Large temperature difference heat exchanger for primary heat network heat exchange station of heating system

A heat supply system and heat exchanger technology, which is applied in the field of large temperature difference heat exchangers in the primary heat network heat exchange station of the heat supply system, can solve the problems of hydraulic imbalance in the heat supply system, reduce transmission and distribution flow, and pressure head loss, etc., to achieve Reduce transmission and distribution energy consumption, reduce unbalanced heat loss, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

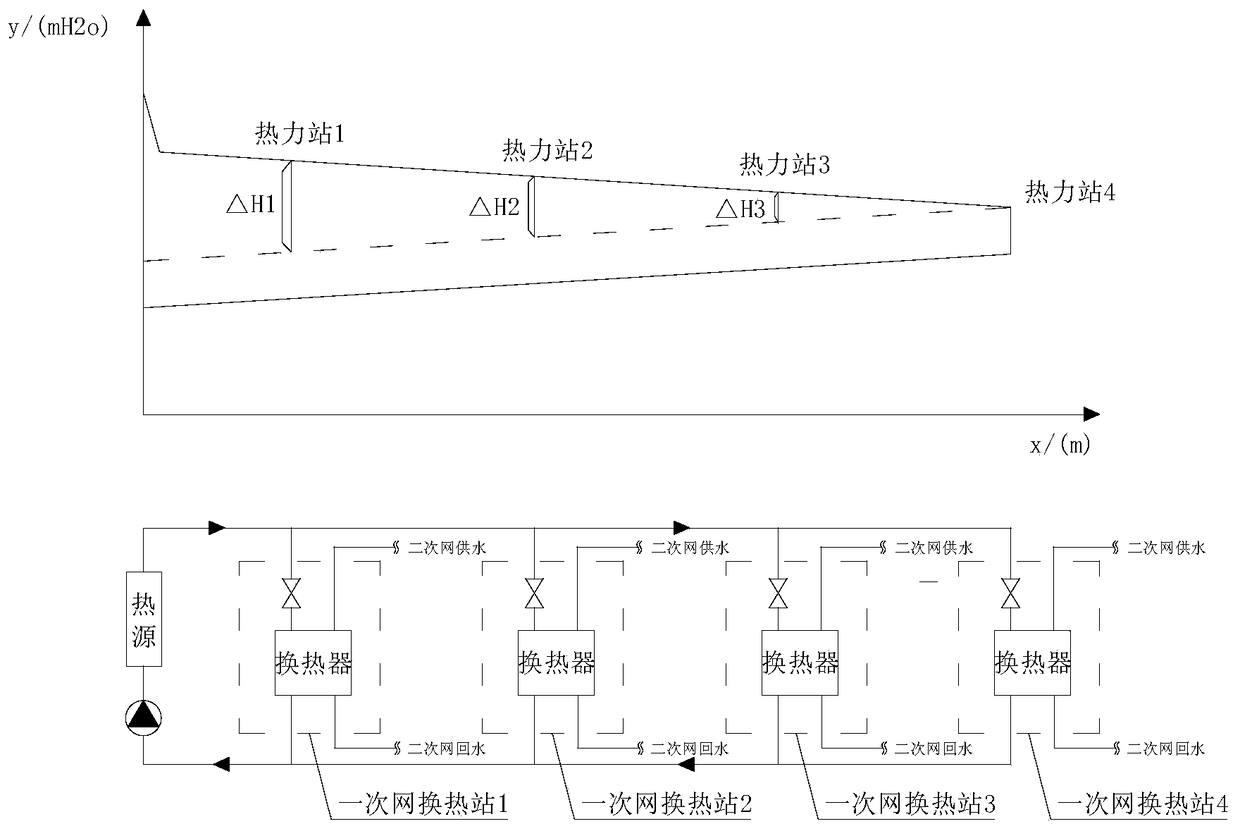

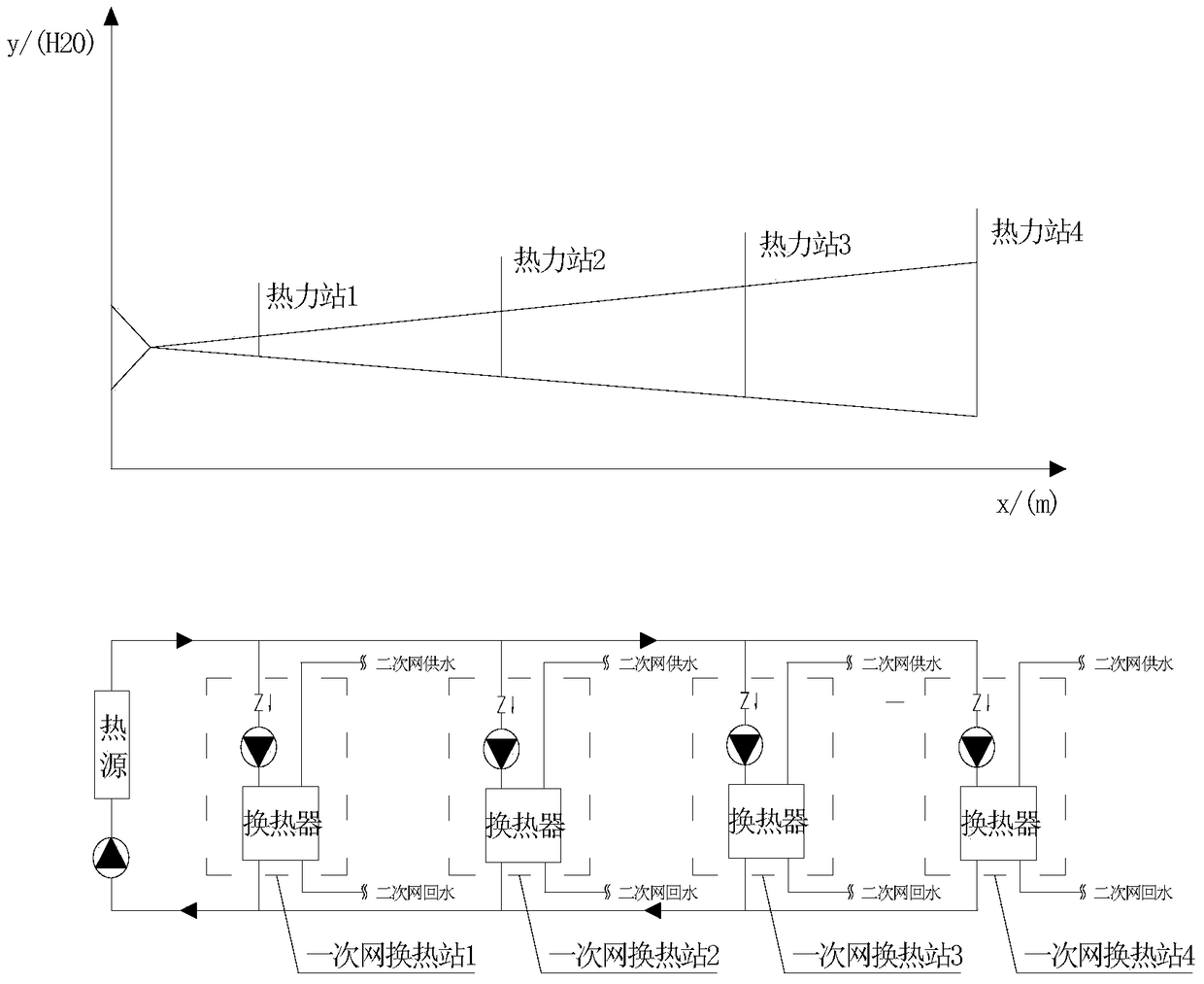

Problems solved by technology

Method used

Image

Examples

Embodiment 1

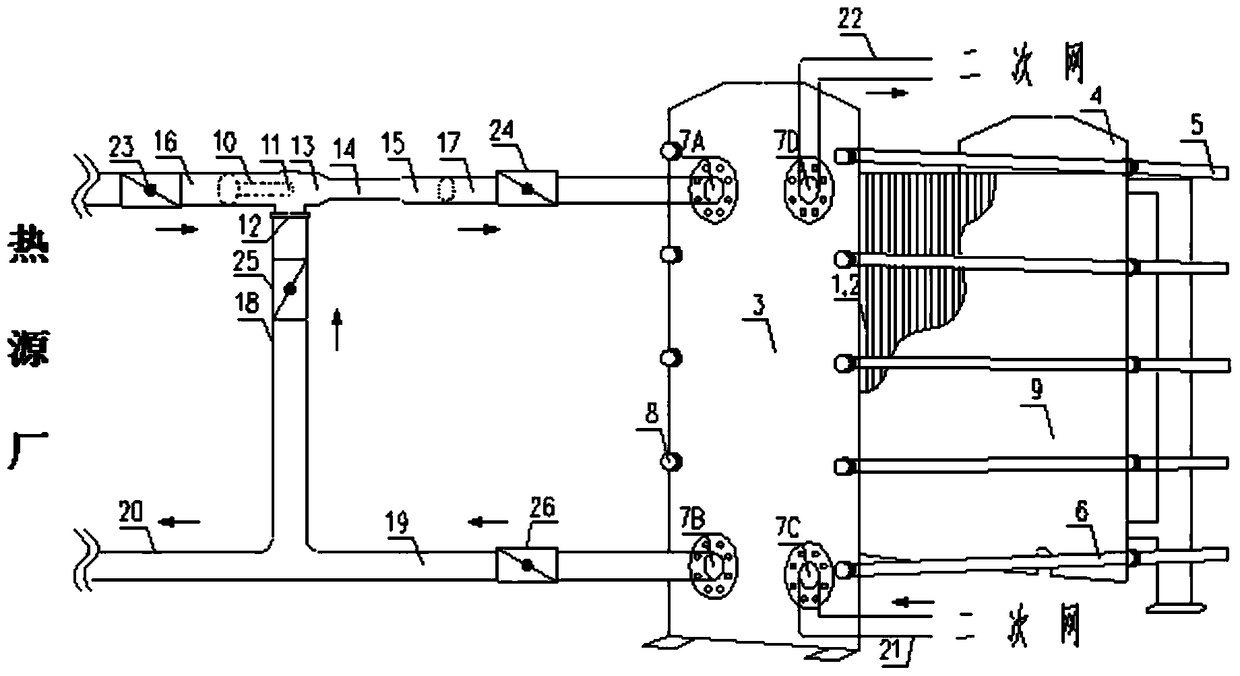

[0032] Such as image 3 As shown, the large temperature difference heat exchanger of the primary heat network heat exchange station of the heating system in this embodiment is applied to the heat supply system of a new building, connected with the heat source plant and the secondary network, and undertakes the heat exchange work on the primary network side. The heat exchanger is composed of plate heat exchange components, flow distribution components and connecting devices;

