Patents

Literature

36results about How to "Reduce pinch effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

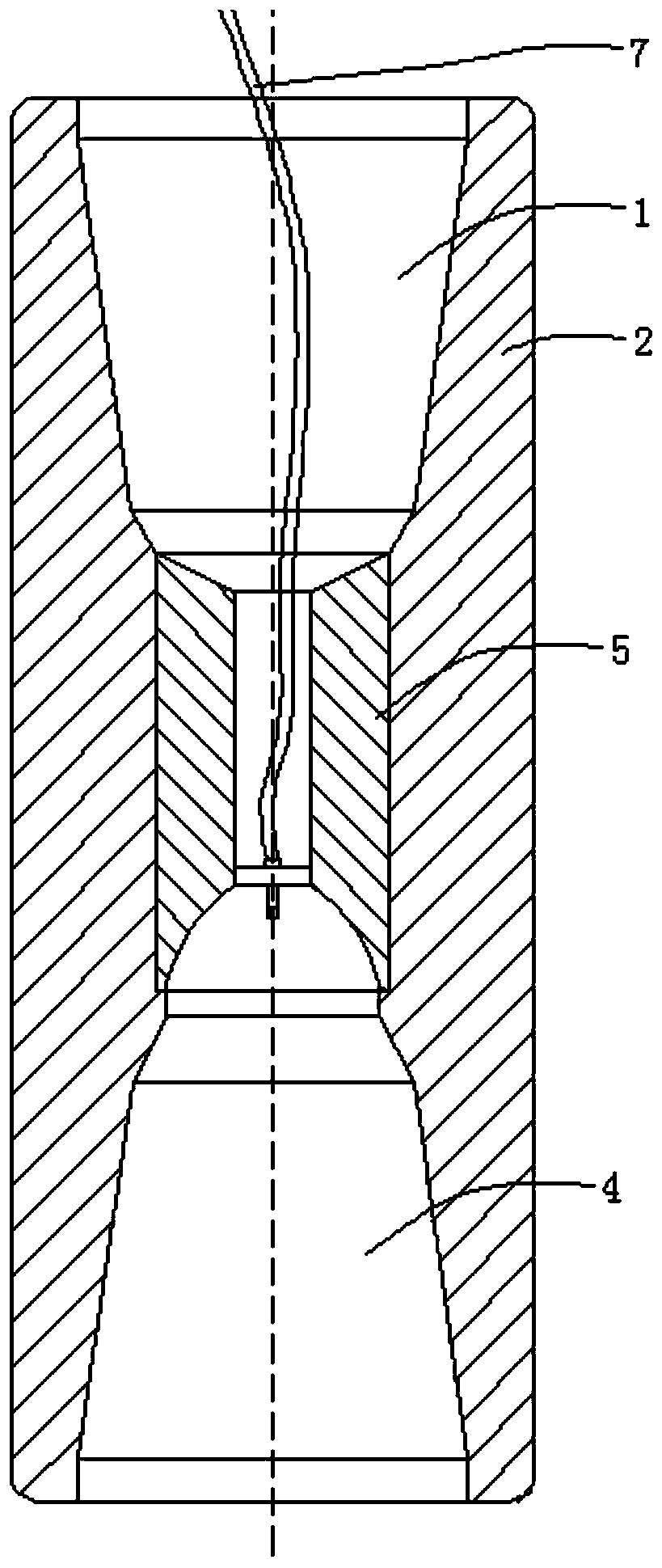

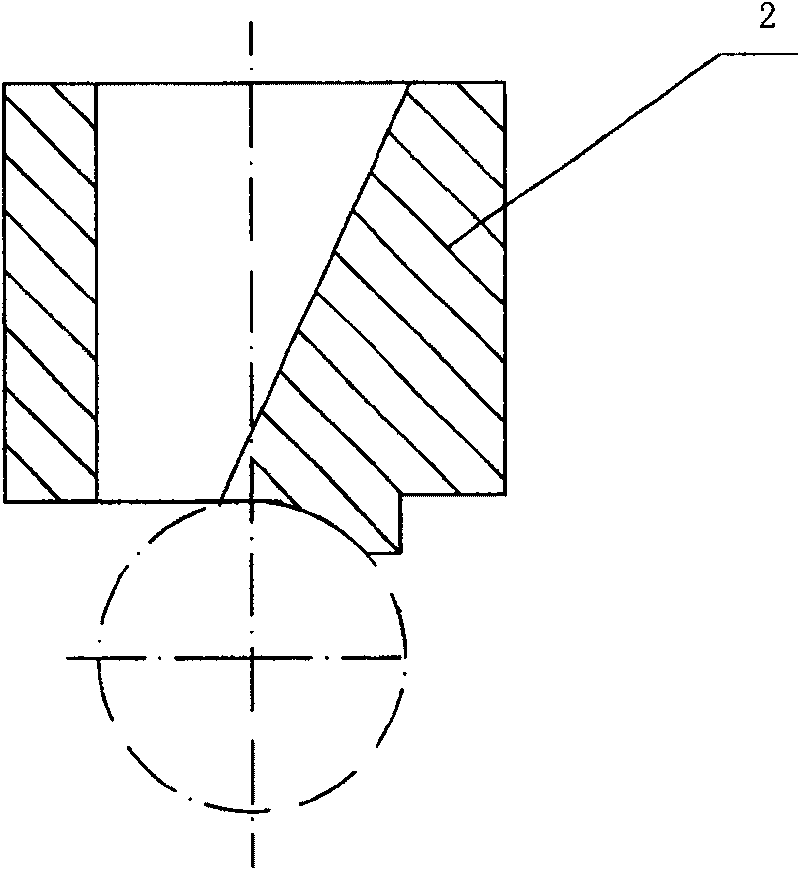

Hydraulic pulse well drilling equipment

InactiveCN1786409AReduce pinch effectReduced crushing strengthLiquid/gas jet drillingVibration drillingImpellerStator

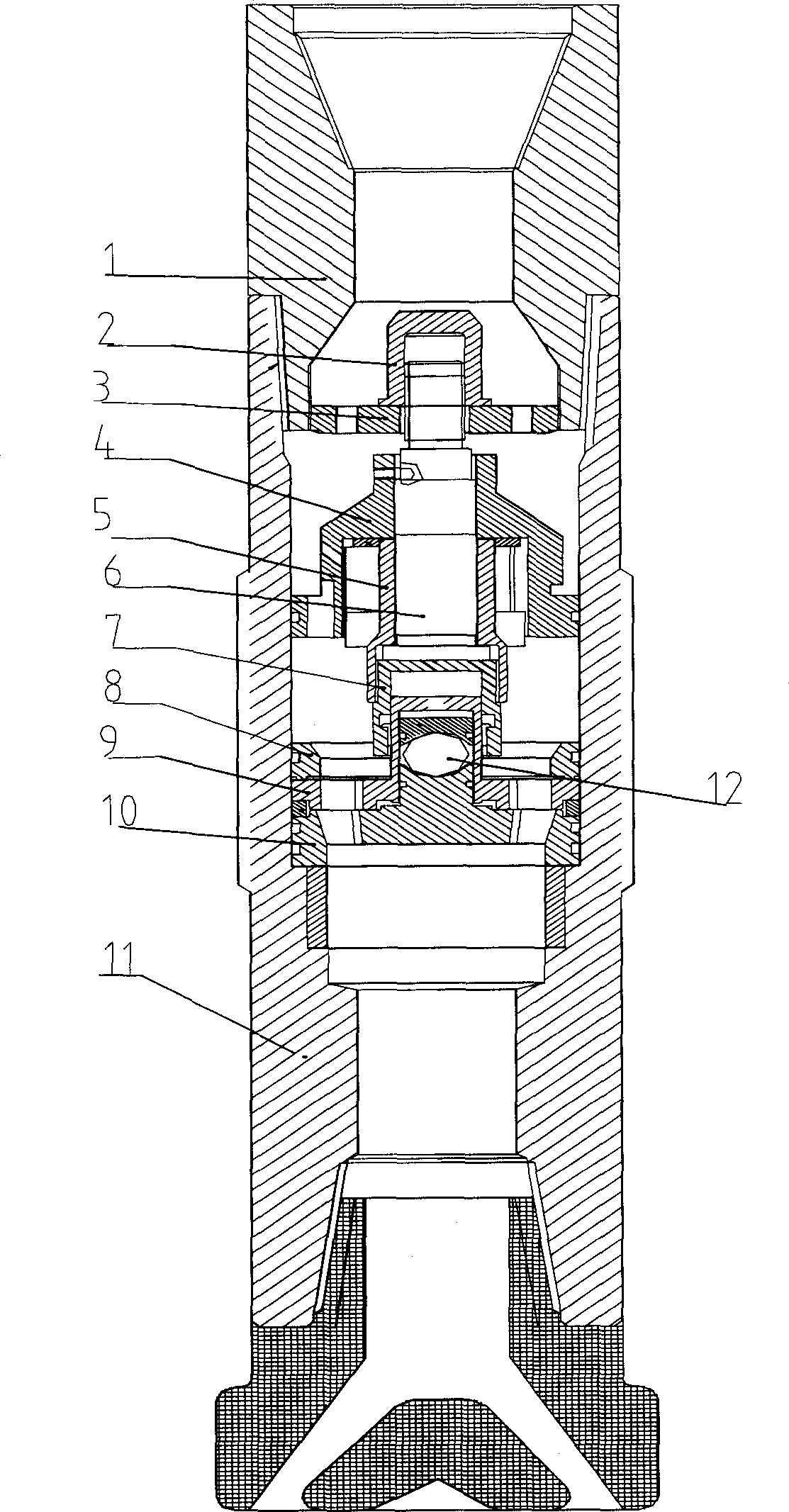

The invention discloses petroleum industry well drilling working underground tool. It is made up of joint, hanging plate, end cap, shunting rebel tool, impeller, shaft, cover, gland, rotor, stator, identity, and ball bearing. The invention is connected to the up of the drilling bit. While drilling, part of the drilling fluid drive impeller to make the rotor rotate by shunting rebel tool. When the flow passage of the rotor and stator are sealed, its area is the minimum. When the flow passages are circulated, the area is the maximum. High pressure pulsation jetting is formed at lower reaches to improve drilling speed. The other part of the drill fluid pass through the shunting hole to prevent drilling fluid from interrupting caused by impeller blocking to reduce tool application risk.

Owner:SHENGLI PETROLEUM ADMINISTRATION BUREAU DRILLING TECH ACAD SINOPEC

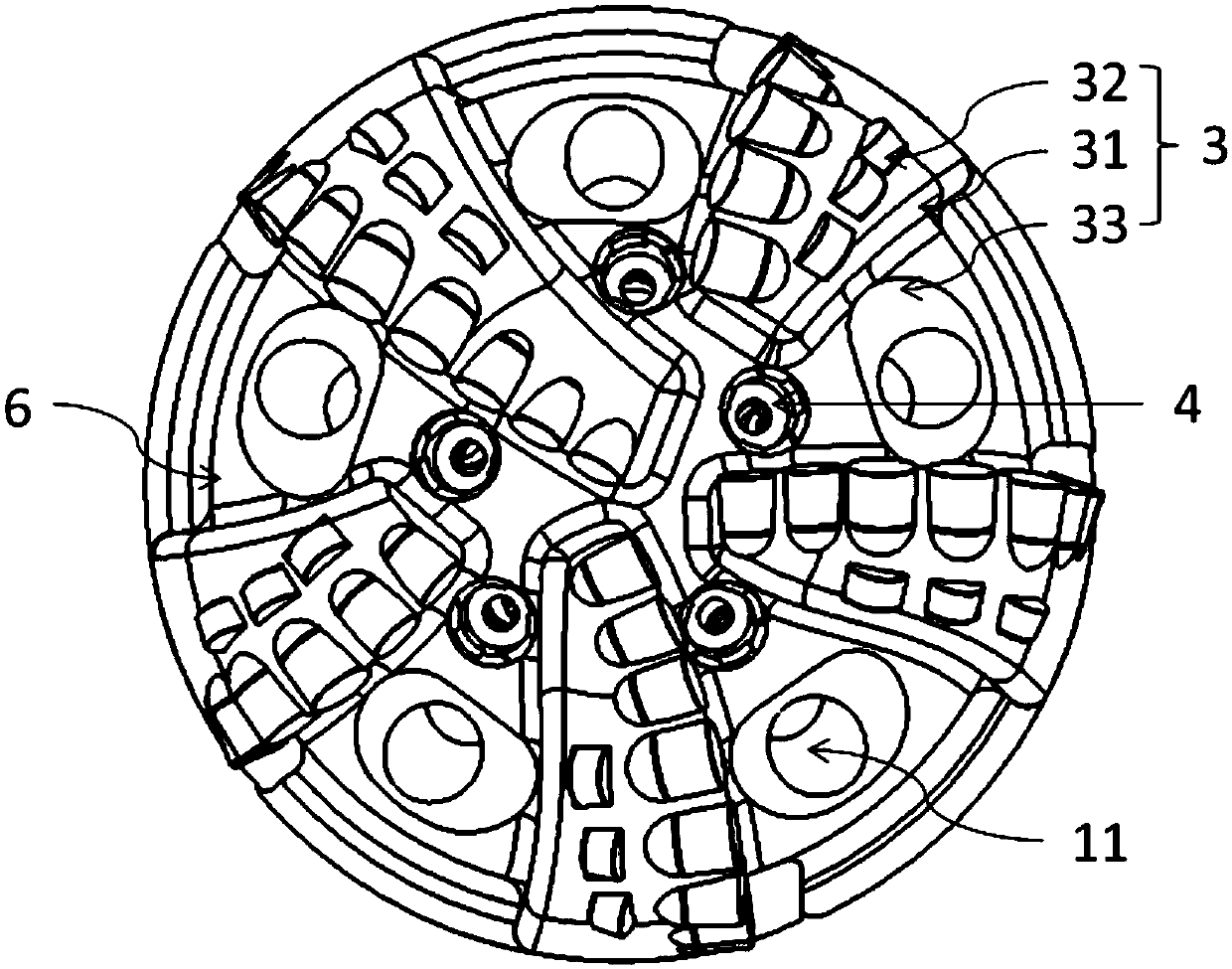

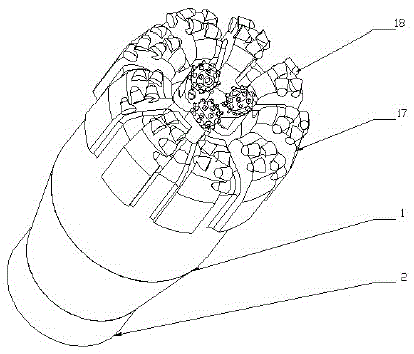

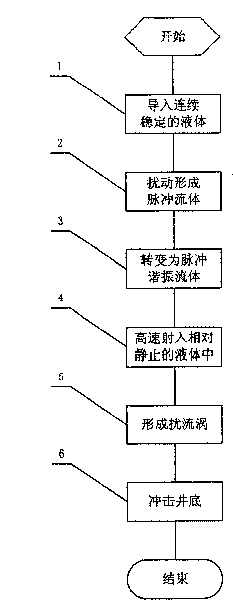

Self-rotation pulse internal grinding drill bit for horizontal well

InactiveCN106285493AImprove efficiencyReduce power consumptionDrill bitsConstructionsJet flowResonance

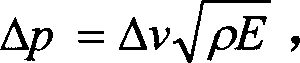

The invention discloses a self-rotation pulse internal grinding drill bit for a horizontal well. Different from conventional PDC drill bits, the self-rotation pulse internal grinding drill bit is additionally provided with a pulse rotary jet grouting rock breaking device, a negative pressure swabbing device and a rock cuttings internal grinding device. The pulse rotary jet grouting rock breaking device comprises a resonant tube, a downward jetting runner, a self-rotation nozzle and a cutter wing. High-pressure pulse jet flow is generated by stimulating liquid resonance based on an organ pipe, so that hydraulic power is increased to improve rock breaking efficiency; rock breaking is achieved through shear stretching under forward jet flow of the self-rotation nozzle, and self-propelling force of the drill bit is provided through lateral jet flow; the negative pressure swabbing device comprises a reverse high-speed runner and a swabbing chamber, negative pressure is formed in the swabbing chamber by means of the high-speed property of reverse jet flow based on a jet pump, rock cuttings are swabbed to return to the top, and then chip hold effect is reduced; the rock cuttings internal grinding device comprises a mixing chamber, a throat portion, an accelerating chamber, an internal grinding chamber, an internal grinding body, a bypass and a diffusion chamber, rock cuttings are smashed through high-pressure acting force and water-wedge effect between particles and between particles and the internal grinding body, rock carrying is helped, and a cutting bed can be removed.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Self-oscillation pulse reinforcement type inner grinding drill bit

InactiveCN106285482AIncrease water powerNon-uniform pulse jetDrill bitsConstructionsResonant cavityResonance

The invention discloses a self-oscillation pulse reinforcement type inner grinding drill bit. Different from a conventional PDC drill bit, a pulse generation device, a self-oscillation pulse generation device, a self-oscillation pulse reinforcement device, a negative pressure swabbing device and a rock debris inner grinding device are additionally arranged. The pulse generation device comprises a drilling fluid flow pass, a feeding cavity, a resonant cavity, a resonant pipe outlet and a shunting area, and generates pulsed jet through resonance of stimulation liquid based on an organ pipe. The self-oscillation pulse reinforcement device comprises a lower spraying flow pass, a self-oscillation spray nozzle and a cutter wing, and forms a large-size vortex ring structure through the self-oscillation spray nozzle based on a Helmholtz resonant cavity to reinforce pulsed jet. The negative pressure swabbing device comprises a reverse high-speed flow pass and a swabbing cavity, and forms negative pressure in the swabbing cavity by the aid of reverse jet high-speed characteristic to swab rock debris. The rock debris inner grinding device comprises a mixing cavity, a throat channel, an acceleration cavity, an inner grinding cavity, an inner grinding body, a bypass and a diffusion cavity, and is used for crushing the rock debris based on high-pressure action force and a water wedge effect, rock carrying is facilitated, and a cuttings bed is removed.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

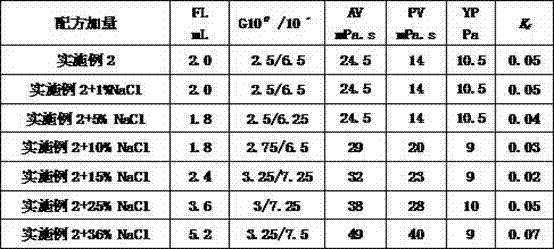

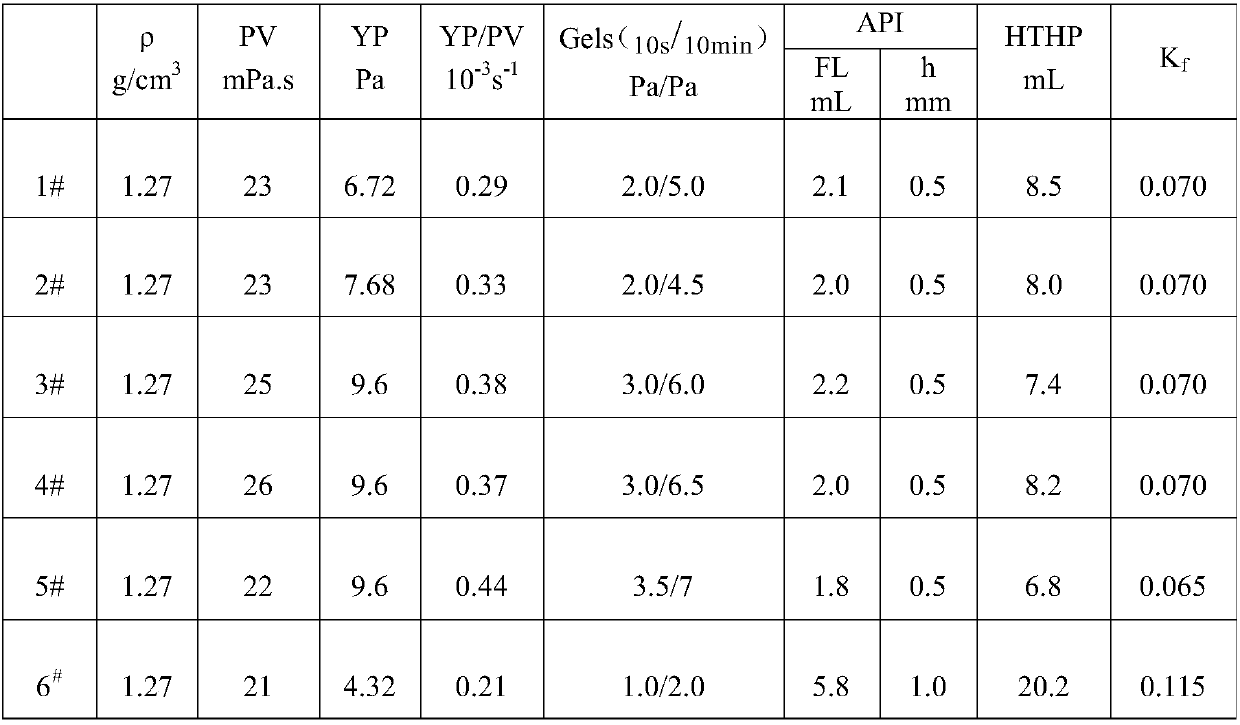

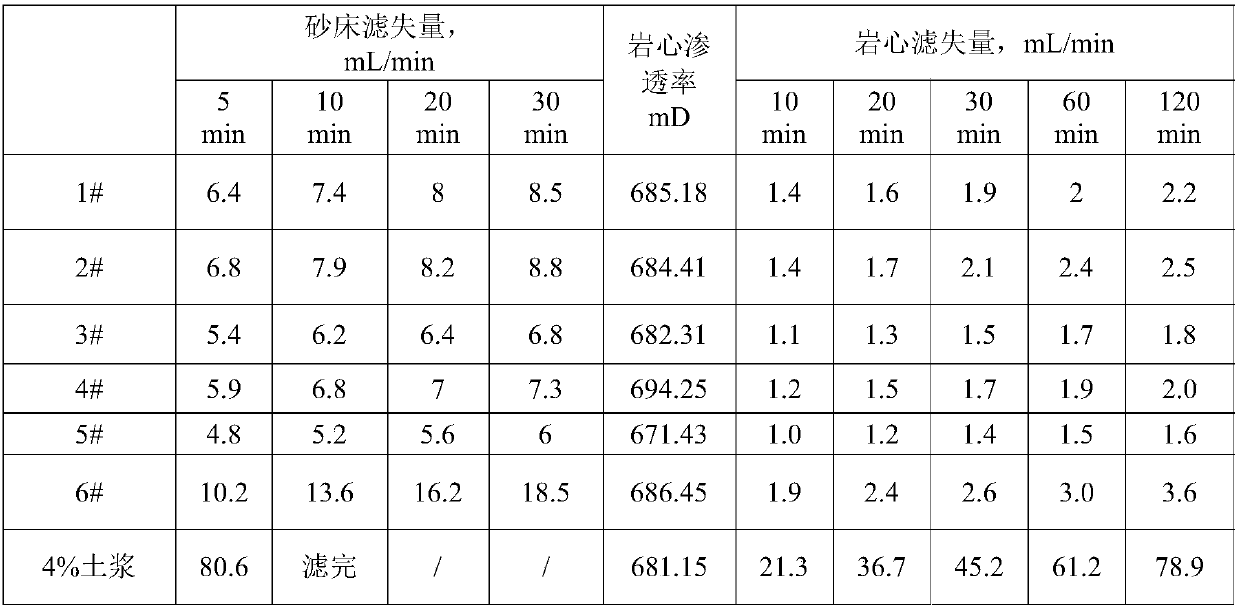

Drilling fluid completion fluid for increasing drilling speed and preparation method of drilling fluid completion fluid

