High-magnetic-induction high-silicon non-oriented silicon steel plate and preparation method thereof

A technology of oriented silicon steel and high magnetic induction, which is applied in the field of high magnetic induction and high silicon non-oriented silicon steel sheet and its preparation, can solve the problems of large environmental load, many manufacturing processes, and high equipment requirements, so as to improve the magnetic induction intensity and reduce production costs. , the effect of shortening the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

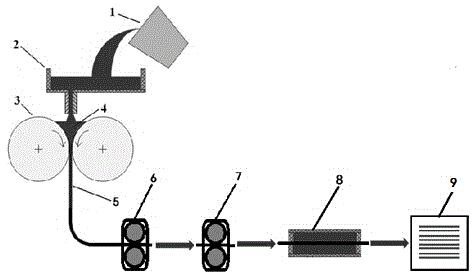

Image

Examples

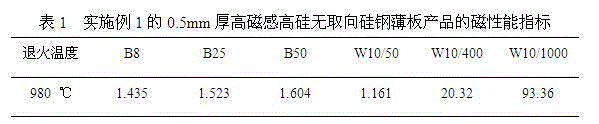

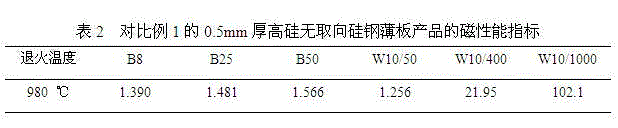

Embodiment 1

[0025] The chemical composition of the high magnetic induction high-silicon non-oriented silicon steel sheet of this embodiment is: Si: 6.4%, Ce: 0.005%, N: 0.0029%, S: 0.002%, P: 0.012%, O: 0.0023%, C: 0.0031%, the balance being Fe.

[0026] The preparation method of the present embodiment is carried out according to the following steps:

[0027] (1) Smelting: use melting furnace 1 to smelt molten steel that meets the chemical composition requirements of high-silicon steel, and obtain the chemical composition by weight percentage as Si: 6.4%, Ce: 0.005%, N: 0.0029%, S: 0.002%, P: 0.012%, O: 0.0023%, C: 0.0031%, and the balance is molten steel of Fe;

[0028] (2) Casting and rolling: the above-mentioned molten steel is cast into the tundish 2 at 1430°C, and under the protection of an argon atmosphere, the molten steel flows through the tundish into the void composed of two counter-rotating crystallization rollers 3 and side sealing plates. A molten pool 4 is formed in the ca...

Embodiment 2

[0047] The chemical composition of the high magnetic induction high-silicon non-oriented silicon steel sheet of this embodiment is: Si: 6.4%, Ce: 0.01%, N: 0.0029%, S: 0.002%, P: 0.012%, O: 0.0023%, C: 0.0031%, the balance being Fe.

[0048] The preparation method of the present embodiment is carried out according to the following steps:

[0049] (1) Smelting: use melting furnace 1 to smelt molten steel that meets the chemical composition requirements of high-silicon steel, and obtain the chemical composition by weight percentage as Si: 6.4%, Ce: 0.001%, N: 0.0029%, S: 0.002%, P: 0.012%, O: 0.0023%, C: 0.0031%, and the balance is molten steel of Fe;

[0050] (2) Casting and rolling: the above-mentioned molten steel is cast into the tundish 2 at 1430°C, and under the protection of an argon atmosphere, the molten steel flows through the tundish into the void composed of two counter-rotating crystallization rollers 3 and side sealing plates. A molten pool 4 is formed in the cav...

Embodiment 3

[0058] The chemical composition of the high magnetic induction non-oriented silicon steel sheet in this embodiment is: Si: 6.5%, Ce: 0.014%, N: 0.0032%, S: 0.0027%, P: 0.018%, O: 0.0025%, C: 0.0041%, the balance is Fe.

[0059] The preparation method of the present embodiment is carried out according to the following steps:

[0060] (1) Smelting: use melting furnace 1 to smelt molten steel that meets the chemical composition requirements of high-silicon steel, and the obtained chemical composition is Si: 6.5%, Ce: 0.014%, N: 0.0032%, S: 0.0027%, P: 0.018%, O: 0.0025%, C: 0.0041%, the balance is molten steel of Fe;

[0061] (2) Casting and rolling: the above-mentioned molten steel is cast into the tundish 2 at 1480°C, and under the protection of an argon atmosphere, the molten steel flows through the tundish into the void composed of two counter-rotating crystallization rollers 3 and side sealing plates. A molten pool 4 is formed in the cavity, and the superheat degree of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com