Underground rotational flow solid-liquid separation well drilling speed increasing tool

A liquid separation and tool technology, which is applied in the field of downhole swirling solid-liquid separation drilling speed-increasing tools, achieves the effects of small impact, good stability, and prolonging the life of the drill bit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

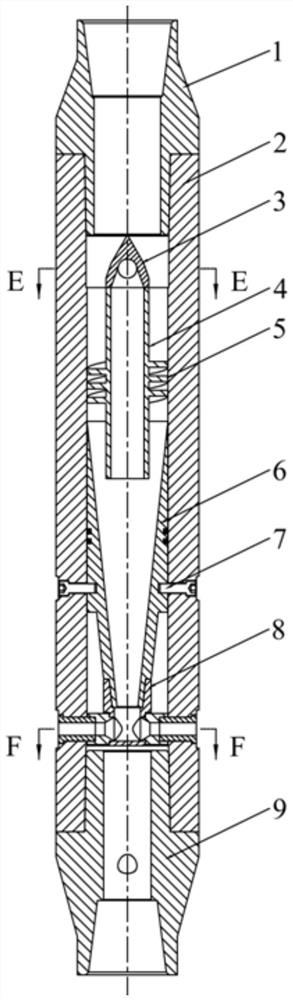

[0020]The main structure of the downhole swirling solid-liquid separation drilling speed-increasing tool described in this embodiment includes an upper joint 1, an outer cylinder 2, an overflow pipe suspension seat 3, an overflow pipe 4, a guide vane 5, a conical cylinder 6, and a positioning bolt 7. The lower diverter seat 8, the lower joint 9, the nozzle seat 10 and the side nozzle 11, the upper joint 1 and the lower joint 9 are connected to the two ends of the tool outer cylinder 2 through threads, the upper joint 1 is connected with the external drill string, and the lower joint 9 It is connected with the external drill bit; there is an inlet channel 12 in the middle of the upper joint 1, and an outlet channel 19 is opened in the middle of the lower joint 9; the upper joint 1 presses the overflow pipe suspension seat 3 on the boss in the outer cylinder 2; The overflow pipe 4 is fixed on the lower end of the overflow pipe suspension seat 3 by bolts, and the outer side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com