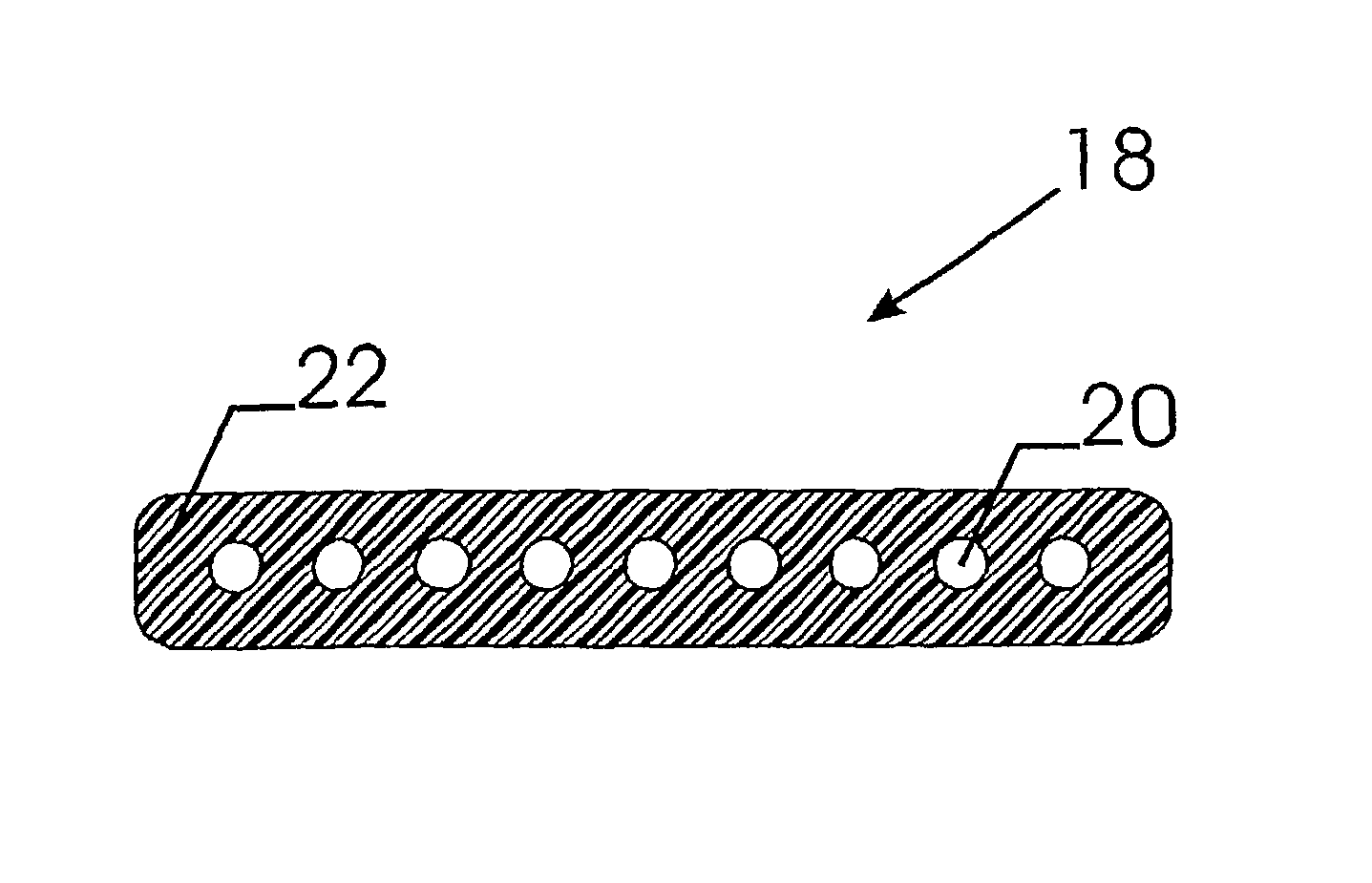

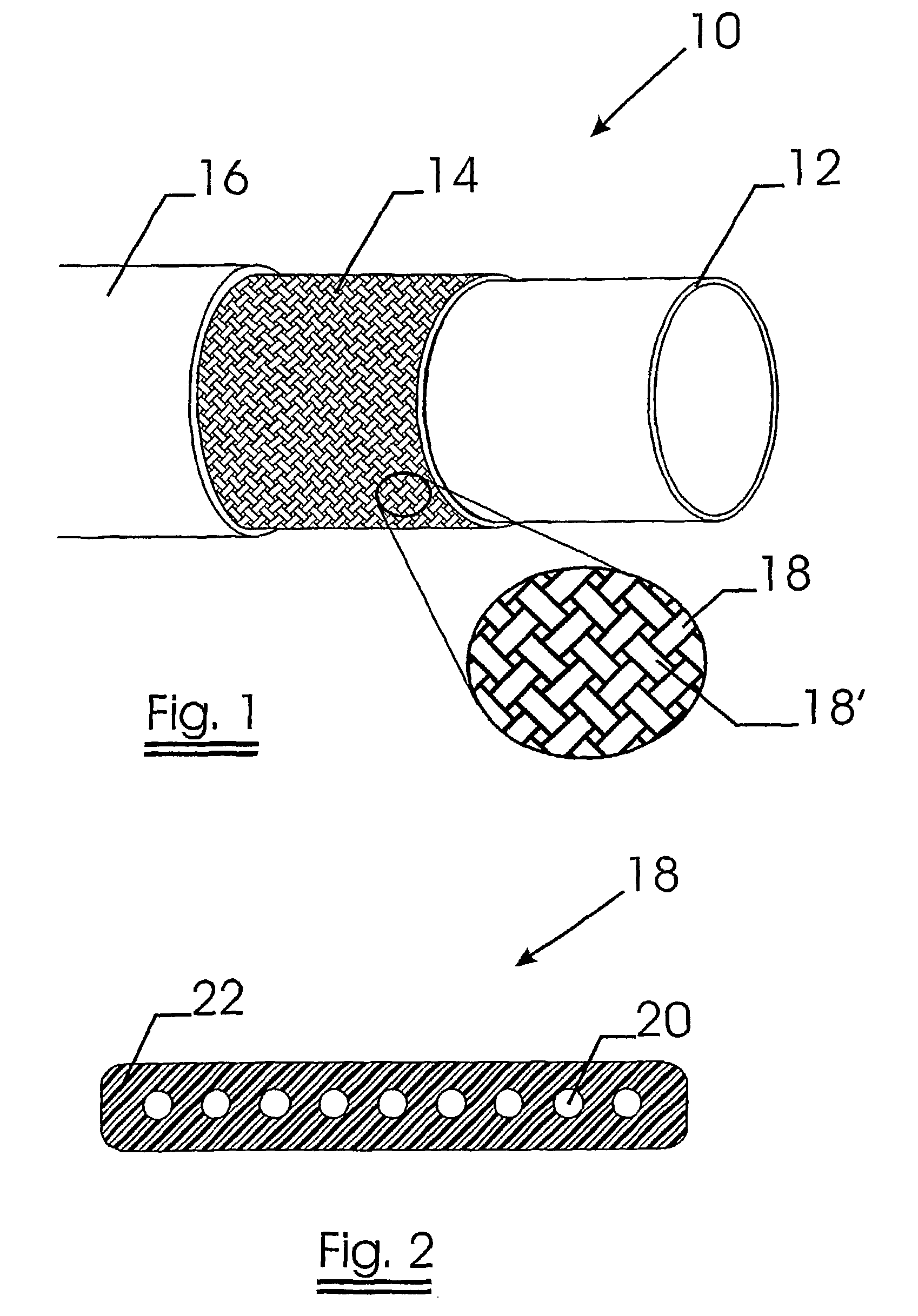

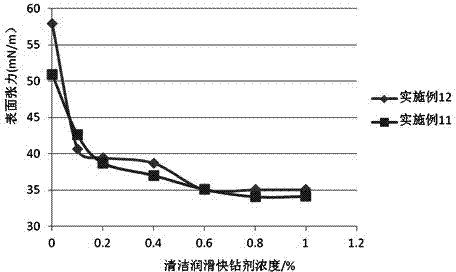

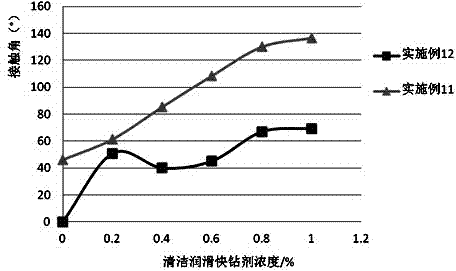

InactiveCN103897675AGood suspension rock carrying capacityGood shear thinningDrilling compositionSodium BentoniteSurface-active agents

The invention relates to a drilling fluid completion fluid for increasing drilling speed and a preparation method of the drilling fluid completion fluid. The drilling fluid completion fluid is prepared from the following components in parts by weight: a continuous liquid phase, 0.2-1 part of a cleaning and lubrication fast drilling agent, 0.1-1 part of anhydrous sodium carbonate, 2-3 parts of clay, a tackifier, a filtrate reducer, 0-10 parts of an inhibitor, 0-1 part of a surfactant, 1-3 parts of a plugging agent and 0.1-10 parts of a weighting agent, wherein fresh water is used as the continuous liquid phase; sodium bentonite is used as the clay; lignite resin, or a sulfonate copolymer filtrate reducer, or sulfomethyl phenol formaldehyde resin is used as the filtrate reducer; super-fine calcium carbonate or expanded graphite is used as the plugging agent; barite or manganese tetraoxide is used as the weighting agent. The drilling fluid completion fluid disclosed by the invention has the advantages that the drilling fluid completion fluid can keep a low solid-phase content under the high density conditions, has excellent capacities of cleaning and wetting a mud-proof drum, preventing water blocking damage, resisting temperature and salt, lubricating to reduce frictional resistance, inhibiting and preventing collapse, and plugging, and can be used for stabilizing the wall of a well, increasing initial water loss of the drilling fluid, reducing a chip hold-down effect and increasing the drilling speed.

Owner:CHINA PETROCHEMICAL CORP +1

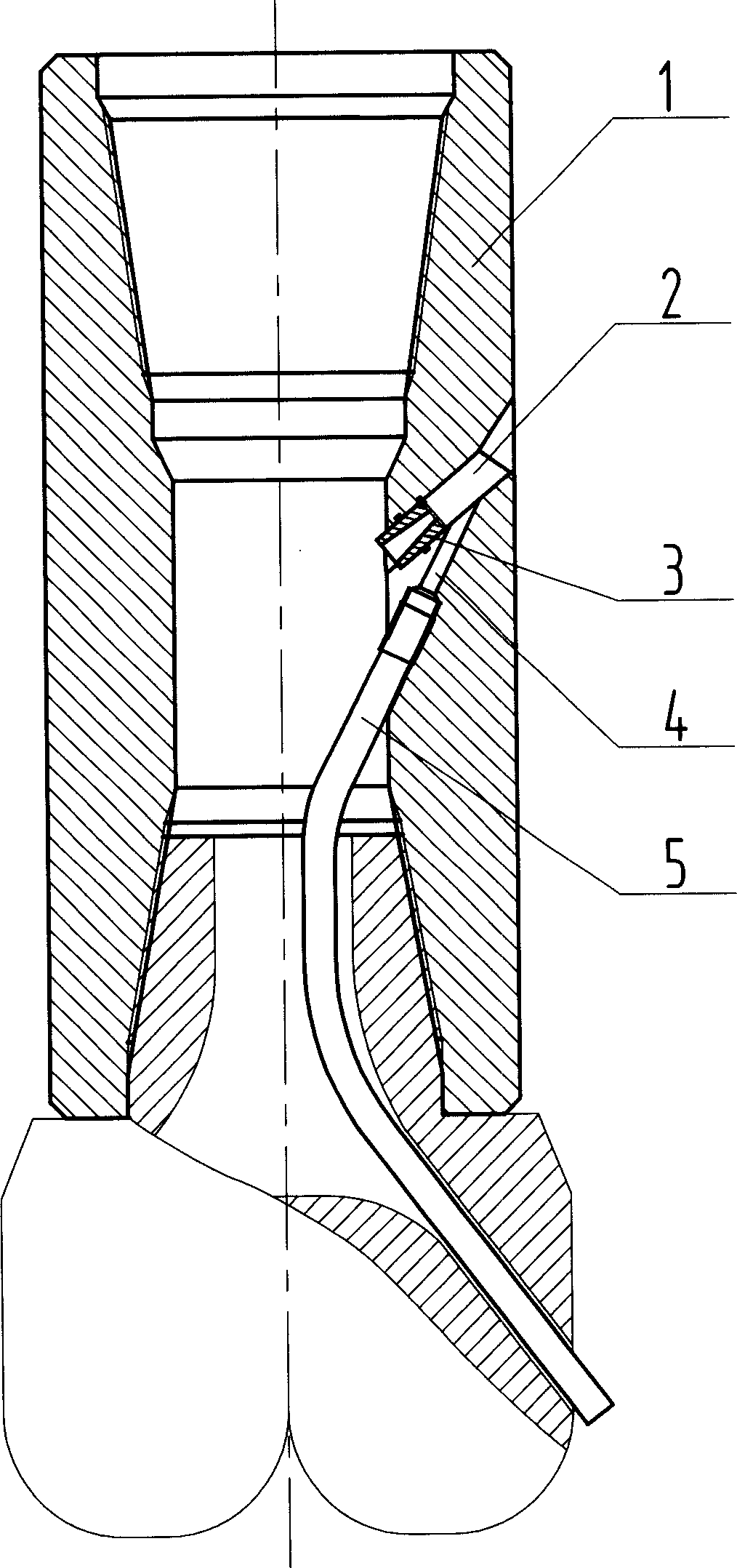

Underground pulsing jet drill bit device

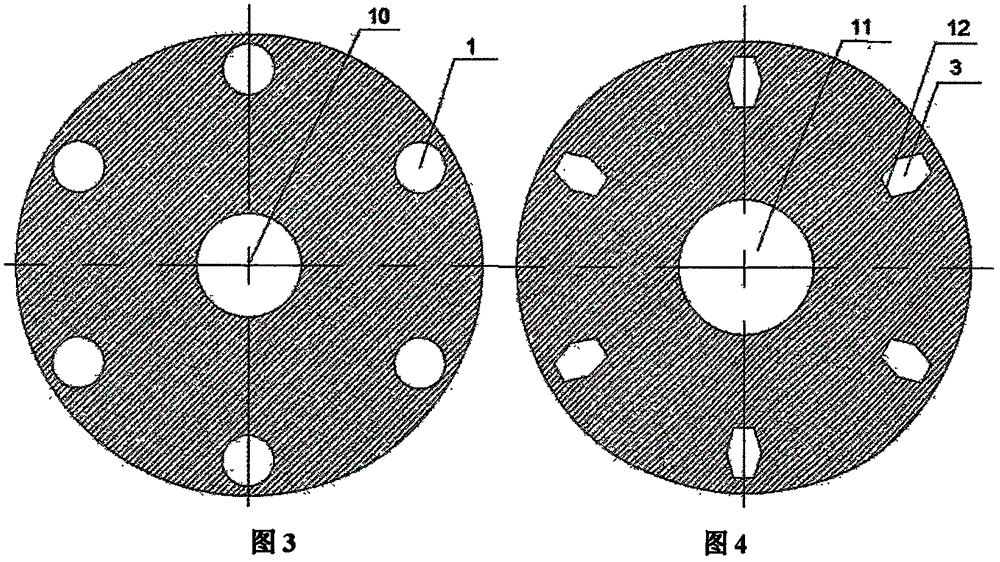

The invention relates to an underground pulsing jet drill bit device. A double-end sleeve, a drill bit connector and a drill bit body are sequentially screwed; the upper end of the drill bit body is provided with a drill bit water cavity; a plurality of drill bit water holes are distributed in the bottom wall of the drill bit water cavity; all of the drill bit water holes are uniformly distributed by using the axial line as the center; each drill bit water hole downwards extends and is communicated with a corresponding spray hole formed in the lower end surface of the drill bit body; the center of the double-end sleeve and the center of the drill bit connector are provided with a center water passage communicated with the drill bit water cavity; a static valve disc is arranged on the bottom wall of the drill bit water cavity; static valve disc water holes are formed in the static valve disc; each static valve water hole has the same hole diameter as the drill bit water hole and is in one-to-one corresponding communication with the corresponding drill bit water hole; a movable valve disc capable of rotating around the axial line covers the static valve disc; at least one movable valve disc water hole is formed in the movable valve disc; and the movable valve disc water hole has the same hole diameter as the static valve disc water hole, and is positioned on the same circumference as the static valve disc water hole. The drill bit device has the advantages that the shaft bottom cleaning effect can be improved; and the hydraulic rock breaking capability can be improved.

Owner:CHINA PETROCHEMICAL CORP +2

Runner cross central whirl spraying negative pressure pulse drill bit

InactiveCN106246110AImprove efficiencyReduce power consumptionDrill bitsConstructionsSpray nozzleThroat

The invention discloses a runner cross central whirl spraying negative pressure pulse drill bit. The drill bit is characterized by comprising a pulse jet generating device, a central whirl spraying rock breaking device and a negative-pressure swabbing device, wherein the pulse jet generating device comprises a drilling fluid runner, a feeding cavity, a resonant cavity, a resonant pipe outlet and a shunt area, and generates pulse jet by exciting fluid resonance based on an organ pipe, thereby improving the rock breaking efficiency; the central whirl spraying rock breaking device comprises a central self-rotating nozzle, a spray-down bypass runner, a spray-down central self-rotating runner and a blade, rotates to realize forward jet shear tensile rock breaking based on high-pressure water jet, and performs lateral jet to provide self-feeding force for the drill bit, so that the rock breaking and rock cleaning efficiency is improved in combination with the spray-down bypass runner; the negative-pressure swabbing device comprises a reverse high-speed runner, a swabbing cavity, a mixing cavity, a throat and a chip return cavity, negative pressure is formed in the swabbing cavity by means of the high-speed characteristics of reverse fluid based on a jet pump, and rock chips are swabbed, so that the chip hold down effect is reduced.

Owner:SINOPEC CHONGQING FULING SHALE GAS EXPLORATION & DEV +1

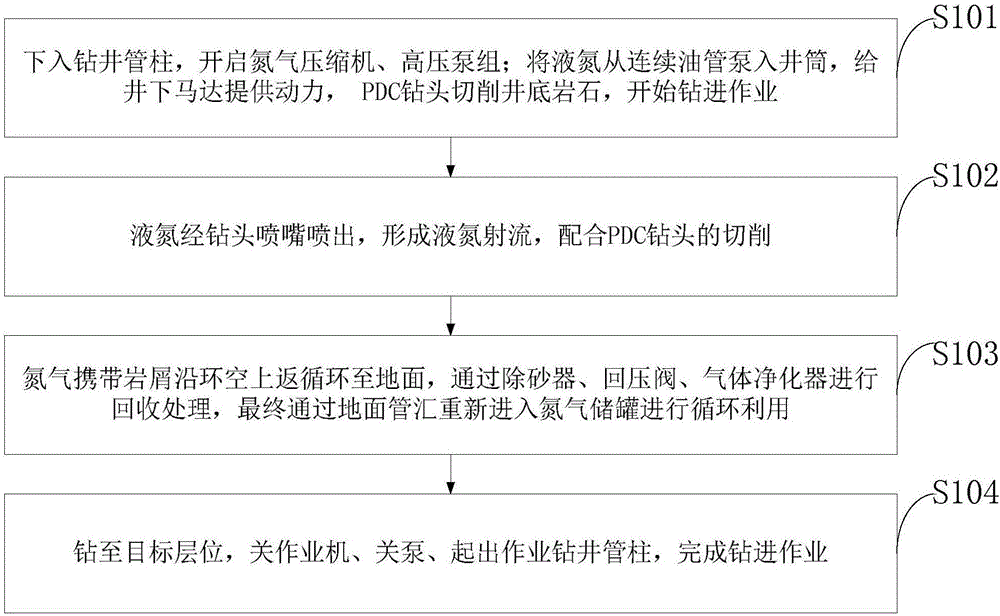

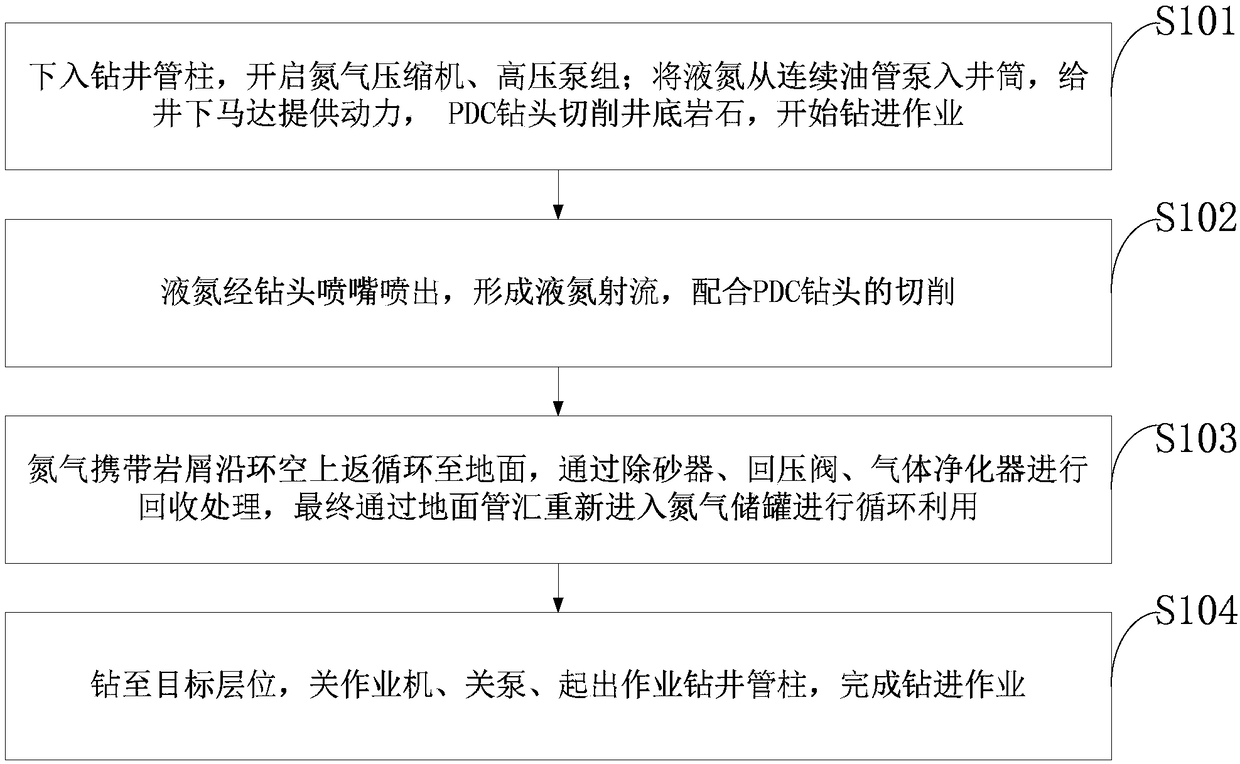

Drilling system and method for improving tundra drilling efficiency

InactiveCN106401463AImprove drilling efficiencySolve complex underground problemsIce drillingInsulationDecompositionHydrate decomposition

The invention discloses a drilling system and method for improving tundra drilling efficiency. The drilling method comprises the following steps of: adopting a downward drilling pipe column, starting a nitrogen gas compressor and a high-pressure pump unit; pumping liquid nitrogen into a shaft from a continuous oil pump, providing power to an underground motor, cutting shaft-bottom rocks by a PDC drill bit, and starting drilling operation; spraying out the liquid nitrogen through a spray nozzle of the drill bit to form liquid nitrogen jet flow which is matched with cutting of the PDC drill bit; upwards returning and circulating nitrogen gas along with rock debris to ground along an annular space, and recycling through a sand remover, a back pressure valve and a gas purifier; and drilling to a target layer, thereby completing drilling operation. Liquid-nitrogen fracturing effect is beneficial for expanding cracks generated inside rocks, so that rock breaking efficiency is effectively improved; the temperature of liquid nitrogen is extremely low, and liquid nitrogen is vaporized to absorb heat in an upward return process, so that decomposition of natural gas hydrates is effectively restrained, a well wall is kept stable, and underground complexity is prevented; and in an operation process, liquid nitrogen is recycled, so that the process is simple, is economical and is good in field applicability.

