Sand soil remediation agent as well as preparation method and application thereof

A soil remediation agent and sandy land technology, applied in the fields of application, soil conditioning materials, chemical instruments and methods, etc., can solve problems such as weak remediation ability, achieve the adjustment of soil porosity, improve aggregate structure, and increase soil water holding capacity and organic matter The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The sandy land soil remediation agent of embodiment 1 obtains by following operation steps:

[0039] According to the dosage in Table 1, fermented soybean (bio-organic fertilizer), biochar, Pleurotus eryngii fungi residue, polymer water-absorbent resin, sodium carboxymethylcellulose, polyacrylamide and polyuronic acid are mixed, stirred Uniform, fermented and decomposed to obtain mixture A;

[0040] The mixture A was granulated under steam conditions, and dried at 80°C for 30 minutes to obtain a sandy land soil restoration agent.

Embodiment 2-5

[0042] The sandy land soil remediation agent of Examples 2-5 is exactly the same as that of Example 1 in terms of preparation method and raw material types, the difference being that the dosage of each raw material is different, as shown in Table 1 for details.

[0043] Each raw material dosage (unit: kg) of table 1 embodiment 1-5 sandy land soil remediation agent

[0044] raw material Example 1 Example 2 Example 3 Example 4 Example 5 fermented soybeans 30 40 50 60 70 bio-charcoal 6 7 8 9 10 Pleurotus eryngii mushroom residue 10 14 18 22 25 High Molecular Water Absorbent Resin 8 8 8 8 8 Sodium carboxymethyl cellulose 3 3 3 3 3 Polyacrylamide 5 5 5 5 5 polyuronic acid 6 6 6 6 6

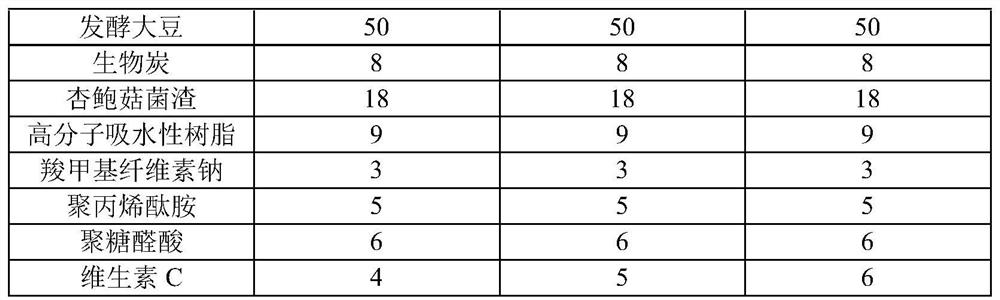

Embodiment 6-9

[0046]The preparation method and raw material types of the sandy soil restoration agent of Examples 6-9 are exactly the same as those of Example 3, the difference is that the dosage of each raw material is different, as shown in Table 2 for details.

[0047] Each raw material dosage (unit: kg) of table 2 embodiment 6-9 sandy land soil remediation agent

[0048] raw material Example 6 Example 7 Example 8 Example 9 fermented soybeans 50 50 50 50 bio-charcoal 8 8 8 8 Pleurotus eryngii mushroom residue 18 18 18 18 High Molecular Water Absorbent Resin 5 6 10 6 Sodium carboxymethyl cellulose 2.5 2 2.5 4 Polyacrylamide 5 5 5 5 polyuronic acid 6 6 6 6

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com