Runner cross central whirl spraying negative pressure pulse drill bit

A cross-flow channel technology, applied in the field of oil and gas well drilling, can solve the problems of low mechanical penetration rate, affecting drilling efficiency, limited improvement of mechanical penetration rate, etc., and achieve the effect of low power consumption, small friction resistance and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

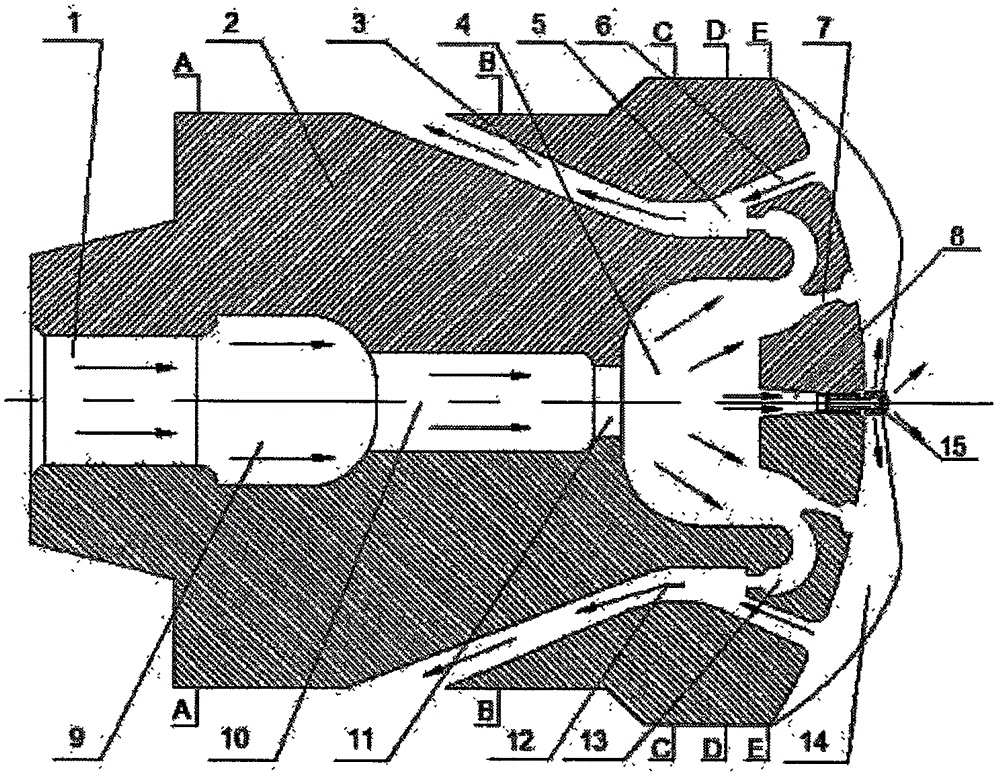

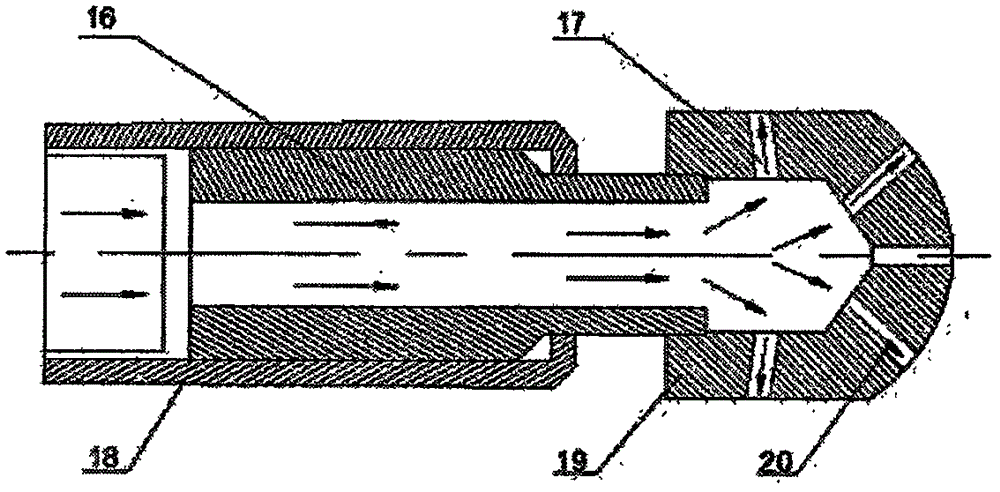

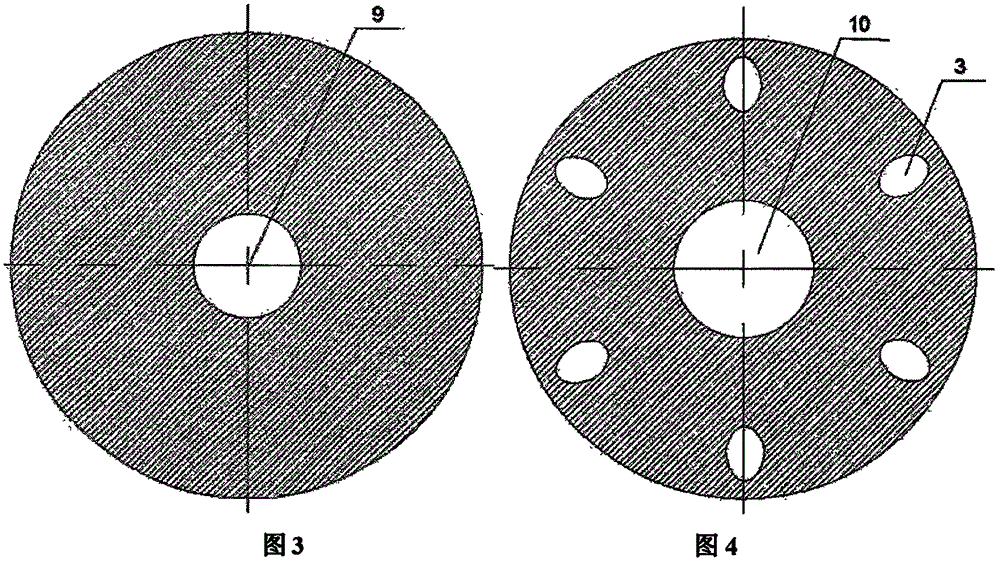

[0036] Such as figure 1 As shown in the figure, a negative pressure pulse drill bit used for flow channel cross type center jet spraying, including: 1. Drilling fluid flow channel, 2. Drill body, 3. Chip return cavity, 4. Diversion area, 5. Mixing cavity, 6 . Negative pressure pumping chamber, 7. Side branch channel of downspout, 8. Center self-rotating flowway of downspray, 9. Feed cavity, 10. Resonant cavity, 11. Outlet of resonant tube, 12. Throat, 13. Reverse To the high-speed runner, 14, the blade, and 15 self-rotating nozzles. The self-rotating nozzle includes: 16. a self-rotating central axis body, 17. a side nozzle, 18. a nozzle shell, 19. a self-rotating body, and 20. a forward nozzle. It is mainly divided into three parts: the pulse generation part, the rock breaking part of the central rotary spraying and the negative pressure swabbing upward return part.

[0037] The pulse generation part includes a drilling fluid flow channel 1, a feed cavity 9, a resonant cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com