Owner:SOUTHWEST PETROLEUM UNIV

Jet flow drill bit with variable chip groove

InactiveCN109611030AAids in cutting and crushingRelieve pressureDrill bitsHydraulic actionWell drilling

The invention discloses a jet flow drill bit with a variable chip groove, and relates to the field of oil and gas well drilling. The jet flow drill bit comprises a body extending along an axis and provided with a runner; a cutting mechanism is arranged on the body and used for cutting rocks; a first jet flow nozzle communicating with the runner is arranged at the lower end of the body and used forjetting flows to the bottom of a well and flushing rock debris particles generated by the cutting mechanism; a chip groove extending in an axis direction is formed in the side wall of the body; a notch for accommodating a sealing plate is formed in the side wall of the body; a first channel communicating with the runner and the notch is formed in the body in the radial direction; a telescopic mechanism in transmission with the sealing plate is arranged in the first channel; and the telescopic mechanism can drive the sealing plate to move in the radial direction under the hydraulic action of the flow channel, so that the chip groove has a blocking state and a smooth state. The state of the chip groove can be changed according to the working state of the drill bit, so that the using effectof the jet drill bit is improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

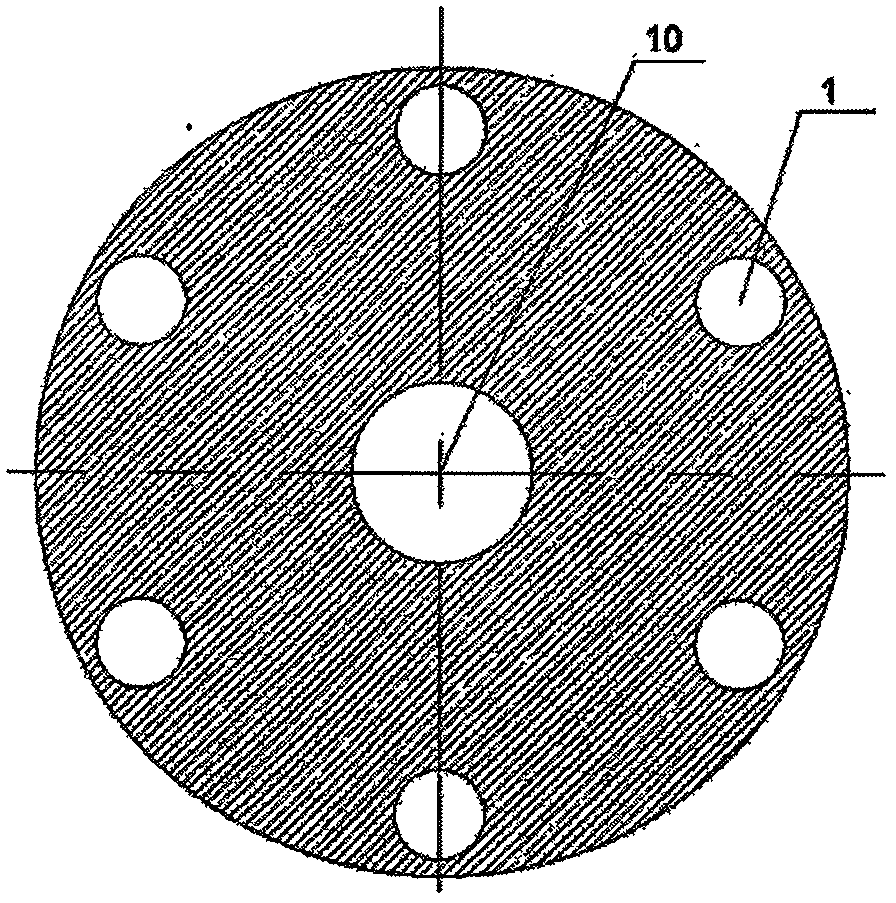

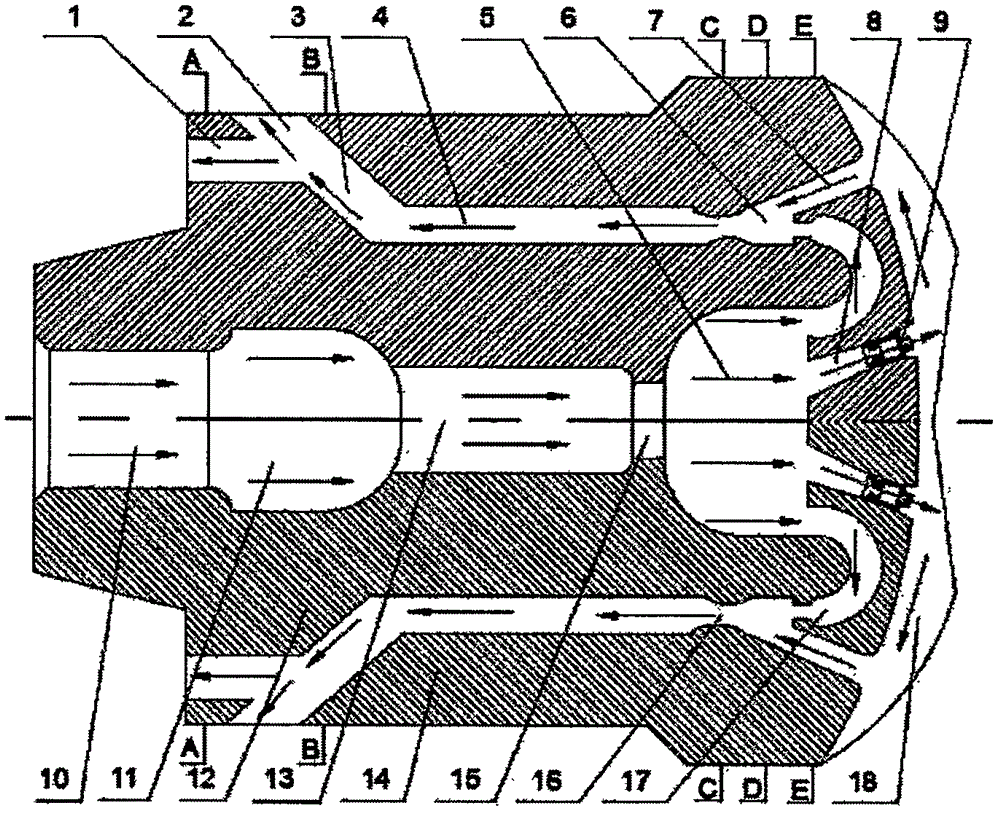

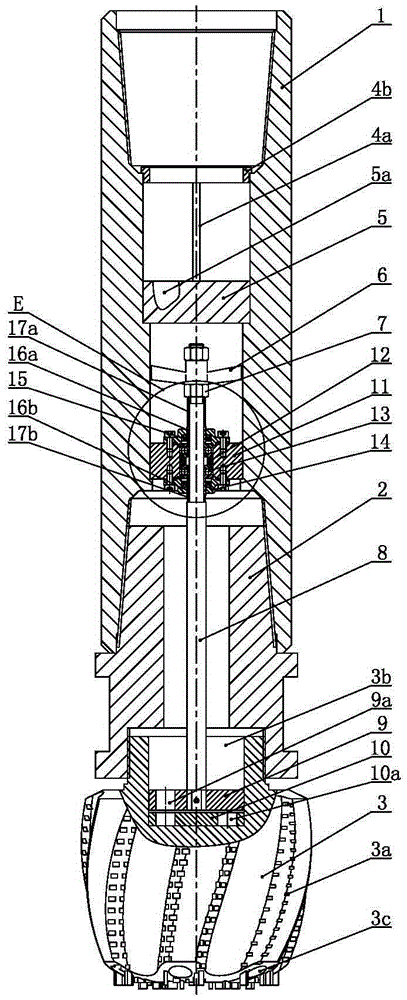

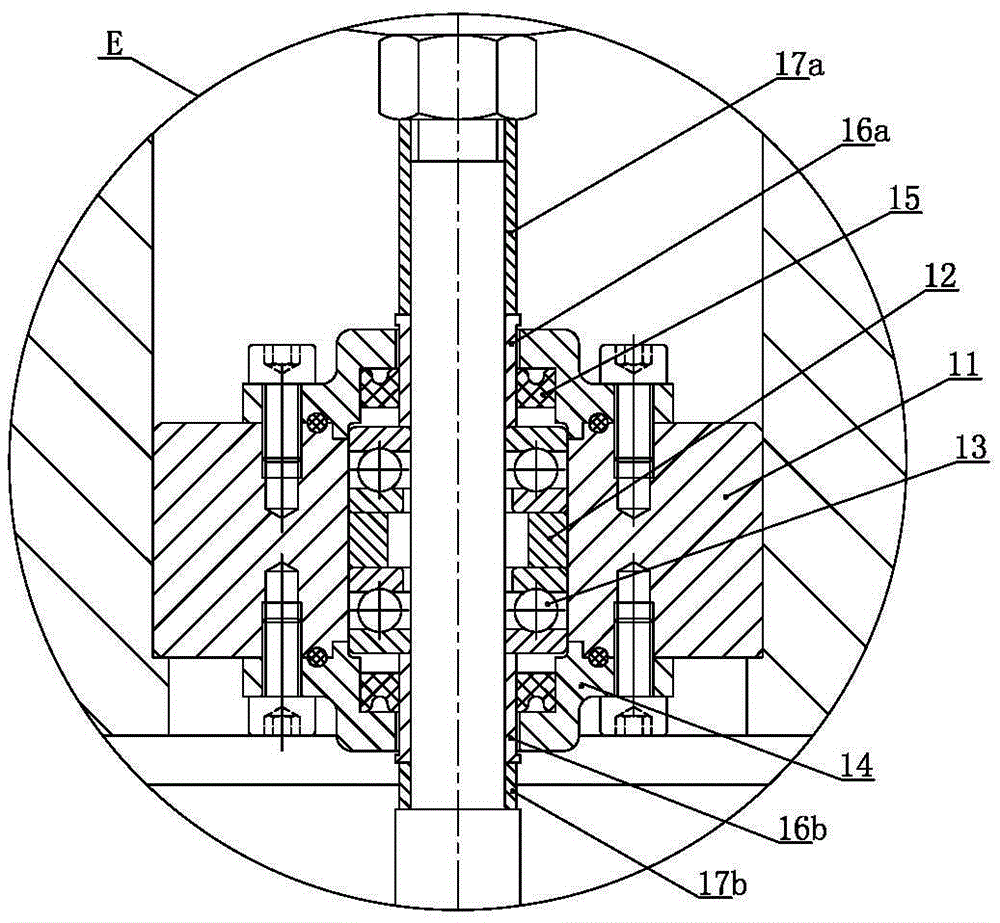

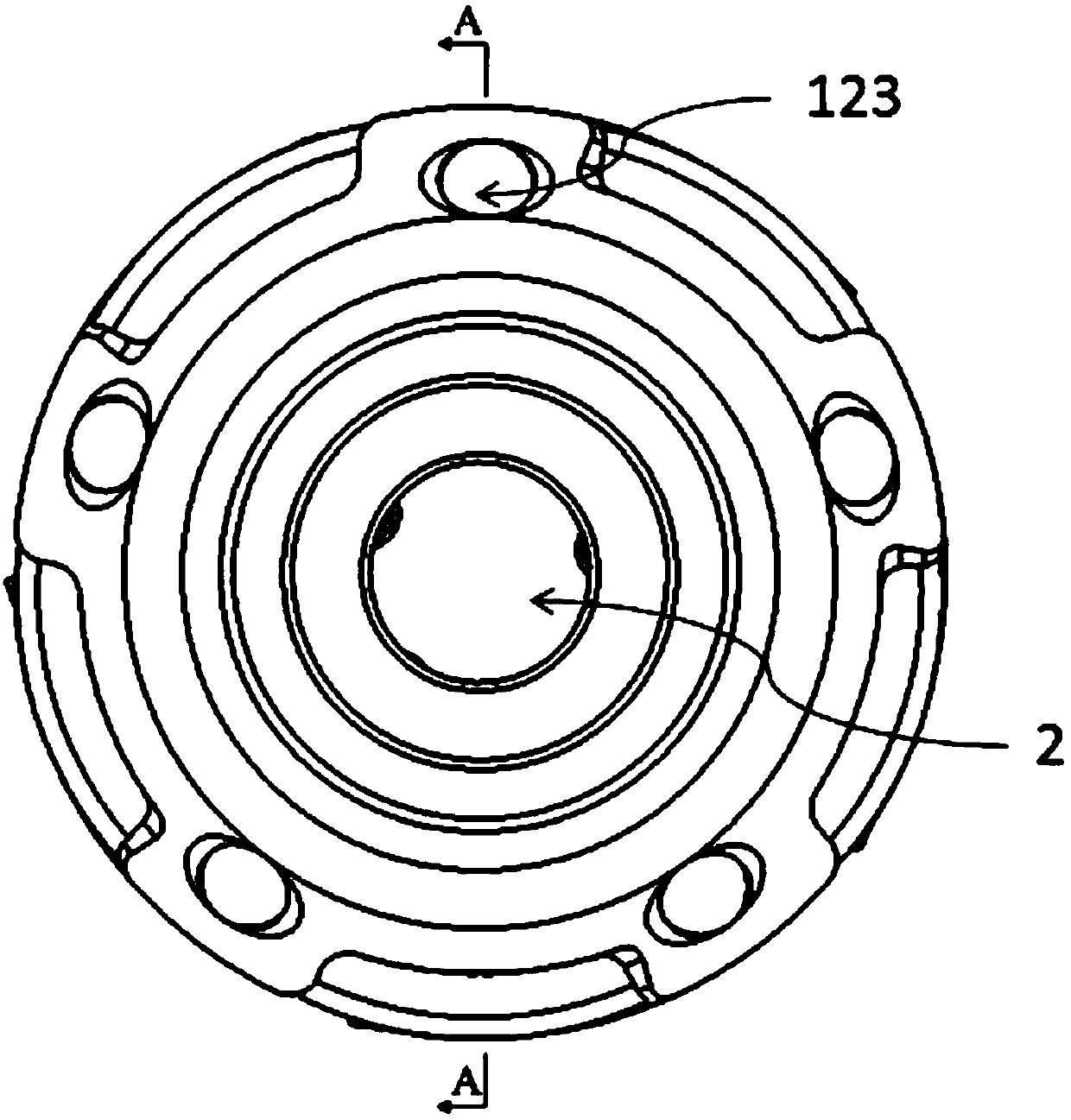

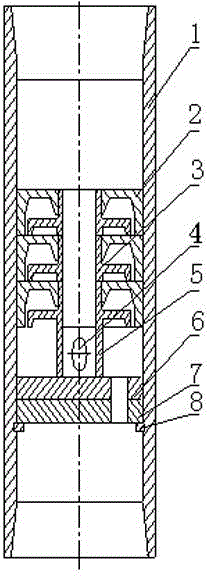

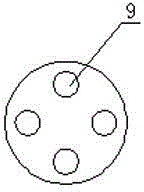

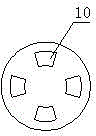

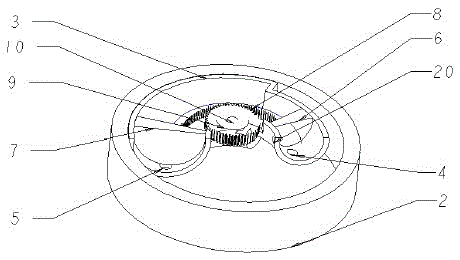

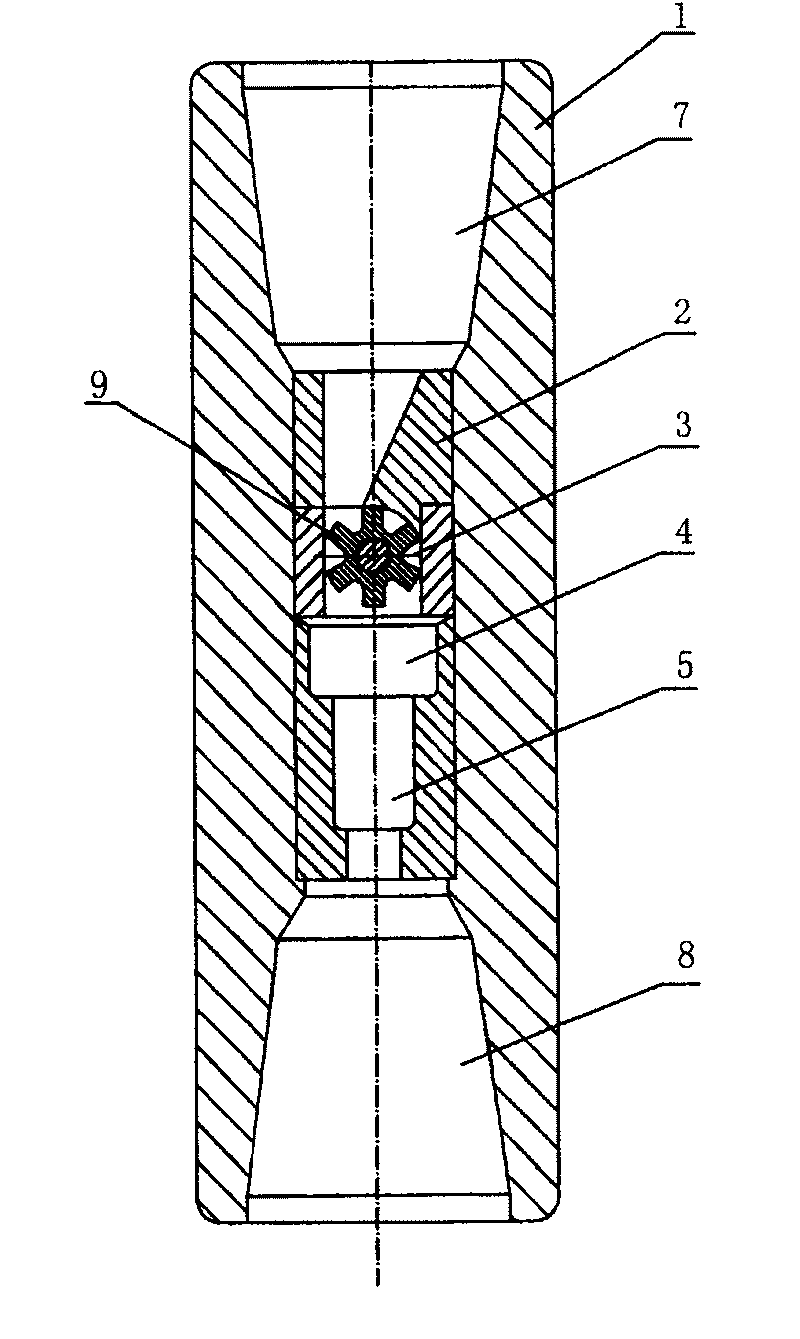

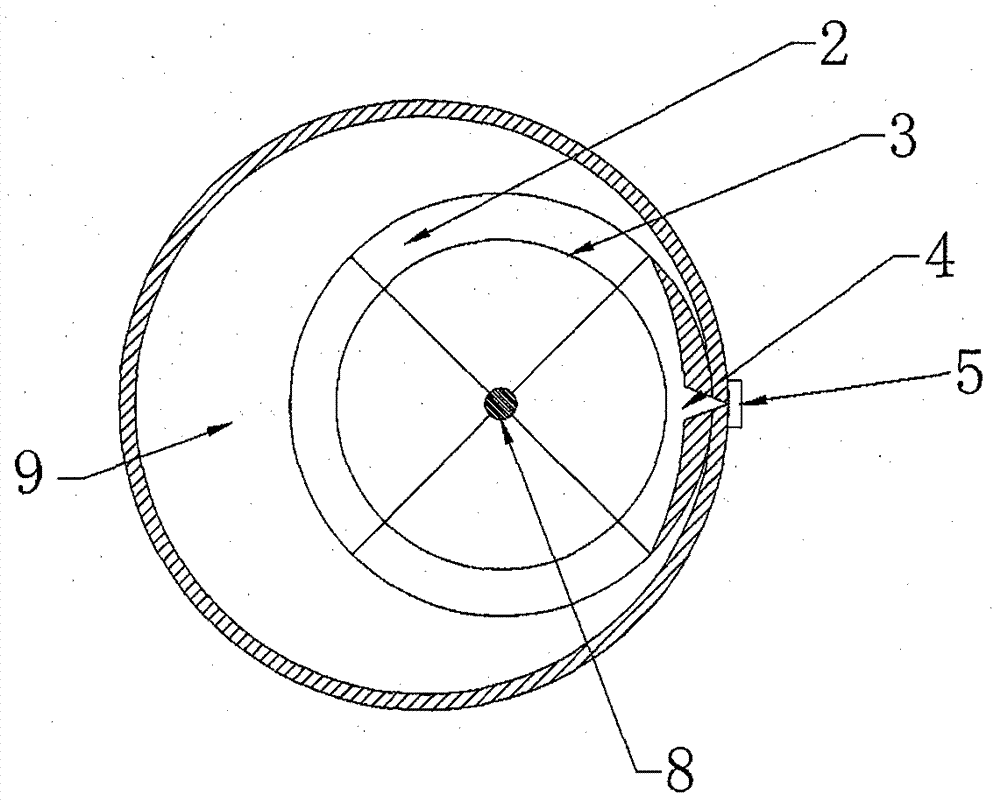

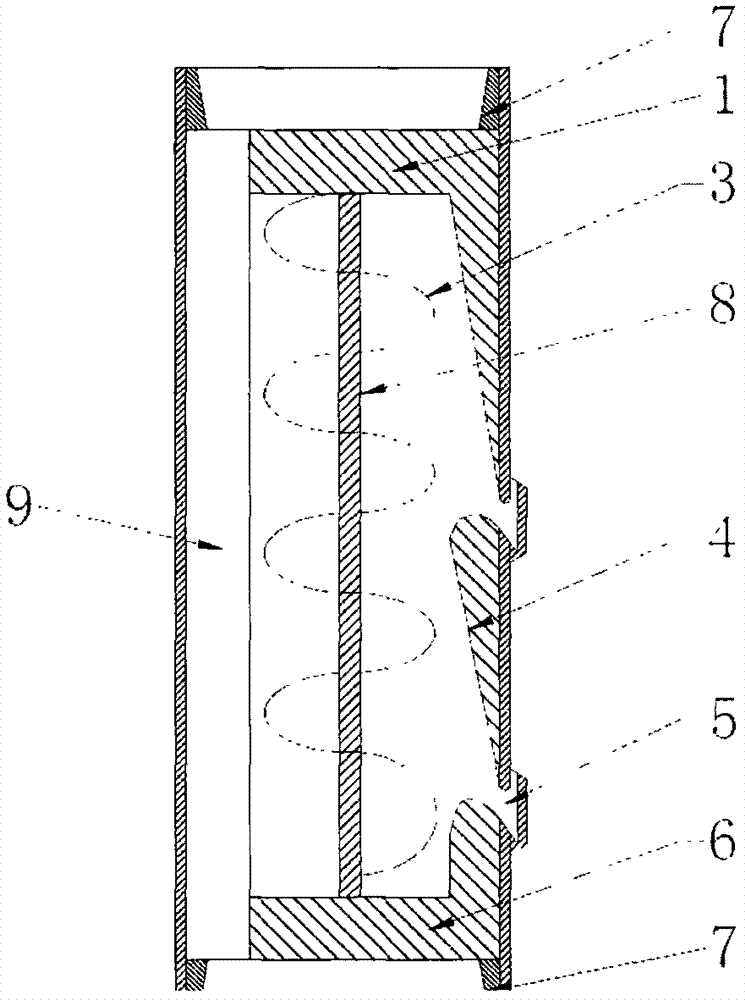

