High-wind-speed auxiliary agitation drying apparatus

A technology for auxiliary stirring and drying equipment, applied in drying, drying machine, lighting and heating equipment and other directions, can solve the problems of low drying efficiency, uneven heating air flow, internal structure damage, etc., to improve drying Efficiency, improve drying effect, drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

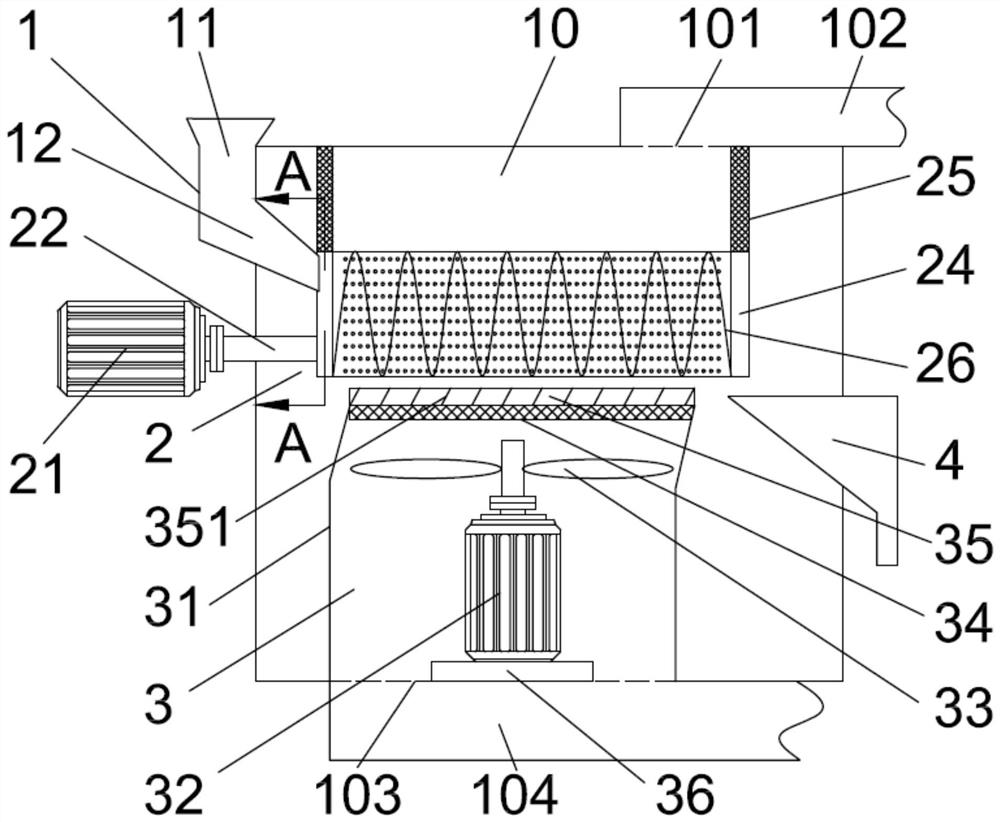

[0035] Such as Figure 1~5 As shown, a high wind speed assisted stirring drying equipment includes a device body 10, which is characterized in that: the device body 10 includes a feeding device 1, a stirring device 2, a drying device 3 and a discharge collecting device 4;

