Method and special device for treating lithium hexafluorophosphate synthetic tail gas with simple process flow

A technology of lithium hexafluorophosphate and process flow, applied in the field of lithium hexafluorophosphate synthesis tail gas treatment, can solve the problems such as inability to achieve effective separation of HCl and HF, limited application scope of by-product hydrochloric acid, high-risk production environment, etc., to simplify the device and reduce the gas flow resistance. , the effect of broadening the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

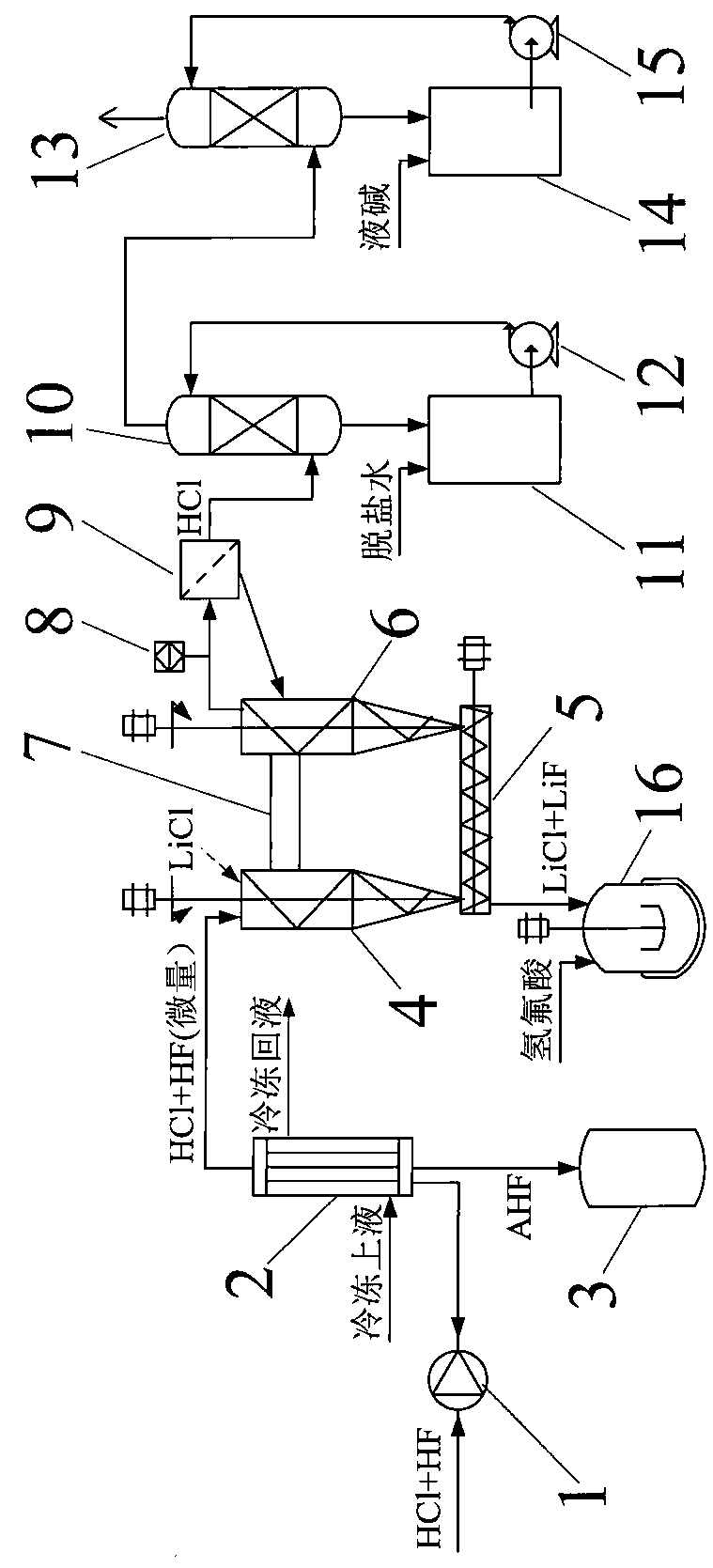

[0031] A method for treating the tail gas of lithium hexafluorophosphate synthesis. The tail gas (mainly composed of HCl and HF) at the outlet of the lithium hexafluorophosphate synthesis reactor is pressurized by a booster fan and then sent to the condenser. Most of the HF gas in the mixed gas is cooled and condensed in the condenser. The liquid is recovered to the anhydrous hydrogen fluoride receiving tank (the condensation recovery rate of HF gas can reach about 80%), and the mixed gas (mainly composed of HCl and a small amount of HF) exiting the condenser passes through the closed first First-stage conical stirred reactor, horizontal spiral conveying reactor, second-stage conical spiral stirred reactor, the trace amount of HF in the mixed gas reacts with the LiCl powder pre-added in the stirred reaction device (reaction products are HCl and LiF) , the LiCl powder in the second-stage stirred reactor passes through the material balance tube (the stock of the material in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com