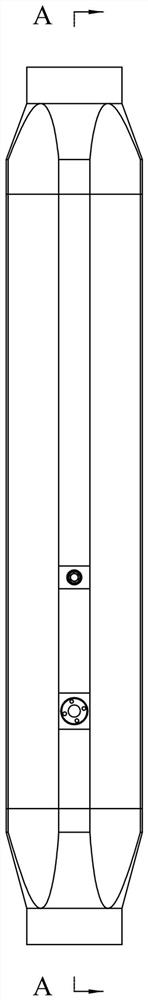

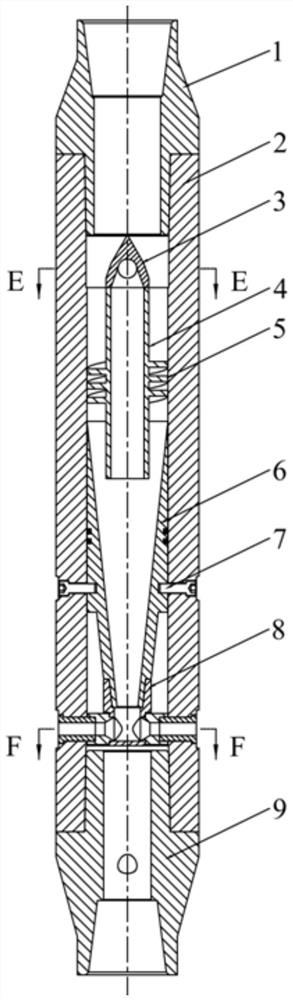

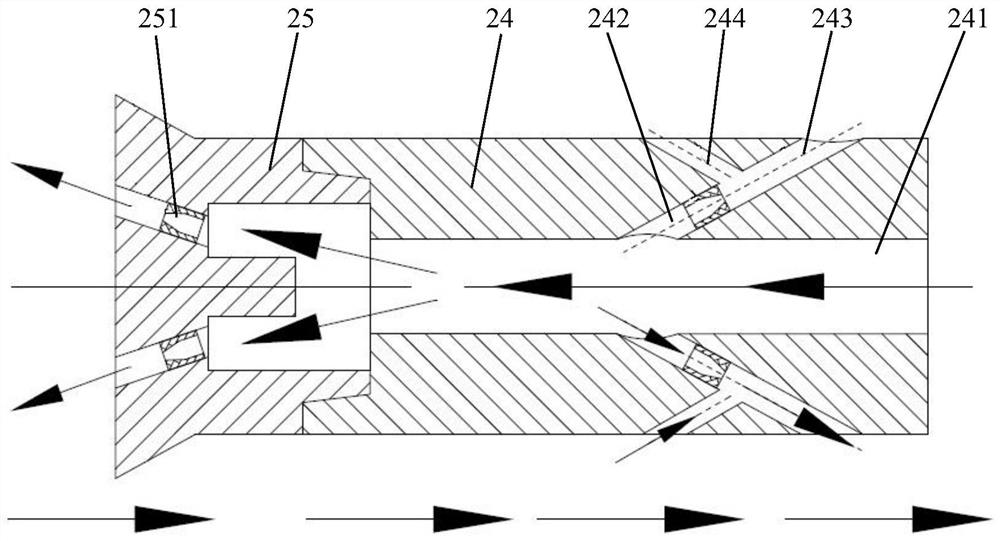

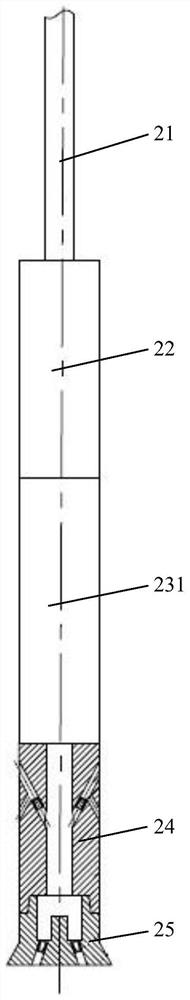

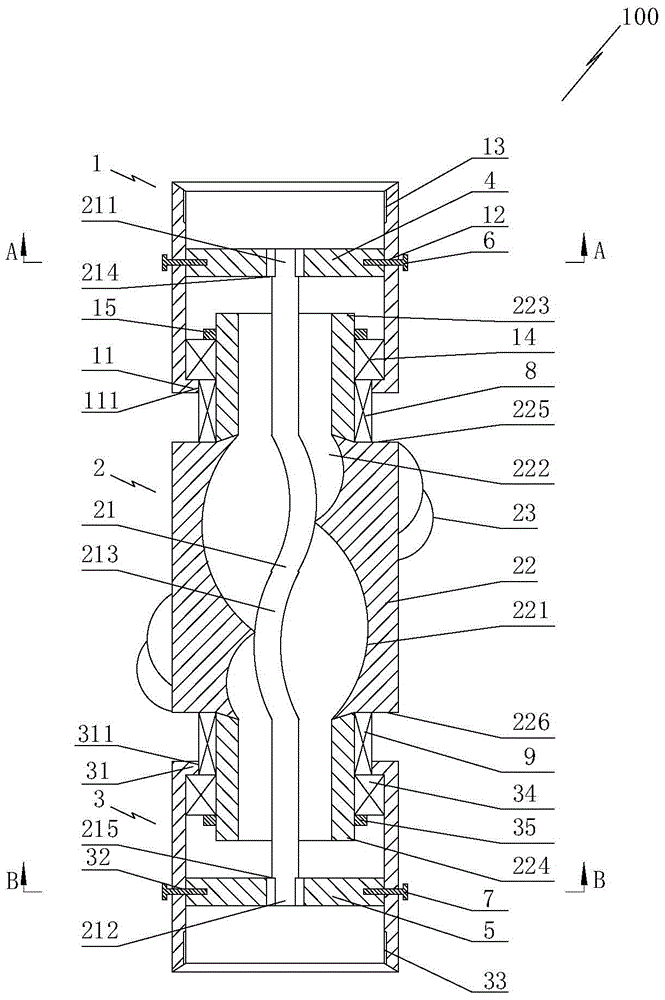

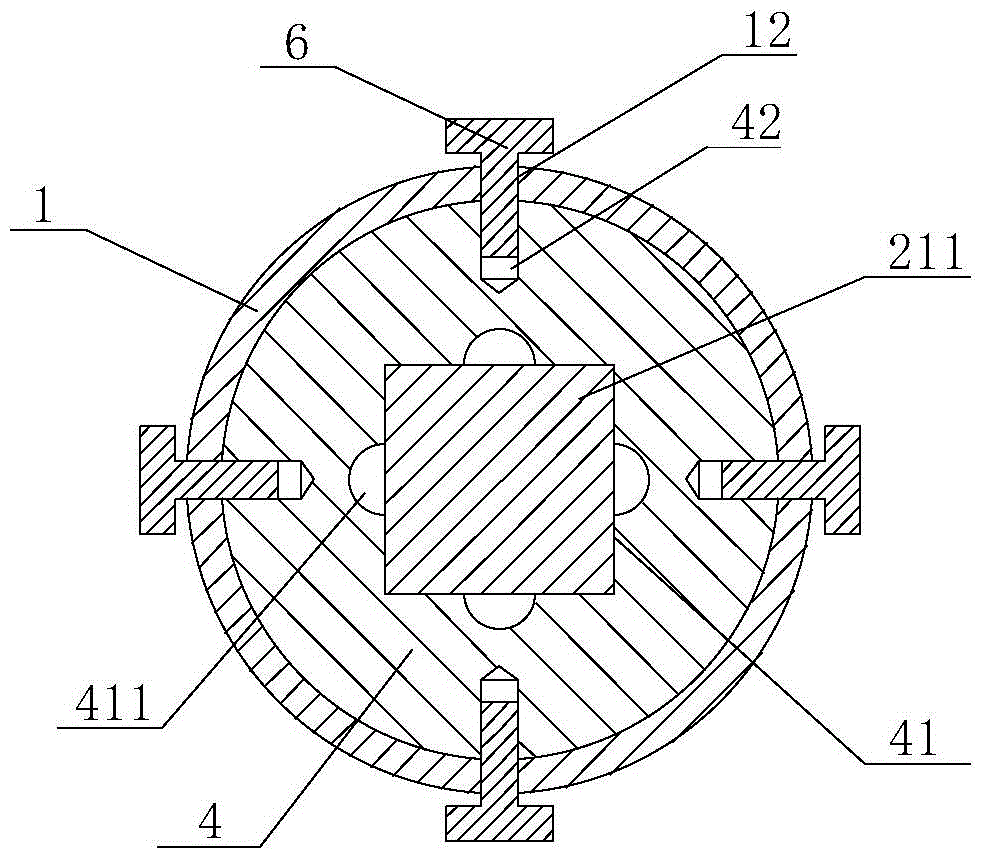

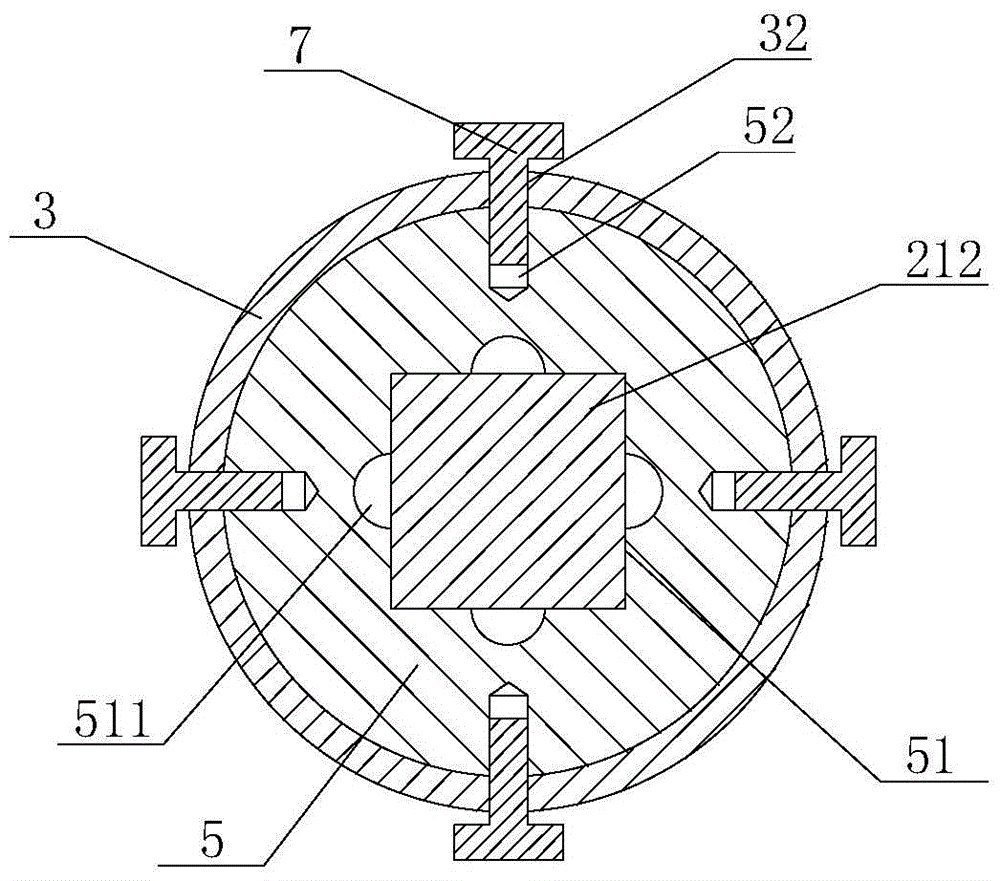

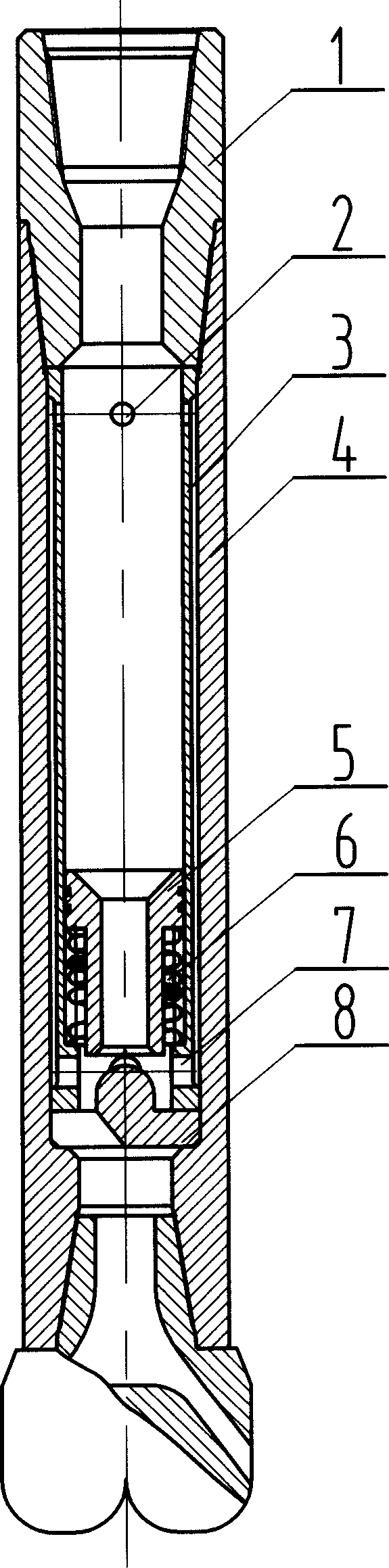

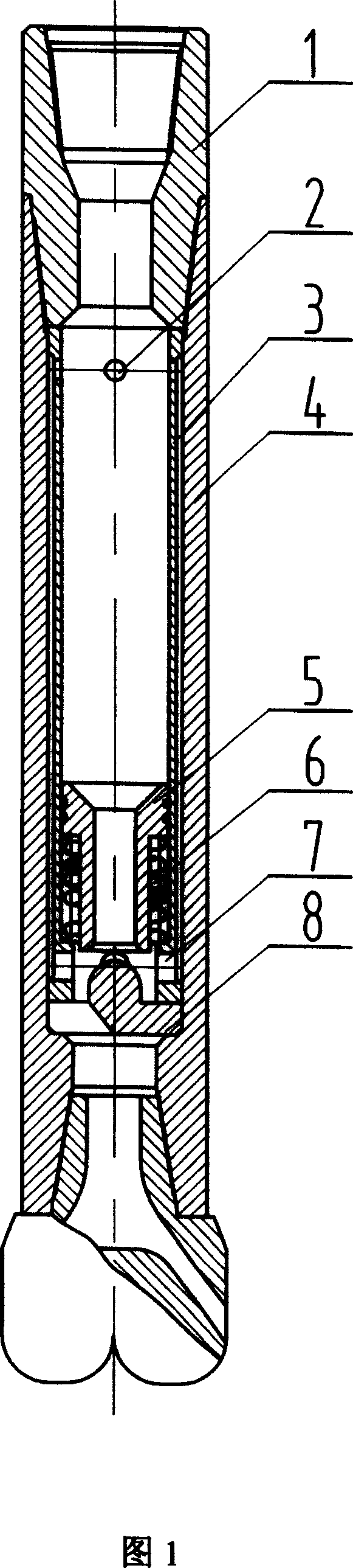

Downhole low-pressure pulse jet modulator

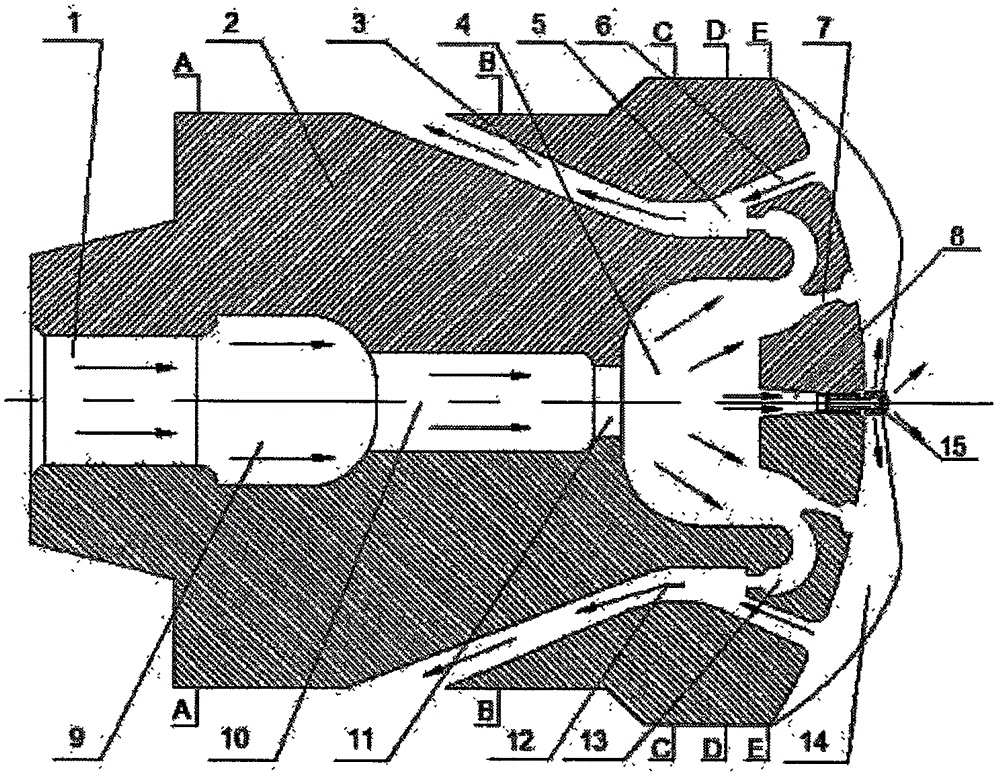

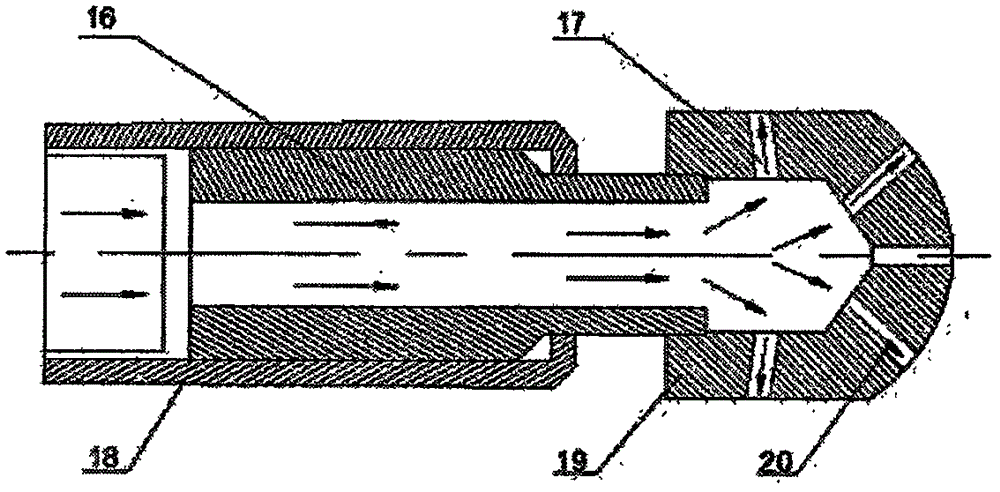

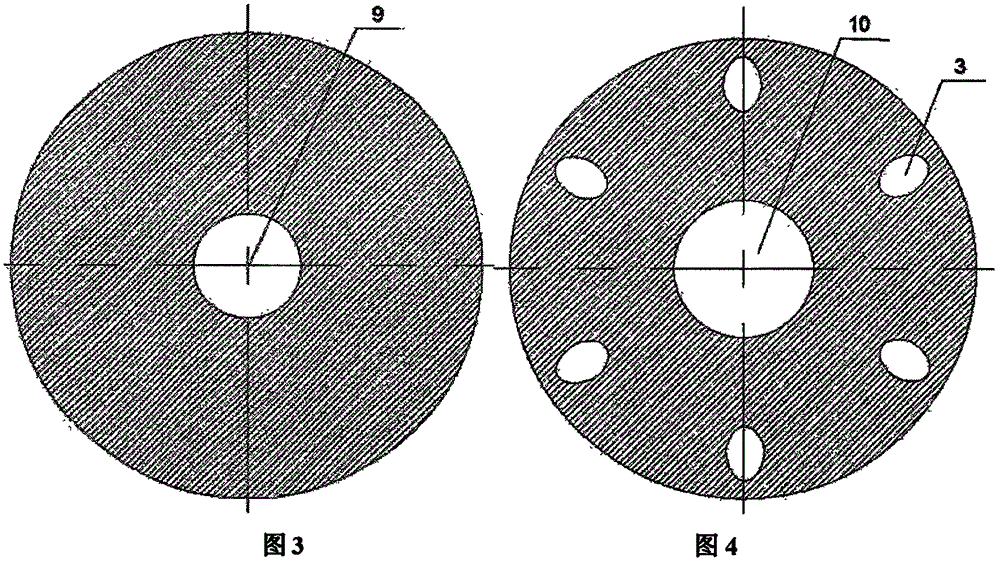

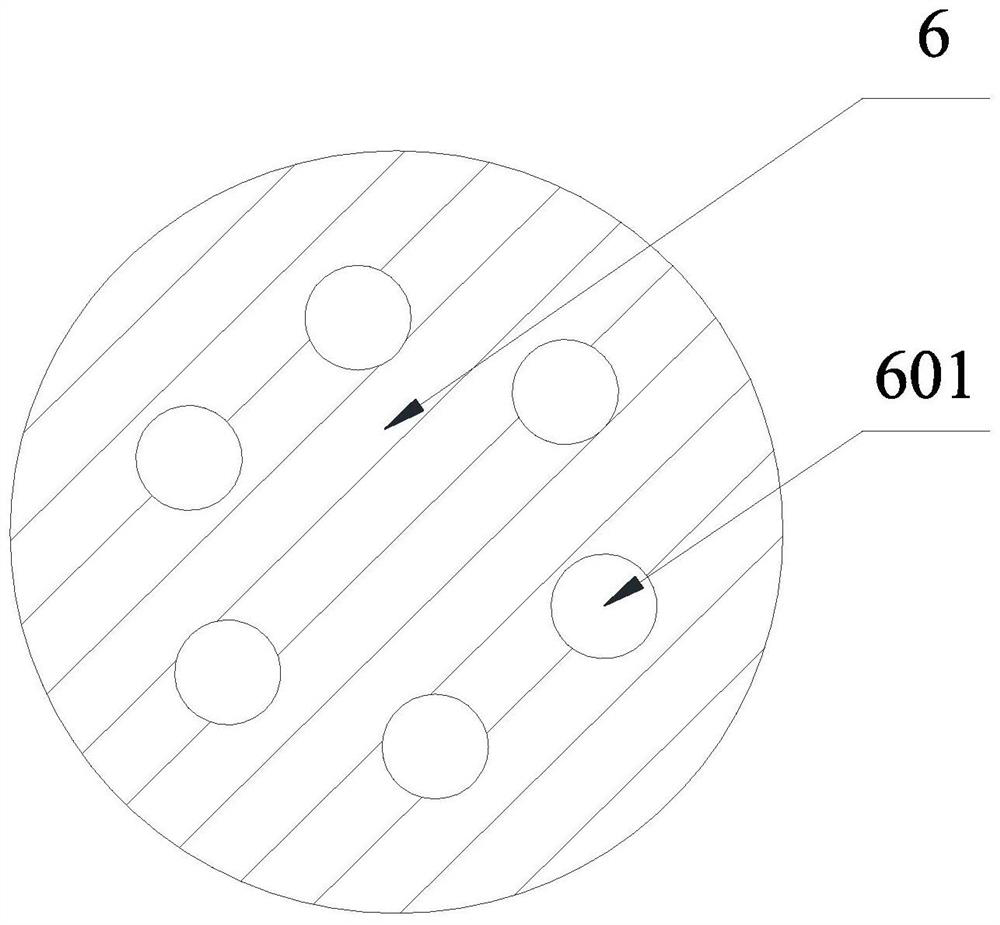

The invention discloses a downhole low-pressure pulse jet modulator. The downhole low-pressure pulse jet modulator mainly comprises an outer casing 1 as well as turbine unit stators 2, turbine unit rotors 3, an upper mushroom valve 6 and a lower mushroom valve 7 which are mounted in the outer casing 1, wherein the turbine unit stators 2 are fixed in the outer casing 1; the turbine unit rotors 3 are mounted in the turbine unit stators 2 and form rotation fit with the turbine unit stators 2; an axial channel is formed in the turbine unit rotors 3, and a fluid feeding port 4 is formed in the lower part of the axial channel; the upper mushroom valve 6 is connected and fixed at the lower end of the turbine unit rotors 3; the lower mushroom valve 7 is fixed in the outer casing 1 below the upper mushroom valve 6; a plurality of mutually communicated upper mushroom valve flow channels 9 and lower mushroom valve flow channels 10 are axially distributed in the upper mushroom valve 6 and the lower mushroom valve 7 respectively; the upper mushroom valve 6 and the lower mushroom valve 7 are in rotating seal fit. The downhole low-pressure pulse jet modulator has the advantages that the modulator is simple in structure, convenient to operate and mount, safe and reliable, the drilling rock breaking efficiency is increased, and the comprehensive cost for drilling is reduced.

