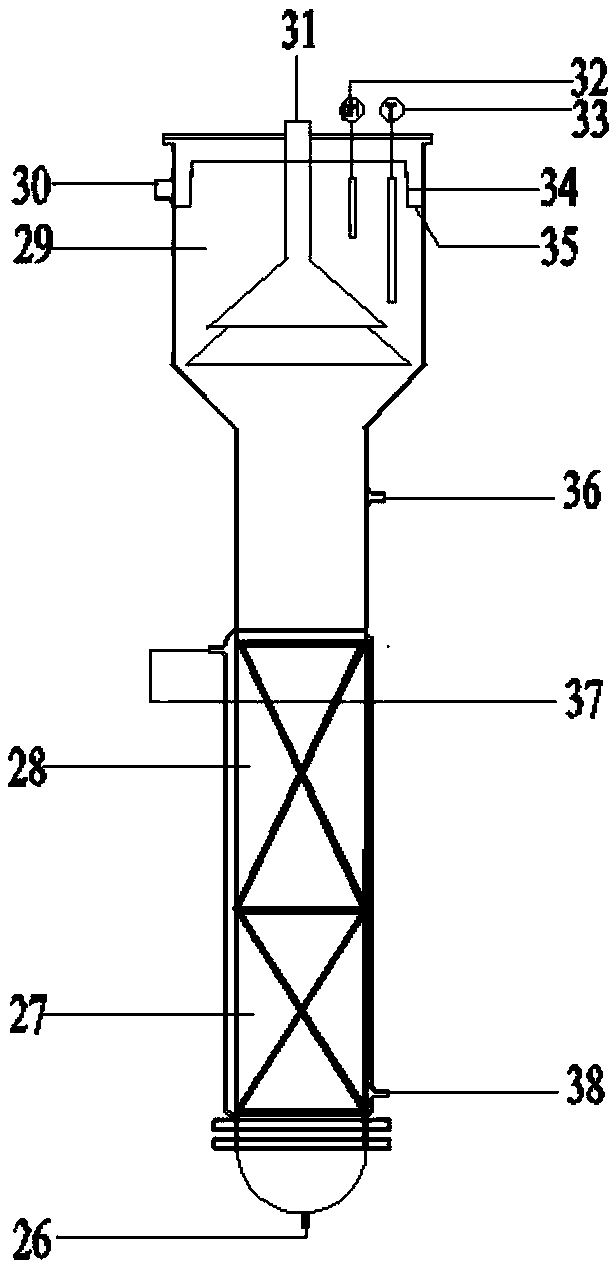

[0076] like Figure 3-5 As shown, a kind of aerobic expanded bed, described aerobic expanded bed 5 successively is reaction area, connection section and water outlet area 29 from bottom to top, and reaction area and water outlet area 29 are connected by connection section;

[0077] The cross-sectional area of the water outlet zone 29 is greater than that of the reaction zone;

[0078] The bottom of the reaction zone is provided with a water inlet 26;

[0079] The reaction zone is followed by a supporting layer 27 and a packing area 28 from bottom to top. The supporting layer 27 is filled with graded gravel particles; the filling area 28 is filled with small particle size fillers with a diameter of 1-3mm;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com