Well bottom hydraulic suction pressure lowering drilling tool

A drilling tool and hydraulic technology, which is applied to drilling equipment, drill bits, earthwork drilling and production, etc., can solve the problems of easy well damage, well hole expansion, large investment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

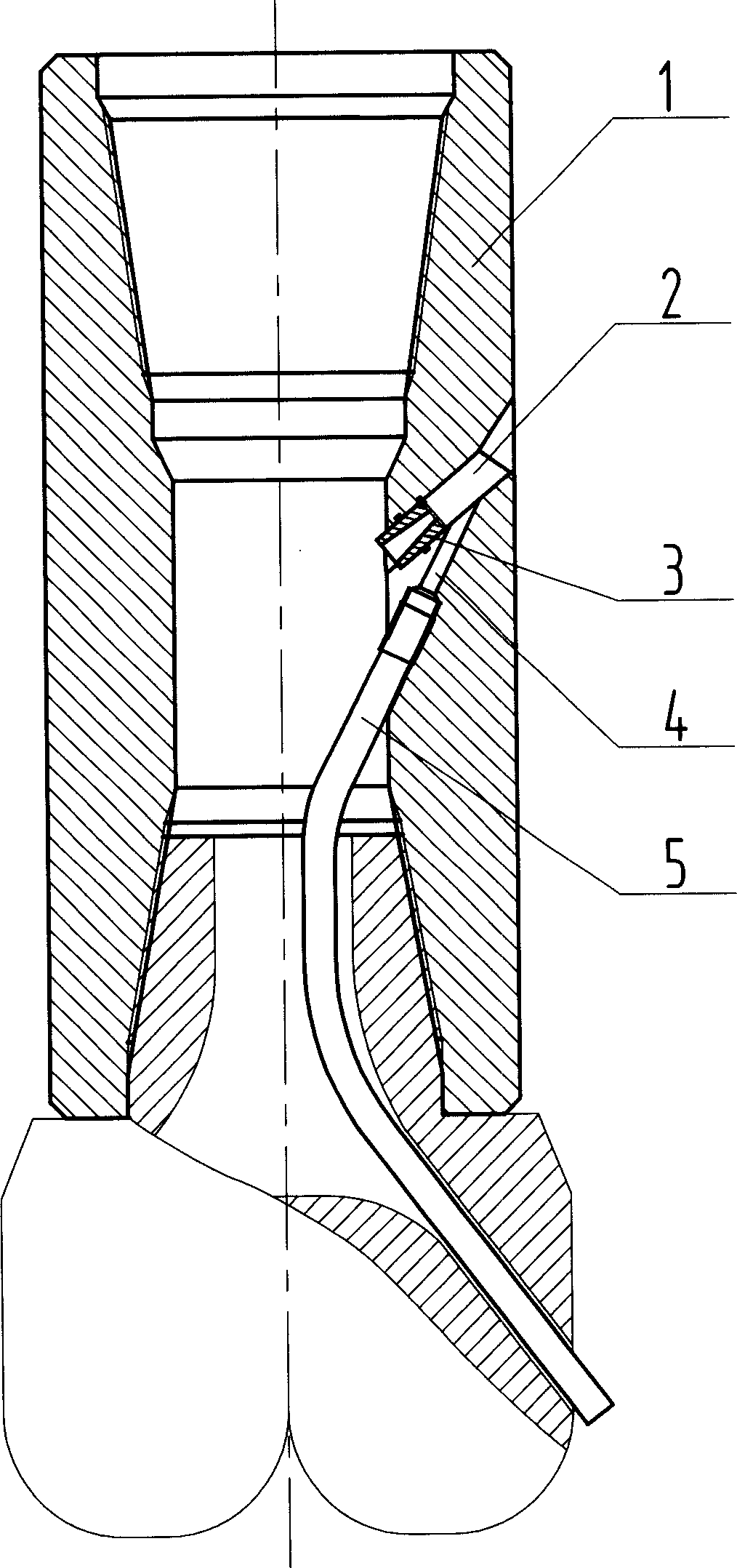

[0008] The present invention will be further described now in conjunction with the accompanying drawings of the description.

[0009] When the present invention is used to form a local low pressure at the bottom of the well, the drill bit connecting nipple [1] is axially penetrated, the two ends are processed with threads, the upper end and the lower end are respectively connected with the drill string and the drill bit, and in the middle of the drill bit connecting nipple [1] A low-pressure chamber [2] is processed, and the outlet of the low-pressure chamber [2] points to the direction of the annular space. ] installed in the low-pressure chamber [2] close to the inner wall of the drill nipple [1], and an ejection cavity [4] is processed at the exit of the injection nozzle [3] and the middle of the drill nipple [1]. The axis of the chamber [4] intersects the axis of the low-pressure chamber [2]. In the ejection chamber [4], one end close to the inner wall of the drill joint p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com