Underground pulsing jet drill bit device

A pulse jet and drill bit technology, which is applied in the direction of drill bits, drilling equipment, earthwork drilling, etc., can solve the problems of unrealistic, unreliable power transmission, and difficult control of pulse devices, so as to improve the rock-clearing and rock-breaking ability and impact force Small, big impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

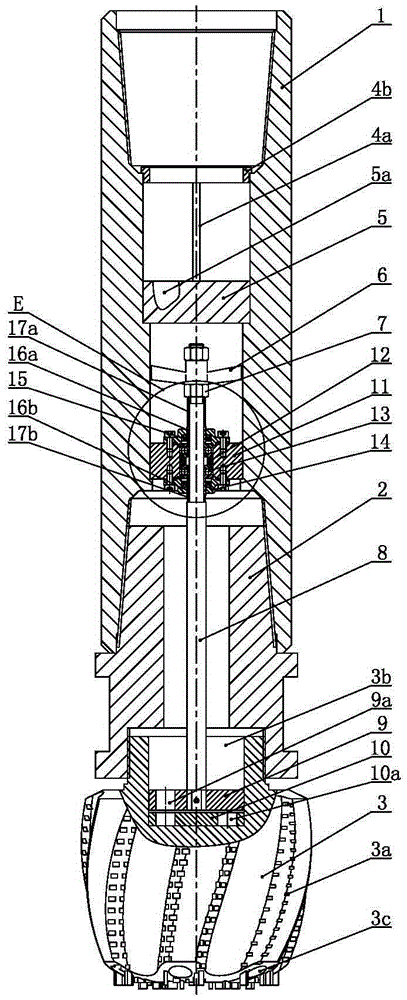

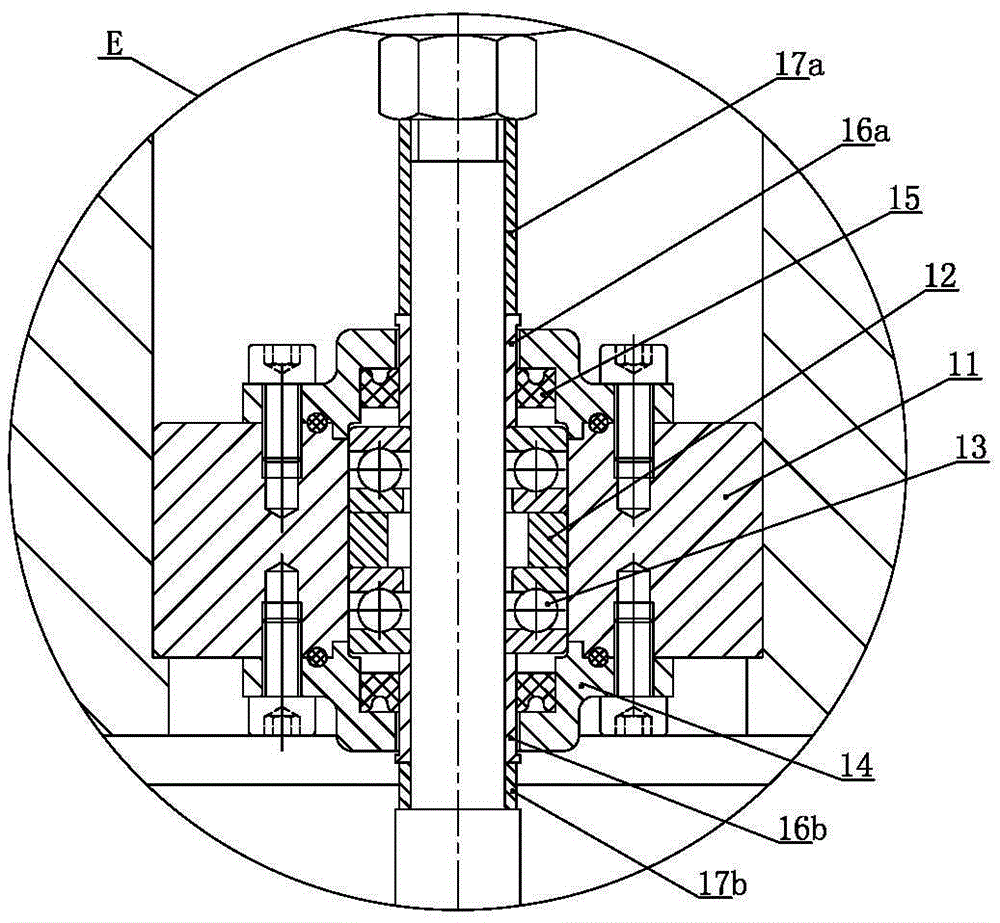

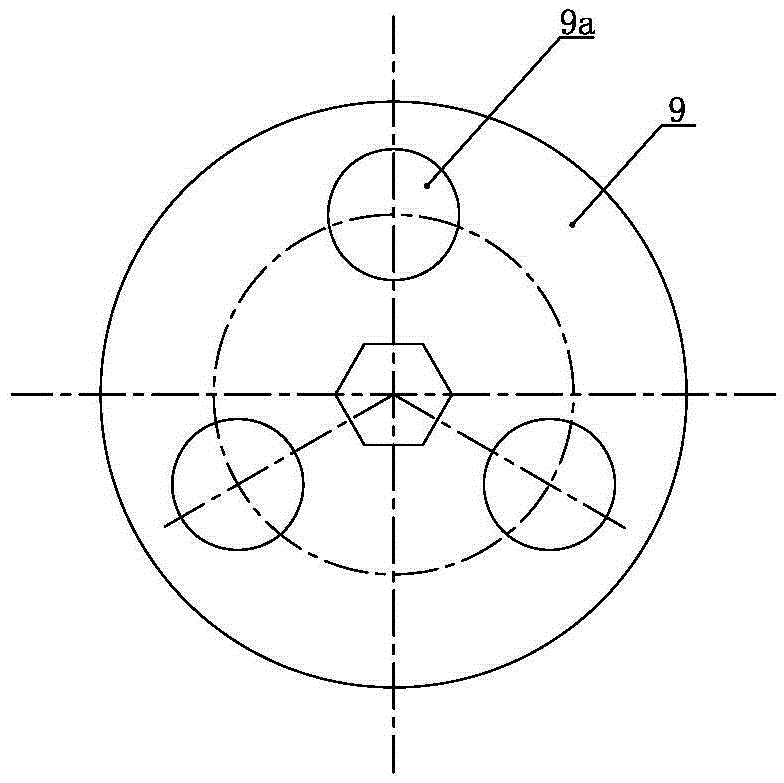

[0033] like Figure 1 to Figure 8 As shown, the downhole pulse jet drill bit device of the present invention comprises a coaxial double female sleeve 1, a drill joint 2 and a drill body 3, the lower end of the double female sleeve 1 is screwed with the upper end of the drill joint 2, and the lower end of the drill joint 2 It is screwed with the upper end of the drill body 3, the lower end of the drill body 3 is equipped with a blade 3a, the upper end of the drill body 3 is provided with a drill water chamber 3b extending downward along the axis, and the bottom wall of the drill water chamber 3b is distributed with multiple Each drill bit water hole 3c, each drill bit water hole 3c is evenly distributed on the same circumference with the axis as the center, each drill bit water hole 3c extends downward respectively and communicates with the spray hole on the lower end surface of the drill bit body 3 respectively; double female sleeve 1 The center of the drill joint 2 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com