Drilling fluid as well as preparation method and application thereof

A drilling fluid and coating agent technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of restricting drilling speed increase, hidden dangers of electrical testing of borehole wall completion, etc., and achieve reduction of cuttings holding effect, Excellent shear thinning property and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

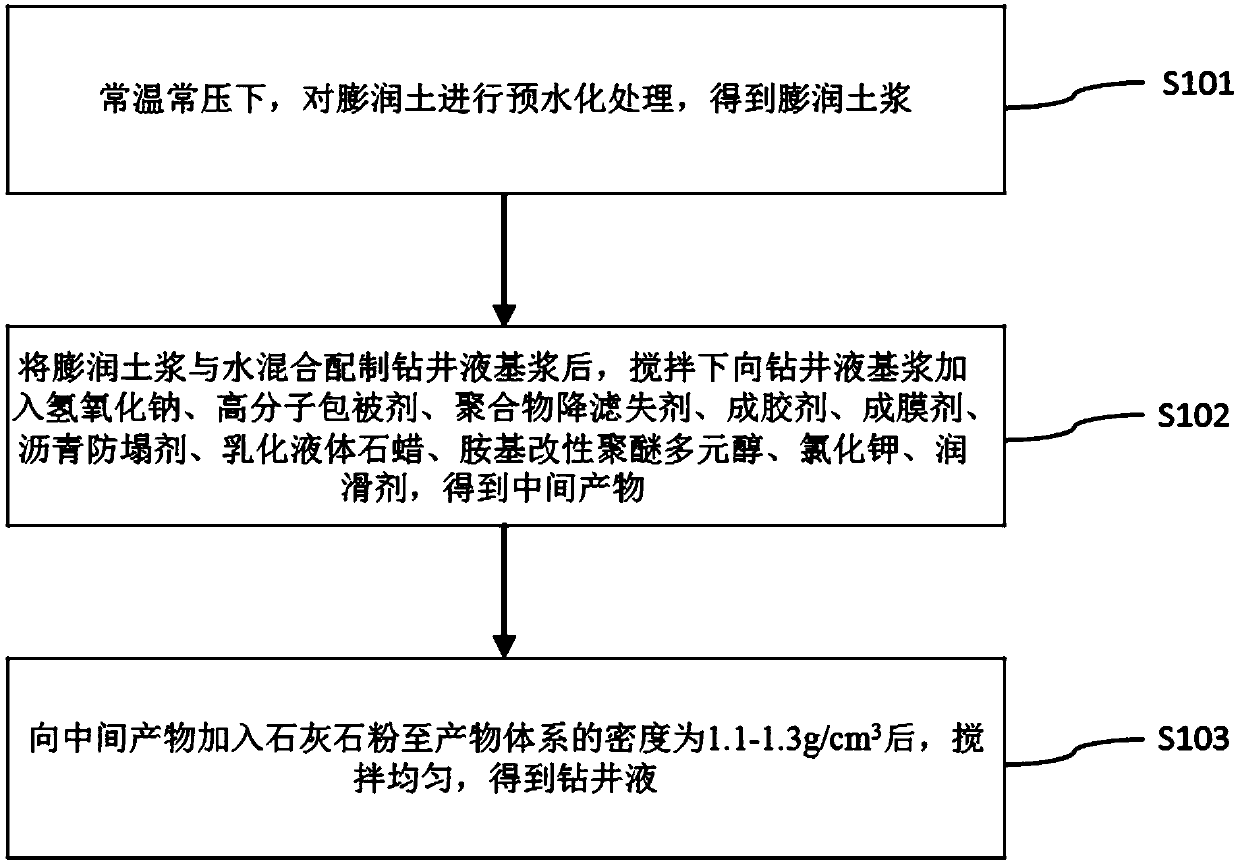

[0054] figure 1 Be the flow chart of drilling fluid preparation method of the present invention, as figure 1 Shown, the present invention provides a kind of preparation method of above-mentioned any drilling fluid, comprises the following steps:

[0055] S101: performing prehydration treatment on bentonite under normal temperature and pressure to obtain bentonite slurry;

[0056] S102: After mixing bentonite slurry with water to prepare drilling fluid base slurry, add sodium hydroxide, polymer coating agent, polymer fluid loss reducer, gelling agent, film forming agent, Collapsing agent, emulsified liquid paraffin, amino-modified polyether polyol, potassium chloride, and lubricant to obtain an intermediate product;

[0057] S103: Add limestone powder to the intermediate product until the density of the product system is 1.1-1.3g / cm 3 Finally, stir evenly to obtain drilling fluid.

[0058] At the beginning of the preparation, the bentonite needs to be prehydrated, that is, ...

Embodiment 1

[0074] The drilling fluid of the present embodiment comprises the following components according to mass percentage:

[0075] Bentonite: 4%

[0077] Potassium polyacrylamide: 0.4%

[0078] Vinyl monomer / cellulose graft copolymer: 1.5%

[0079] Highly cross-linked modified starch: 0.5%

[0080] Film former: 1%

[0081] White asphalt: 2%

[0082] Emulsified liquid paraffin: 1.0%

[0083] Amino-modified polyether polyol: 1.0%

[0085] Fatty alcohol compounds: 2%

[0086] Limestone powder: 41.5%

[0087] The balance is water

[0088] The density of the above-mentioned drilling fluid is 1.27g / cm 3 .

[0089] The preparation method of the drilling fluid of the present embodiment may further comprise the steps:

[0090] 1. Under normal temperature and pressure, pre-hydrate bentonite to obtain bentonite slurry;

[0091] 2. According to the requirements of drilling fluid components, a certain amount of benton...

Embodiment 2

[0094] The drilling fluid of the present embodiment comprises the following components according to mass percentage:

[0095] Bentonite: 4%

[0096] Sodium hydroxide: 0.2%

[0097] Potassium polyacrylamide: 0.2%

[0098] Acrylamide and sodium acrylate copolymer coating agent (80A51): 0.2%

[0099] Vinyl monomer / cellulose graft copolymer: 1.5%

[0100] Highly cross-linked modified starch: 0.5%

[0101] Film former: 1%

[0102] Oxidized bitumen: 2%

[0103] Emulsified liquid paraffin: 1%

[0104] Amino-modified polyether polyol: 1%

[0105] Potassium chloride: 6%

[0106] Fatty alcohol compounds: 2%

[0107] Limestone powder: 41.5%

[0108] The balance is water.

[0109]The density of the above-mentioned drilling fluid is 1.27g / cm 3 .

[0110] The preparation method of the drilling fluid of the present embodiment may further comprise the steps:

[0111] 1. Under normal temperature and pressure, pre-hydrate bentonite to obtain bentonite slurry;

[0112] 2. Accordin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com