Owner:SINOPEC SHENGLI PETROLEUM ENG CO LTD DRILLING TECH RES INST

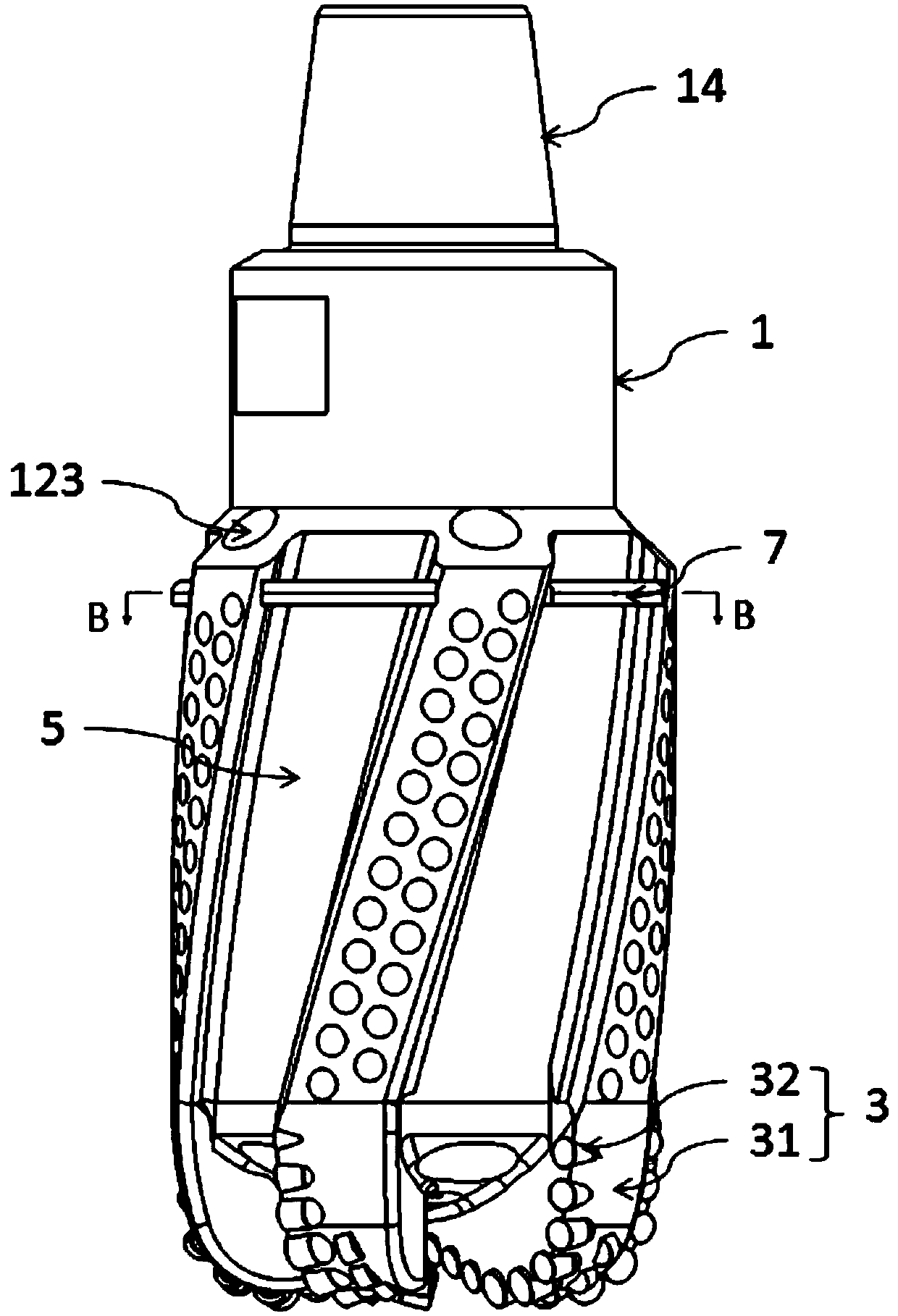

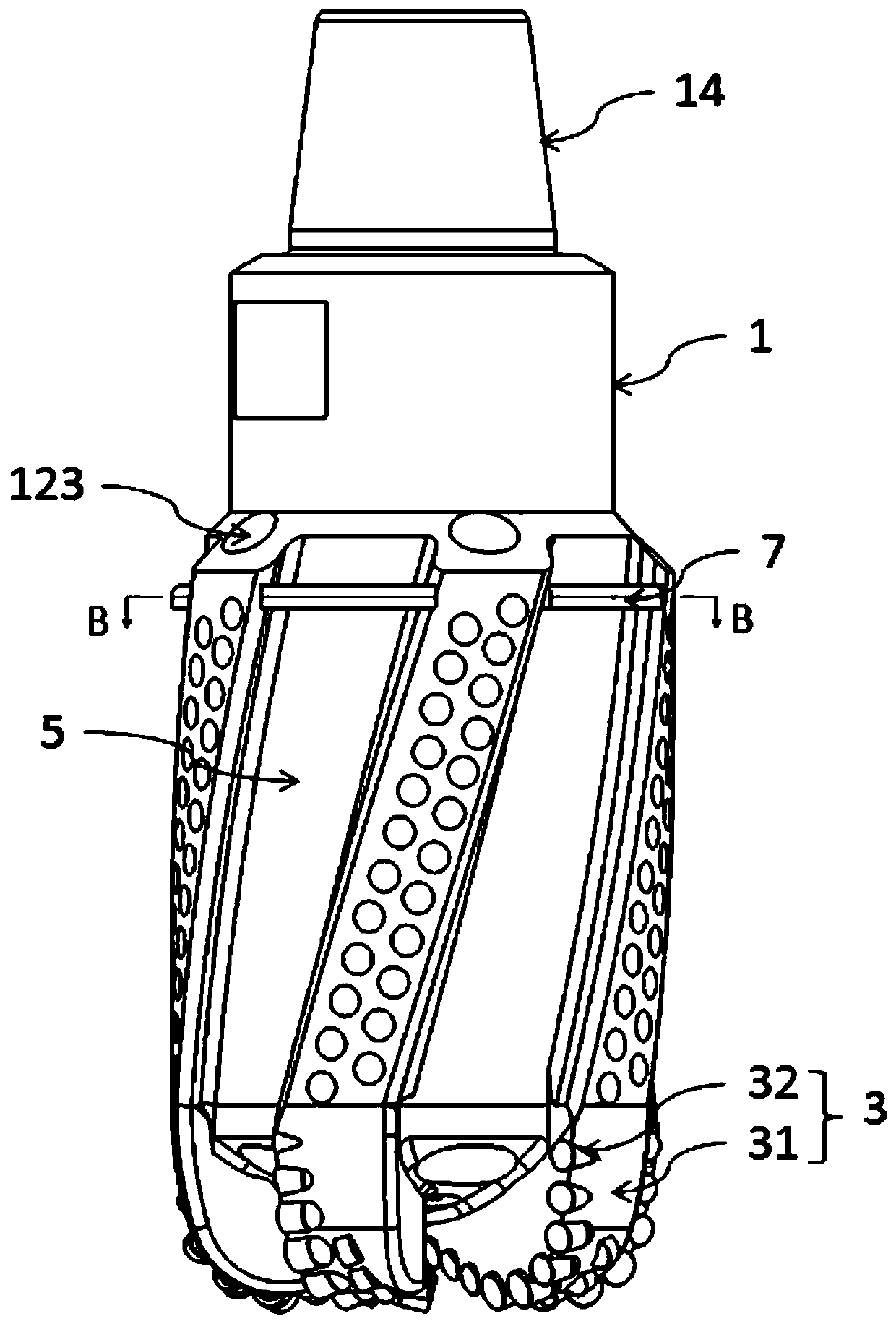

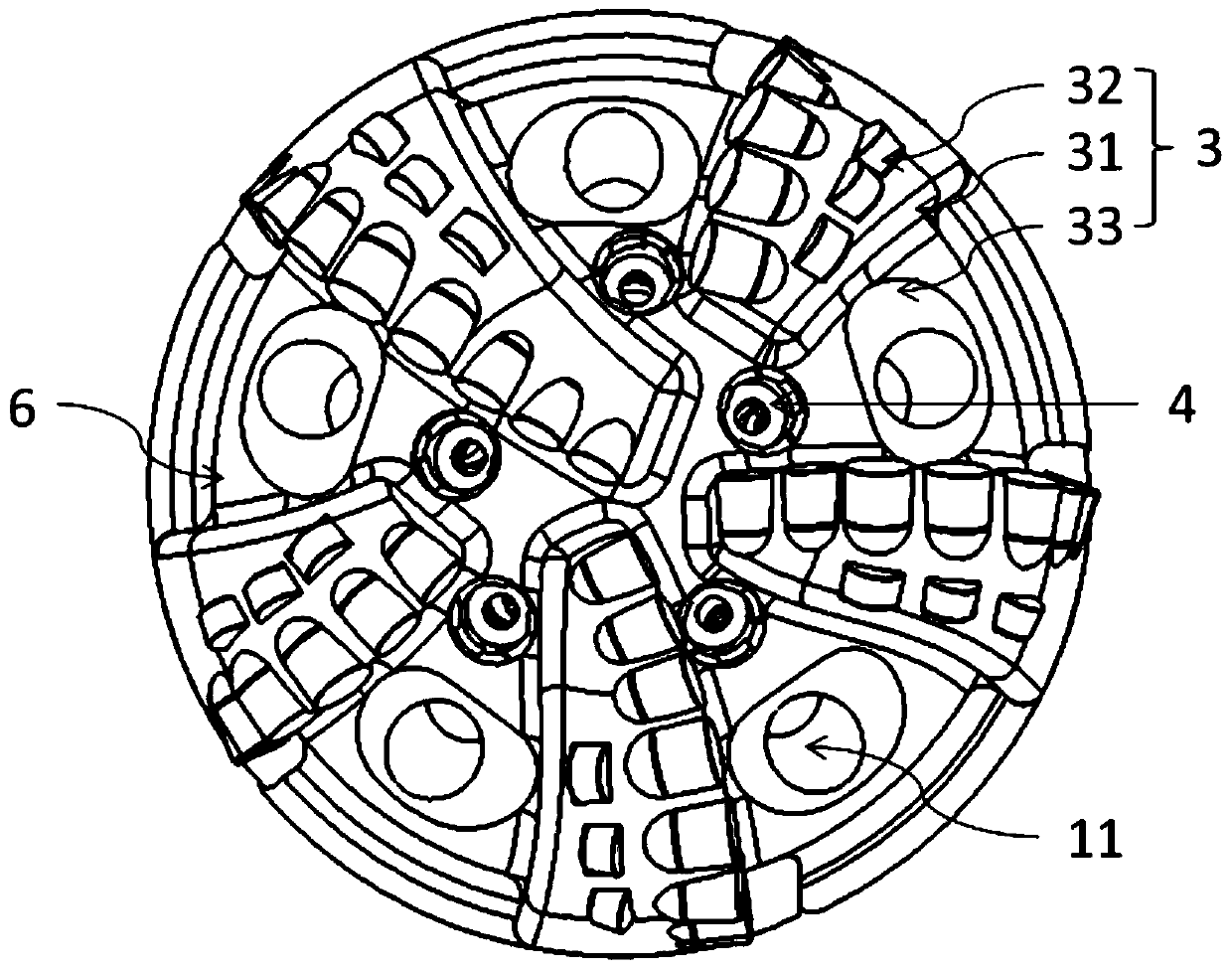

Active rotary telescopic compound bit applicable to deep difficult-to-drill hard formation

InactiveCN105649536AReduce intensityImprove mechanical propertiesDrill bitsPolycrystalline diamondWide mouth

The invention relates to an active rotary telescopic compound bit applicable to a deep difficult-to-drill hard formation. The bit mainly comprises a bit body, a power end casing, a rack piston cylinder, a narrow-mouth piston, a wide-mouth piston, an arc-shaped rack, a gear, a drilling fluid through hole, a telescopic column, a three-hole flat plate, legs, cones, cone teeth, runner ports and drainage ports, wherein the narrow-mouth piston is connected with the wide-mouth piston by the aid of the arc-shaped rack; the gear embedded inside the rack piston cylinder is meshed with the arc-shaped rack, and the drilling fluid through hole is formed in the center of the gear; the lower end of the gear is fixedly connected with the telescopic column, the tail end of the telescopic column is fixedly connected with the three-hole flat plate, PDC (polycrystalline diamond compact) blades and the cones are arranged at the lower end of the bit body simultaneously, and the PDC blades are evenly arranged in the circumferential direction of the outer wall of the bit body; the telescopic column drives the cones on the three-hole flat plate to axially penetrate through the central groove, and axial movement of the cones is realized. According to the compound bit, the drilling fluid flow is controlled actively, so that the rock breaking efficiency is substantially improved, the drilling cycle is shortened, and the drilling cost is reduced.

Owner:SOUTHWEST PETROLEUM UNIV

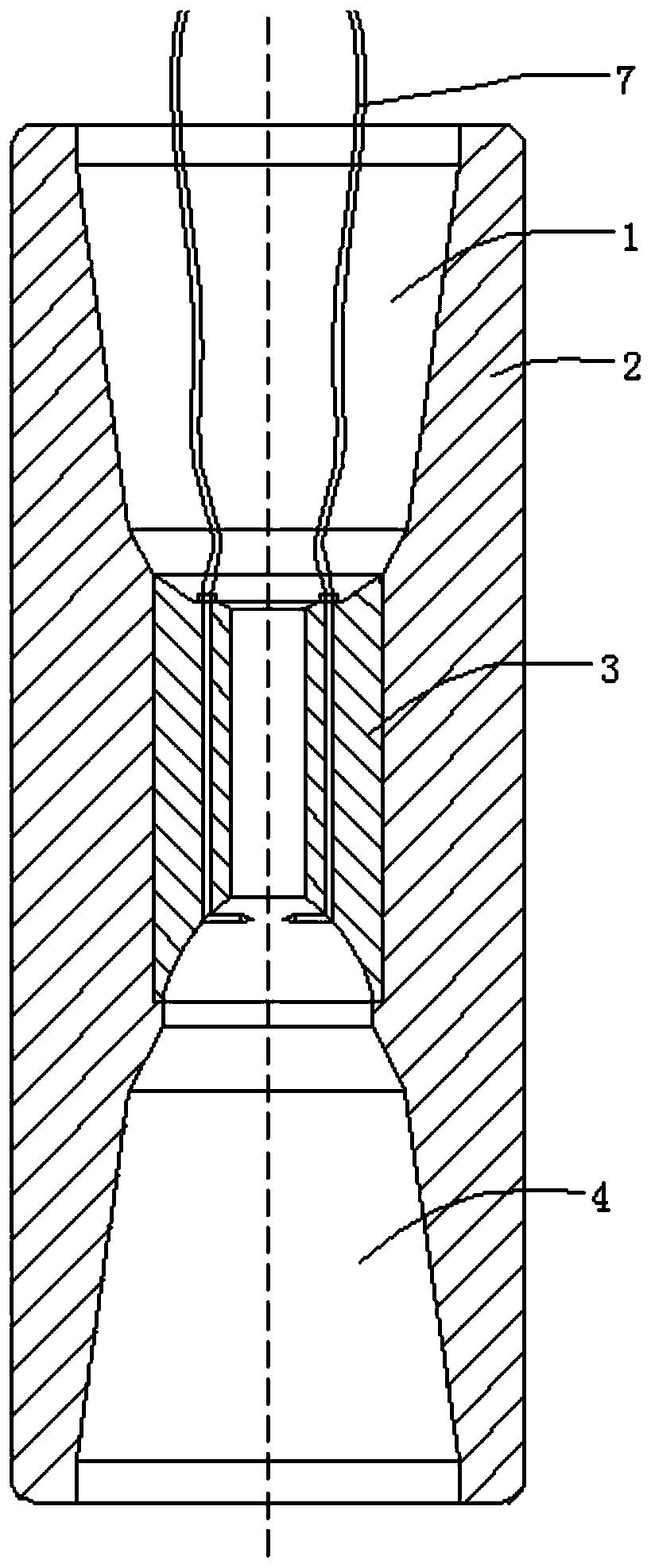

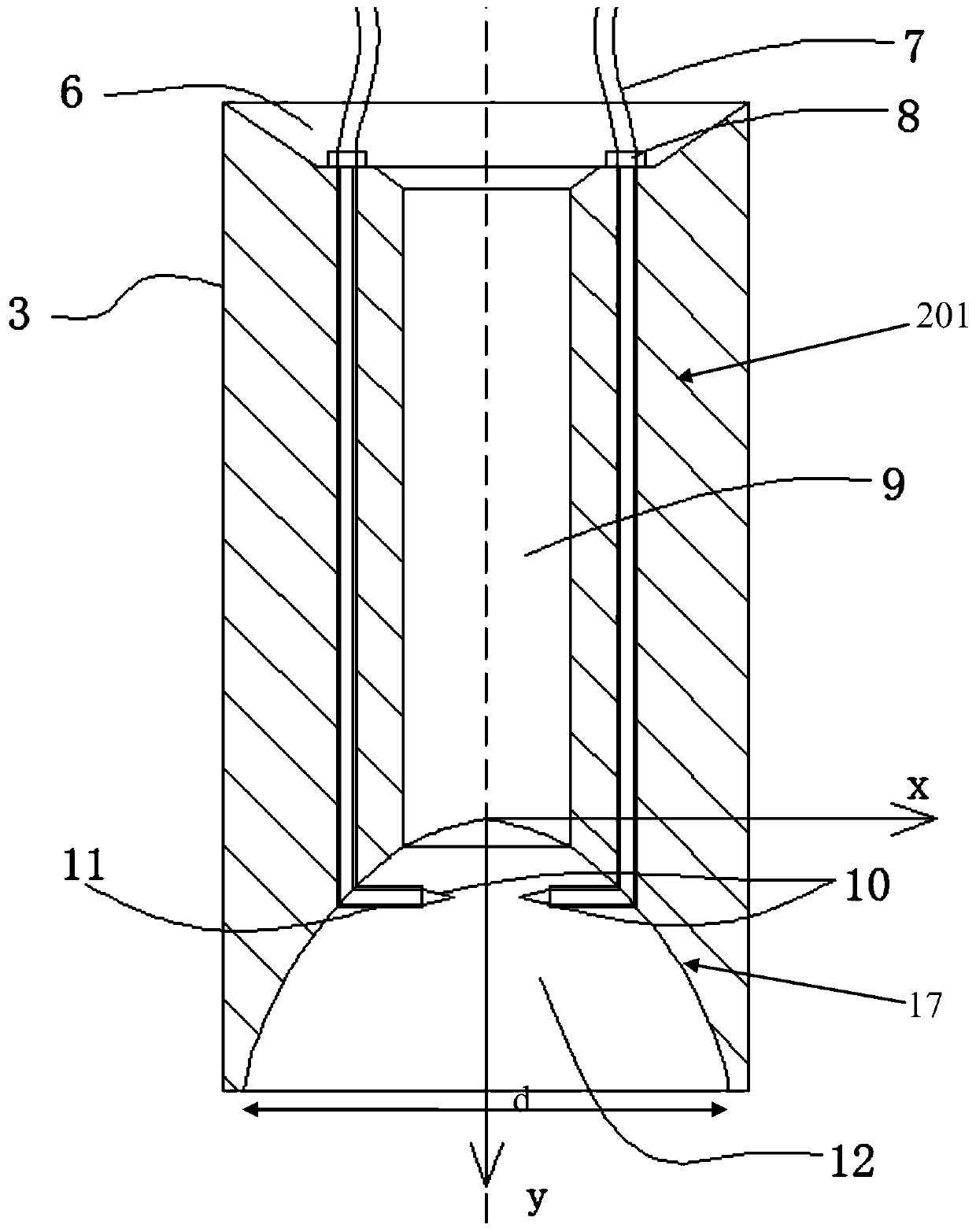

Liquid-phase discharge shock wave drilling device

InactiveCN110552616AImprove stress conditionReduce the "holding effect"Liquid/gas jet drillingDirectional drillingShock waveElectricity

The invention discloses a liquid-phase discharge shock wave drilling device. The device comprises a shell provided with a fluid inlet section and a fluid outlet section, wherein a liquid-electricity pulse generator is arranged in the shell, and comprises a hollow body, a central flowing channel is formed in the middle of the body, a diversion opening is formed in the upper part of the body, a fluid outlet, a first electrode and a second electrode are formed at the lower part of the body, an electrode gap is formed between the two electrodes, the middle point of the electrode gap is located right below the central flowing channel, a rotary parabolic cavity is formed at the fluid outlet, a rotary parabolic cavity cross section parabola is formed in the section of the rotary parabolic cavity,and a parabolic vertex serves as an origin, the central axis of the shell serves as a y axis, the line which is perpendicular to the central axis of the shell serves as an x axis, the parabolic equation is that y equals a*2, wherein a is a constant. According to the device, the rock breaking can be assisted, and the drilling cost is saved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Central rotary jetting pulse internal-grinding drilling bit

InactiveCN106285491AImprove efficiencyReduce power consumptionDrill bitsConstructionsThroatResonant cavity

The present invention discloses a central rotary jetting pulse internal-grinding drilling bit. Different from a conventional PDC drilling bit, the central rotary jetting pulse internal-grinding drilling bit is added with a pulse generating device, a central rotary jetting rock breaking device, a negative pressure swabbing device, and a rock cuttings internal-grinding device. The pulse generating device comprises a drilling fluid flow channel, a feeding cavity, a resonant cavity, a resonant tube outlet, and a diverging area, and based on an organ pipe, generates pulse jets by exciting fluid resonance. The central rotary jetting rock breaking device comprises a down-jet bypass flow channel, a down-jet central self-rotating flow channel, a central self-rotating nozzle, and a blade; and based on mutual coordination between the down-jet bypass flow channel and the self-rotating nozzle, the rock breaking and rock clearing efficiency is improved. The negative pressure swabbing device comprises a reverse high-speed flow channel, and a swabbing cavity; negative pressure is formed in the swabbing cavity based on the high-speed characteristic of reverse jets to swab rock cuttings, and the cuttings hold-down effect is reduced. The rock cuttings internal-grinding device comprises a mixing cavity, a throat, an accelerating cavity, an internal-grinding cavity, an internal-grinding body, a bypass, and a dispersing cavity, and is used for breaking rock cuttings based on a high pressure acting force and a water-wedge effect; the cuttings carrying efficiency is improved; and a cuttings bed is cleaned.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

High-temperature abrasive jet drilling system and drilling method

ActiveCN111305755AHigh degree of non-uniform heatingIncrease heatBlast gunsThermal drillingThermodynamicsMicrowave

The invention relates to a high-temperature abrasive jet drilling system and a drilling method, and belongs to the field of petroleum exploration and development. The system consists of a ground pumpset, a microwave generating device, a coiled tubing, a waveguide tube, a microwave antenna, a heating cavity, a temperature sensor, a pressure sensor, a high-temperature abrasive jet device and the like. According to the drilling method, the actions of abrasive jet and rock thermal cracking are taken into comprehensive consideration, and high-temperature abrasive jet acts on shaft bottom rocks inconjunction with the principle of microwave heating, thereby realizing efficient rock breaking. Through the adoption of the method, the problems of the low rate of penetration, short service life of adrill bit, the poor rock breaking effect and the like for deep hard formation and high abrasiveness formation in the existing conventional drilling technology are solved, and strong support is provided for the efficient development of the deep oil and gas resources in China.

Owner:CHINA PETROLEUM & CHEM CORP +1

Well bottom hydraulic suction pressure lowering drilling tool

A well drilling tool able to decrease the pressure at well bottom by hydraulic sucking for increasing the drilling efficiency is composed of drill bit and its short joint segment, low-pressure cavity, jet nozzle, jet cavity and sucking tube. A high-speed jet from said nozzle is generated by the difference between the pressures in drilling column and annular space to form a local low pressure near the nozzle outlet. A sucking tube is used to deliver the low pressure to well bottom.

Owner:SHENGLI PETROLEUM ADMINISTRATION BUREAU DRILLING TECH ACAD SINOPEC

Waterpower pulse cavitation jet well drilling device and drill bit

InactiveCN101105115BEnsure safetyReduce confining pressureDrill bitsLiquid/gas jet drillingCavitationWell drilling