[0033] Among them, the plate heat exchange assembly includes: several heat exchange plates 1, plate seals 2, fixed pressure plate 3, movable pressure plate 4, upper guide beam 5, lower guide beam 6, heat medium inlet 7A as the pipe interface, heat medium Outlet 7B, refrigerant inlet 7C and refrigerant outlet 7D, compression bolts 8 and protective cover 9; among them, several heat exchange plates 1 are arranged alternately, located between the fixed platen 3 and the movable platen 4, and each heat exchange...

Embodiment 2

[0063] The large temperature difference heat exchanger of the primary heat network heat exchange station of the heating system in this embodiment is applied to the overall transformation of the heating system of the existing building, and the heat exchanger on the original primary network side is replaced by the heat exchanger of the present invention. The entire pipe diameter of the connected heating pipe network will not be replaced, and all manual balance valves and self-balance valves will be opened to the maximum or removed. The pipe diameter of the connection device of the heat exchanger of the present invention matches the pipe diameter of the existing heat supply pipe network, and the specifications of the selected plate heat exchange components are smaller than those of the original heat exchanger.

[0064] The original transmission and distribution flow of the heat supply system of the existing building is set as Q, and the injection valve 23 on the connecting device ...

Embodiment 3

[0066] The large temperature difference heat exchanger of the primary heat network heat exchange station of the heating system in this embodiment is applied to the partial transformation of the heat supply system of the existing building, and the flow distribution component and the coupling device of the present invention are installed in the heat exchange of the original primary network side On the heat exchanger (ordinary plate heat exchanger), the whole pipe diameter of the heating pipe network connected to it is not replaced, and all manual balancing valves and self-balancing valves are opened to the maximum or removed. The pipe diameter of the coupling device of the present invention matches the pipe diameter of the existing heating pipe network.

[0067] Connect the main water supply pipe 16 of the connecting device with the heat source plant, the mixed water inlet pipe 17 is connected with the heat medium inlet of the original heat exchanger, the delivery pipe 19 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com