Single-side rotational flow speed-increasing tool for drilling fluid of deep well drilling bottom

A drilling fluid and drilling technology, applied in wellbore/well components, earth-moving drilling, flushing wellbore, etc., can solve the problems of decreased ROP, obstructing the timely removal of bottom-hole cuttings, and increased drill bit wear, etc. ROP, shortening the drilling time of a single well, and reducing the effect of drilling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

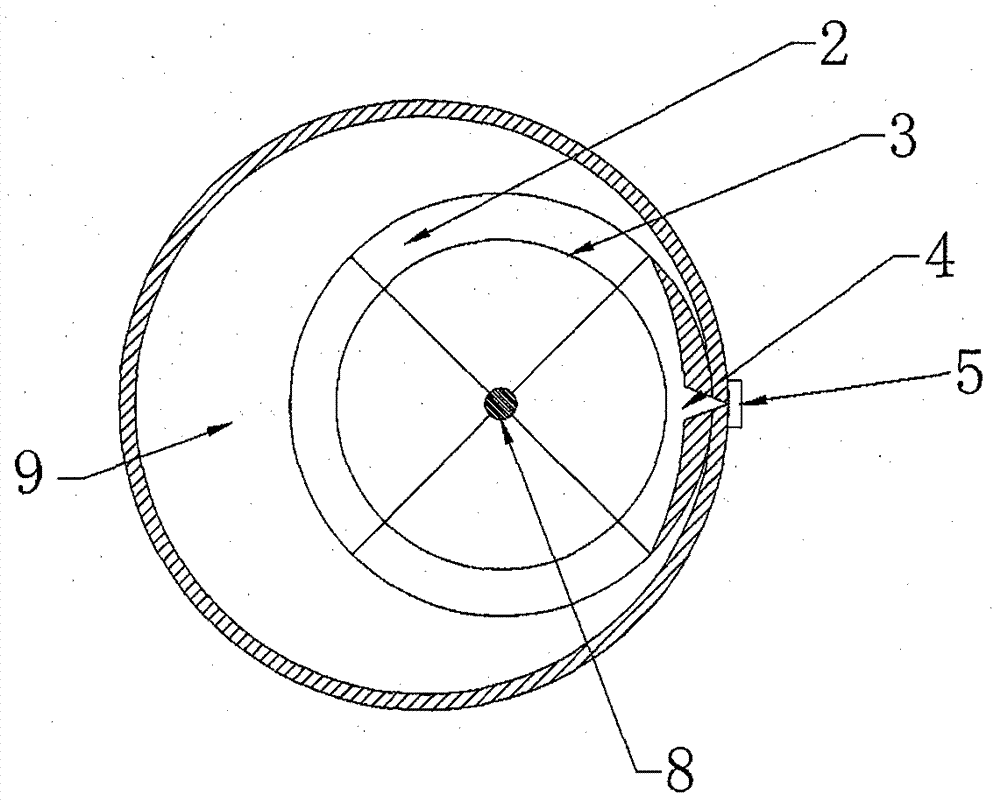

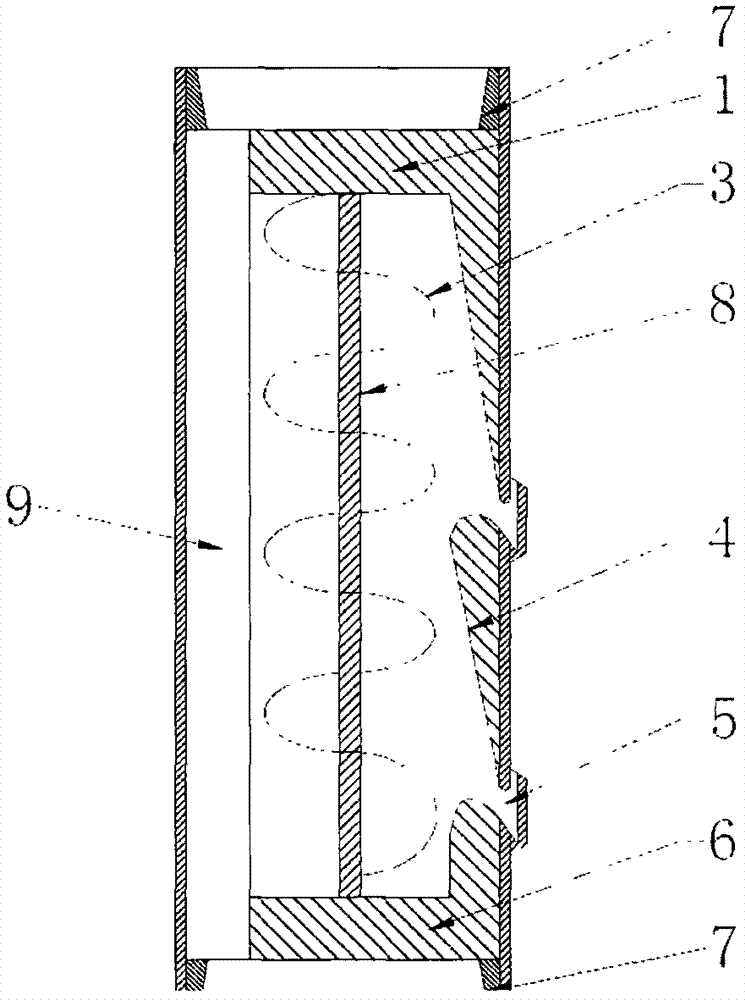

[0015] The following is attached figure 1 , describe the present invention in detail, as follows:

[0016] The deep well drilling bottomhole drilling fluid unilateral swirl speed-up tool consists of a liquid inlet 1, a support rod 2, a helical impeller 3, a V-shaped groove 4, a solid discharge injection port 5, a liquid outlet 6 and a screw thread 7.

[0017] Drilling fluid is pressurized and pumped from the ground into the ground, and is divided into two parts when it flows from the upper drill pipe through the deep well drilling bottom hole drilling fluid single side swirl speed increasing tool: one part passes through the bottom hole drilling fluid single side swirl speed increasing tool of deep well drilling The space 9 flows out directly; the other part flows from the liquid inlet 1 into the deep well drilling bottom hole drilling fluid unilateral swirling speed-up tool.

[0018] The drilling fluid that flows into the deep well drilling bottom hole drilling fluid through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com