Peanut yoghurt with high water-holding capacity and preparing method of peanut yoghurt

A production method and technology of water holding capacity, applied in the field of high water holding capacity peanut yoghurt and its production, can solve the problems affecting the sensory quality of products and consumers' psychological judgment, and achieve rich yoghurt varieties, good taste and rich nutrition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

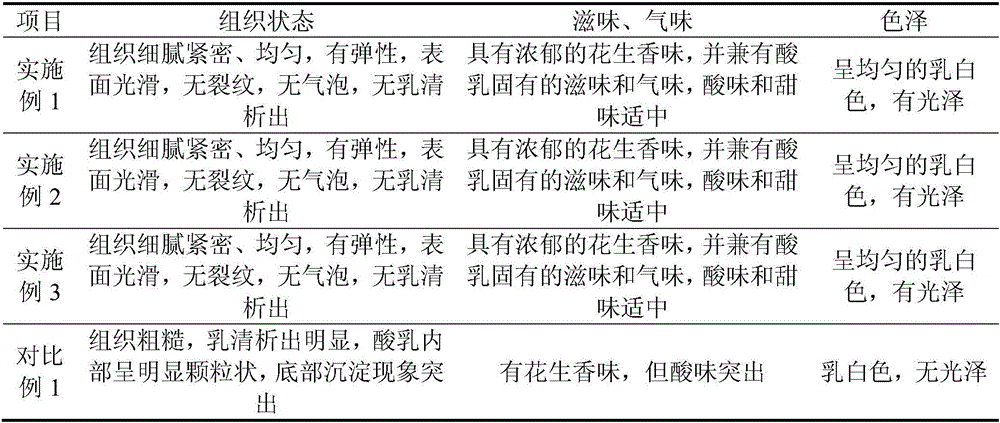

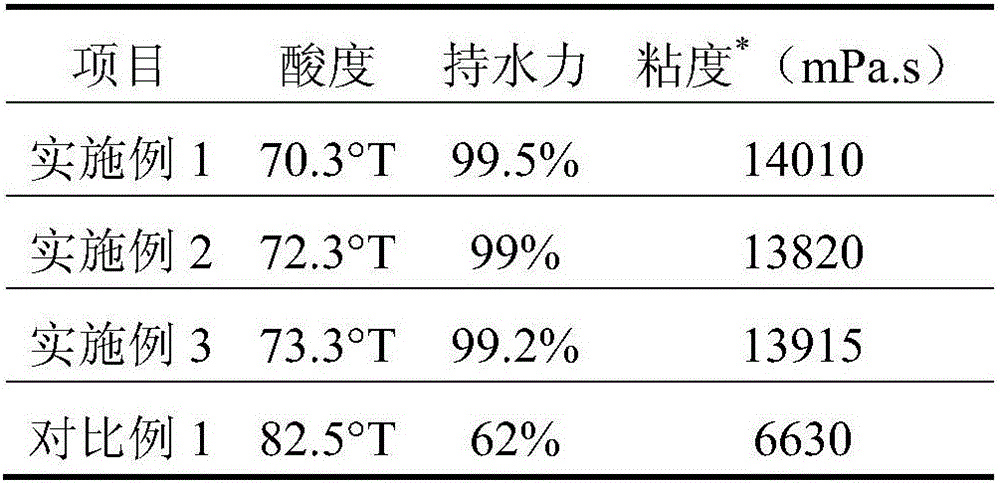

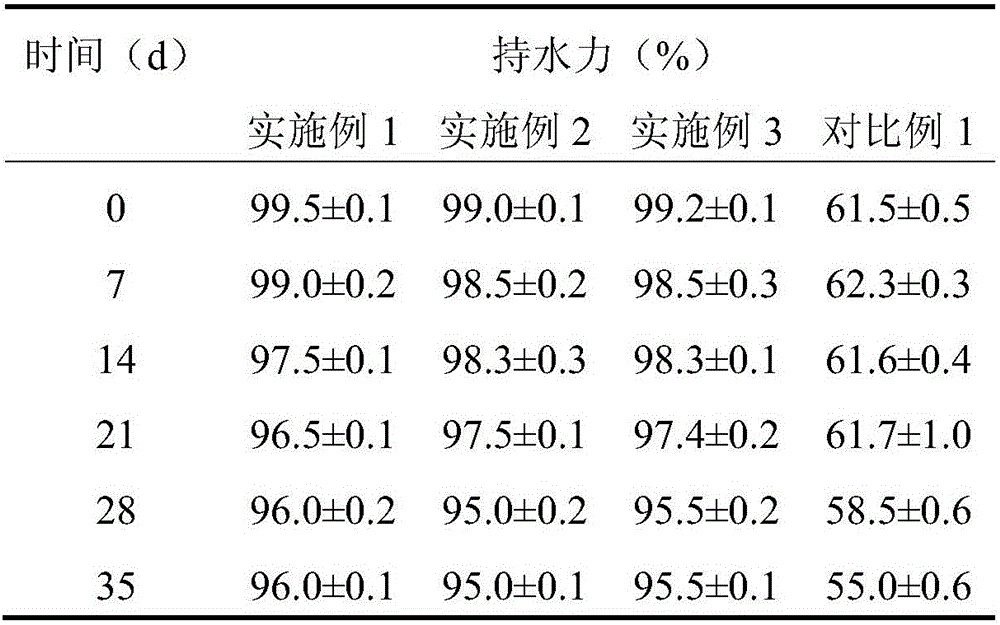

Examples

Embodiment 1

[0043] (1) First mix 100g of large-grained raw peanuts and 200g of small-grained raw peanuts, then mix with 2L of water at room temperature, soak overnight (14-15h) and peel off;

[0044] (2) Raw peanuts after peeling are beaten with 1.8 L of deionized water boiled and cooled to room temperature. Use the batch mode of the beater, beat 30 times for 5 seconds each time to make peanut milk, let the prepared peanut milk stand for a while, then filter it with sterilized gauze, and replenish the volume to 1.8L with deionized water to obtain uniform peanut milk ;

[0045] (3) Add 108g of white sugar and 90g of milk powder into the peanut milk, pasteurize (65°C, 20-30min), and stir while sterilizing;

[0046] (4) Cool the pasteurized material at room temperature and shake it gently while cooling; after cooling to 40-45°C, add 0.36g of Hansen YC-381 bacteria powder and Danisco YO-MIX300 under aseptic conditions (The ingredients are Lactobacillus bulgaricus and Streptococcus thermophi...

Embodiment 2

[0050] 1. Preparation method

[0051] (1) First mix 100g of large-grained raw peanuts and 300g of small-grained raw peanuts, then mix with 4L of water at room temperature, soak overnight (14-15h) and then peel off;

