Self-oscillation pulse reinforcement type inner grinding drill bit

A technology of self-oscillating and grinding drill bits, which is applied in the field of oil and gas well drilling, and can solve problems such as poor drilling, inability to remove cuttings beds in horizontal wells, restrictions on ROP and drilling costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

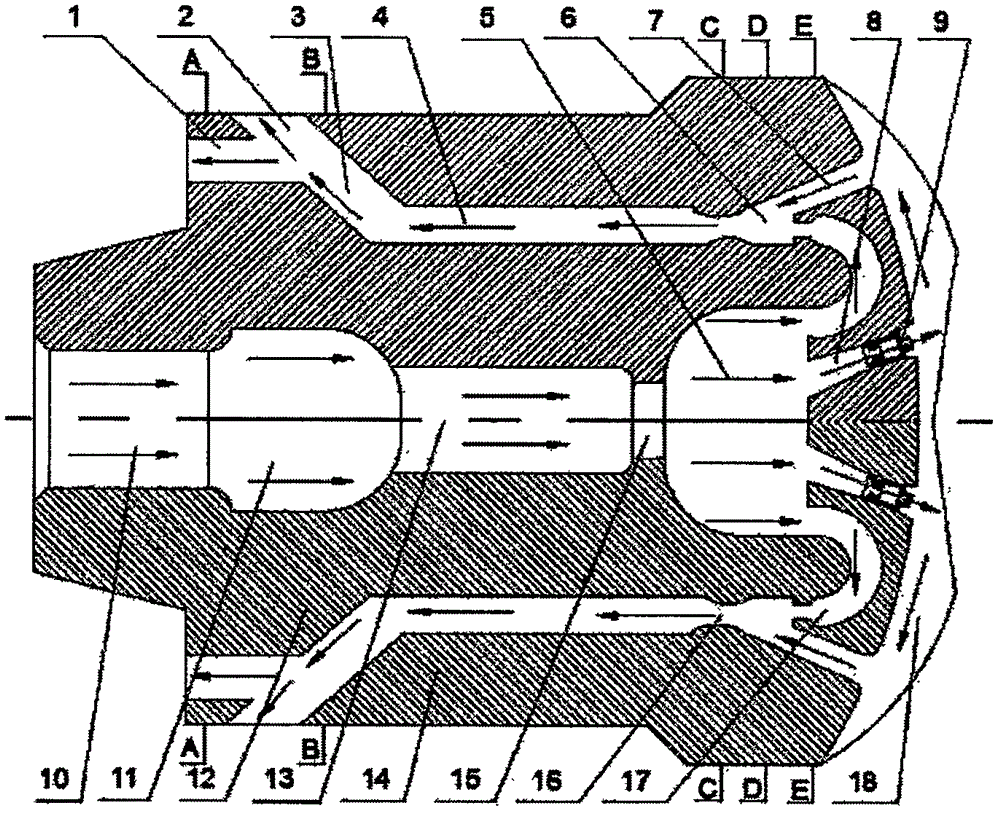

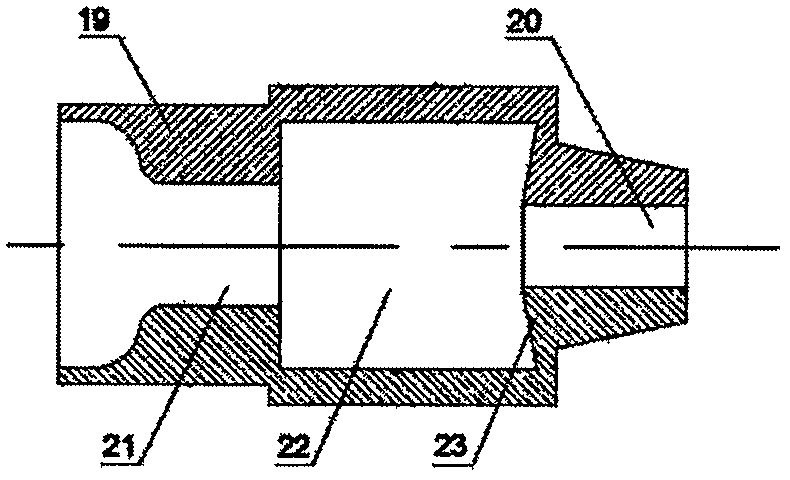

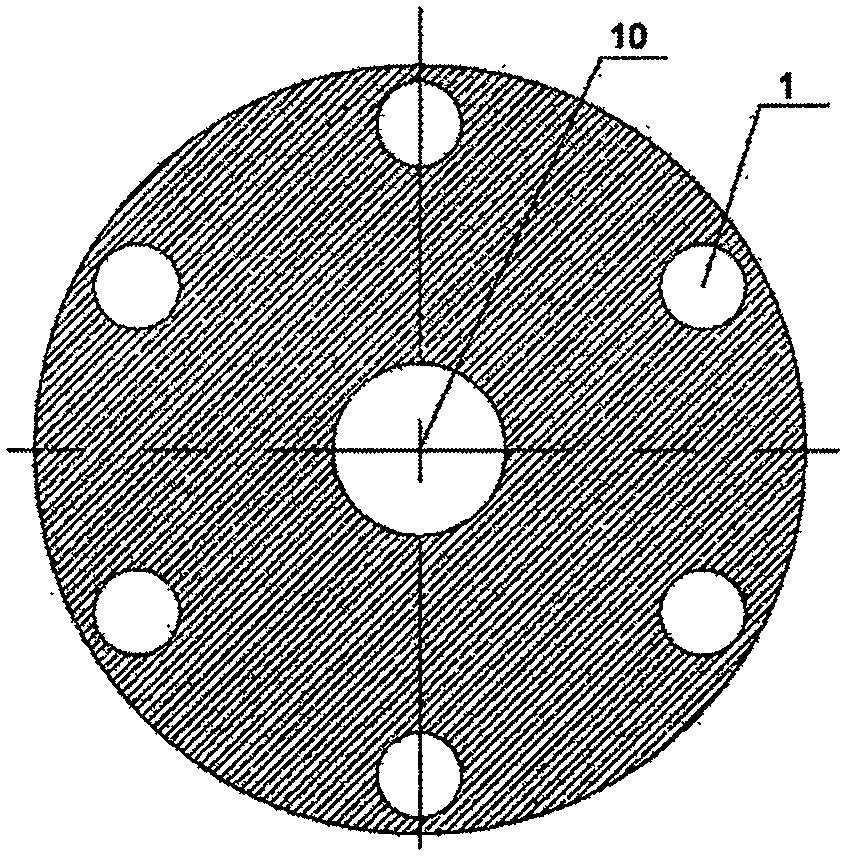

[0035] Such as figure 1 As shown, a self-excited oscillation pulse enhanced internal grinding drill bit includes: 1. Diffusion chamber, 2. Bypass, 3. Internal grinding chamber, 4. Acceleration chamber, 5. Diversion area, 6. Mixing chamber, 7. Swabbing cavity, 8. Downspout flow channel, 9. Self-excited oscillation nozzle, 10. Drilling fluid flow channel, 11. Feed cavity, 12. Internal grinding body, 13. Resonant cavity, 14. PDC bit body, 15, resonance tube outlet, 16, throat, 17, reverse high-speed flow channel, 18, knife wing. The self-excited oscillation nozzle includes a nozzle body 19 , a lower nozzle 20 , an upper nozzle 21 , an oscillation chamber 22 and an impact wall 23 . It is mainly divided into four parts: pulse generation part, self-excited oscillation pulse enhancement part, negative pressure pumping part and particle internal grinding part.

[0036] The pulse generation part includes a drilling fluid flow channel 10, a feed cavity 11, a resonance cavity 13, a res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com