Active rotary telescopic compound bit applicable to deep difficult-to-drill hard formation

A composite drill bit and hard formation technology, applied in drill bits, drilling equipment, earthwork drilling, etc., can solve the problems of restricting exploration and development, high drilling costs, frequent tripping and other problems, so as to improve drilling rock breaking efficiency and shorten drilling. The effect of improving cycle and rock breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The invention is further described in conjunction with accompanying drawings and embodiments:

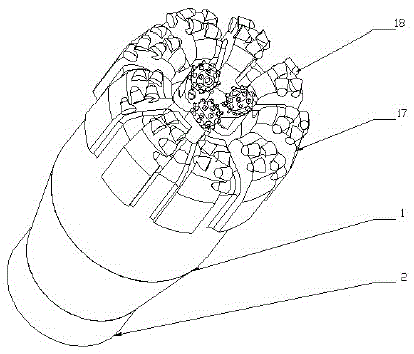

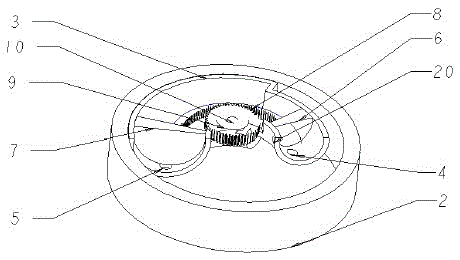

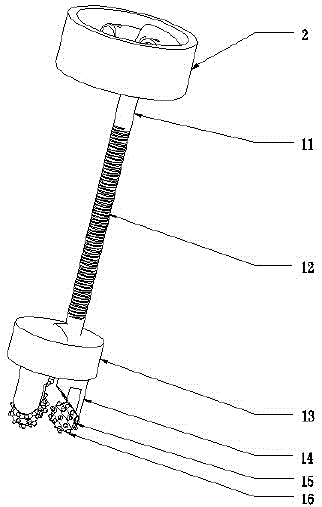

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention is an active rotating telescopic compound drill bit suitable for deep hard-drilling hard formations, mainly composed of a drill body 1, a power end casing 2, a rack piston cylinder 3, a first safety valve hole 4, and a second safety valve Hole 5, narrow-mouth piston 6, wide-mouth piston 7, arc-shaped rack 8, gear 9, drilling fluid through hole 10, telescopic column 11, trapezoidal external thread 12, three-hole flat plate 13, tooth palm 14, gear wheel 15, Cone teeth 16, PDC blades 17, PDC teeth 18, runner openings 19, and discharge openings 20. The upper section of the drill body 1 is fixedly connected to the power end casing 2, and the power end casing 2 is embedded with a section of two ends. Rack-piston cylinders 3 with different areas; the rack-piston cylinder 3 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com