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

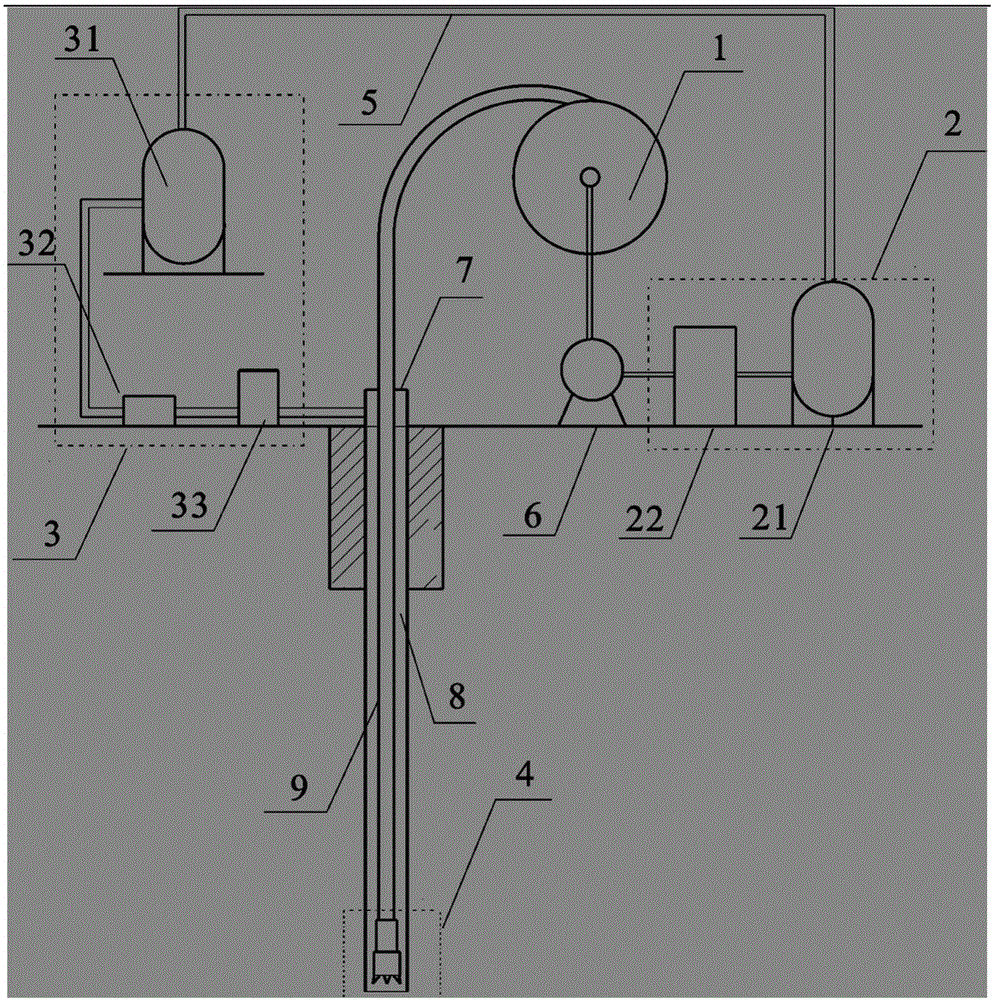

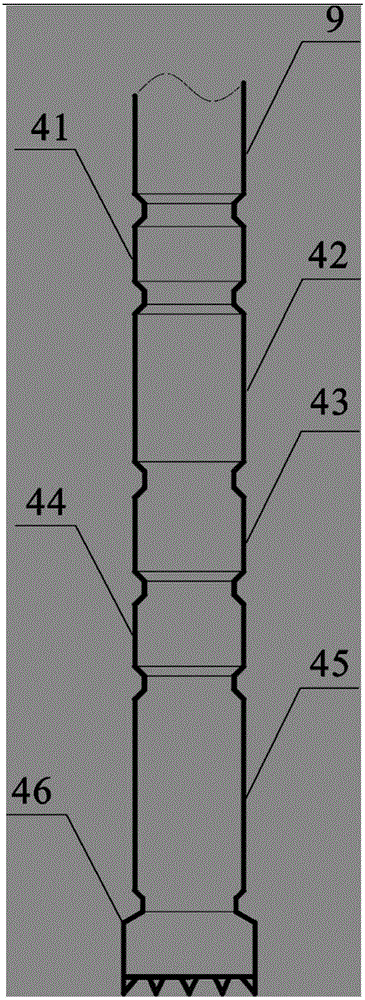

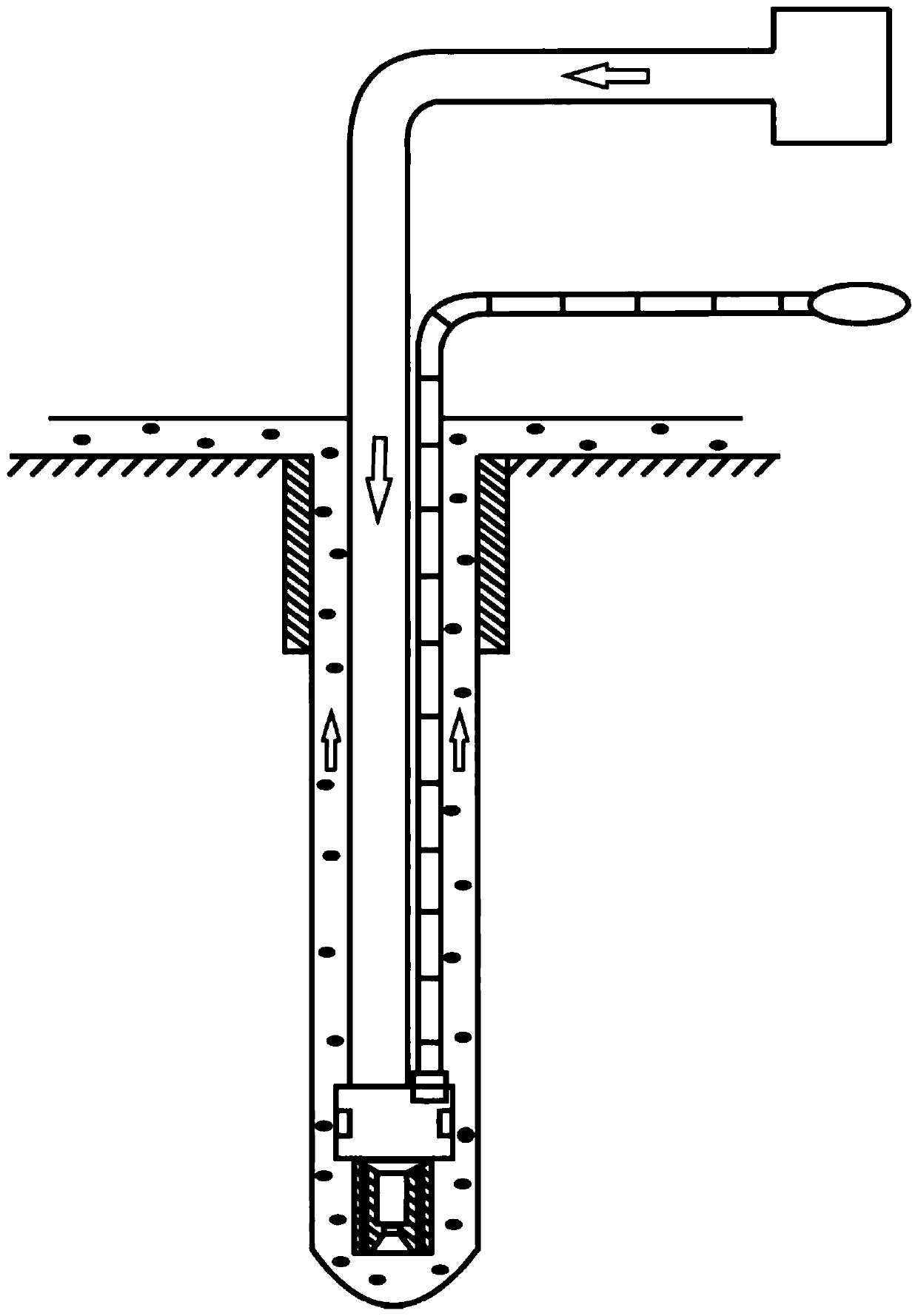

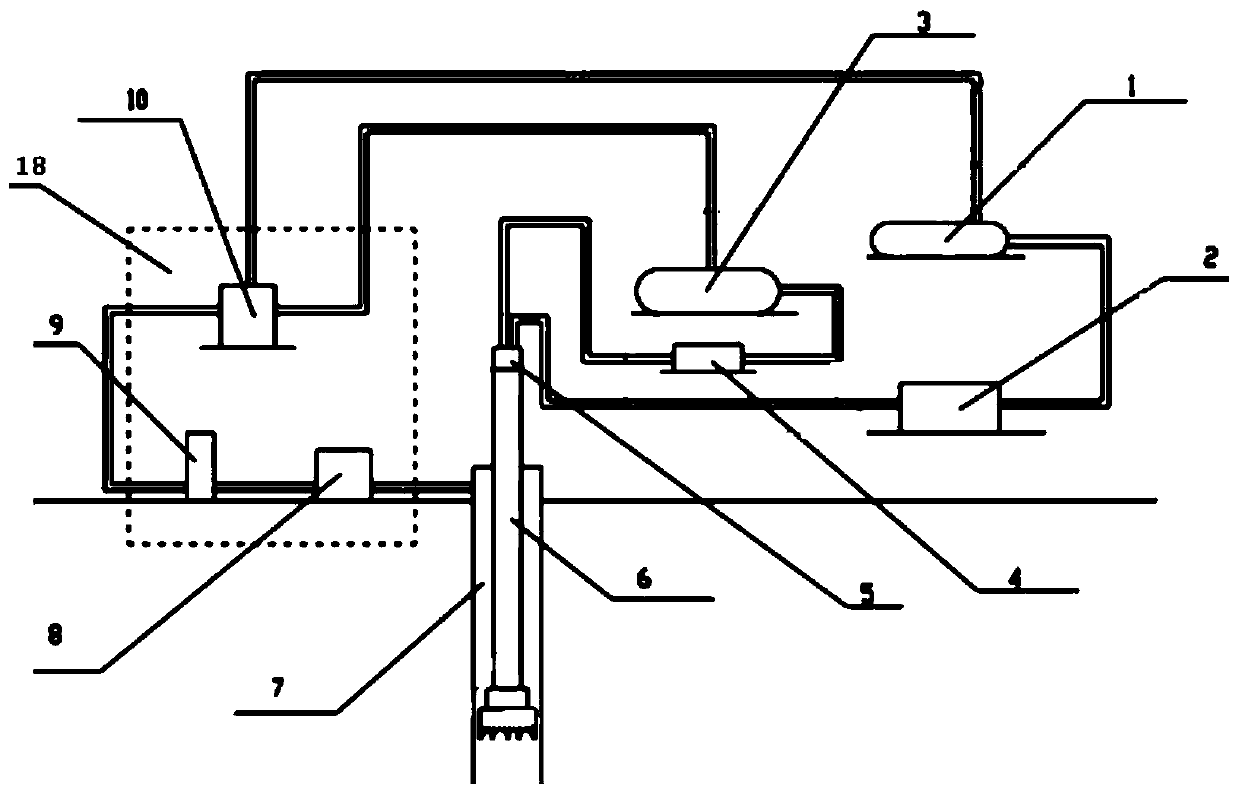

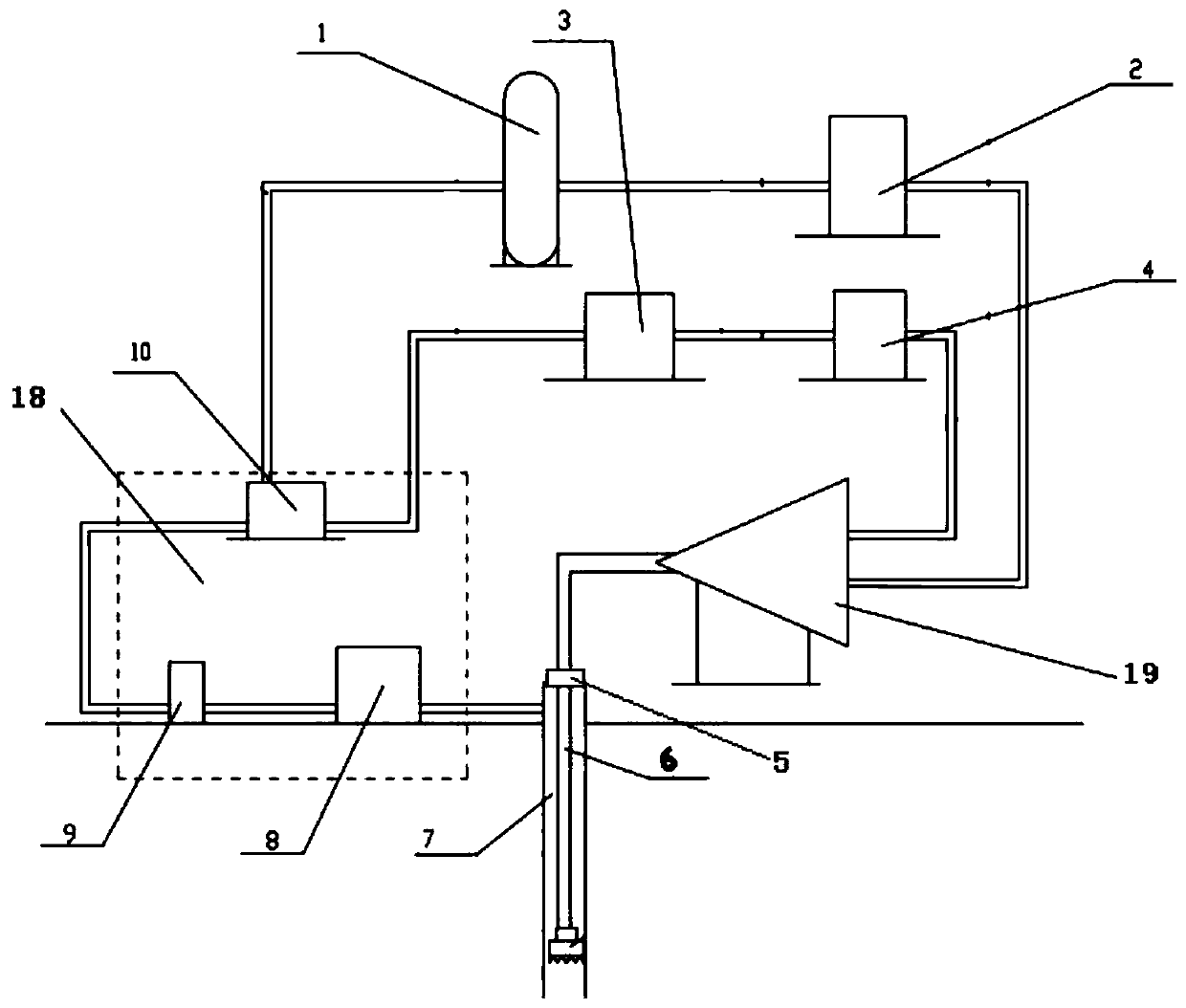

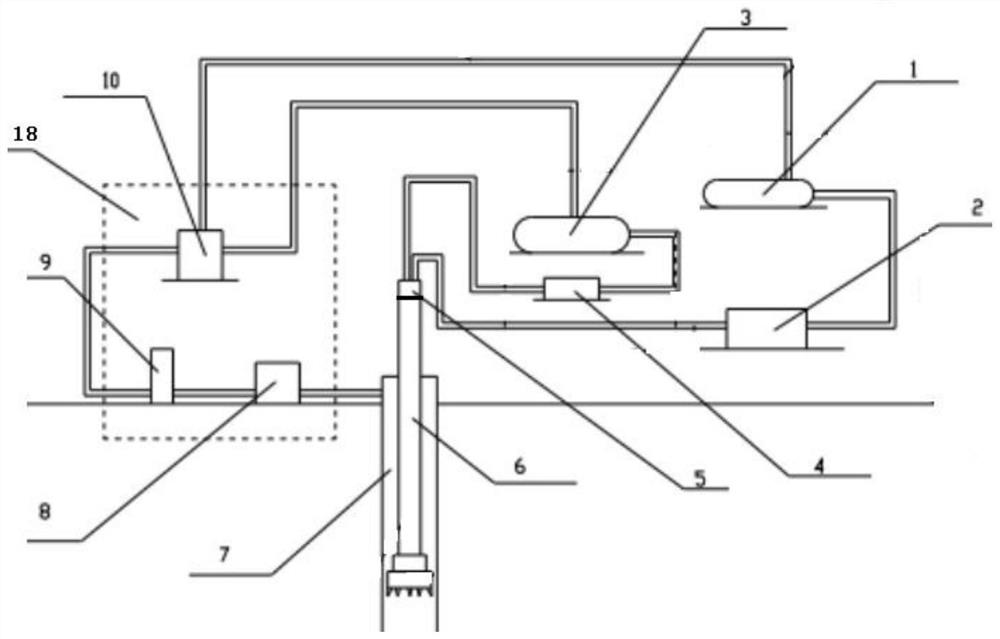

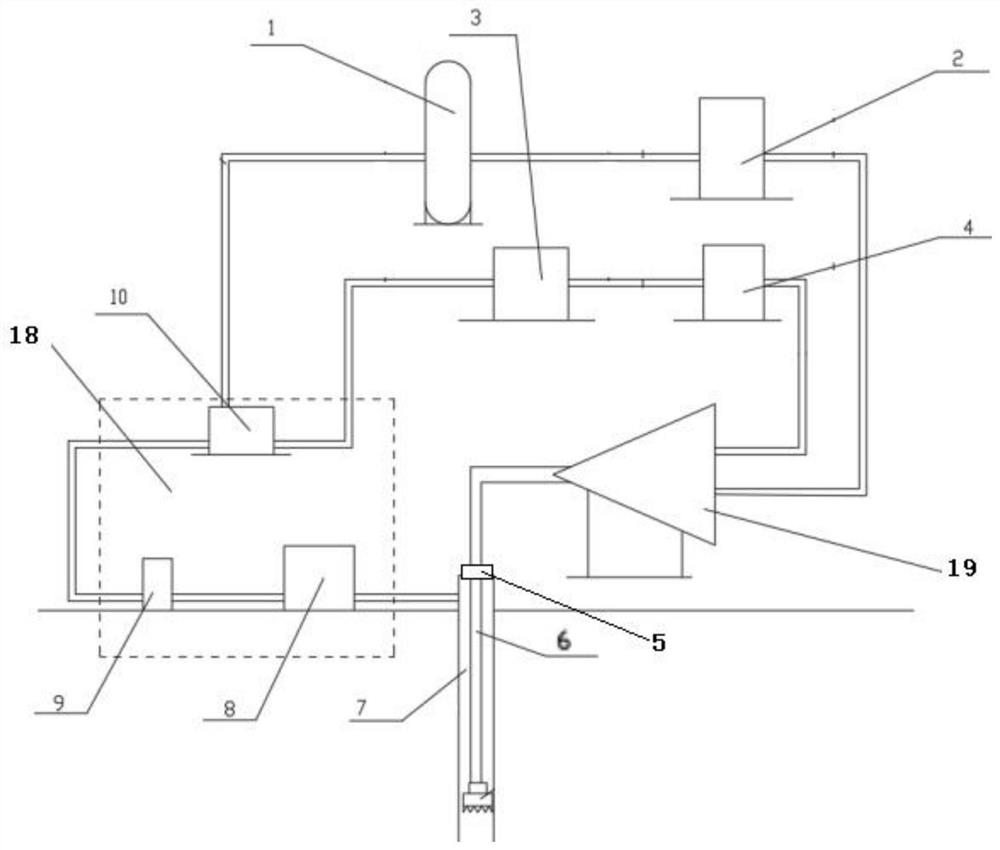

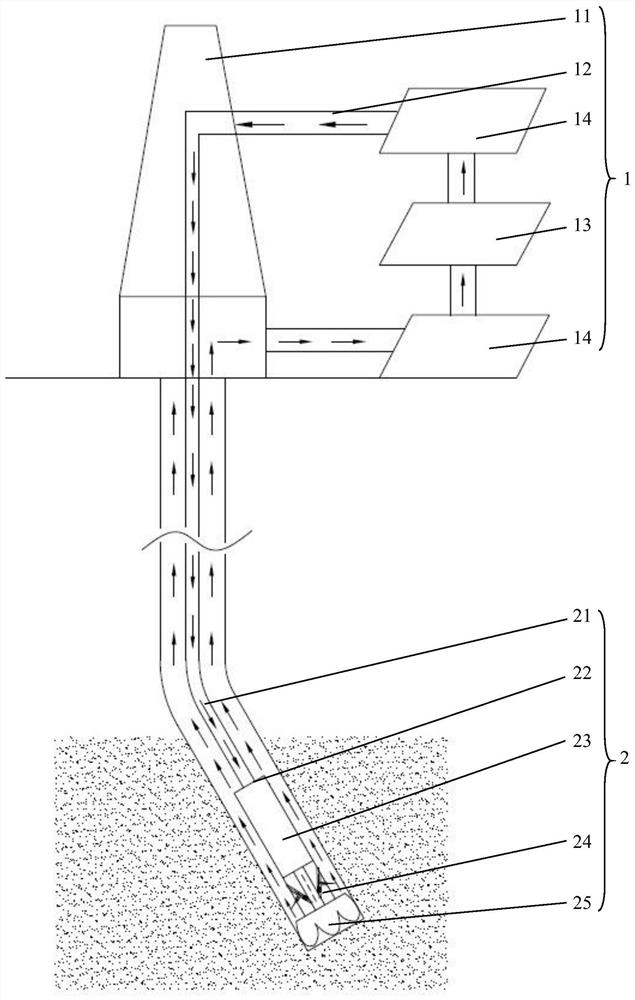

Dual-wall screw well drilling system based on gas-liquid two-phase drive

InactiveCN110344752AReduce thermal wearImprove continuous operation abilityConstructionsLiquid/gas jet drillingDirectional wellUniversal joint

A dual-wall screw well drilling system based on gas-liquid two-phase drive comprises a ground system, a well opening device and a downhole drilling tool assembly. The ground system comprises a gas storage and collection tank and a liquid storage and collection tank, wherein the gas storage and collection tank and the liquid storage and collection tank communicate with the well opening device through an air compressor and a liquid high-pressure pump correspondingly and then are connected with a gas-liquid two-phase flow recovery device. The gas-liquid two-phase flow recovery device comprises asand recover, a back-pressure valve and a ground gas-liquid separation device. The downhole drilling tool assembly comprises a dual arm drilling rod I connected with the well opening device. The lowerportion of the dual arm drilling rod I is sequentially connected with a short joint, a dual-wall screw motor, a universal joint, a downhole gas-liquid separation device I, a dual arm drill rod II anda drill bit. According to the dual-wall screw well drilling system, the problem that an air screw is prone to being damaged under a well can be reduced, the rock breaking efficiency can be improved,and therefore safe, rapid and economical well drilling can be achieved on a horizontal well and a directional well.

Owner:SOUTHWEST PETROLEUM UNIV

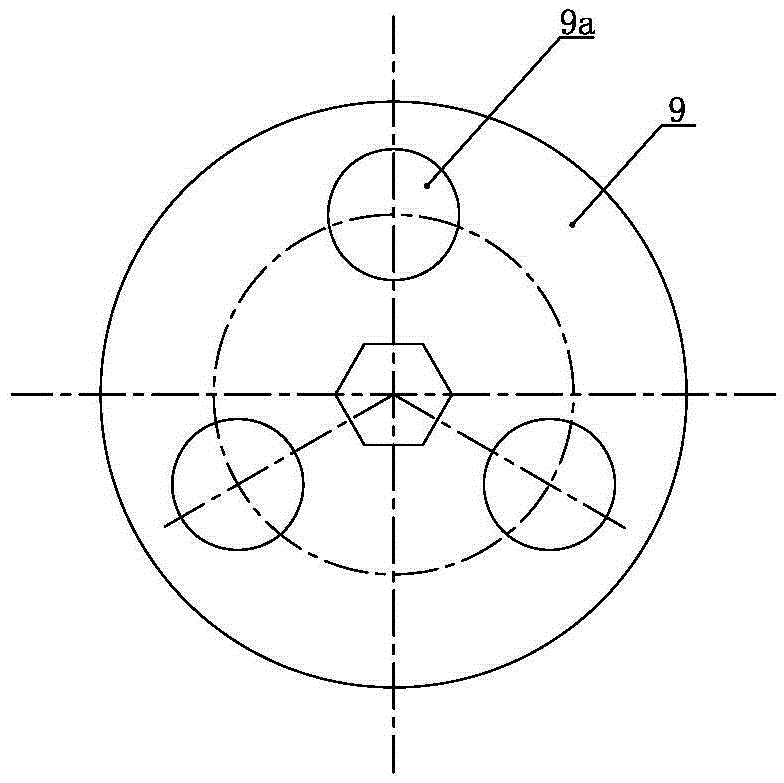

A Downhole Pulse Jet Drill Bit Device

The invention relates to an underground pulsing jet drill bit device. A double-end sleeve, a drill bit connector and a drill bit body are sequentially screwed; the upper end of the drill bit body is provided with a drill bit water cavity; a plurality of drill bit water holes are distributed in the bottom wall of the drill bit water cavity; all of the drill bit water holes are uniformly distributed by using the axial line as the center; each drill bit water hole downwards extends and is communicated with a corresponding spray hole formed in the lower end surface of the drill bit body; the center of the double-end sleeve and the center of the drill bit connector are provided with a center water passage communicated with the drill bit water cavity; a static valve disc is arranged on the bottom wall of the drill bit water cavity; static valve disc water holes are formed in the static valve disc; each static valve water hole has the same hole diameter as the drill bit water hole and is in one-to-one corresponding communication with the corresponding drill bit water hole; a movable valve disc capable of rotating around the axial line covers the static valve disc; at least one movable valve disc water hole is formed in the movable valve disc; and the movable valve disc water hole has the same hole diameter as the static valve disc water hole, and is positioned on the same circumference as the static valve disc water hole. The drill bit device has the advantages that the shaft bottom cleaning effect can be improved; and the hydraulic rock breaking capability can be improved.

Owner:CHINA PETROCHEMICAL CORP +2

Single-side rotational flow speed-increasing tool for drilling fluid of deep well drilling bottom

The invention relates to a single-side rotational flow speed-increasing tool for drilling fluid of the deep well drilling bottom. The single-side rotational flow speed-increasing tool is mainly composed of a liquid inlet, supporting rods, a helical impeller, V-shaped grooves, solid discharging injection ports and a liquid outlet. According to the tool, the problems of high density of the drilling fluid of the deep well drilling bottom, the serious pressure holding effect and the low mechanical drilling speed are solved. The concrete implementation process of the single-side rotational flow speed-increasing tool for the drilling fluid of the deep well drilling bottom comprises the following steps that when the drilling fluid flowing from top to bottom flows through the single-side rotational flow speed-increasing tool for the drilling fluid of the deep well drilling bottom, part of the drilling fluid directly flows out from the space out of the single-side rotational flow speed-increasing tool for the drilling fluid of the deep well drilling bottom, and the other part of the drilling fluid flows into the single-side rotational flow speed-increasing tool for the drilling fluid of the deep well drilling bottom from the liquid inlet. The high-pressure and high-speed drilling fluid impacts the helical impeller of the single-side rotational flow speed-increasing tool for the drilling fluid of the deep well drilling bottom to rotate in high speed, the helical impeller rotatably transports solid particles in the drilling fluid into the V-shaped grooves, and after collected the by the V-shaped grooves, the separated solid particles are injected out of drilling rods from the two upper and lower solid discharging injection ports. The tool can effectively reduce the pressure holding effect in the deep well bottom, the mechanical drilling speed is improved, and the cost is reduced.

Owner:CNPC DRILLING RES INST +1

Underground rotational flow solid-liquid separation well drilling speed increasing tool

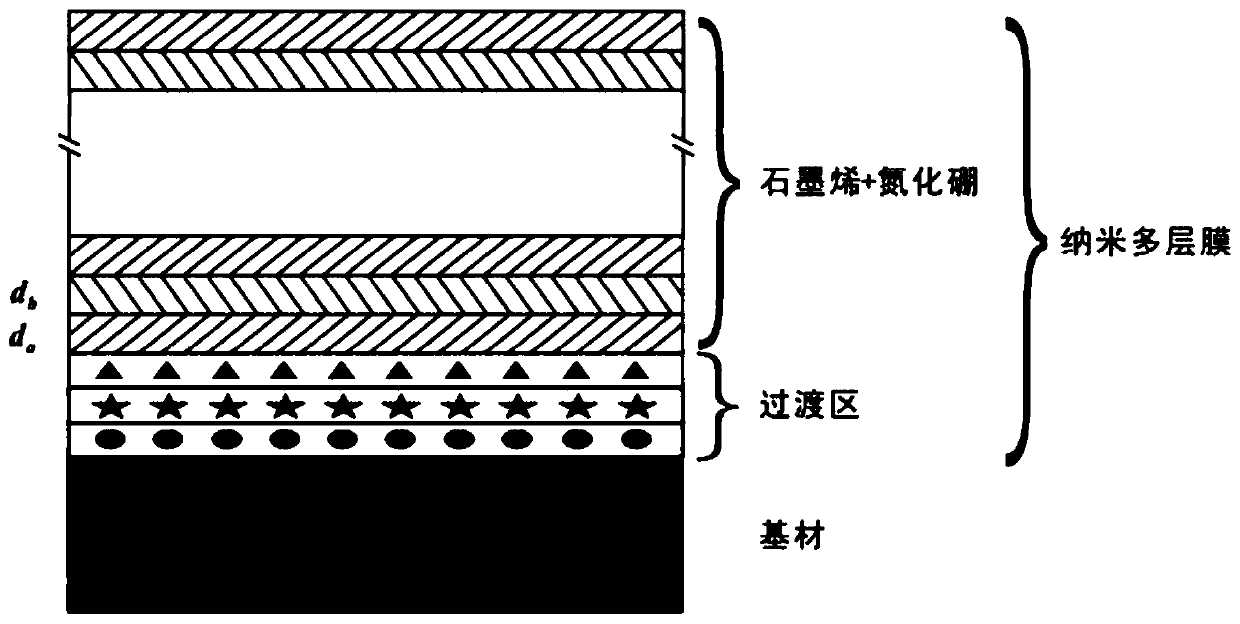

ActiveCN112282676AReduce pinch effectImprove cleaning effectDrill bitsCentrifugal force sediment separationPhysicsGeotechnical engineering

The invention belongs to the technical field of oil and gas drilling, and relates to an underground rotational flow solid-liquid separation well drilling speed increasing tool. A guide vane structureis utilized to generate a rotational flow field, a hydraulic rotational flow separation principle is utilized to realize solid-liquid separation of drilling fluid in the tool, and the solid content ofthe drilling fluid sprayed to the bottom of a well is decreased through the underground rotational flow separation effect. The chip hold down effect of the drilling fluid on well bottom rock debris is reduced, the clearing effect of the drilling fluid on the rock debris is improved, the rock breaking environment of a well bottom drill bit is improved, thus the well drilling speed is increased, the abrasion speed of the drill bit can further be reduced through the low-solid-content drilling fluid, and the service life of the drill bit is prolonged.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

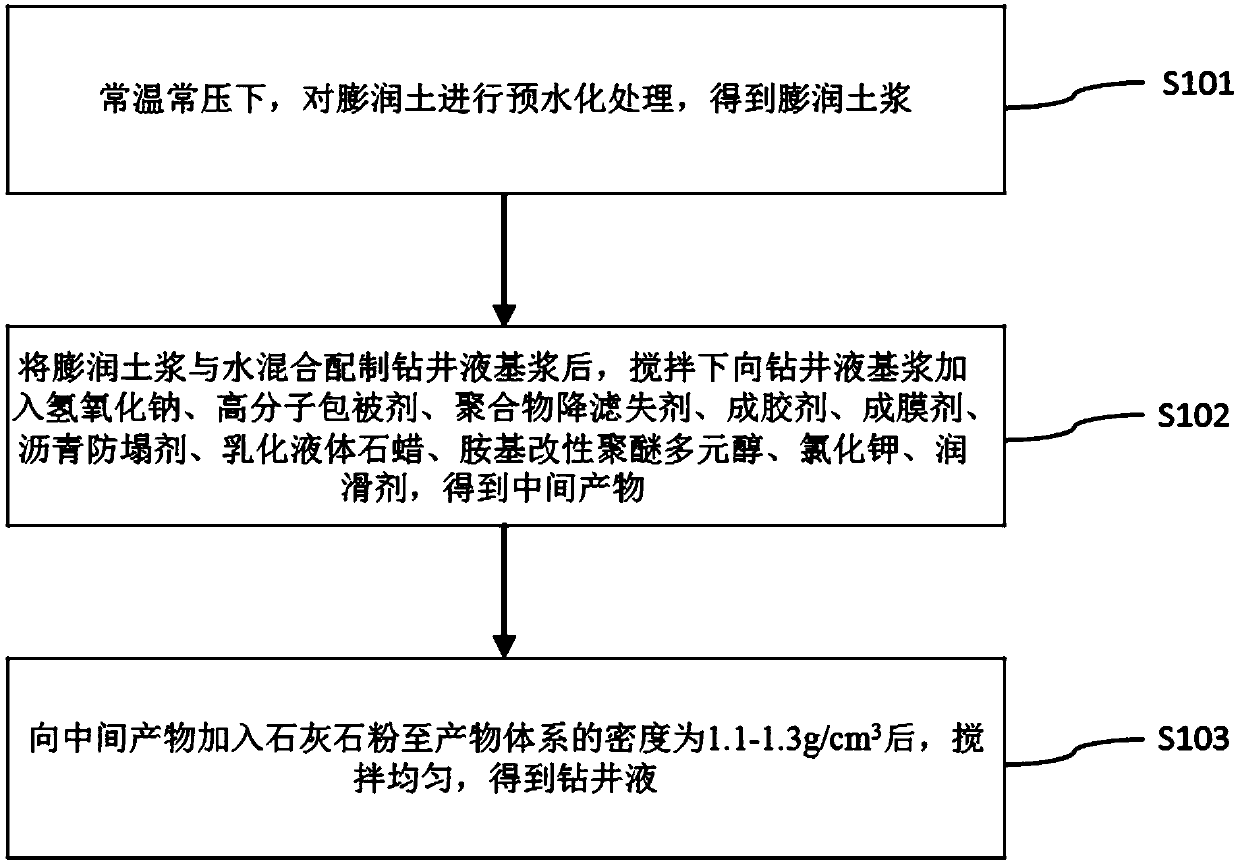

Drilling fluid as well as preparation method and application thereof

InactiveCN111087980ALow densityGood shear thinningDrilling compositionMaterials scienceSodium hydroxide

The invention provides a drilling fluid as well as a preparation method and application thereof. The drilling fluid is prepared from the following components in percentage by mass: 2-5% of bentonite,0.1-0.2% of sodium hydroxide, 0.2-0.9% of a polymer coating agent, 1-2% of a polymer filtrate reducer, 0.2-1% of a gelatinizing agent, 1-2% of a film-forming agent, 1-3% of an asphalt anti-collapse agent, 0.5-2% of emulsified liquid paraffin, 1-3% of amino modified polyether polyol, 3-7% of potassium chloride, 1-3% of a lubricant and 8-50% of limestone powder, and the balance being water. The density of the drilling fluid is 1.1-1.3 g / cm<3>. When the drilling fluid is used for drilling, the drilling speed can be increased, the purposes of stabilizing the wall of a shale stratum and reducing the pressing effect of rock debris can be achieved, and the drilling fluid is particularly suitable for drilling of a shale-containing stratum.