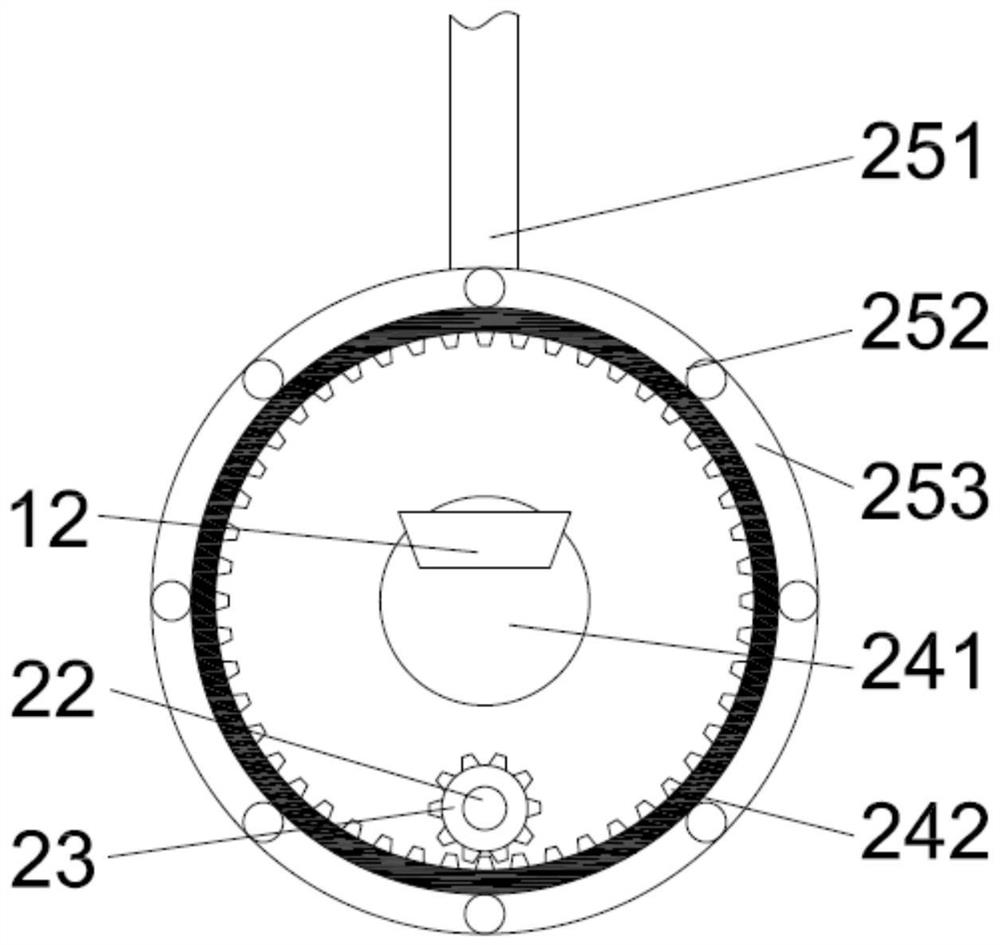

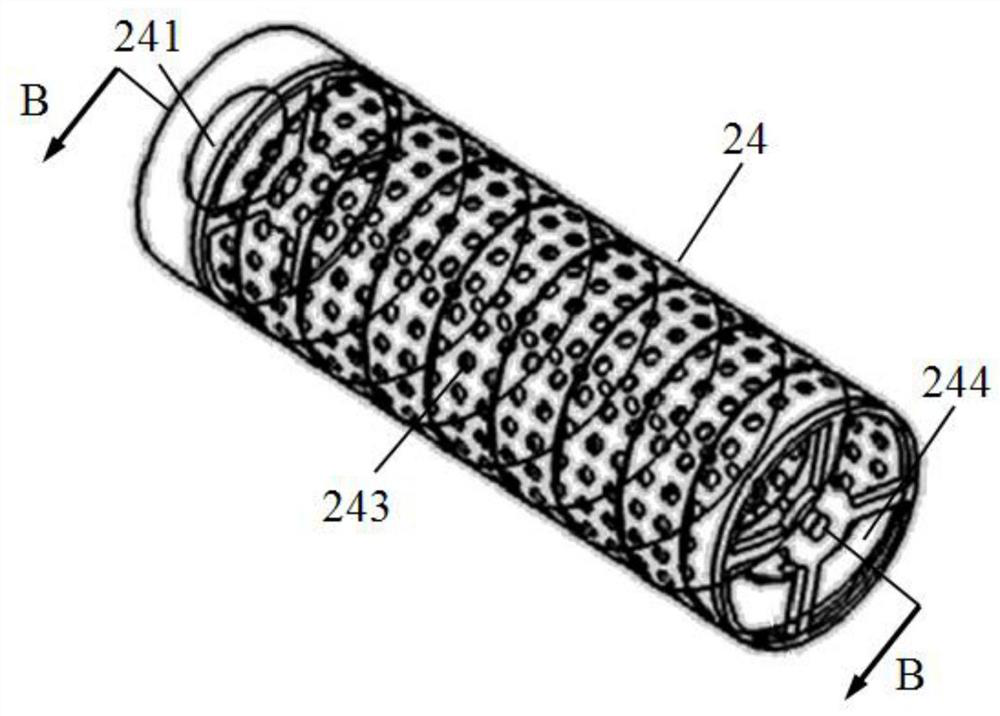

[0036]Wherein, the stirring device 2 comprises a stirring motor 21, an output shaft 22, a driving gear 23, an overturning drum 24, a connecting device 25 and a spiral blade 26; It is fixedly connected with the output shaft 22 through a coupling; the output shaft 22 runs through the equipment body 10 and extends into the inside of the equipment body 10, and the end of the output shaft 22 away from the stirring motor 21 is fixedly sleeved with the drive gear 23; the connection device 25 includes a connecting rod 251 and connecting ring 252, one end of the connecting rod 251 is fixedly connected to the top of the inner wall of the device body 10, and the other end is fixedly connected to the top of the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com