[0052] (2) Raw peanuts after peeling are beaten with 3.2 L of deionized water boiled and cooled to room temperature. Use the batch mode of the beater, beat 30 times for 5 seconds each time to make peanut milk, let the prepared peanut milk stand for a while, then filter it with sterilized gauze, and replenish the volume to 3.2L with deionized water to obtain uniform peanut milk ;

[0053] (3) Add 224g white granulated sugar and 192g milk powder into peanut milk, pasteurize (65°C, 20-30min), and stir while disinfecting;

[0054] (4) The pasteurized material is cooled at room temperature and shaken gently while cooling. After cooling to 40-45°C, add 0.32g of Hansen YC-381 bacteria powder and 0.96g of Danisco YO-MIX300 (the ingredients are Lactobacillus bulgaricus ...

Embodiment 3

[0058] (1) First mix 100g of large-grained raw peanuts and 100g of small-grained raw peanuts, then mix with 2L of water at room temperature, soak overnight (14-15h) and then peel off;

[0059] (2) Peeled raw peanuts are beaten with 800 mL of deionized water after boiling and cooling. Use the batch mode of the beater, beat 30 times for 5 seconds each time to make peanut milk, let the prepared peanut milk stand for a while, then filter it with sterilized gauze, and replenish the volume to 0.8L with deionized water to obtain uniform peanut milk ;

[0060] (3) Add 32g of white sugar and 24g of milk powder into the peanut milk, pasteurize (65°C, 20-30min), and stir while disinfecting;

[0061] (4) The pasteurized material is cooled at room temperature and shaken gently while cooling. After cooling to 40-45°C, add 0.08g of Hansen YC-381 bacteria powder and 0.08g of Danisco YO-MIX300 bacteria powder under aseptic conditions. After fully stirring, sterilize the special glass bottle,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com