Owner:PETROCHINA CO LTD

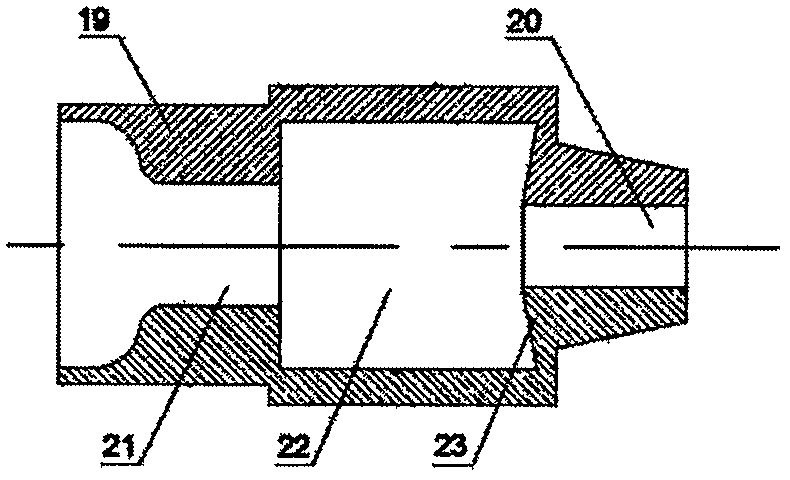

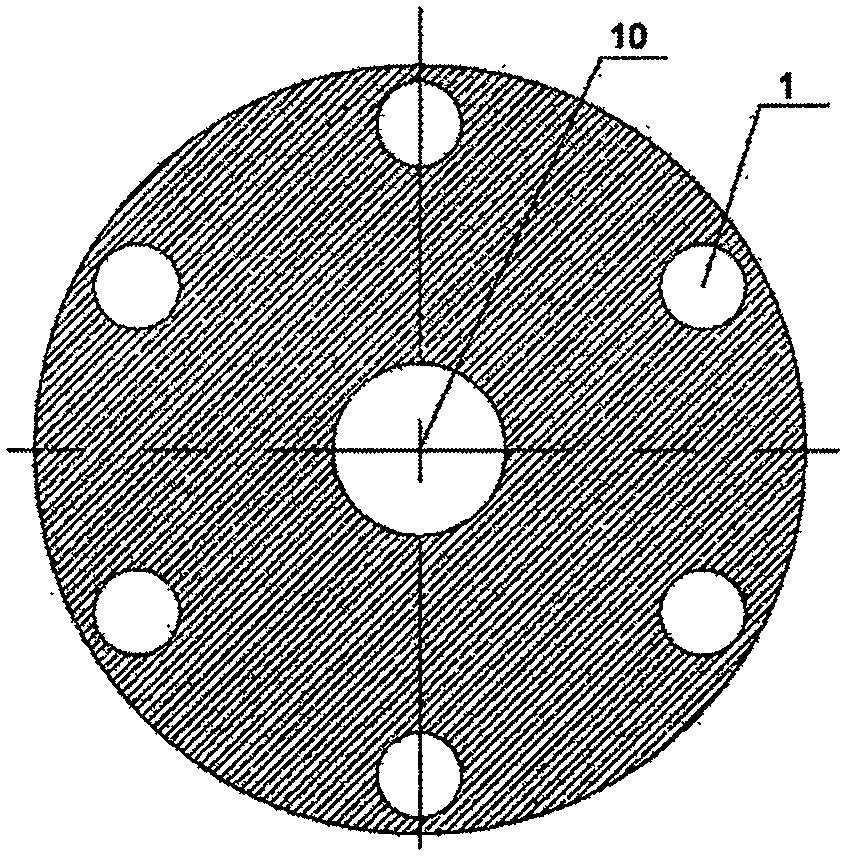

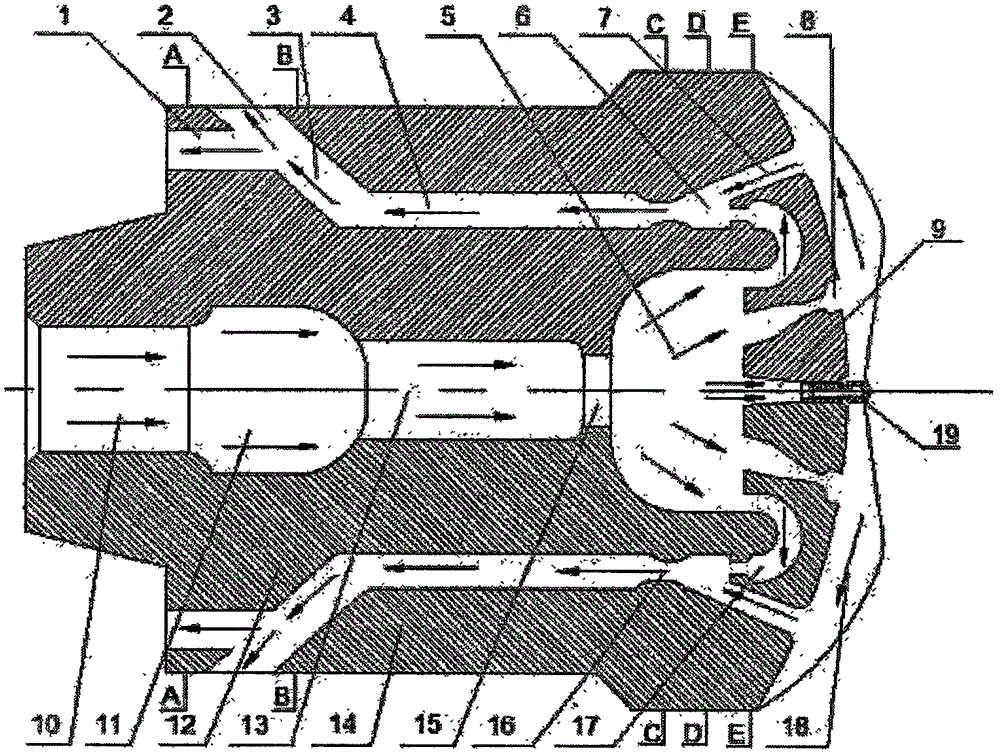

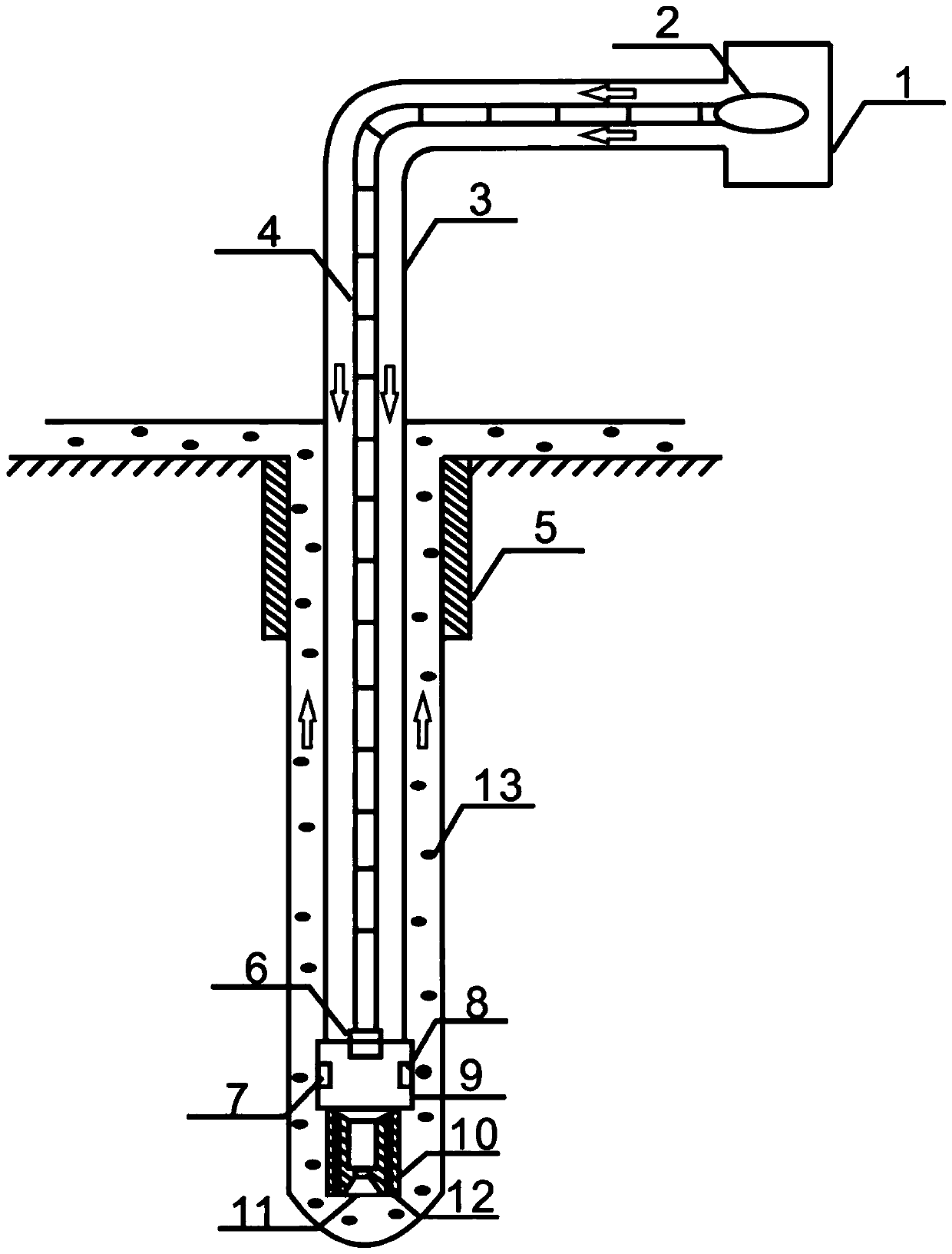

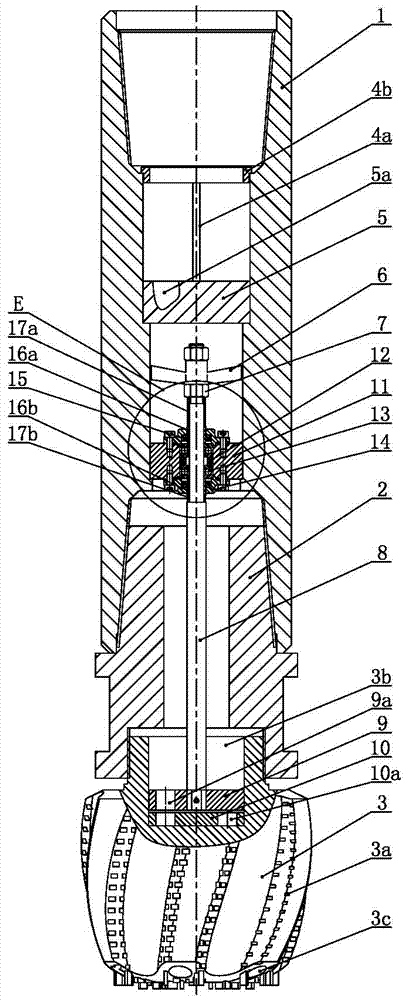

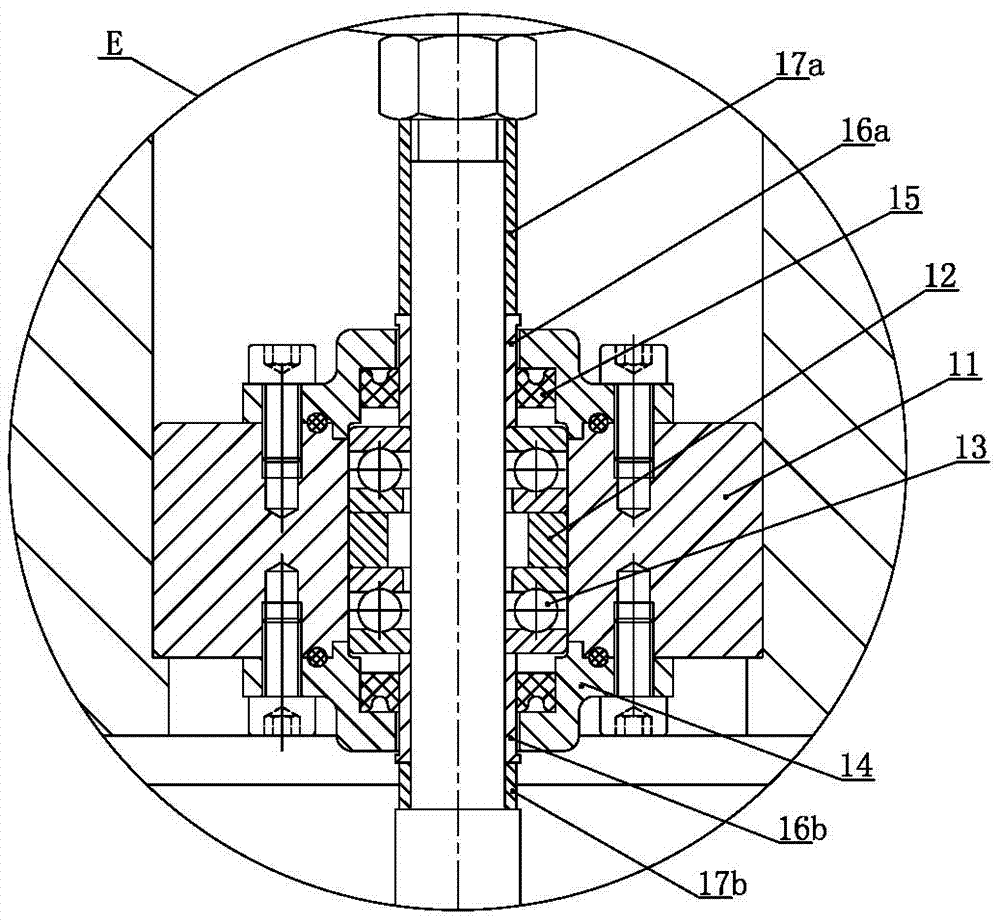

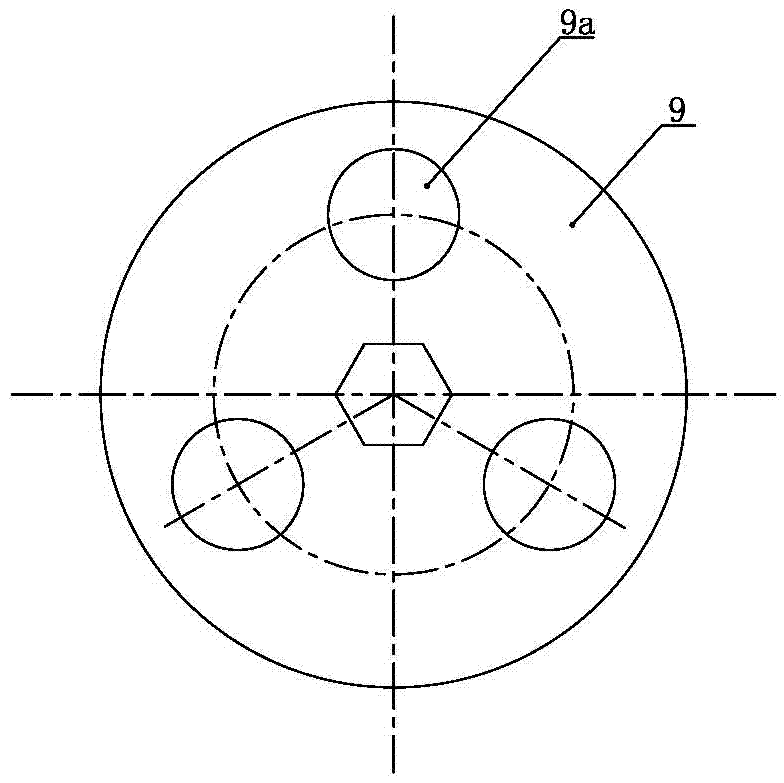

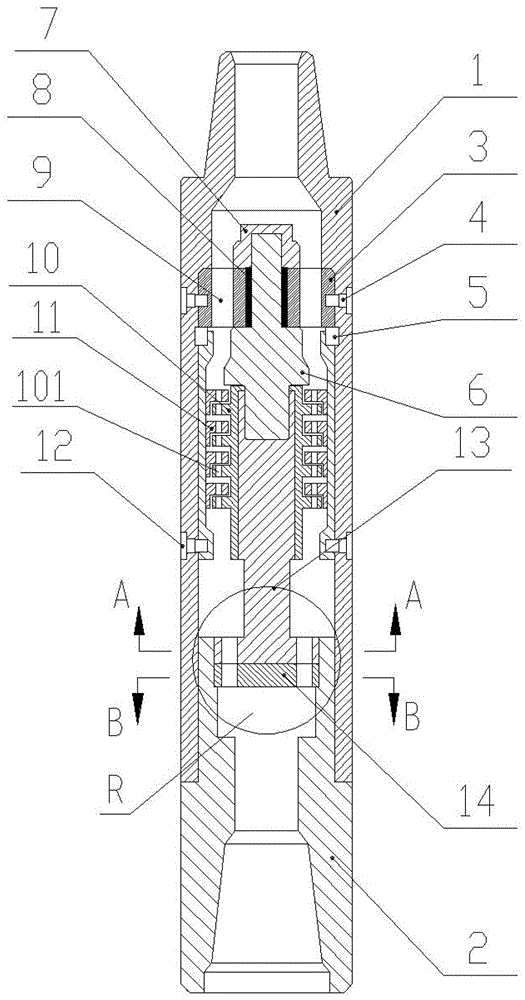

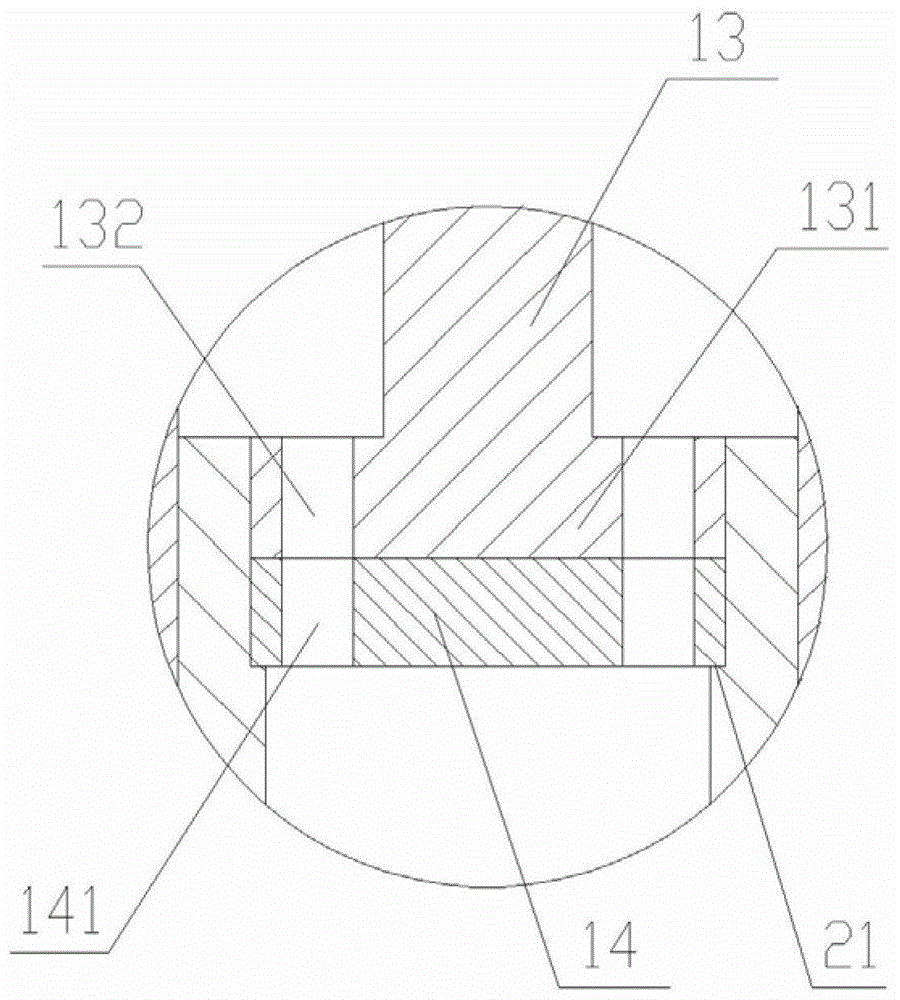

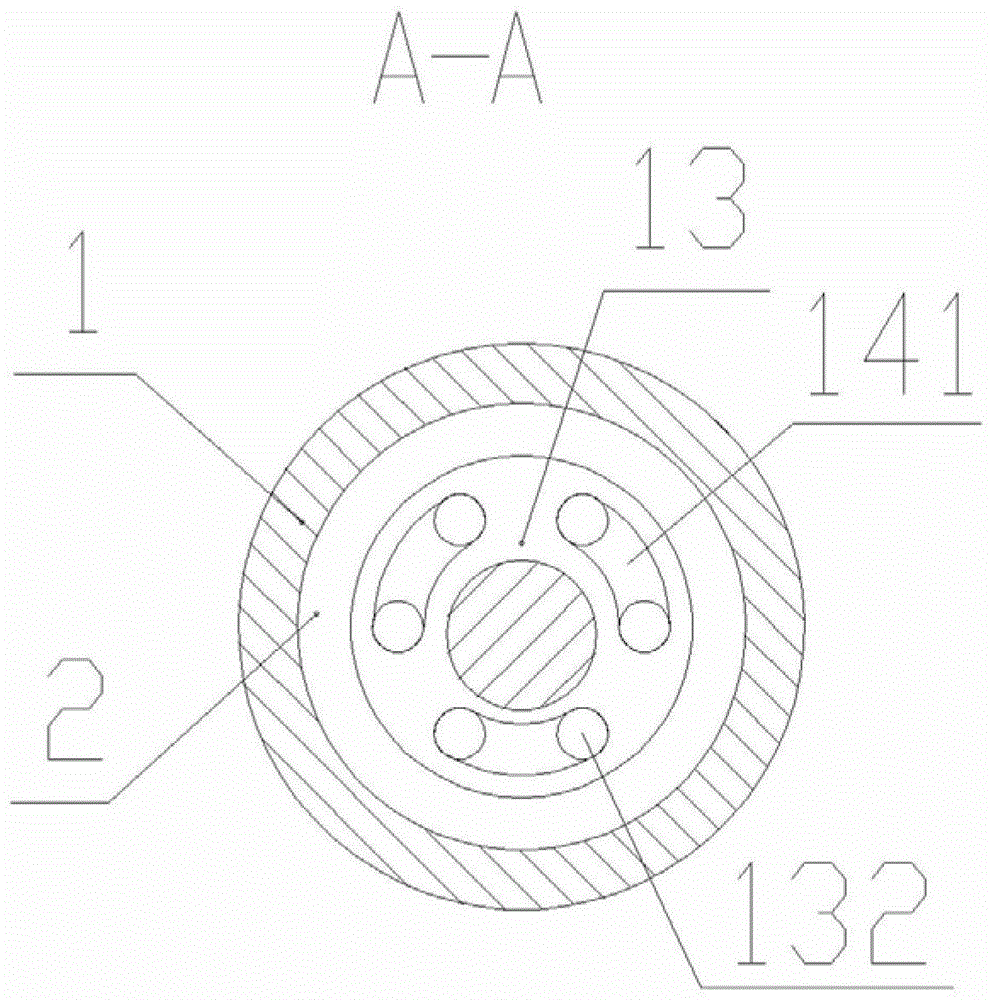

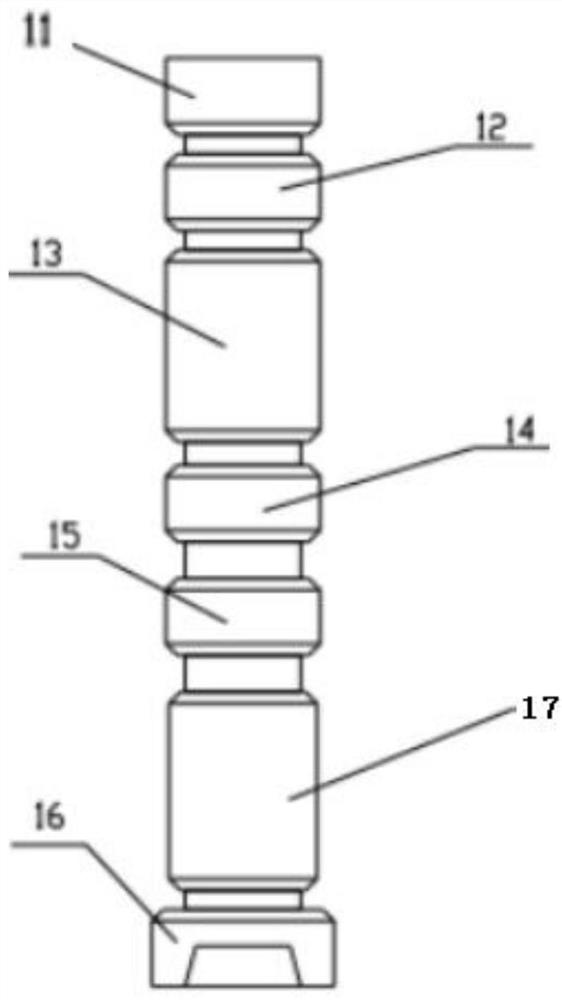

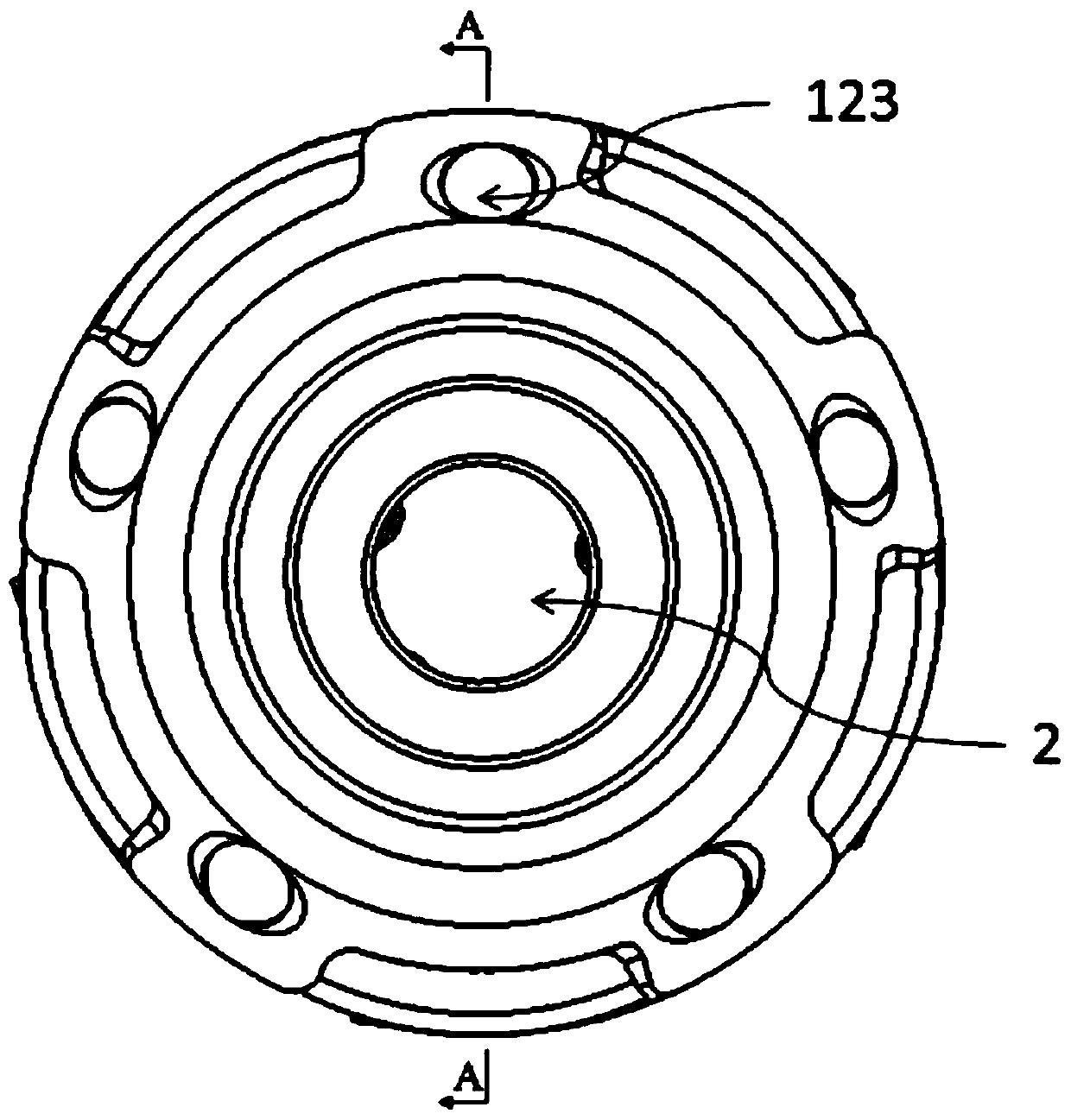

Downhole high frequency pressure pulse generator

The invention discloses an underground high-frequency pressure pulse generator. The underground high-frequency pressure pulse generator comprises a generator housing (1) and a bit short section (2); a connecting shaft (6) and a transmission shaft (13) are arranged inside the generator housing (1) in turn; a power drilling tool rotor (10) and a power drilling tool stator (11) which are matched with each other are arranged between the transmission shaft (13) and the generator housing (1); one end of the transmission shaft (13) is provided with a flange plate (131); a throttle plate (14) is arranged to be closely connected with the flange plate (131); the flange plate (131) is provided with a water hole (132); the throttle plate (14) is provided with a water channel (141). Compared with the existing drilling device, high-frequency pressure pulses are applied to a bit and accordingly the underground environment can be improved, the cuttings carrying capacity of the drilling fluid can be improved, the hold-down effect of the drilling fluid can be effectively reduced, and the drilling speed can be improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Double-wall screw drilling system based on gas-liquid two-phase drive

InactiveCN110344752BReduce thermal wearImprove continuous operation abilityConstructionsLiquid/gas jet drillingHorizontal wellsDirectional well

A dual-wall screw well drilling system based on gas-liquid two-phase drive comprises a ground system, a well opening device and a downhole drilling tool assembly. The ground system comprises a gas storage and collection tank and a liquid storage and collection tank, wherein the gas storage and collection tank and the liquid storage and collection tank communicate with the well opening device through an air compressor and a liquid high-pressure pump correspondingly and then are connected with a gas-liquid two-phase flow recovery device. The gas-liquid two-phase flow recovery device comprises asand recover, a back-pressure valve and a ground gas-liquid separation device. The downhole drilling tool assembly comprises a dual arm drilling rod I connected with the well opening device. The lowerportion of the dual arm drilling rod I is sequentially connected with a short joint, a dual-wall screw motor, a universal joint, a downhole gas-liquid separation device I, a dual arm drill rod II anda drill bit. According to the dual-wall screw well drilling system, the problem that an air screw is prone to being damaged under a well can be reduced, the rock breaking efficiency can be improved,and therefore safe, rapid and economical well drilling can be achieved on a horizontal well and a directional well.

Owner:SOUTHWEST PETROLEUM UNIV

Variable flute jet drill

The invention discloses a jet flow drill bit with a variable chip groove, and relates to the field of oil and gas well drilling. The jet flow drill bit comprises a body extending along an axis and provided with a runner; a cutting mechanism is arranged on the body and used for cutting rocks; a first jet flow nozzle communicating with the runner is arranged at the lower end of the body and used forjetting flows to the bottom of a well and flushing rock debris particles generated by the cutting mechanism; a chip groove extending in an axis direction is formed in the side wall of the body; a notch for accommodating a sealing plate is formed in the side wall of the body; a first channel communicating with the runner and the notch is formed in the body in the radial direction; a telescopic mechanism in transmission with the sealing plate is arranged in the first channel; and the telescopic mechanism can drive the sealing plate to move in the radial direction under the hydraulic action of the flow channel, so that the chip groove has a blocking state and a smooth state. The state of the chip groove can be changed according to the working state of the drill bit, so that the using effectof the jet drill bit is improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Under-pressure composite well drilling device and technology for deep high-temperature well

PendingCN113187384AReduce positive differential pressureExtend your lifeFlushingDrilling machines and methodsThermodynamicsWell drilling

The invention discloses an under-pressure composite well drilling device and technology for a deep high-temperature well. A ground drilling part comprises a drilling machine, a drilling fluid cooling system and drilling fluid circulating systems; an underground drilling tool part comprises a drill rod, a drill collar, a power assembly, a near-bit pressure reduction short section and a drill bit; the near-bit pressure reduction short section is provided with an annular channel; a plurality of suction flow channels are uniformly formed in the circumferential direction of the annular channel; sand mixing throat pipes communicating with the suction flow channels are arranged on the outer side wall of the near-bit pressure reduction short section in the circumferential direction; the outer side wall of the near-bit pressure reduction short section is further provided with pumping and suction flow channels; and the pumping and suction flow channels communicate with the nodes of the suction flow channels and the sand mixing throat pipes. According to the invention, the combined action of three modes of impact, rotation and thermal cracking is comprehensively utilized to destroy rocks at the bottom of a well, the near-bit pressure reduction short section generates local negative pressure in the annular channel at a near-bit position, and a drilling fluid which is just sprayed out of an energy-gathered nozzle to impact the bottom of the well and then carries rock debris to move up to the ground is sucked, so that the positive pressure difference at the bottom of the well is reduced, and the hold-down effect is reduced.

Owner:BEIJING INST OF EXPLORATION ENG

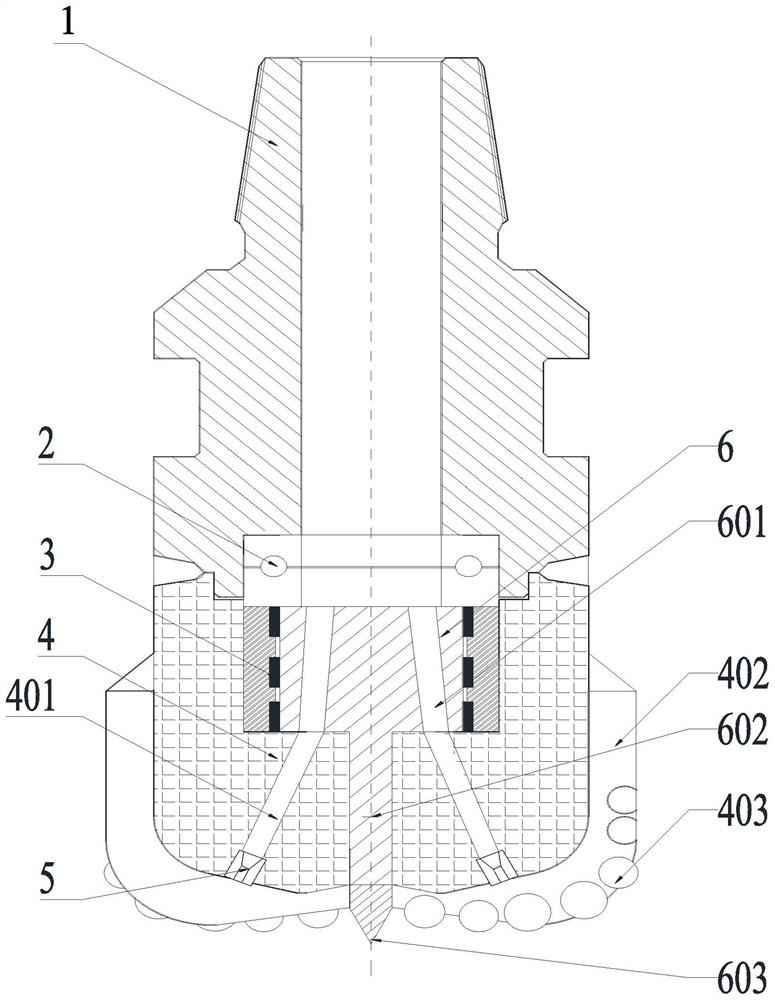

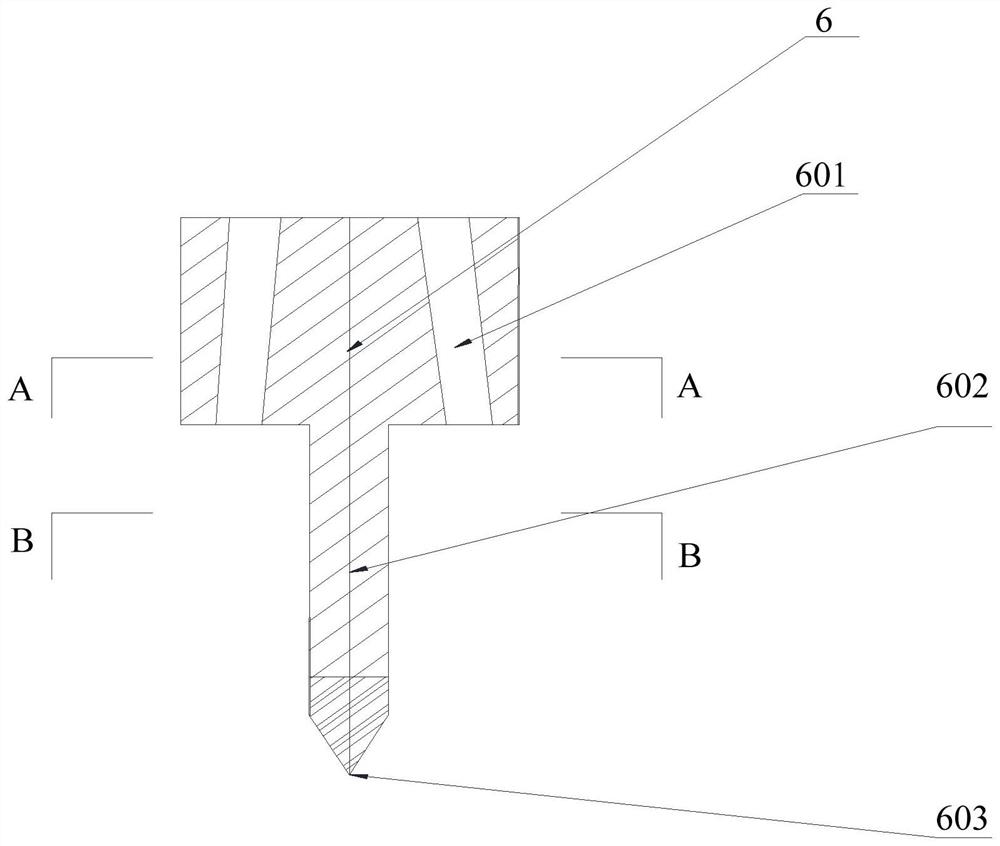

Drill bit based on central multi-edge tooth modulation pulse jet flow and drilling method thereof

PendingCN114753769AImprove rock clearing effectIncrease drilling speedDrill bitsLiquid/gas jet drillingJet flowEngineering

The drill bit comprises a drill bit connector, a drill bit crown part, a nozzle and a flow adjusting body, a blade is arranged on the outer side of the drill bit crown part, a plurality of cutting teeth are arranged on the blade, and the drill bit connector and the drill bit crown part jointly form a hollow channel. The flow adjusting body is supported in the hollow channel, the end of the flow adjusting body protrudes out of the drill bit crown, the part, protruding out of the drill bit crown, of the flow adjusting body is a center press-in rock crushing tooth, a drill bit flow channel communicated with the hollow channel is formed in the drill bit crown, and a flow adjusting body overflowing hole is formed in the flow adjusting body. The top end of the flow adjusting body overflowing hole is communicated with the hollow channel in the drill bit connector, the bottom end of the flow adjusting body overflowing hole can be communicated with the drill bit flow channel when the flow adjusting body rotates, and a nozzle is installed at the bottom end of the drill bit flow channel. According to the drill bit for modulating the pulse jet flow based on the center multi-edge tooth, the pulse jet flow is generated on the premise that no other tools are connected, the aim of improving the well bottom rock cleaning effect is achieved, and the drilling speed is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Drilling system and method for improving drilling efficiency in permafrost

InactiveCN106401463BImprove rock breaking efficiencyIncrease drilling speedIce drillingInsulationDecompositionHydrate decomposition

The invention discloses a drilling system and method for improving tundra drilling efficiency. The drilling method comprises the following steps of: adopting a downward drilling pipe column, starting a nitrogen gas compressor and a high-pressure pump unit; pumping liquid nitrogen into a shaft from a continuous oil pump, providing power to an underground motor, cutting shaft-bottom rocks by a PDC drill bit, and starting drilling operation; spraying out the liquid nitrogen through a spray nozzle of the drill bit to form liquid nitrogen jet flow which is matched with cutting of the PDC drill bit; upwards returning and circulating nitrogen gas along with rock debris to ground along an annular space, and recycling through a sand remover, a back pressure valve and a gas purifier; and drilling to a target layer, thereby completing drilling operation. Liquid-nitrogen fracturing effect is beneficial for expanding cracks generated inside rocks, so that rock breaking efficiency is effectively improved; the temperature of liquid nitrogen is extremely low, and liquid nitrogen is vaporized to absorb heat in an upward return process, so that decomposition of natural gas hydrates is effectively restrained, a well wall is kept stable, and underground complexity is prevented; and in an operation process, liquid nitrogen is recycled, so that the process is simple, is economical and is good in field applicability.

Owner:SOUTHWEST PETROLEUM UNIV

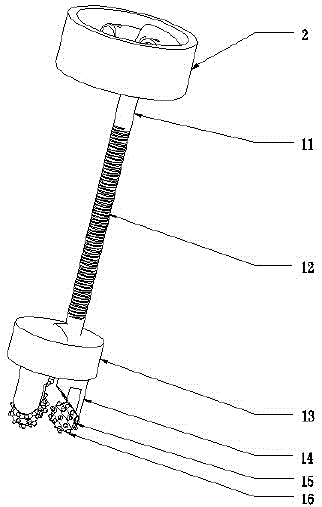

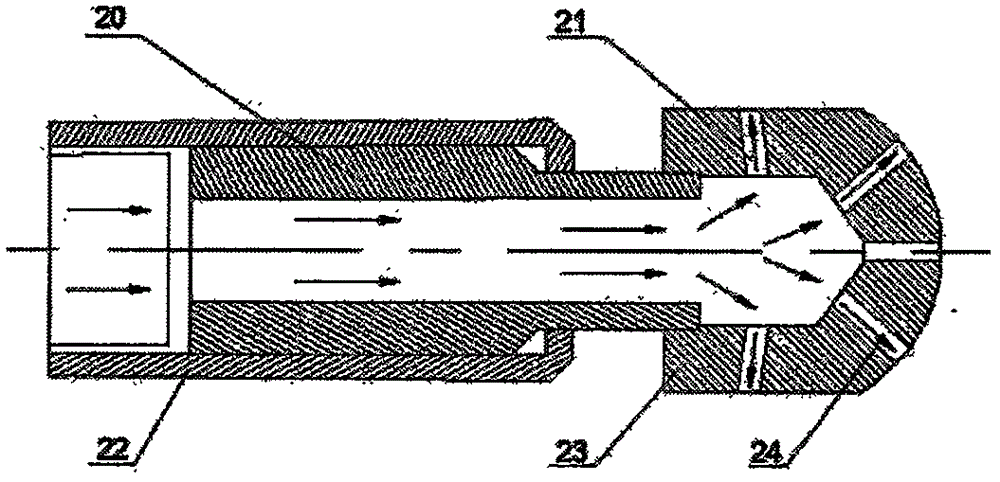

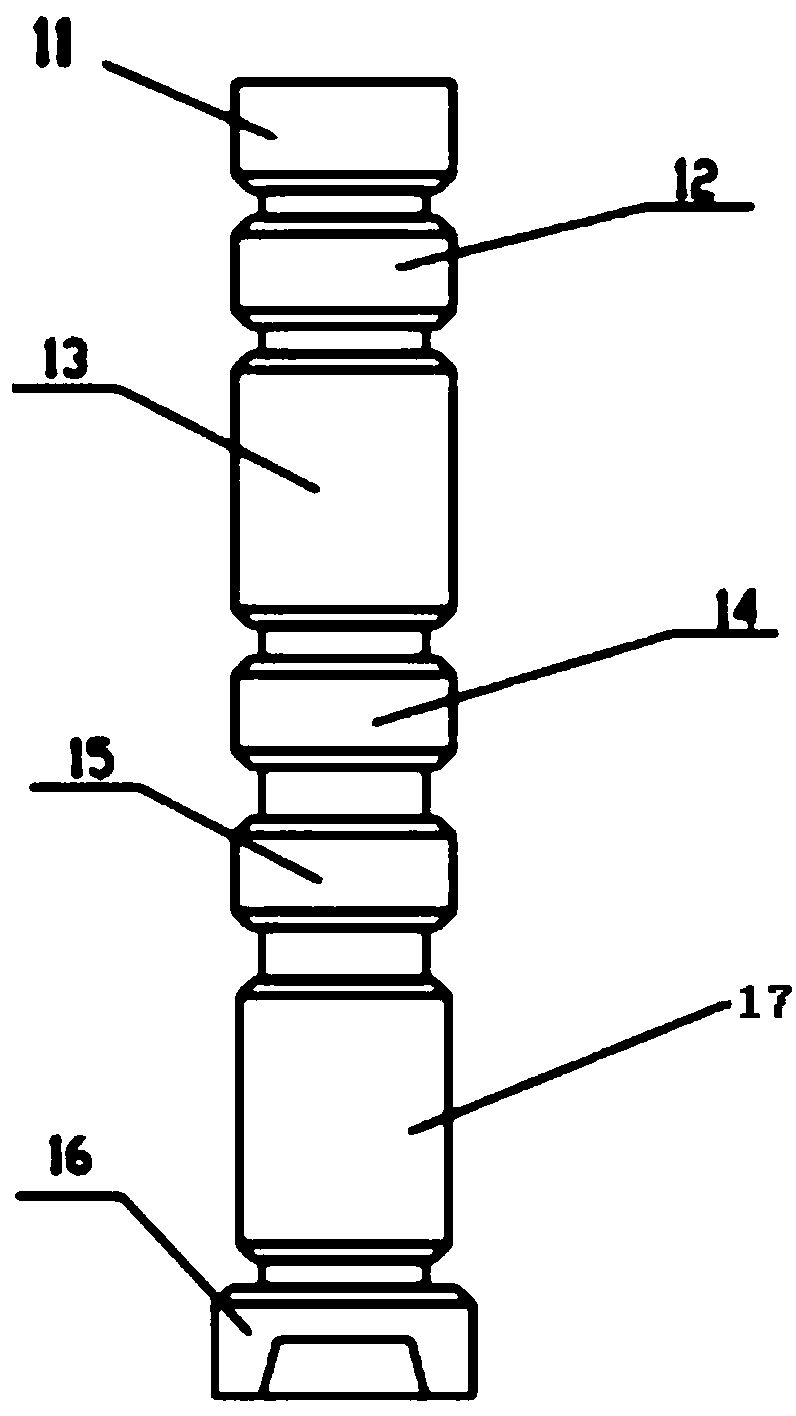

Near the drill bit local buck short

ActiveCN104481433BReduce local pressureReduce differential pressureDrilling rodsFlushingWell drillingSpiral blade

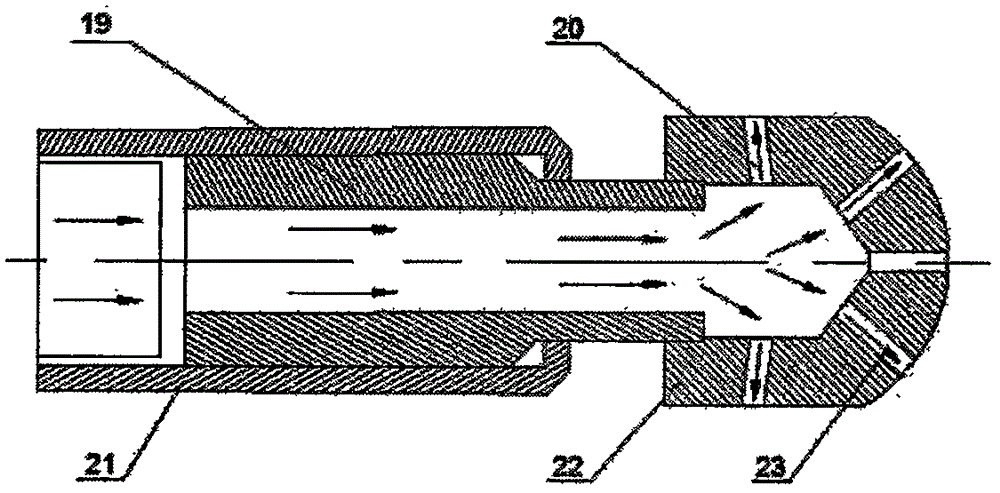

The invention provides a near-bit local pressure reduction short joint which sequentially comprises an upper connector, a spiral rising flow generator and a lower connector from top to down. A first torque transfer block is fixedly connected inside the upper connector, and a second torque transfer block is fixedly connected inside the lower connector. The spiral rising flow generator comprises a transmission mandrel, a rotary outer sleeve and spiral blades, wherein the upper end of the transmission mandrel penetrates through and is fixed to a first torque transfer through hole formed in the first torque transfer block, the lower end of the transmission mandrel penetrates through and is fixed to a second torque transfer through hole formed in the second torque transfer block. A spiral section is arranged in the middle of the transmission mandrel and is sleeved with the rotary outer sleeve, and a screwing hole is formed in the rotary outer sleeve. The spiral blades are arranged on the outer wall of the rotary outer sleeve. The near-bit local pressure reduction short joint effectively reduces well bottom pressure difference, reduces hold-down effect and rock breakage strength and improves well drilling speed. In addition, the near-bit local pressure reduction short joint is simple in structure, convenient to use, safe and reliable.

Owner:PETROCHINA CO LTD

Near drill local low pressure drilling tool

A well drilling tool able to generate local low pressure near the drill bit for increasing drilling speed is composed of commutating jointer, internal tube, casing, slide valve with spring, and limited blocking head. It features that the channel of drilling liquid is periodically blocked to generate negative pressure and the negative pressure is delivered to well bottom.

Owner:SHENGLI PETROLEUM ADMINISTRATION BUREAU DRILLING TECH ACAD SINOPEC

Near drill local low pressure drilling tool

InactiveCN100343472CReduce crush strengthReduce manufacturing costDrill bitsWell drillingEngineering

A well drilling tool able to generate local low pressure near the drill bit for increasing drilling speed is composed of commutating jointer, internal tube, casing, slide valve with spring, and limited blocking head. It features that the channel of drilling liquid is periodically blocked to generate negative pressure and the negative pressure is delivered to well bottom.

Owner:SHENGLI PETROLEUM ADMINISTRATION BUREAU DRILLING TECH ACAD SINOPEC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com